In the world of construction and heavy machinery, the intricate systems and components play a crucial role in ensuring optimal performance and reliability. A comprehensive grasp of these elements is essential for operators and technicians alike, facilitating effective maintenance and efficient operation.

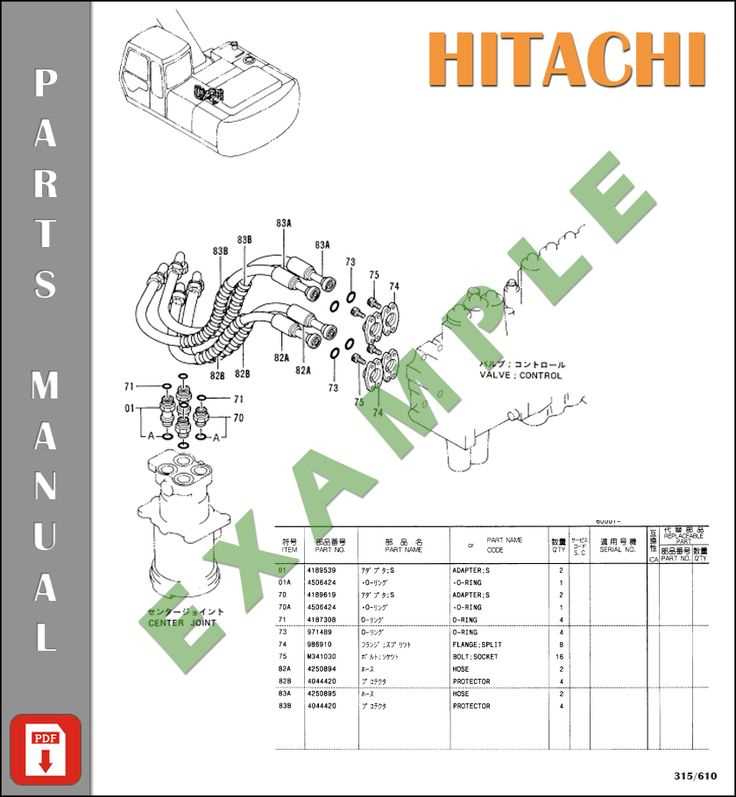

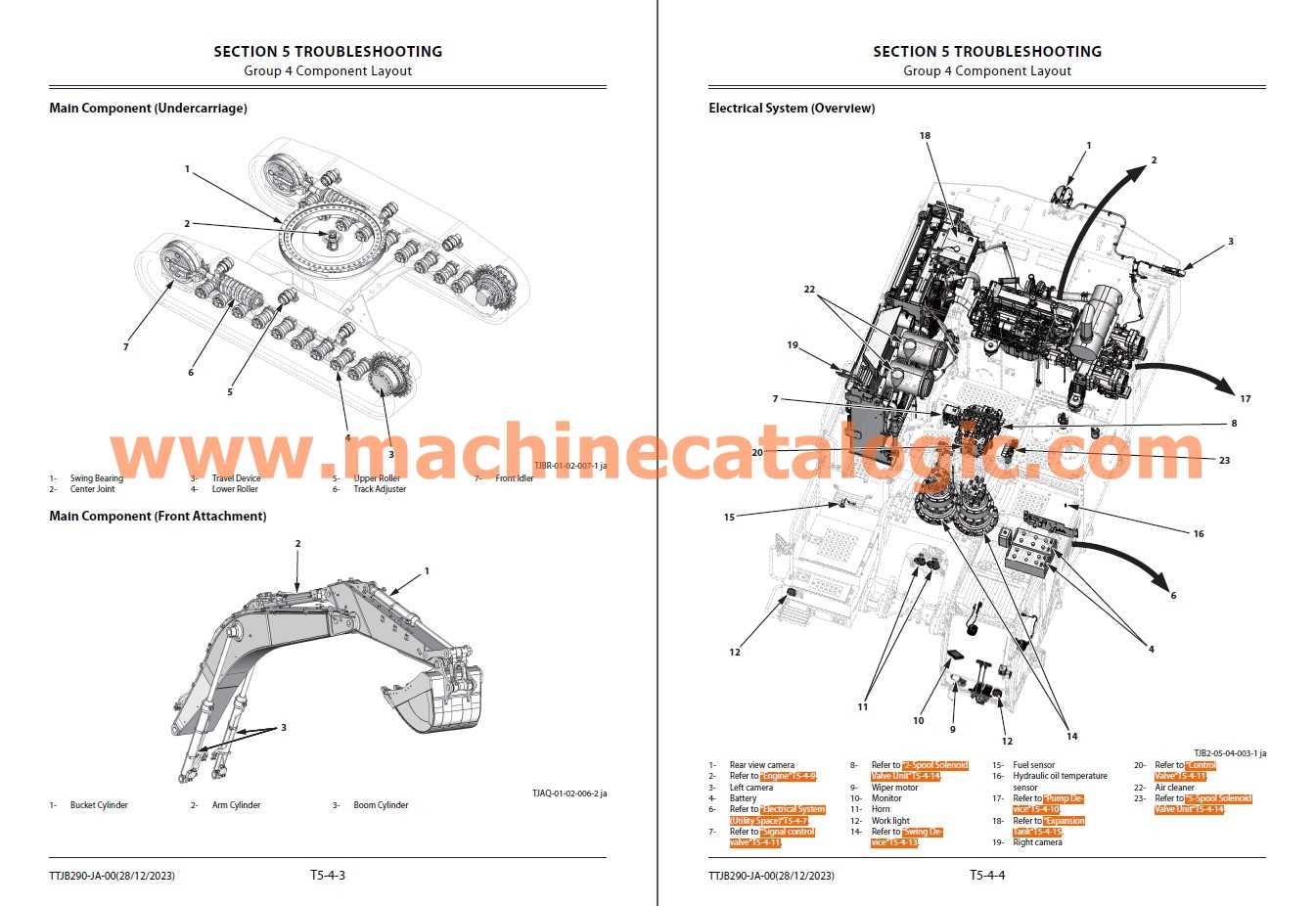

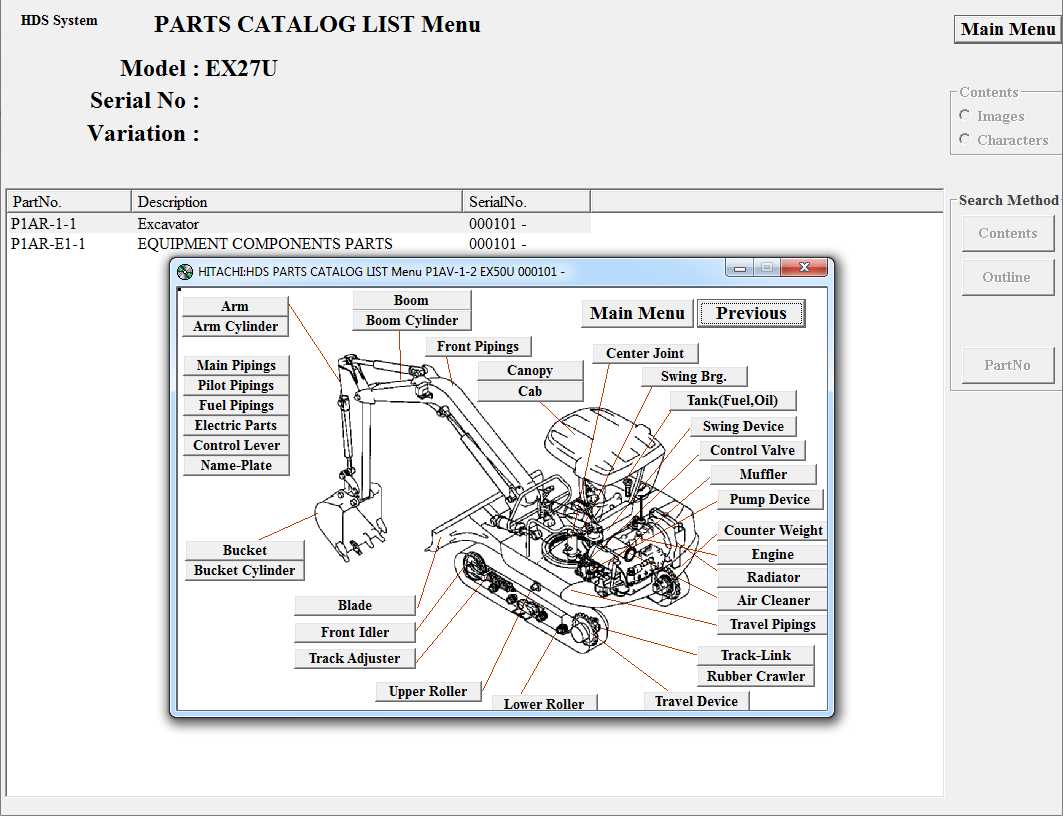

Visual representation of mechanical assemblies can greatly enhance the understanding of their functionality and interconnections. By exploring various configurations and layouts, one can gain insights into how each segment contributes to the overall operation of the machinery.

Whether you are a seasoned professional or a newcomer to the field, delving into the specifics of these mechanisms will ultimately lead to improved knowledge and skills. This guide aims to provide clarity and detail, enabling users to better navigate the complexities of these powerful machines.

Understanding Hitachi Excavator Components

Grasping the intricacies of heavy machinery is essential for effective operation and maintenance. This section will explore the various elements that constitute these powerful machines, focusing on their functions and interrelationships. A clear comprehension of these components enhances both efficiency and longevity.

Key Elements

- Hydraulic System: Responsible for power transmission.

- Undercarriage: Provides stability and mobility.

- Cab Structure: Ensures operator comfort and control.

- Engine: Powers the entire system.

Functions of Each Element

- Hydraulic System: Facilitates movement through fluid pressure.

- Undercarriage: Supports the weight and allows movement across various terrains.

- Cab Structure: Houses controls and offers protection to the operator.

- Engine: Generates the necessary power for operation.

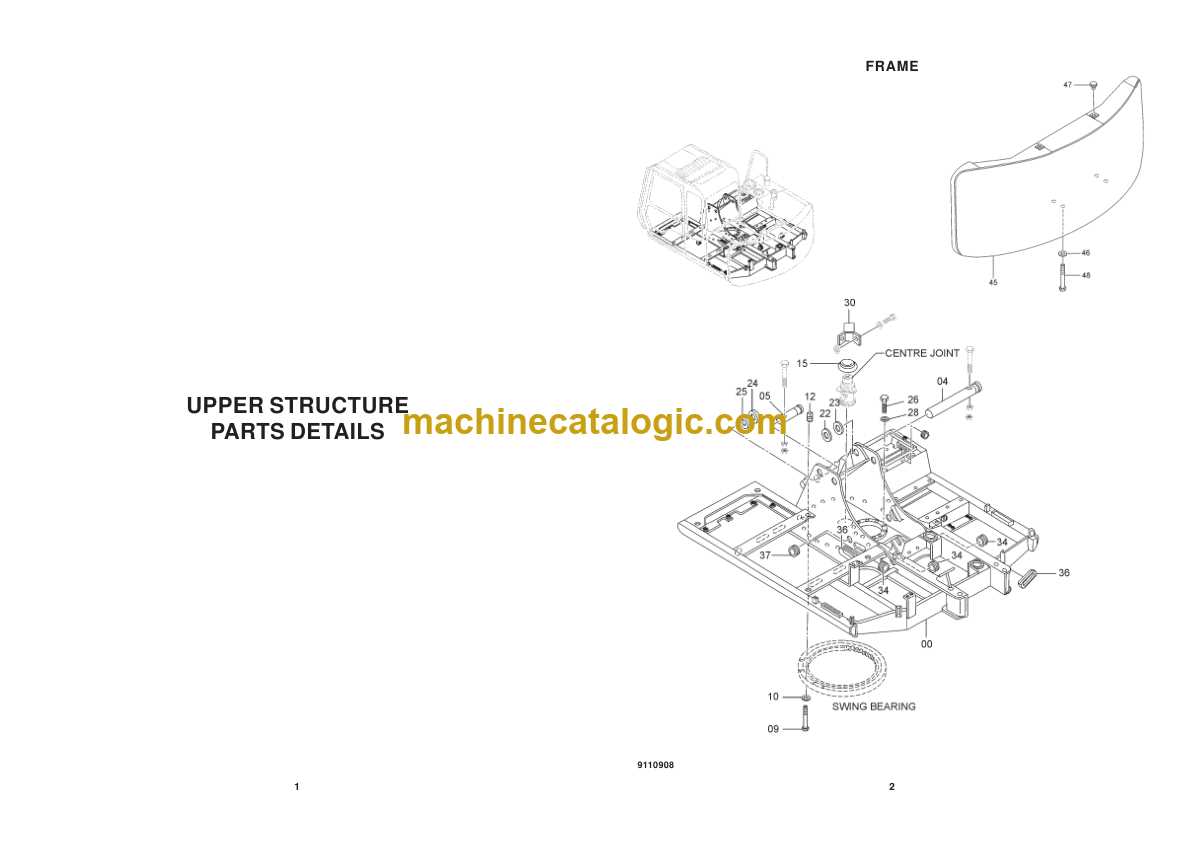

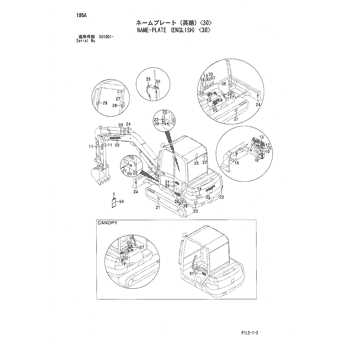

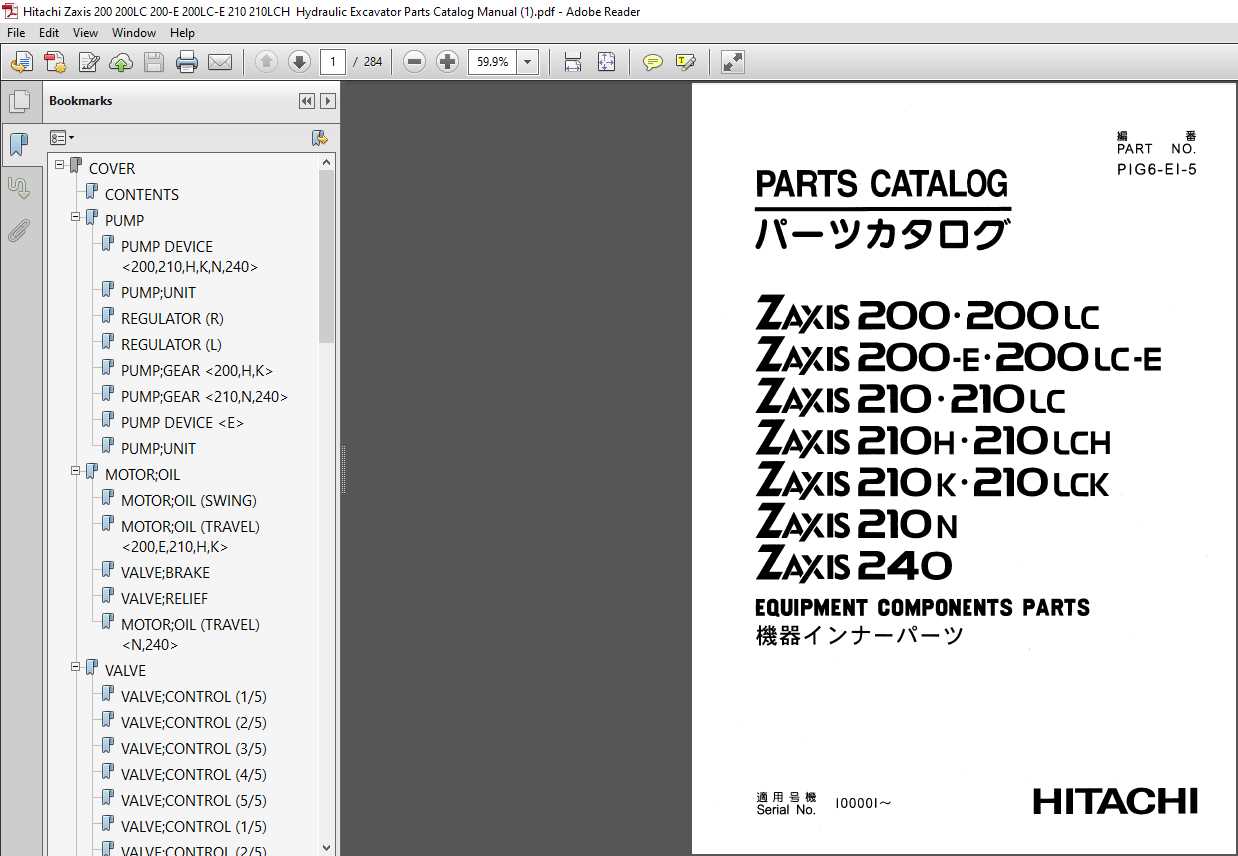

Overview of Excavator Parts

This section provides a comprehensive look at the essential components that contribute to the functionality and efficiency of heavy machinery used in construction and excavation tasks. Understanding these elements is crucial for maintenance, repair, and optimal performance in various applications.

Key Components

The major elements involved include the structural frame, hydraulic systems, and attachment tools. Each plays a pivotal role in ensuring the equipment operates smoothly and meets operational demands.

Functionality and Maintenance

Proper upkeep of these components ensures longevity and reliability. Regular inspections and timely replacements can prevent major breakdowns and enhance overall productivity.

| Component | Function |

|---|---|

| Frame | Supports all other components and provides stability. |

| Hydraulic System | Generates the power needed for movement and operation. |

| Attachments | Facilitate various tasks, such as digging or lifting. |

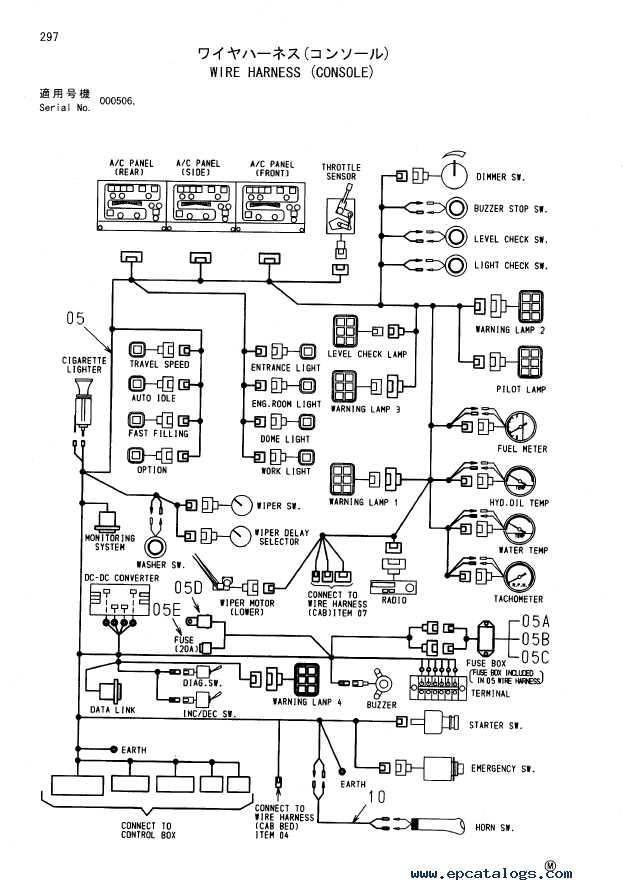

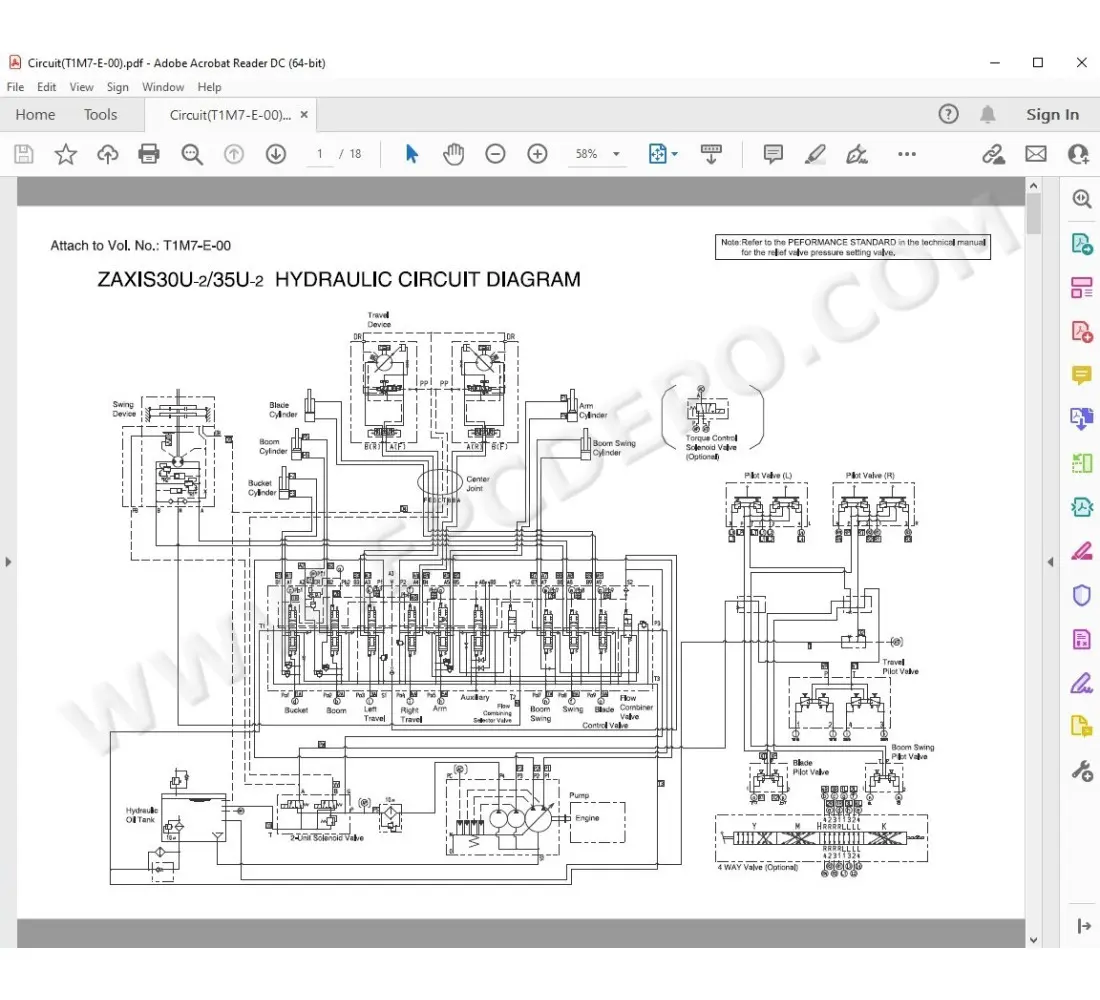

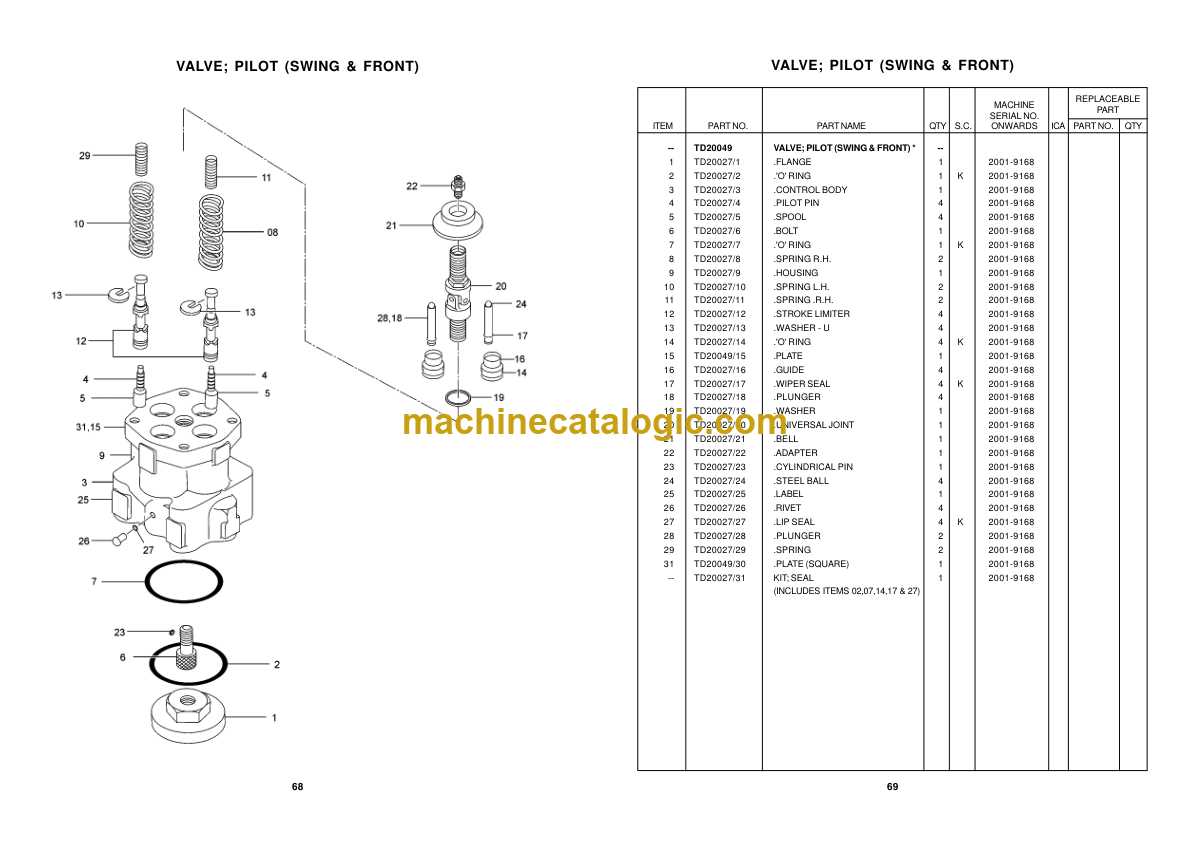

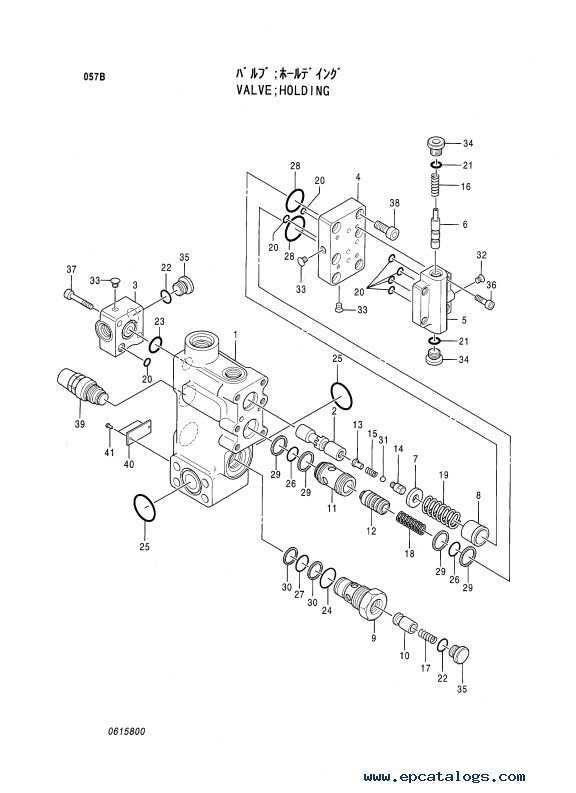

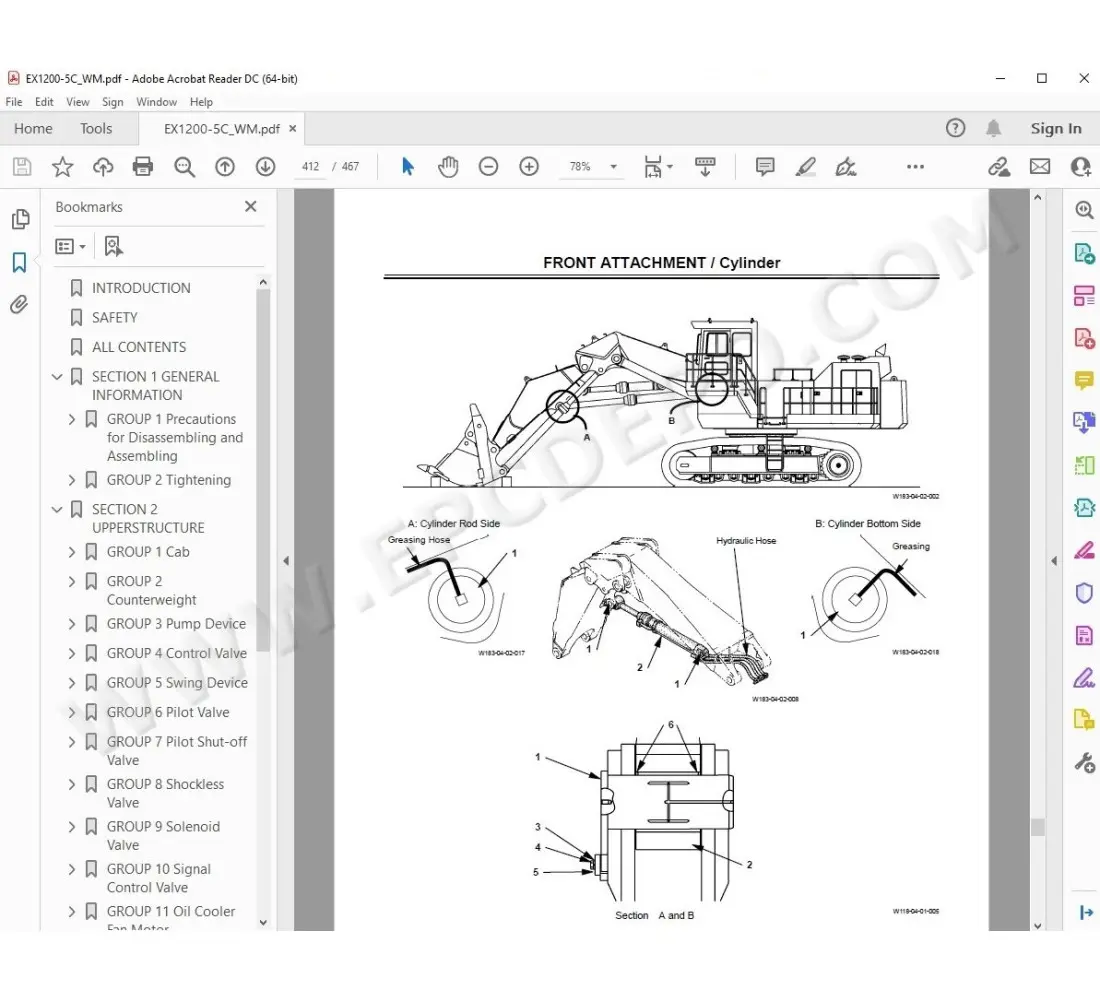

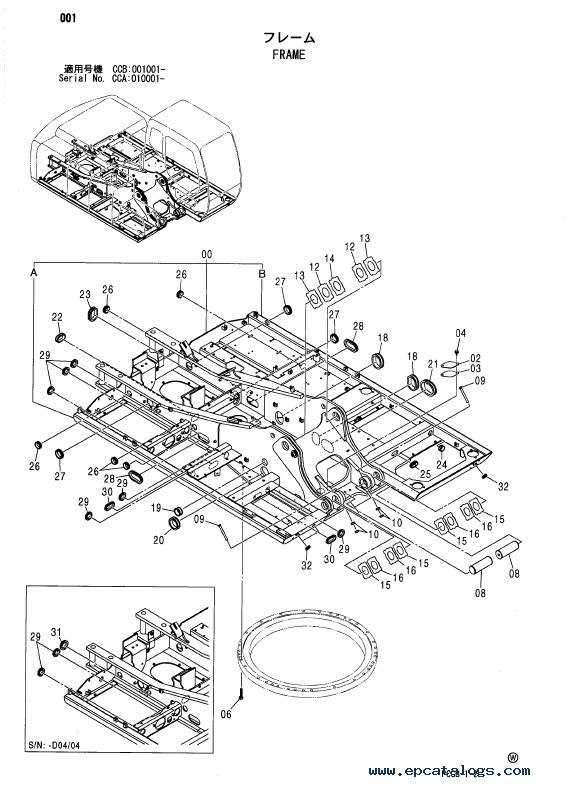

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in understanding complex machinery. They serve as essential tools for maintenance, assembly, and troubleshooting, ensuring that users can navigate intricate systems with ease.

Enhancing Understanding

Accurate visuals facilitate comprehension by breaking down components into understandable segments. Key benefits include:

- Visual clarity that simplifies intricate structures.

- Identification of individual elements and their functions.

- Support for effective communication among technicians and operators.

Streamlining Maintenance and Repairs

Well-crafted representations are vital for efficient servicing. They provide:

- Step-by-step guidance for assembly and disassembly.

- Quick reference points for troubleshooting issues.

- Reduction of errors during maintenance, saving time and resources.

In summary, precise visual aids are indispensable in the management and upkeep of machinery, promoting safety and efficiency in operations.

Common Parts in Hitachi Models

This section explores essential components found in various models, emphasizing their roles and importance in overall functionality. Understanding these elements is crucial for maintenance and repair, ensuring optimal performance and longevity.

Hydraulic System Components

The hydraulic system is vital for movement and operation. Key elements include the pump, which generates fluid pressure, and the cylinders, responsible for translating that pressure into motion. Regular checks on these components can prevent major failures.

Engine and Transmission Elements

The engine powers the machinery, while the transmission transfers that power effectively. Critical items such as the fuel injectors and filters must be maintained to ensure smooth operation and efficiency. Proper upkeep is essential for longevity.

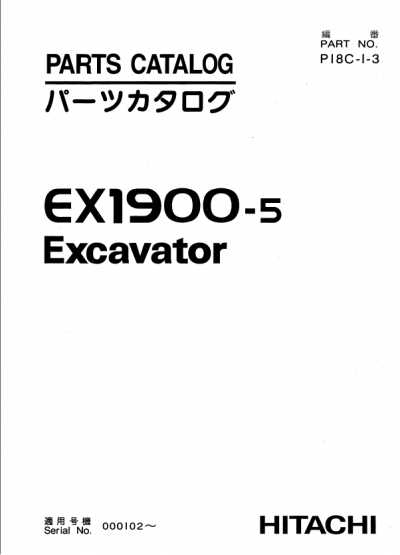

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of machinery. These visual guides provide a detailed overview of components and their relationships, enabling users to identify necessary items and their configurations.

1. Familiarize Yourself with Symbols: Each visual representation uses specific symbols to denote different elements. Take time to learn what each symbol represents to avoid confusion.

2. Examine the Legend: Most illustrations include a legend or key that explains the symbols and codes used. This is an essential tool for interpretation and should be referenced frequently.

3. Identify Sections: Diagrams are often divided into sections for clarity. Focus on one area at a time to ensure a thorough understanding of that part before moving on.

4. Note the Numbering System: Components are usually numbered for easy identification. Cross-reference these numbers with a list to find specific items quickly.

5. Contextualize the Information: Always consider the function of each component within the whole system. Understanding how parts work together will enhance your comprehension of the visual guide.

By mastering these techniques, you can confidently navigate technical illustrations and improve your ability to service machinery effectively.

Maintenance Tips for Excavator Parts

Proper upkeep of machinery components is crucial for optimal performance and longevity. Regular attention not only enhances efficiency but also prevents unexpected breakdowns, ultimately saving time and costs.

Routine Inspections

- Check for wear and tear regularly.

- Inspect seals and gaskets for leaks.

- Examine hydraulic lines for any signs of damage.

Lubrication Practices

- Ensure all moving parts are properly lubricated.

- Use the recommended lubricant types to avoid complications.

- Schedule lubrication at consistent intervals to maintain smooth operation.

Identifying Worn Components

Recognizing deteriorated elements in machinery is essential for maintaining optimal performance and prolonging lifespan. Various indicators can signal that a component requires attention, helping operators take proactive measures before issues escalate.

Visual Inspection

Conducting a thorough visual examination is often the first step. Look for signs of wear such as cracks, excessive rust, or unusual discoloration. Surface irregularities may indicate that a part is nearing the end of its useful life.

Functional Testing

In addition to visual checks, operational assessments can reveal hidden problems. Unusual noises during operation or decreased efficiency may suggest that specific elements are compromised. Timely identification can lead to effective repairs and prevent further damage.

Replacement Parts: What to Consider

When seeking components for heavy machinery, several crucial factors should guide your decision-making process. Understanding the implications of quality, compatibility, and longevity can significantly impact both performance and safety.

Quality is paramount; always opt for reputable manufacturers to ensure reliability and durability. Subpar components can lead to inefficiencies and costly repairs in the long run.

Next, consider compatibility with your specific machine model. Mismatched components can hinder functionality and may void warranties. Consulting a reliable source for specifications can be beneficial.

Finally, evaluate the cost-effectiveness of your options. While it may be tempting to choose the cheapest route, investing in high-quality components often yields better overall value and fewer issues over time.

Resources for Parts Diagrams

Accessing accurate and detailed illustrations is crucial for maintenance and repair tasks. These visual aids serve as essential tools for understanding the layout and function of various components within machinery. Utilizing reliable resources ensures that technicians can efficiently identify and replace elements, promoting the longevity and performance of equipment.

Online platforms often host extensive libraries of schematics and technical manuals. Manufacturer websites are a primary source, providing official documents that include comprehensive breakdowns of assemblies. Additionally, specialized forums and communities can offer valuable insights and user-generated content, featuring diagrams and discussions that enhance understanding.

Physical manuals are another excellent resource, often available through dealerships or equipment suppliers. These printed guides frequently accompany machinery and contain vital information about assembly configurations and part specifications.

Lastly, training programs and workshops can provide hands-on experience with these illustrations, enabling operators and mechanics to develop a deeper comprehension of equipment structure and functionality. Leveraging a combination of these resources will significantly improve the effectiveness of maintenance efforts.

Aftermarket vs. OEM Parts

The choice between alternative components and those from the original manufacturer is crucial for equipment maintenance and longevity. Each option presents unique benefits and considerations that can influence performance and cost-effectiveness.

Quality and Performance

Original components typically ensure compatibility and reliability, while alternative components may offer competitive pricing and adequate performance. Understanding the nuances of each can aid in making an informed decision.

Cost Considerations

Pricing varies significantly between the two options. Original components often come with a premium price tag, while alternatives might appeal due to lower costs, but it’s essential to assess the potential trade-offs in quality.

| Feature | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | High | Variable |

| Cost | Higher | Lower |

| Warranty | Often included | Limited |

| Availability | Specific to manufacturer | Widely available |

Key Features of Hitachi Excavators

This section explores the essential characteristics that define these robust machines, showcasing their efficiency and adaptability in various environments.

- Advanced Hydraulics: Provides superior lifting power and control.

- Fuel Efficiency: Designed to minimize fuel consumption while maximizing output.

- Operator Comfort: Ergonomically designed cabins with intuitive controls enhance user experience.

- Durability: Built with high-quality materials to withstand harsh conditions.

- Versatile Attachments: Compatible with a wide range of tools for different applications.

These features collectively contribute to their ultimate performance in construction and excavation tasks.

Benefits of Regular Maintenance

Consistent upkeep of machinery plays a crucial role in ensuring optimal performance and longevity. Regular checks can significantly enhance efficiency, reduce downtime, and prevent costly repairs.

Enhanced Reliability: Routine servicing ensures that all components are functioning correctly, leading to increased dependability in operations.

Cost Savings: By identifying potential issues early, maintenance can avert major breakdowns, ultimately saving money on repairs and replacements.

Improved Safety: Regular assessments help to identify hazards and mitigate risks, promoting a safer working environment for operators.

Prolonged Lifespan: Consistent attention to machinery ensures that parts wear evenly, extending the overall life of the equipment.

Optimal Performance: Well-maintained machinery operates at peak efficiency, which translates into better productivity and output quality.

In summary, regular maintenance is essential for achieving the ultimate performance and reliability of equipment.

Finding a Reliable Parts Supplier

When it comes to maintaining heavy machinery, sourcing quality components is essential for optimal performance and longevity. A dependable supplier not only provides the necessary items but also ensures that they meet the required standards of quality and compatibility. This section will guide you through the process of identifying trustworthy vendors.

Consider the following criteria when searching for a reliable supplier:

- Reputation: Research the supplier’s history and customer feedback. A strong reputation often indicates reliable service.

- Quality Assurance: Ensure that the vendor offers components that meet industry standards, with appropriate certifications.

- Availability: Check the range of products available. A supplier with a diverse inventory can better meet your specific needs.

- Pricing: Compare prices among different vendors, but be cautious of deals that seem too good to be true, as they may compromise on quality.

- Customer Support: Evaluate the level of service provided. A responsive support team can make a significant difference when issues arise.

- Delivery Times: Timely delivery is crucial for minimizing downtime. Ensure the supplier can meet your scheduling needs.

By taking these factors into account, you can select a supplier that will not only meet your immediate requirements but also build a long-term partnership for all your machinery needs.