In the realm of commercial kitchen apparatus, comprehending the intricate layout of essential components is crucial for optimal functionality. A well-structured overview of these elements not only enhances maintenance practices but also extends the lifespan of the machinery.

Familiarity with the individual sections allows users to identify issues swiftly, ensuring that operations run smoothly. This understanding fosters a proactive approach to equipment care, ultimately minimizing downtime.

Moreover, exploring these configurations can aid in the efficient training of new staff, making them more adept at handling the tools at their disposal. By delving into the specifics, users can achieve the ultimate efficiency in their culinary processes.

Understanding Hobart Meat Saw Functionality

The intricate design of cutting equipment plays a crucial role in the efficiency and effectiveness of food processing. Each component works harmoniously to ensure precision and safety while handling various types of ingredients. A deeper exploration into these mechanisms reveals how they contribute to optimal performance and user experience.

Key Components and Their Roles

Every unit consists of essential elements that facilitate its operation. The blade, for instance, is engineered for durability and sharpness, enabling it to tackle tough materials with ease. Additionally, the frame provides stability, allowing for steady movement during use. Understanding these key components enhances one’s ability to maintain and operate the equipment efficiently.

Maintenance for Longevity

Regular upkeep is vital to ensure the longevity of such machinery. Routine checks on the motor and belts help prevent breakdowns and extend operational life. Users who delve into maintenance practices are more likely to achieve consistent results and maximize their investment.

Essential Components of Meat Saws

Understanding the fundamental elements of cutting machines is crucial for optimal performance and longevity. Each component plays a significant role in ensuring efficiency and safety during operation.

| Component | Description |

|---|---|

| Blade | The primary tool for slicing through materials, available in various sizes and tooth configurations to suit different tasks. |

| Motor | Drives the blade, providing the necessary power to cut through tough substances effortlessly. |

| Table | A sturdy surface where the material is placed, designed to support various weights and sizes. |

| Guard | An essential safety feature that protects the user from accidental contact with the moving blade. |

| Feed Mechanism | Controls the movement of the material towards the blade, ensuring consistent and precise cuts. |

Common Issues with Hobart Saws

In any equipment designed for heavy-duty use, encountering problems is not uncommon. Understanding these challenges can help operators maintain optimal performance and ensure safety during operation. This section will explore typical concerns that users may face, along with solutions to enhance reliability.

Frequent Mechanical Failures

One prevalent issue is the malfunction of mechanical components, which can lead to operational delays. Regular inspection of belts, blades, and bearings is crucial. Replacing worn-out parts promptly can prevent further complications and enhance the equipment’s lifespan.

Electrical System Complications

Another area of concern is the electrical system. Faulty wiring or malfunctioning switches can disrupt functionality. Users should routinely check connections and ensure all electrical components are in good working condition to mitigate risks.

Maintenance Tips for Meat Saws

Proper upkeep of cutting equipment is essential for ensuring longevity and optimal performance. Regular maintenance not only enhances efficiency but also minimizes the risk of malfunctions. Following a structured maintenance routine can lead to better results and increased safety for users.

Routine Cleaning

Maintaining cleanliness is crucial. After each use, thoroughly clean all surfaces to remove any residue. Use a mild detergent and warm water to avoid damaging components. Ensure that no food particles are left behind, as they can harbor bacteria and affect the quality of future operations.

Regular Inspections

Conduct frequent inspections to identify wear and tear. Check for signs of rust, loose screws, or any irregularities in performance. Addressing minor issues promptly can prevent costly repairs later. Additionally, lubricate moving parts as recommended by the manufacturer to ensure smooth operation.

Safety first: Always disconnect power before performing maintenance tasks. Regular upkeep is not just about efficiency; it’s also about safeguarding users and extending the lifespan of the equipment.

Choosing the Right Replacement Parts

Selecting the appropriate components for your equipment is crucial for maintaining efficiency and ensuring safety during operation. A well-informed choice can significantly extend the lifespan of your machinery while minimizing potential downtime.

When considering replacements, keep the following factors in mind:

- Compatibility: Ensure that the component matches the specifications of your model to avoid performance issues.

- Quality: Opt for high-grade materials that can withstand rigorous use, which ultimately contributes to durability.

- Manufacturer Reputation: Choose products from reputable manufacturers known for their reliability and customer support.

Additionally, assessing the following can enhance your decision-making process:

- Cost: While affordability is important, prioritize quality over price to prevent frequent replacements.

- Reviews and Recommendations: Research feedback from other users to gauge the effectiveness and reliability of the component.

- Warranty: Check for warranty options that provide peace of mind in case of defects or issues post-purchase.

By carefully evaluating these aspects, you can ensure that the components you choose will meet your operational needs effectively and contribute to the overall functionality of your machinery.

Safety Guidelines

Ensuring safety while operating heavy-duty cutting equipment is paramount. Adhering to proper protocols minimizes risks and promotes a secure working environment. Always prioritize personal well-being and that of others in proximity.

1. Personal Protective Equipment: Always wear appropriate gear, including cut-resistant gloves, safety goggles, and non-slip footwear. This reduces the risk of injury during operation.

2. Pre-Operation Inspection: Conduct a thorough check of the machine before use. Look for any signs of wear or damage that could lead to malfunctions.

3. Proper Training: Only trained personnel should operate the equipment. Ensure everyone is familiar with operational procedures and emergency protocols.

4. Keep Work Area Clean: Maintain a tidy workspace to prevent accidents. Remove any obstacles or spills that could pose hazards.

5. Emergency Procedures: Be aware of emergency shutdown procedures and ensure that all operators know how to react in case of a malfunction.

By following these guidelines, operators can effectively mitigate risks and ensure a safe working environment for all involved.

Advantages of Using Meat Saws

Employing specialized cutting equipment offers numerous benefits in food preparation and processing. These tools enhance efficiency and precision, leading to superior outcomes in various culinary settings.

- Increased Efficiency: These devices significantly reduce the time required for cutting large quantities of protein.

- Precision Cuts: They provide uniform slices, ensuring consistent quality for cooking and presentation.

- Safety Features: Advanced designs often include safety mechanisms that protect users from accidental injuries.

- Versatility: Suitable for different types of products, from large portions to smaller cuts.

- Durability: Built with robust materials, they are designed to withstand heavy use and last over time.

These advantages make such tools an ultimate choice for professionals in the culinary industry.

Comparing Hobart Models and Features

When it comes to selecting equipment for food preparation, understanding the differences among various models is crucial. Each variant brings its own unique set of functionalities and specifications, catering to diverse operational needs. This section aims to highlight the distinctions in design and performance across popular versions, helping you make an informed choice.

Durability and Construction play a significant role in equipment selection. Certain models are built with robust materials designed to withstand heavy usage, while others may prioritize lightweight designs for ease of movement. Assessing the longevity and structural integrity of each variant can greatly impact your investment decision.

Performance and Efficiency are key factors that differentiate models. Some versions are engineered for high-speed operations, ideal for busy environments, whereas others may focus on precision cutting, providing superior control. Evaluating the power and speed settings available can help align your choice with your specific requirements.

Safety Features also vary significantly. Certain designs incorporate advanced safety mechanisms to protect users during operation, while others may lack these essential features. Understanding the safety protocols built into each model is critical for ensuring a secure working environment.

Maintenance and Ease of Use should not be overlooked. Some variants are designed for straightforward cleaning and upkeep, while others may require more complex procedures. Considering the maintenance needs can save time and effort in the long run.

By comparing these aspects, you can better navigate the options available and select the right equipment to meet your specific needs and preferences.

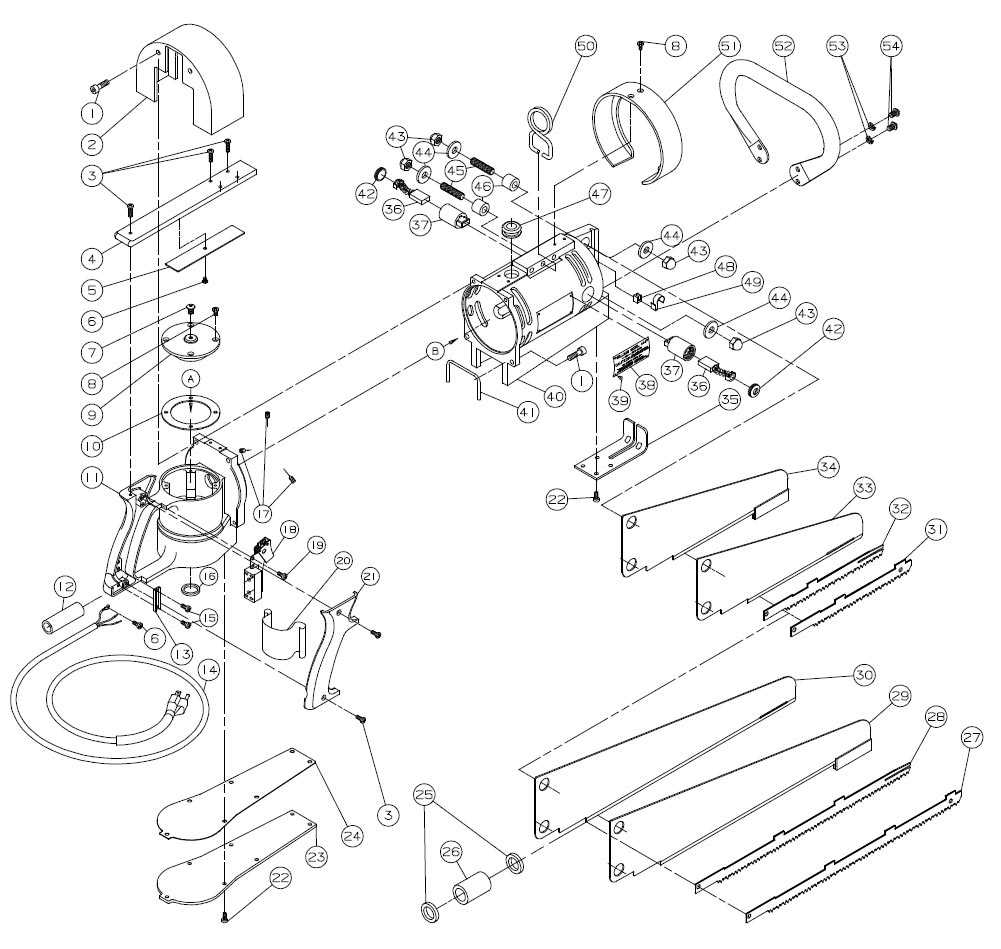

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for efficient maintenance and repairs. These visual representations provide a detailed overview of components, allowing users to identify and locate individual elements easily. Familiarity with the structure and symbols used can significantly enhance your ability to work with machinery.

First, examine the layout carefully. Each element is typically numbered or labeled, facilitating quick reference. Take note of the accompanying legend, which explains the symbols and designations utilized throughout the illustration. This reference is invaluable for comprehending the relationships between different components.

Next, pay attention to the arrangement of parts. Often, they are grouped based on their function or proximity to one another, which can offer insights into the assembly process. Understanding how parts interact can aid in troubleshooting issues more effectively.

Finally, consider any notes or additional information provided. These annotations often include important details such as assembly instructions, maintenance tips, or safety precautions, enhancing your overall understanding and efficiency. By mastering these aspects, you can streamline your repair and maintenance efforts significantly.

Where to Purchase Spare Parts

Finding the right components for your equipment is essential for maintaining its performance and longevity. Whether you need replacements or upgrades, knowing where to look can save you time and ensure you get quality items.

Here are some reliable sources for sourcing these components:

- Official Manufacturers: Check the website of the original manufacturer. They often have dedicated sections for replacement items.

- Authorized Dealers: Locate authorized retailers who sell genuine components, ensuring compatibility and quality.

- Online Marketplaces: Platforms like eBay or Amazon often have a variety of options, but be sure to check seller ratings and reviews.

- Specialty Supply Stores: Look for local or online stores specializing in industrial supplies; they may carry a wide range of necessary components.

- Second-Hand Options: Consider looking at classified ads or auctions for used items that may still be in good condition.

Always verify the specifications and compatibility of any item before making a purchase to ensure it meets your needs effectively.