In the world of construction and heavy-duty tasks, the efficiency of a tool often hinges on its internal structure and individual elements. A comprehensive examination of a specific model can unveil the intricacies that contribute to its overall performance. By analyzing these components, users can enhance their understanding and maintenance practices, ensuring longevity and reliability.

Many professionals rely on detailed representations to navigate the complex assembly of their equipment. These visual aids serve as valuable resources, allowing operators to identify each segment’s role and functionality. With a clear grasp of the tool’s architecture, users can troubleshoot issues more effectively and perform repairs with confidence.

This exploration not only highlights the importance of each piece but also emphasizes the synergy required for optimal operation. Recognizing how various elements interact empowers users to make informed decisions about upgrades and replacements, ultimately leading to improved productivity on the job site.

Understanding the Hilti TE 70 ATC

This section provides an insightful overview of a powerful tool designed for heavy-duty applications. It explores the components that contribute to its efficiency and versatility in various construction tasks. Understanding these elements is essential for effective usage and maintenance, ensuring optimal performance over time.

Key Features and Benefits

The tool is equipped with advanced features that enhance its functionality. Notably, its robust design allows for prolonged use in demanding environments, making it a preferred choice among professionals. Ergonomics play a crucial role in user comfort, reducing fatigue during extended operations. Moreover, the innovative technology integrated into this equipment ensures precision and reliability, essential for achieving high-quality results.

Maintenance and Care

Regular maintenance is vital for sustaining the performance of this equipment. Users should familiarize themselves with the critical components that require attention, ensuring that each part functions optimally. Routine checks can prevent potential issues and prolong the lifespan of the tool, making it a worthwhile investment for any contractor.

Key Features of the TE 70 ATC

The tool in question boasts a range of innovative characteristics designed to enhance performance and efficiency in heavy-duty applications. Its robust engineering ensures reliability and durability, making it a preferred choice for professionals in various industries.

- Powerful Motor: Equipped with a high-performance motor that delivers exceptional torque and speed for demanding tasks.

- Versatile Functionality: Capable of handling various drilling and chiseling tasks, providing flexibility for multiple applications.

- Advanced Vibration Control: Features advanced technology to minimize user fatigue during prolonged operation.

- Ergonomic Design: Crafted with user comfort in mind, ensuring a secure grip and ease of handling.

- Durable Construction: Built with high-quality materials that withstand tough job site conditions and extend tool life.

These attributes contribute to its reputation as a reliable tool that meets the rigorous demands of construction and renovation projects.

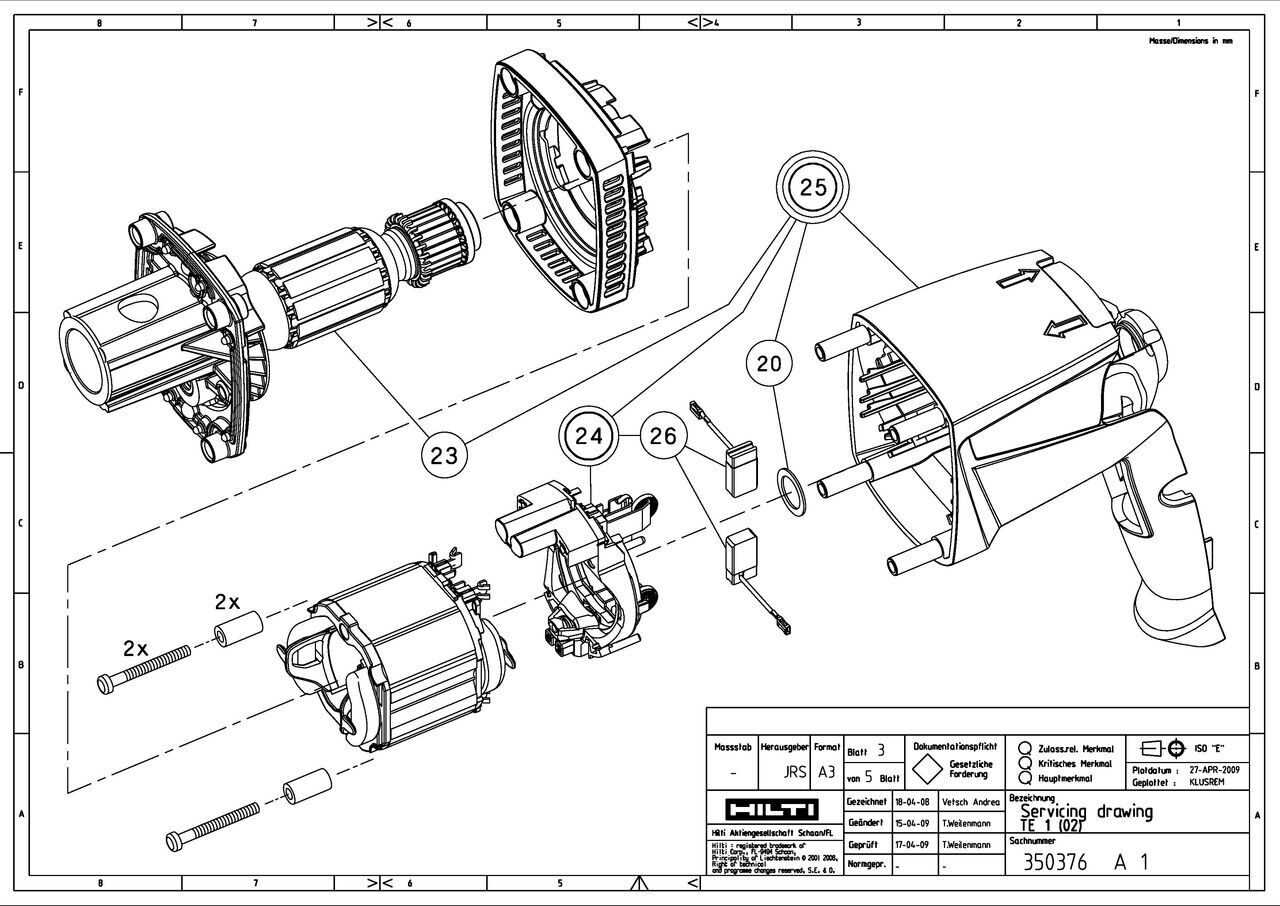

Components Overview of TE 70 ATC

This section provides an in-depth examination of the essential elements that comprise the TE 70 model. Understanding these components is crucial for optimal operation and maintenance. Each part plays a vital role in enhancing the performance and efficiency of the tool, contributing to its overall functionality.

Motor Assembly: The heart of the device, the motor assembly drives the entire mechanism. It is designed for robust performance, ensuring reliability under heavy usage.

Gearbox: This component transmits power from the motor to the tool’s working end. Its engineering allows for precise control over speed and torque, making it adaptable to various tasks.

Drilling Mechanism: A critical feature, this part facilitates effective penetration into various materials. It is engineered to handle both rotary and hammering actions, providing versatility in applications.

Handle Grip: Designed for user comfort and control, the handle grip enhances the overall experience, reducing fatigue during prolonged use.

Safety Features: Integrated safety mechanisms protect the user and the tool itself. These include overload protection and ergonomic designs that minimize the risk of accidents.

In summary, each element of this powerful tool is meticulously crafted to ensure high performance, safety, and user satisfaction. Understanding these components allows for better maintenance and effective usage.

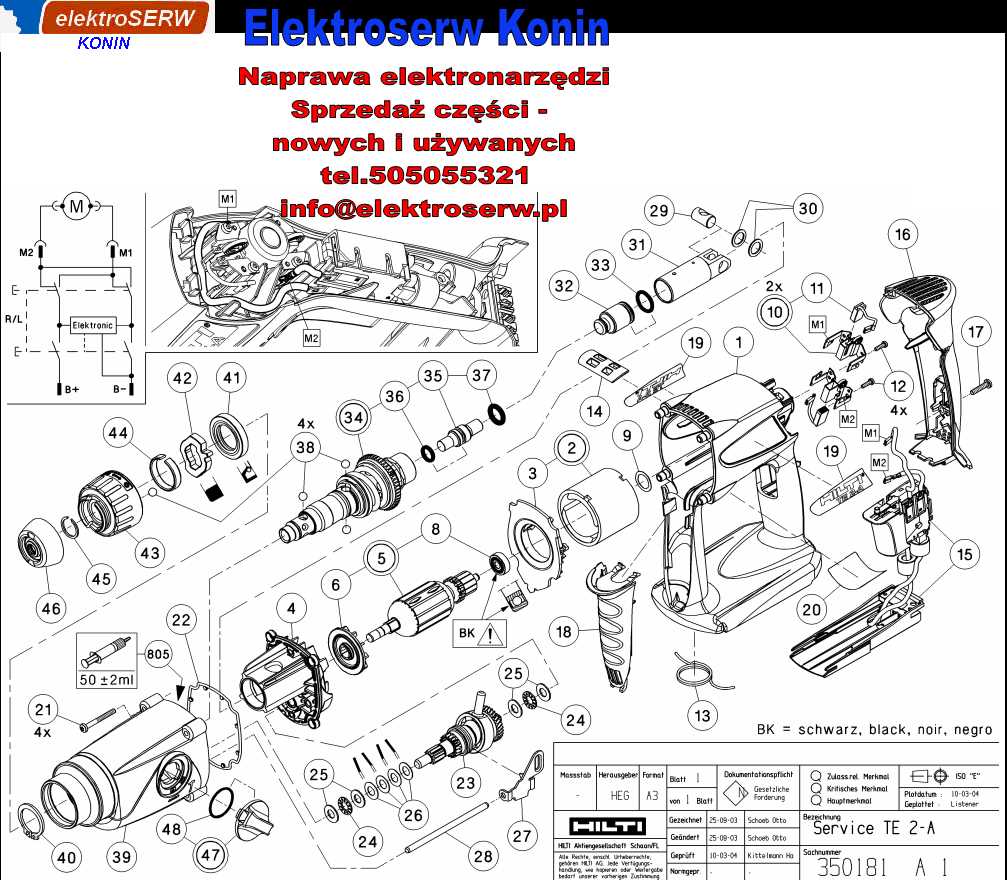

How to Read Parts Diagrams

Understanding technical illustrations is essential for efficient maintenance and repair of tools. These visuals provide a clear representation of components and their interconnections, enabling users to identify and source the necessary items effectively.

Key Elements of Technical Illustrations

- Labels: Each component is usually accompanied by a label, which helps in identifying its name and function.

- Numbering System: Parts are often numbered sequentially, corresponding to a list or catalog for easy reference.

- Connections: Lines or arrows may indicate how various elements interact with each other, showing the assembly or disassembly order.

Steps to Interpret Visual Representations

- Familiarize yourself with the layout of the illustration, noting the general structure and arrangement of parts.

- Check the legend or key, if available, to understand the symbols and notations used.

- Follow the numbering to locate each item on the accompanying list, which usually provides detailed descriptions and specifications.

- Pay attention to any highlighted areas that may indicate critical components or common failure points.

By mastering the ability to decode these visual guides, users can streamline their maintenance tasks and ensure their equipment operates smoothly.

Common Issues with TE 70 ATC

The robust tool is designed for heavy-duty applications, yet it can encounter various challenges that affect its performance. Understanding these common problems can help users maintain efficiency and extend the lifespan of the equipment.

Frequent Malfunctions

One of the primary issues users face is jamming. This can occur due to debris accumulation or inadequate lubrication, leading to decreased functionality. Regular cleaning and appropriate maintenance are essential to mitigate this problem.

Power Fluctuations

Another concern is inconsistent power delivery. This may stem from electrical faults or worn components, resulting in reduced drilling efficiency. Monitoring the tool’s electrical connections and replacing any faulty parts can help maintain optimal performance.

Maintenance Tips for TE 70 ATC

Proper upkeep of your heavy-duty tool is essential for optimal performance and longevity. Regular maintenance not only ensures efficiency but also prevents costly repairs and downtime. Here are some valuable tips to keep your equipment in top shape.

Routine Inspection

- Check for any visible wear and tear on the exterior.

- Examine the cord and plug for any signs of damage.

- Ensure that all moving parts are functioning smoothly.

Cleaning Procedures

- Remove dust and debris from ventilation openings to prevent overheating.

- Use a soft brush to clean the tool’s surface and components.

- Periodically inspect and clean the chuck to maintain grip and accuracy.

Following these guidelines will enhance the reliability and lifespan of your tool, allowing you to complete projects efficiently.

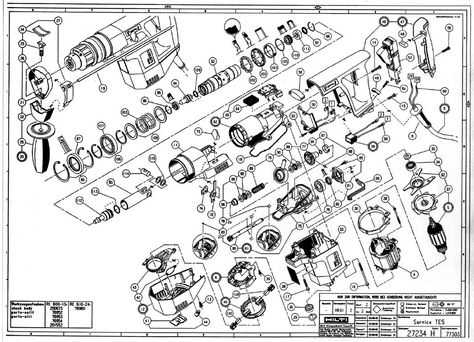

Replacement Parts Availability

Ensuring the continuous functionality of your equipment relies heavily on the availability of essential components. When repairs are necessary, having access to the correct items is crucial for minimizing downtime and maintaining efficiency in operations. This section explores the options available for sourcing replacement elements, emphasizing convenience and reliability.

Authorized Distributors play a vital role in providing high-quality components. They typically stock a wide range of items, ensuring that users can find what they need quickly. Additionally, these suppliers often offer expert advice on installation and compatibility, making the process smoother for everyone involved.

Another avenue to consider is online marketplaces, where a variety of options are available at competitive prices. Many vendors specialize in aftermarket solutions, which can provide a cost-effective alternative to original components. However, it’s essential to verify the quality and compatibility of these alternatives to avoid potential issues down the line.

Lastly, checking with manufacturers directly can be beneficial. They often provide comprehensive support, including guidance on which components are best suited for specific applications. This direct line of communication can enhance your understanding of what is available and help in making informed decisions.

Upgrades for Enhanced Performance

Enhancing the efficiency and longevity of power tools is essential for achieving optimal results in various tasks. By implementing targeted modifications and adopting advanced components, users can significantly boost the functionality and durability of their equipment. This section explores various upgrades that can lead to improved performance.

Key Areas for Improvement

- Power Supply: Upgrading the battery or power cord can provide a more stable energy flow, resulting in increased operational efficiency.

- Drilling Mechanism: Incorporating a high-performance drill bit or enhancing the mechanism can lead to smoother operation and better penetration in tougher materials.

- Ergonomic Features: Adding grip enhancements or weight distribution improvements can reduce fatigue and improve user control.

- Cooling Systems: Installing advanced cooling technology can prevent overheating, thereby extending tool life and maintaining consistent performance.

Benefits of Upgrades

- Increased productivity through faster and more efficient work processes.

- Reduced maintenance costs as improved components tend to last longer.

- Enhanced user comfort and safety, promoting better handling during use.

- Adaptability to various materials and job types, increasing versatility.

By considering these upgrades, users can significantly improve the overall performance and reliability of their tools, ensuring that they meet the demands of both professional and personal projects.

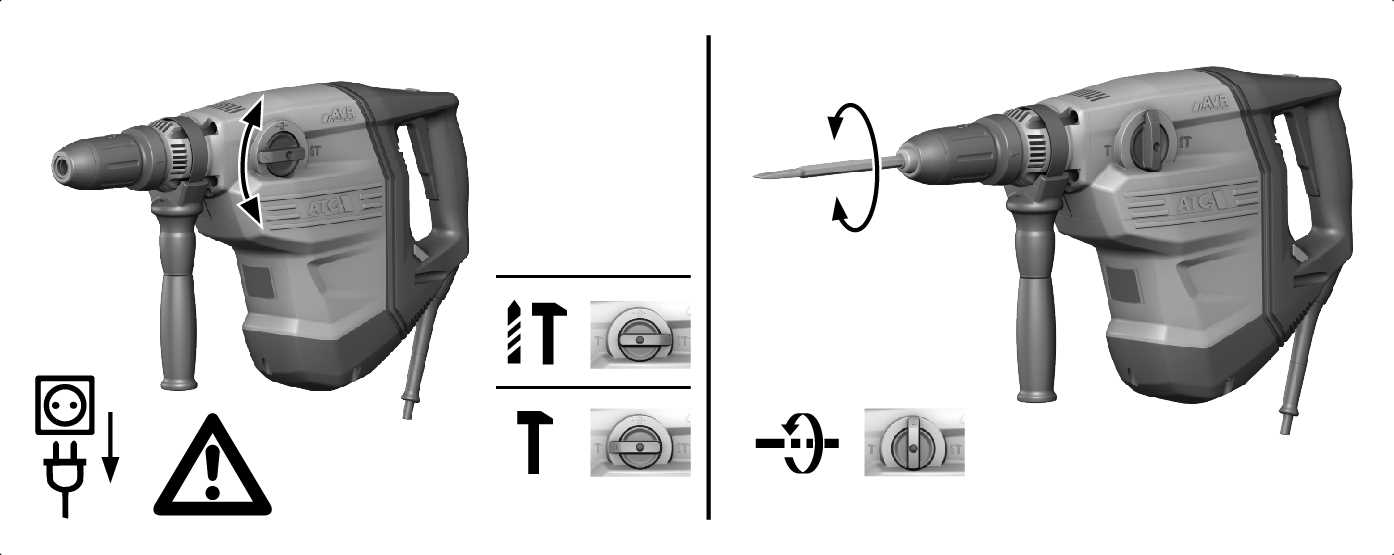

Safety Precautions When Operating

Ensuring a safe working environment is essential when using power tools. Adhering to specific guidelines minimizes the risk of accidents and injuries, promoting both personal safety and the well-being of others in the vicinity. Understanding these precautions will enhance the overall effectiveness and reliability of the equipment during operation.

Personal Protective Equipment

Before beginning any task, it is vital to equip oneself with the appropriate personal protective gear. This includes safety glasses to shield the eyes from debris, ear protection to mitigate noise exposure, and gloves to safeguard the hands from potential hazards. Additionally, sturdy footwear is crucial to protect against falling objects and provide stability while working.

Operational Guidelines

Always familiarize yourself with the equipment’s operating manual before use. Maintain a clean and organized workspace to prevent accidents caused by clutter. Ensure that the tool is in good working condition, checking for any signs of wear or damage. When operating, maintain a firm grip and proper stance to avoid losing control. Never bypass safety features, and always disconnect the tool from the power source when not in use or during maintenance.

Customer Reviews and Feedback

Understanding user experiences and insights is crucial for evaluating the performance and reliability of any tool. Reviews and feedback from customers offer valuable perspectives that can guide potential buyers in making informed decisions. Below are some key observations gathered from user testimonials.

- Durability: Many users commend the robust construction, highlighting its ability to withstand demanding conditions.

- Ease of Use: Feedback often notes the intuitive design, which simplifies operation and reduces learning time for new users.

- Performance: A majority report high satisfaction with the tool’s efficiency, particularly in heavy-duty applications.

However, there are also some common concerns:

- Weight: Some users feel that the tool could be lighter for enhanced portability.

- Noise Level: A few reviews mention that it operates louder than expected, which could be a consideration for indoor use.

- Customer Support: There are mixed feelings about the responsiveness and helpfulness of customer service in certain situations.

Overall, user feedback highlights both strengths and areas for improvement, providing a well-rounded view that can assist others in their purchasing choices.