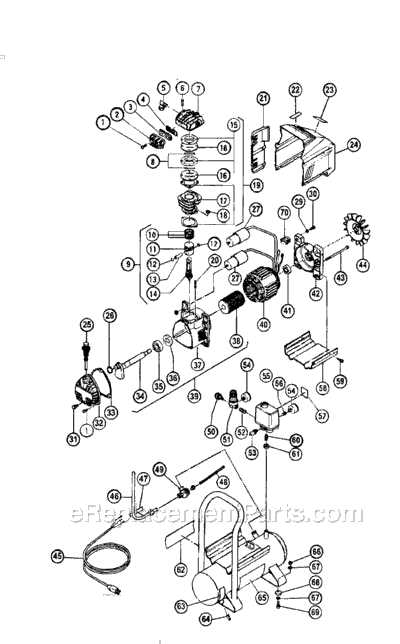

Maintaining and repairing complex machinery often requires a deep understanding of how various components interact. For those who rely on durable and reliable equipment in their day-to-day operations, a clear view of the internal structure is key to ensuring longevity and efficiency. When you’re tasked with identifying specific elements and their placements, having a detailed layout of these components can make the process significantly smoother.

A visual breakdown of a mechanical system allows users to grasp not only the individual elements but also how these pieces function together. It helps to prevent unnecessary downtime by guiding users in replacing or maintaining specific elements without confusion. Such a resource is invaluable for both seasoned professionals and those new to

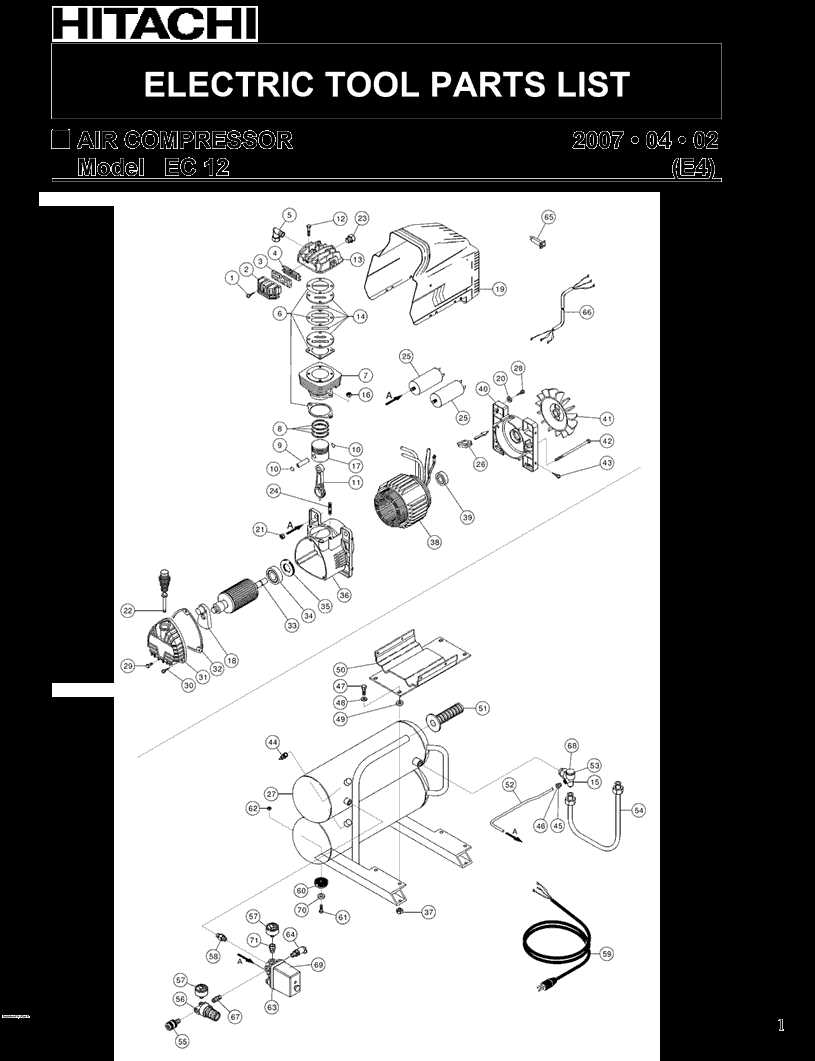

Overview of Hitachi EC12 Components

The machine consists of various essential elements that work together to ensure optimal performance and durability. Each part plays a crucial role in maintaining the device’s reliability, contributing to its overall efficiency and smooth operation. Understanding these components helps in recognizing their function and importance for maintaining and repairing the unit.

Main Operational Parts

Several key elements are responsible for the core operations, from air compression to ensuring proper pressure levels. These include mechanical structures that regulate air flow, electrical components for control, and safety mechanisms to prevent malfunctions.

Additional Functional Units

Alongside the core components, there are secondary elements that support stability and convenience.

Main Parts of Hitachi EC12 Compressor

This section will explore the essential components of a well-known air compressor model, focusing on its key elements that ensure efficient operation. Understanding these core elements will help in maintenance, troubleshooting, and optimal use of the equipment.

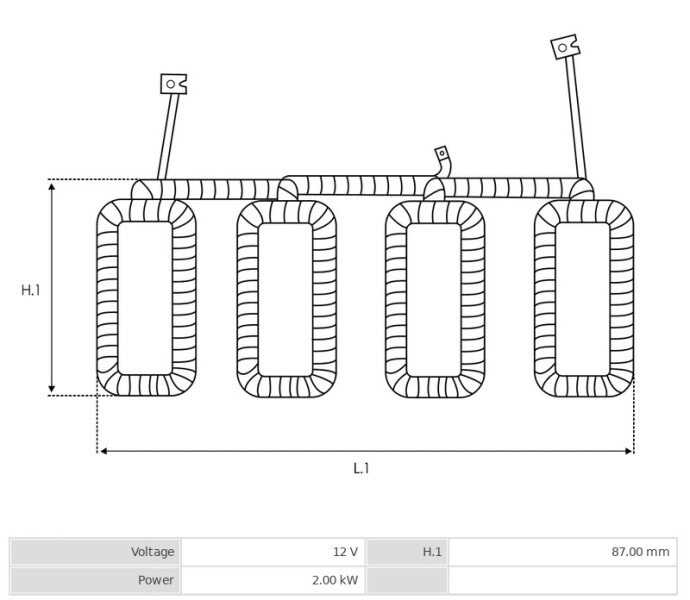

Motor and Power System

The motor drives the entire system, converting electrical energy into mechanical force. This is the primary component responsible for powering the compression process, ensuring that air is efficiently pressurized for various tasks.

- Electric motor – the heart of the unit, driving the air compression process.

- Power cord and switch – provides electricity and controls the activation

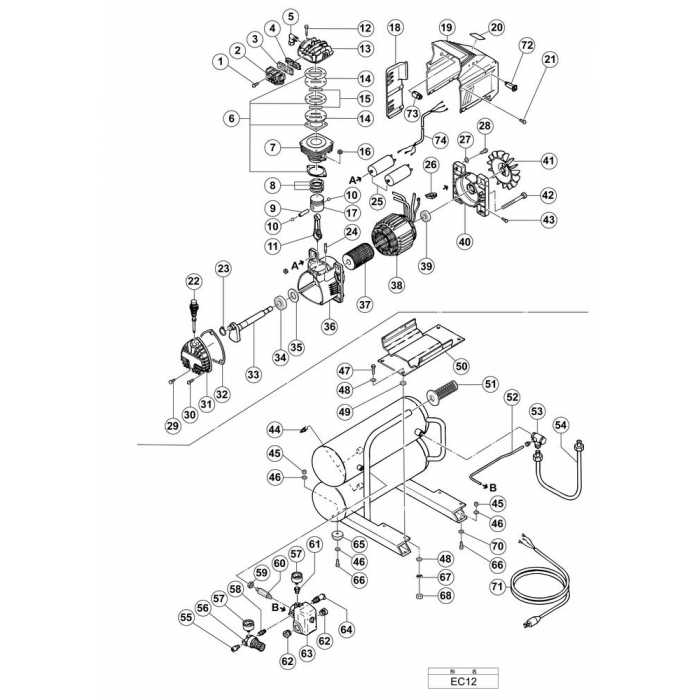

Key Features of the Hitachi EC12

This model offers a combination of reliability and performance, making it a popular choice among users. Its design and functionality are tailored to meet various needs, delivering consistent and efficient results across different applications.

- Durable construction ensures long-lasting performance, even under frequent use.

- Compact and portable, making it easy to transport and store in tight spaces.

- Designed with user-friendly controls that simplify operation for both beginners and professionals.

- Efficient air delivery for powering a range of tools, from basic to more advanced equipment.

- Low maintenance requirements, minimizing downtime

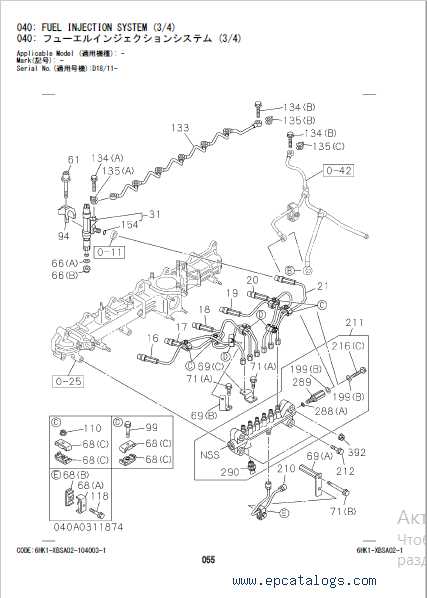

Understanding the Air Tank and Valves

The air tank and valves are crucial components in any pneumatic system. They work together to store and regulate the compressed air, ensuring the system functions smoothly and efficiently. Proper understanding of these parts is key to maintaining optimal performance and preventing potential malfunctions.

The air tank serves as a reservoir, holding compressed air that can be used as needed. This helps to stabilize pressure levels and allows for consistent airflow, even during periods of high demand. Tanks come in various sizes and are designed to handle different pressure ranges, depending on the requirements of the system.

Valves control the flow of air into and out of the tank. These mechanisms regulate pressure, ensure safe operation,

Motor and Pump Assembly Details

The motor and pump are integral components that work together to provide efficient and reliable operation. Their proper functioning is essential for maintaining the overall performance and ensuring smooth operation. In this section, we will focus on the critical elements of these units, explaining their role and interconnections.

Both the motor and the pump consist of various elements that need to be in sync for optimal performance. The motor provides the power necessary to drive the pump, which, in turn, facilitates the movement of fluids or air through the system. Below is an overview of the key components within this assembly.

Component Description Pressure Regulator Functionality

The pressure regulator plays a crucial role in maintaining a consistent pressure level within a system. Its primary function is to ensure that the pressure of the fluid remains stable, preventing fluctuations that could lead to operational inefficiencies or potential damage to connected components.

This device operates by automatically adjusting the flow of the fluid based on the pressure detected within the system. When the pressure exceeds a predetermined threshold, the regulator modulates the flow, allowing excess fluid to escape or diverting it to a different part of the system. Conversely, if the pressure drops below the desired level, it restricts the flow to maintain optimal conditions.

Function Description Pressure Monitoring Continuously tracks the pressure levels within the system. Flow Adjustment Regulates the flow of fluid to maintain desired pressure. Safety Mechanism Prevents overpressure conditions that could damage components. Efficiency Improvement Enhances system performance by ensuring stable pressure levels. Hose and Coupler Connections

Establishing secure and efficient connections between hoses and couplers is essential for the proper functioning of any hydraulic or pneumatic system. These connections ensure that fluids can be transferred smoothly without leaks, maintaining the integrity of the entire operation. Understanding the components involved and their correct assembly is crucial for optimal performance.

Types of Connections

There are various types of couplings designed for different applications. Quick-connect couplers allow for rapid and convenient attachment and detachment of hoses, making them ideal for frequent changes in equipment. On the other hand, threaded connections provide a more permanent solution, ensuring a tight seal for prolonged use. Each type serves its purpose, depending on the specific requirements of the task at hand.

Installation and Maintenance Tips

To achieve the best results, it is vital to ensure that all connections are properly aligned and tightened. Regular inspections can help identify signs of wear or damage, allowing for timely replacements. Using compatible materials and following manufacturer guidelines will significantly enhance the longevity and reliability of the connections.

Maintenance Tips for Hitachi EC12

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Adopting a proactive approach to maintenance can prevent unexpected breakdowns and costly repairs.

Here are some essential practices to consider:

- Conduct routine inspections to check for wear and tear.

- Keep the machine clean to avoid debris buildup that may hinder performance.

- Check and replace fluids as recommended by the manufacturer.

- Ensure all moving parts are lubricated properly to minimize friction.

- Verify that electrical connections are secure and free from corrosion.

By adhering to these guidelines, operators can significantly extend the life of their machinery and maintain optimal functionality.

Troubleshooting Common Issues

When operating machinery, various challenges may arise, impacting performance and efficiency. Identifying and resolving these problems promptly is crucial to maintain optimal functionality. This section provides guidance on addressing frequent concerns that users may encounter during operation.

No Power: If the equipment fails to start, check the power supply connections and ensure the outlet is functioning correctly. Inspect fuses or circuit breakers for any interruptions that may prevent electrical flow.

Unusual Noises: Strange sounds can indicate mechanical issues. Inspect moving parts for wear and tear, ensuring all components are adequately lubricated. If the noise persists, a thorough examination by a professional may be necessary.

Overheating: Excessive heat may lead to equipment malfunction. Ensure proper ventilation around the unit and check for blocked air filters. Regular maintenance is essential to prevent overheating and extend the machine’s lifespan.

Inconsistent Performance: If the operation is erratic, assess the settings and configurations. Verify that all parts are securely attached and functioning correctly. Regular calibration and adjustments can enhance performance reliability.

By addressing these common issues with diligence, users can ensure smoother operation and prolong the life of their equipment.

Replacement Parts Availability

When it comes to maintaining machinery, ensuring access to essential components is crucial for optimal performance. The availability of these necessary items can significantly impact the longevity and efficiency of your equipment. Understanding where and how to source these elements is vital for any user looking to keep their machinery in top condition.

Many suppliers offer a wide range of replacement components, catering to various models and specifications. It is advisable to explore both online and local retailers for an extensive selection. Online platforms often provide detailed catalogs, making it easier to identify compatible items. Additionally, checking with authorized dealers can ensure that you acquire high-quality replacements that meet the required standards.

Furthermore, some manufacturers maintain inventory for popular models, which can streamline the procurement process. Establishing a reliable network of suppliers can enhance your ability to quickly access necessary components, minimizing downtime and maintaining productivity. Regularly reviewing the availability of these items can help in planning maintenance schedules effectively.

Installation Guide for New Components

This section provides a comprehensive overview of the procedures for installing new parts in your equipment. Proper installation is crucial for ensuring optimal performance and longevity. Follow the guidelines closely to achieve a successful setup.

Before beginning the installation process, gather all necessary tools and new components. Ensure that you have a clean workspace to prevent any foreign objects from interfering with the assembly. Familiarize yourself with the specific requirements of each component to avoid mistakes.

Start by carefully removing the old component. Ensure that the equipment is powered off and disconnected from any power sources. Take note of how the old part is installed, as this will assist you in positioning the new one correctly.

Next, install the new component by aligning it with the existing mounts or connections. Apply gentle pressure to secure it in place. Make sure to double-check that all connections are tight and properly fitted to prevent operational issues.

Once the new component is securely installed, conduct a thorough inspection. Ensure that everything is aligned correctly and that there are no loose connections. Power on the equipment and monitor its performance to confirm that the installation was successful.

By following these steps carefully, you can ensure that the new parts are integrated seamlessly, enhancing the functionality and reliability of your equipment.