In modern construction and renovation projects, robust and reliable equipment plays a crucial role in ensuring efficiency and precision. Among the essential tools, certain heavy-duty devices stand out due to their versatility and power. This guide explores the intricate mechanisms and elements of one such tool, breaking down its construction to provide a clearer understanding of how it operates.

To achieve the best performance, it’s important to familiarize yourself with the internal workings and features of this tool. By examining its core elements, you can gain insights into the functions that contribute to its durability and effectiveness in handling various materials. Whether you’re maintaining or upgrading your equipment, knowing these components will help you make informed decisions and maximize its potential.

Through a detailed overview, we will highlight the vital parts of this high-performance device, offering a comprehensive

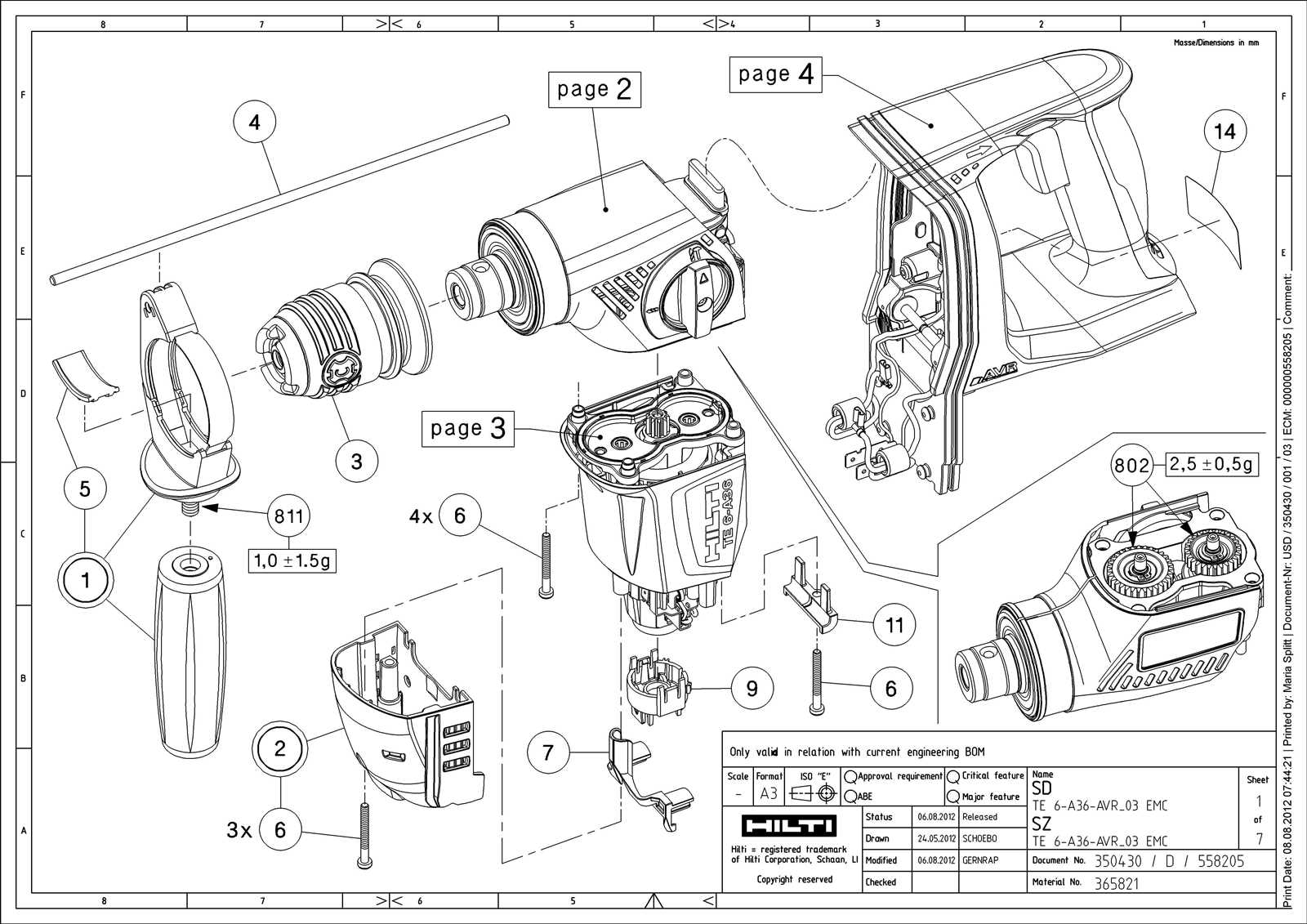

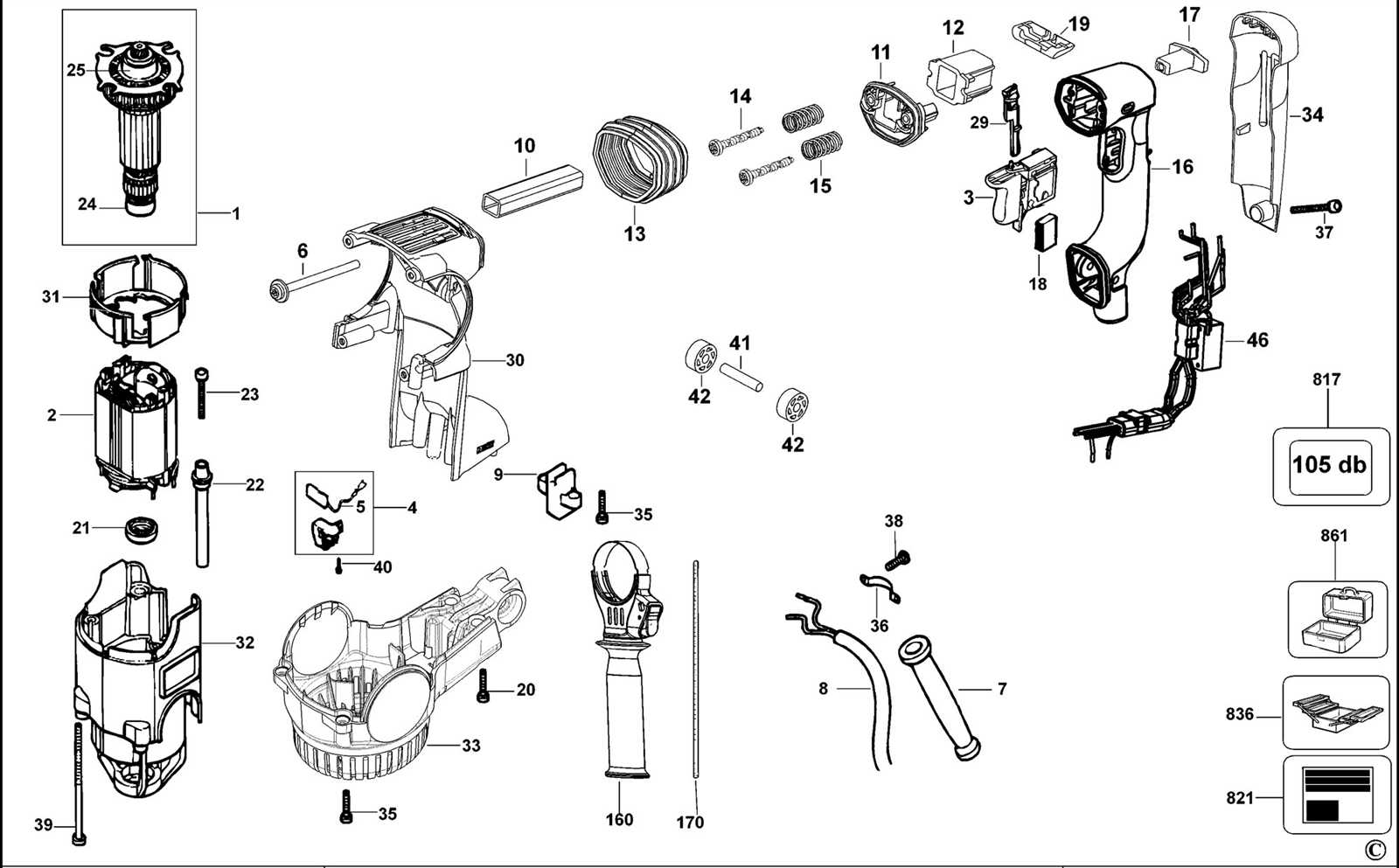

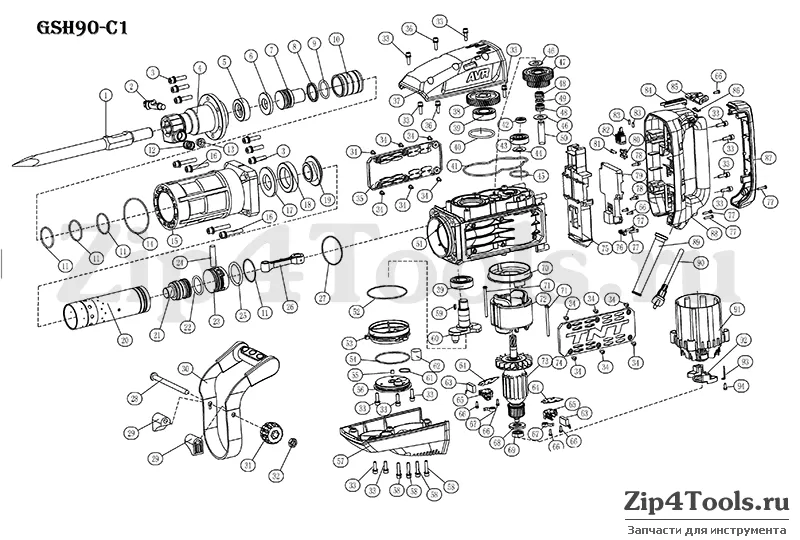

Understanding the Components of the TE 40 AVR

This section delves into the various elements that make up this powerful tool, each contributing to its efficiency and performance. By exploring the key sections and how they interact, users can gain a clearer understanding of the equipment’s functionality and maintenance requirements.

The assembly consists of several crucial parts, each designed for a specific function, ensuring durability and precision. Below is an overview of these main components:

- Handle and Grip: Designed for comfort and control, the handle allows for prolonged use with minimal fatigue.

- Motor Housing: Encases the motor, providing protection and support while ensuring efficient power transmission.

Key Internal Mechanisms of the Hilti Tool

The internal components of the tool play a crucial role in ensuring its reliable operation and durability. These mechanisms are designed to handle tough tasks, offering stability and precision. Understanding how these core elements interact can provide valuable insights into the tool’s performance and longevity.

- Drive System: This essential mechanism converts energy into motion, powering the tool for various applications. It is engineered to deliver consistent force while minimizing wear on other components.

- Impact Mechanism: A vital part of the tool’s functionality, the impact mechanism generates the necessary force for drilling and chiseling through tough materials, optimizing energy use for maximum efficiency.

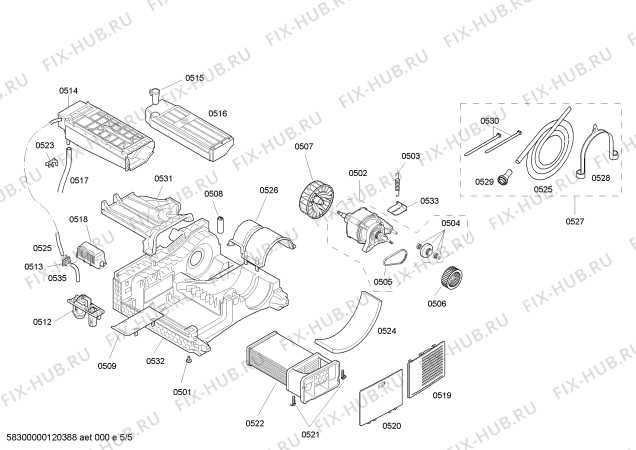

- Cooling System: Effective heat management is crucial for the tool’s longevity. The cooling system works to prevent overheating during prolonged use, ensuring the internal components remain at optimal temperatures.

- Main handle structure: The primary support designed to accommodate a firm grasp while providing durability under heavy use.

- Ergonomic grip: A carefully shaped surface that ensures a comfortable hold, reducing hand strain during extended periods of operation.

- Vibration dampening features: Built-in mechanisms that absorb shocks and minimize vibrations, enhancing user comfort and precision.

- Auxiliary handle: An adjustable component offering extra support and balance when maneuvering the tool in challenging positions.

- Gears: These are responsible for transmitting force between moving parts. Each gear is precisely engineered to handle specific loads and rotational speeds.

- Shafts: These connect the gears and enable the rotation of mechanical elements, providing the necessary torque for operation.

Impact Mechanism: Function and Design

The impact mechanism is a crucial element in tools designed for heavy-duty applications, enhancing their performance through a unique operational method. This system harnesses energy to deliver rapid, high-force strikes, making it effective for various tasks, including drilling and chiseling. Understanding its construction and functionality is essential for optimizing tool use and maintenance.

Functionality Overview

At its core, the impact mechanism operates by converting rotational energy into impactful force. This process involves several key components working in unison:

- Energy Transfer: The mechanism captures kinetic energy generated by the motor.

- Impact Delivery: The energy is then released in short bursts, creating powerful blows.

- Enhanced Efficiency: This method minimizes user fatigue while maximizing productivity.

Design Elements

The design of the impact mechanism encompasses various features that contribute to its effectiveness and durability:

- Durable Materials: Components are typically constructed from high-quality metals to withstand repetitive stress.

- Compact Configuration: A streamlined design allows for easy handling and maneuverability.

- Precision Engineering: Tolerances are meticulously maintained to ensure consistent performance.

Examining the Trigger and Switch Setup

This section delves into the mechanism responsible for controlling the operation of the tool, focusing on the components that allow for precise activation and deactivation. Understanding these elements is crucial for effective usage and maintenance, ensuring optimal performance during various applications.

The trigger and switch arrangement plays a pivotal role in user interaction, enabling smooth operation while enhancing safety measures. Each component must work in harmony to provide responsive control, making it essential to familiarize oneself with their functions and arrangement.

Component Description Functionality Trigger A mechanism that initiates the operation of the device. Allows the user to control the on/off function based on pressure applied. Switch A device that regulates electrical flow within the tool. Ensures the safe activation and deactivation of the power source. Wiring Connective pathways that link the trigger and switch. Facilitates the transmission of signals between components for operational effectiveness. Housing The outer casing that encases the trigger and switch. Provides protection and maintains structural integrity while allowing user access. Casing and External Protection Overview

The casing and external safeguards of power tools play a crucial role in ensuring their durability and functionality. These components are designed to withstand harsh conditions while providing a reliable barrier against environmental factors. A well-constructed outer shell not only protects the internal mechanisms but also enhances user safety during operation.

Different materials and design features are utilized to achieve optimal protection. For instance, high-quality plastics and metal alloys are commonly employed for their strength and resistance to wear. Additionally, the incorporation of ergonomic designs aids in preventing slippage and offers a comfortable grip, which is essential for extended use.

Furthermore, attention to detail in the casing design can significantly impact the tool’s performance. Proper ventilation, sealing mechanisms, and dust-proof features ensure that the internal components remain free from debris and overheating, ultimately extending the lifespan of the tool. Understanding these elements is vital for users looking to maintain and operate their equipment effectively.

Importance of the

Understanding the components and their arrangement within a device is crucial for ensuring optimal performance and longevity. This knowledge allows users to make informed decisions about maintenance, repairs, and enhancements, ultimately leading to better operational efficiency and reliability.

Enhanced Functionality

Comprehending the intricacies of the elements involved contributes significantly to maximizing the utility of the equipment. When users are aware of how each part interacts, they can leverage the device’s full potential, adapting its use to various tasks with greater ease.

Preventive Maintenance

Regular awareness of the various components promotes proactive upkeep, helping to identify potential issues before they escalate into major problems. By knowing the role of each piece, users can implement targeted care strategies that extend the life of the machinery and maintain its effectiveness.

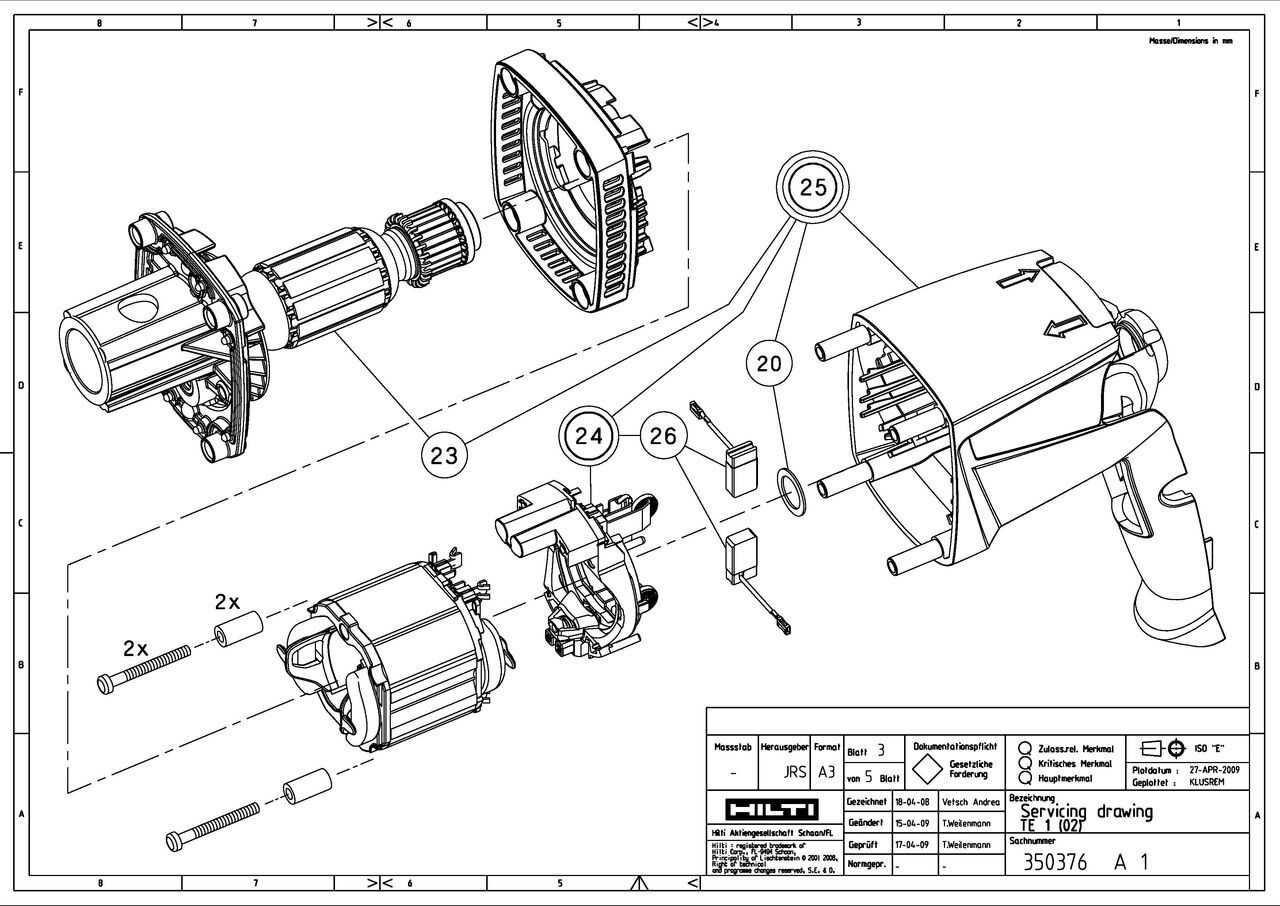

Exploring the Motor Assembly Structure

The motor assembly serves as the core of the tool’s operation, ensuring smooth power delivery and optimal performance. Understanding its layout and function is essential for maintaining efficiency and longevity. The key components are designed to work in unison, creating a reliable mechanism that drives the entire system.

Key Components of the Motor Assembly

The motor assembly comprises several critical elements that include the rotor, stator, and various internal connections. These parts work together to convert electrical energy into mechanical movement. Each element plays a crucial role in ensuring the tool operates at full capacity, providing both power and precision.

Functionality and Maintenance

To maintain optimal functionality, regular inspections of the motor assembly are recommended. Ensuring that the internal components remain in good condition can prevent unnecessary wear and tear. Proper care and periodic cleaning will prolong the life of the motor, ensuring it remains

Handle and Grip Breakdown

The handle and grip assembly plays a critical role in ensuring comfort and control during tool operation. This section provides an overview of the essential components that contribute to user ergonomics, allowing for a secure and stable grip during intense use.

Key elements include the following:

Guide to the Gear System

The internal gear mechanism plays a critical role in ensuring smooth and efficient operation. It is designed to transfer power from the motor to other components, allowing for the controlled movement and optimal functionality of the device. Understanding the structure and function of this system can help in maintaining performance and troubleshooting potential issues.

Main Components of the Gear Mechanism