The intricate world of welding machinery plays a pivotal role in various industrial applications. A comprehensive grasp of the essential elements that make up these devices is crucial for both novices and seasoned professionals. Recognizing how each component interrelates can significantly enhance efficiency and performance.

Every machine consists of a multitude of crucial elements, each serving a specific function. Whether you are troubleshooting issues, performing maintenance, or upgrading your setup, familiarizing yourself with these components can provide valuable insights. Knowledge of their arrangement and operation can lead to improved outcomes and increased longevity of your equipment.

In this section, we will delve into the various sections of welding apparatus, examining their features and interconnections. This exploration will not only aid in understanding functionality but will also empower users to make informed decisions regarding repairs and modifications. Emphasizing the importance of each part ensures that your equipment remains in optimal working condition.

Understanding Hobart Welders

This section explores the essential features and functionalities of a renowned brand known for its quality in metal joining equipment. These machines are pivotal for both amateur and professional users, offering reliability and efficiency in various applications. Grasping the core aspects of these devices can significantly enhance the user experience and overall output.

Key Features

Modern models are equipped with advanced technology that ensures optimal performance and adaptability. With options for different materials and thicknesses, users can achieve precise and consistent results, making these tools indispensable in workshops and construction sites alike.

Maintenance and Care

Proper upkeep is crucial for longevity and effectiveness. Regular inspections and cleaning can prevent wear and ensure the machinery operates at its best, allowing users to focus on their projects without unexpected interruptions.

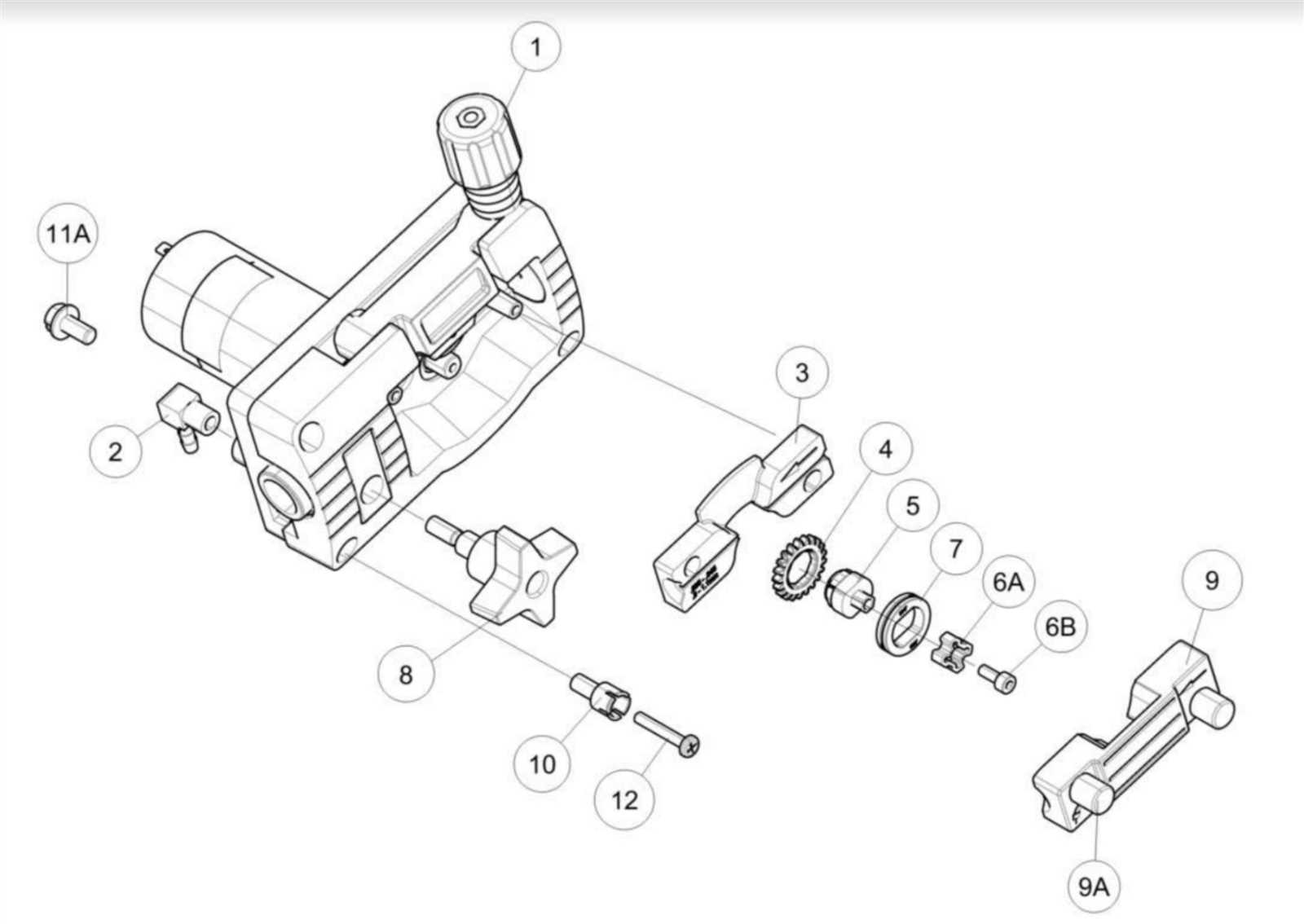

Components of a Hobart Welder

This section explores the essential elements that contribute to the functionality and efficiency of an arc fusing machine. Understanding these components is crucial for maintenance and optimal performance, ensuring the equipment operates effectively in various applications.

Power Supply Unit

The power supply unit is the heart of the device, providing the necessary energy for the melting process. It converts incoming electricity into the required voltage and current, ensuring a stable output for consistent performance.

Electrode Holder

The electrode holder is a pivotal component that secures the welding rod during operation. Its design allows for easy handling and replacement, ensuring the welder can switch rods efficiently to adapt to different materials and joint configurations.

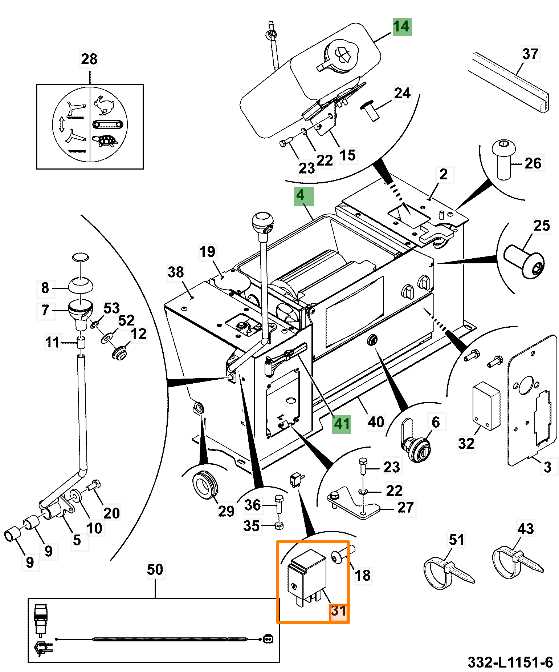

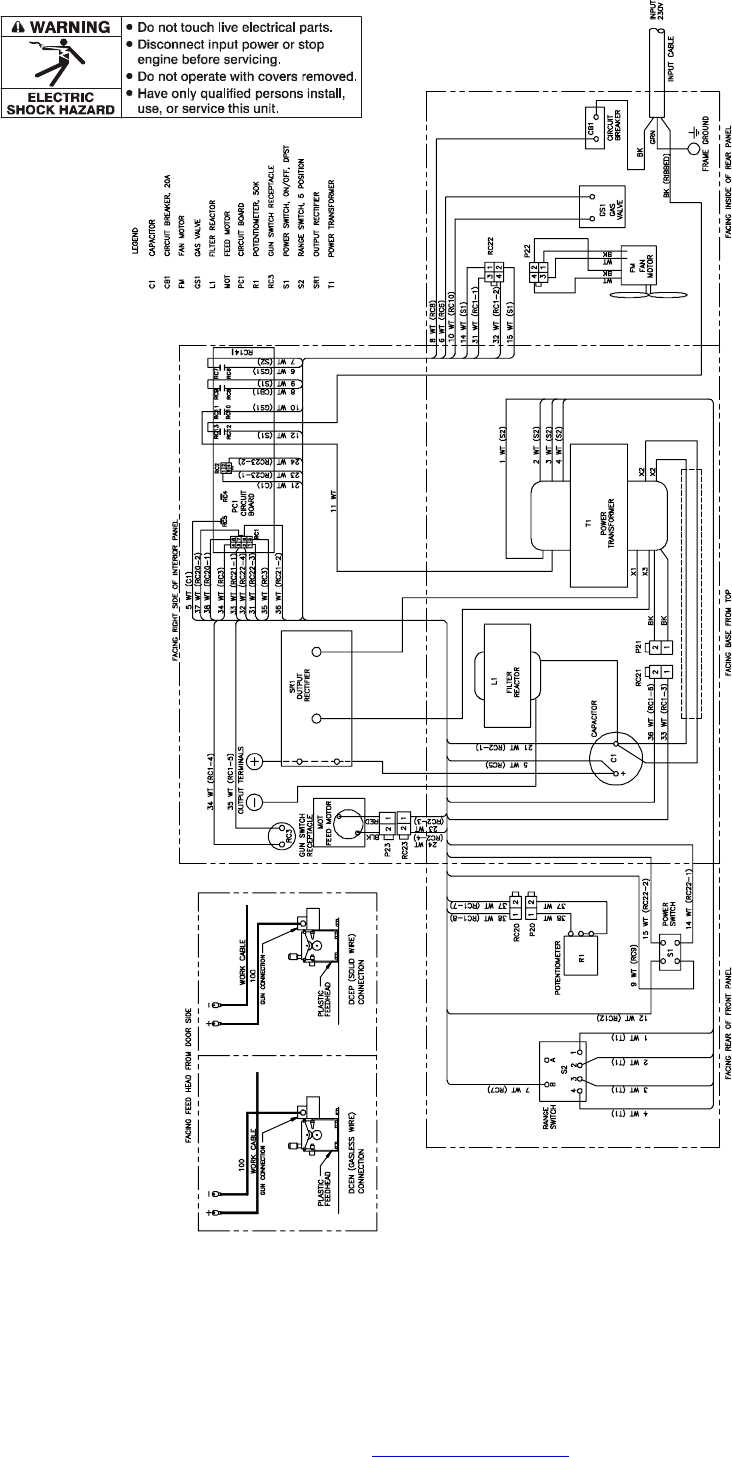

Importance of Diagrams in Maintenance

Visual representations play a crucial role in the upkeep and repair of complex machinery. They provide a clear and organized way to understand the intricate components and their interconnections, facilitating efficient troubleshooting and servicing. By illustrating the relationships between various elements, these visual tools help technicians quickly identify potential issues and implement effective solutions.

Moreover, having access to well-structured visuals enhances training and knowledge transfer among team members. New employees can grasp the overall system layout and functionality faster, leading to improved performance and reduced downtime. When maintenance personnel can easily refer to these illustrations, they are better equipped to follow procedures accurately, minimizing the risk of errors that could result in costly repairs or safety hazards.

In addition, clear visuals support better documentation practices. They can serve as reference points for future maintenance, ensuring consistency and continuity over time. This is particularly beneficial in industries where equipment is subject to rigorous standards and regulations, as it provides a reliable means of demonstrating compliance and accountability.

Common Issues and Solutions

In any mechanical device, users often encounter various challenges that can hinder performance. Understanding these issues and their solutions is crucial for maintaining efficiency and extending the lifespan of equipment. This section outlines some typical problems and practical remedies to help operators get back on track quickly.

Frequent Overheating

One of the most common challenges is overheating, which can lead to reduced efficiency and potential damage. Overheating often occurs due to inadequate cooling or excessive workload. To mitigate this, ensure that the unit has sufficient ventilation and is not operated beyond its recommended capacity. Regular maintenance checks can also help identify and rectify any cooling system issues.

Inconsistent Output Quality

Another prevalent issue is the inconsistency in output quality, which can arise from various factors such as incorrect settings or worn components. To achieve a more uniform result, first verify that the settings align with the material being processed. Additionally, inspect key components for wear and tear; replacing worn parts can significantly enhance performance and output consistency.

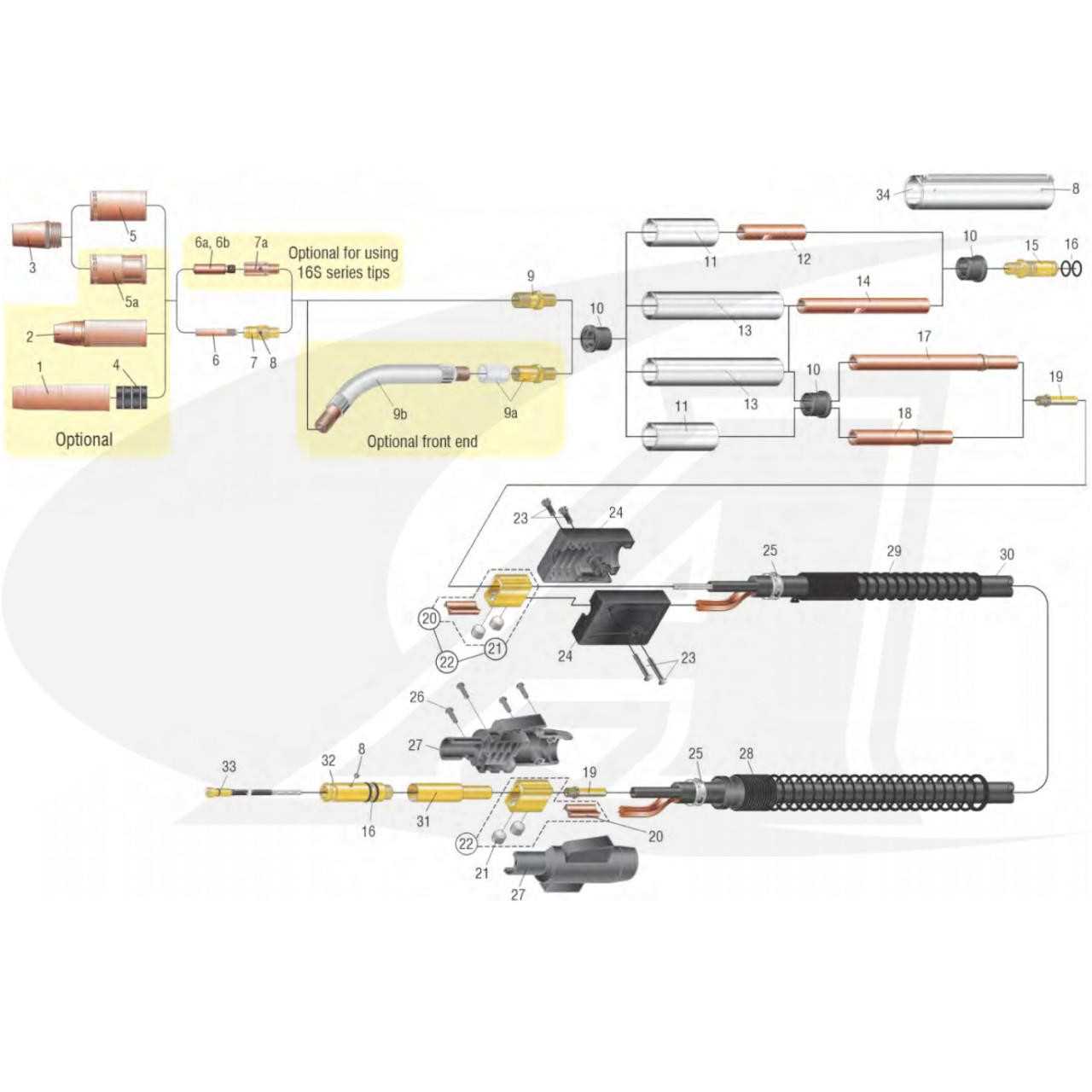

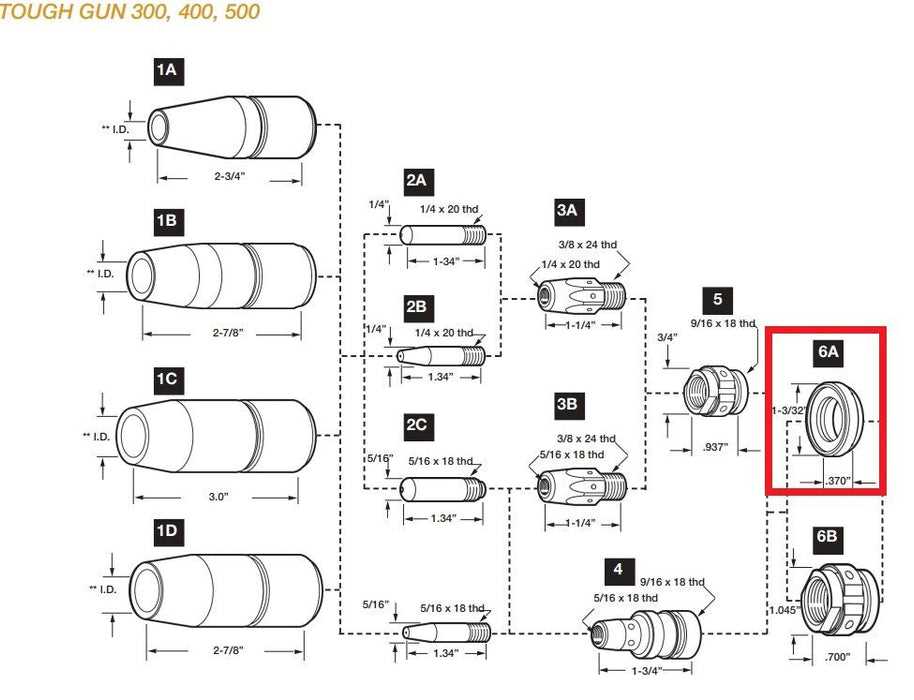

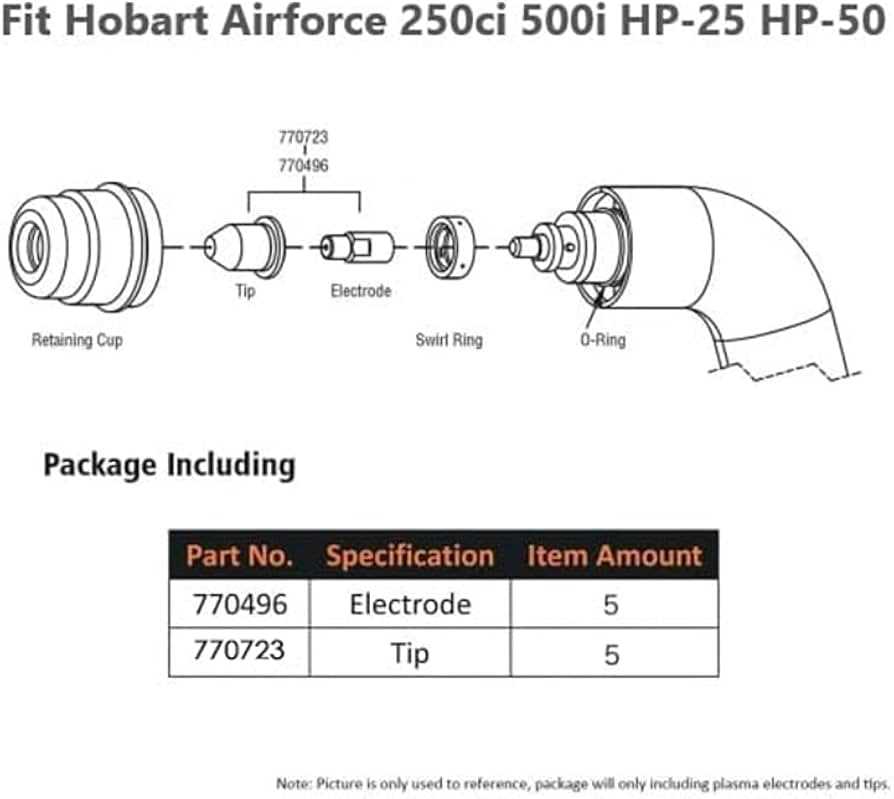

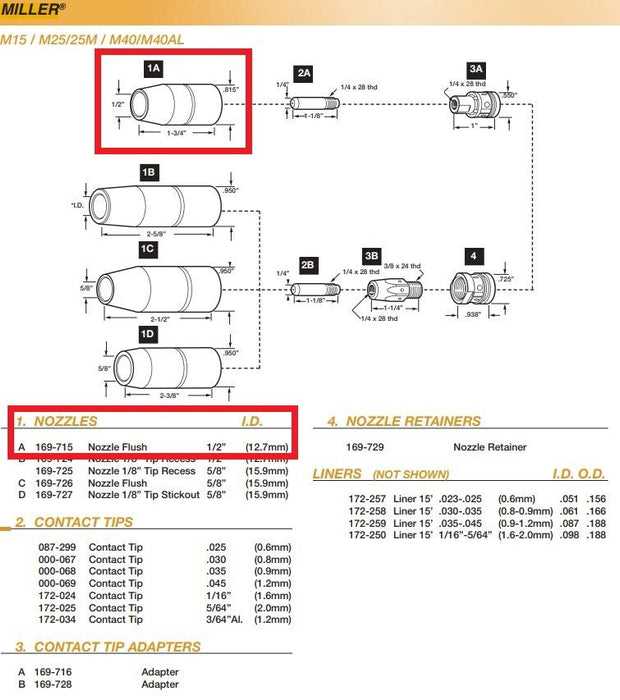

Identifying Parts by Diagram

Understanding the components of equipment is crucial for effective maintenance and troubleshooting. By utilizing a visual representation, users can easily pinpoint each element’s function and location. This not only enhances familiarity with the machinery but also aids in identifying any necessary replacements or repairs.

When analyzing a visual schematic, consider the following steps to improve recognition and understanding:

- Familiarize Yourself with Symbols: Different components are often represented by specific symbols. Learning these can help you quickly identify each part.

- Segment the Visual: Break down the illustration into sections. Focus on one area at a time to avoid feeling overwhelmed.

- Use Labels: Pay attention to any annotations or labels that accompany the visuals. These often provide essential information about each component.

- Compare with Physical Components: If possible, match the visual elements with the actual components in the equipment. This hands-on approach reinforces learning.

By systematically approaching the analysis of these visuals, users can enhance their understanding and efficiency in managing their equipment.

How to Read a Welder Diagram

Understanding a schematic representation of machinery components is essential for effective troubleshooting and maintenance. By familiarizing yourself with the symbols and layouts, you can identify various elements and their functions, enhancing your ability to work with the equipment efficiently.

Follow these steps to effectively interpret a schematic:

- Familiarize with Symbols: Recognize common symbols used to represent different components.

- Analyze the Layout: Observe the arrangement of parts and how they connect to one another.

- Identify Functionality: Understand the role of each component within the system.

- Follow Connections: Trace the pathways to see how energy flows through the system.

- Refer to Documentation: Use accompanying manuals or guides for deeper insight into specific elements.

By mastering these skills, you’ll ultimately enhance your technical proficiency and problem-solving capabilities in equipment handling.

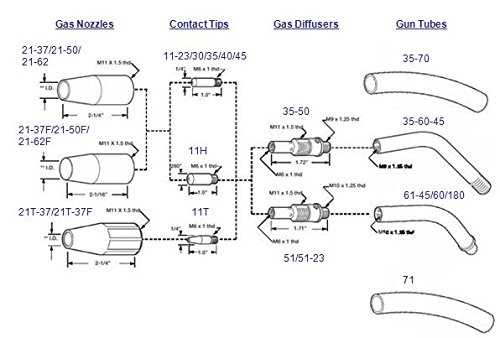

Replacement Parts: What You Need

Ensuring the longevity and optimal performance of your equipment often requires the timely substitution of specific components. Understanding which elements to replace, when to do so, and how to identify the right ones can significantly enhance your operational efficiency. This section aims to guide you through the essentials of component replacement, making maintenance easier and more effective.

| Component | Description | Signs of Wear |

|---|---|---|

| Electrode | The part that conducts current to create an arc. | Decreased performance, inconsistent arc. |

| Nozzle | Directs the flow of shielding gas. | Worn edges, poor gas coverage. |

| Contact Tip | Connects the electrode to the power source. | Burned or eroded tip, poor electrical conductivity. |

| Shielding Gas | Protects the weld from atmospheric contamination. | Inconsistent shielding, discoloration of weld. |

| Power Cable | Transmits electrical energy to the tool. | Frayed insulation, overheating. |

Regular inspection and timely replacement of these critical elements will not only ensure smoother operation but also contribute to the quality of your work. Familiarizing yourself with these components will empower you to make informed decisions about maintenance and upgrades.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance and repairs is paramount to preventing accidents and injuries. Adhering to specific guidelines helps create a secure environment for both the individual performing the work and anyone nearby. This section outlines essential safety measures to follow during the repair process, promoting a culture of caution and awareness.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate PPE, including gloves, goggles, and protective clothing, to shield against potential hazards. |

| Work Area | Keep the workspace organized and free from clutter to reduce the risk of tripping or accidents. |

| Power Supply | Disconnect the power source before beginning any repairs to prevent electric shock or unintended operation. |

| Ventilation | Ensure proper ventilation in the area to avoid the buildup of harmful fumes or gases during maintenance tasks. |

| Tool Inspection | Regularly inspect tools for wear and damage to ensure they are in safe working condition. |

| Emergency Procedures | Familiarize yourself with emergency protocols and have first aid supplies readily available in case of an accident. |

By following these precautions, individuals can significantly minimize risks and ensure a safer repair process. Prioritizing safety not only protects oneself but also contributes to a more efficient and effective maintenance routine.

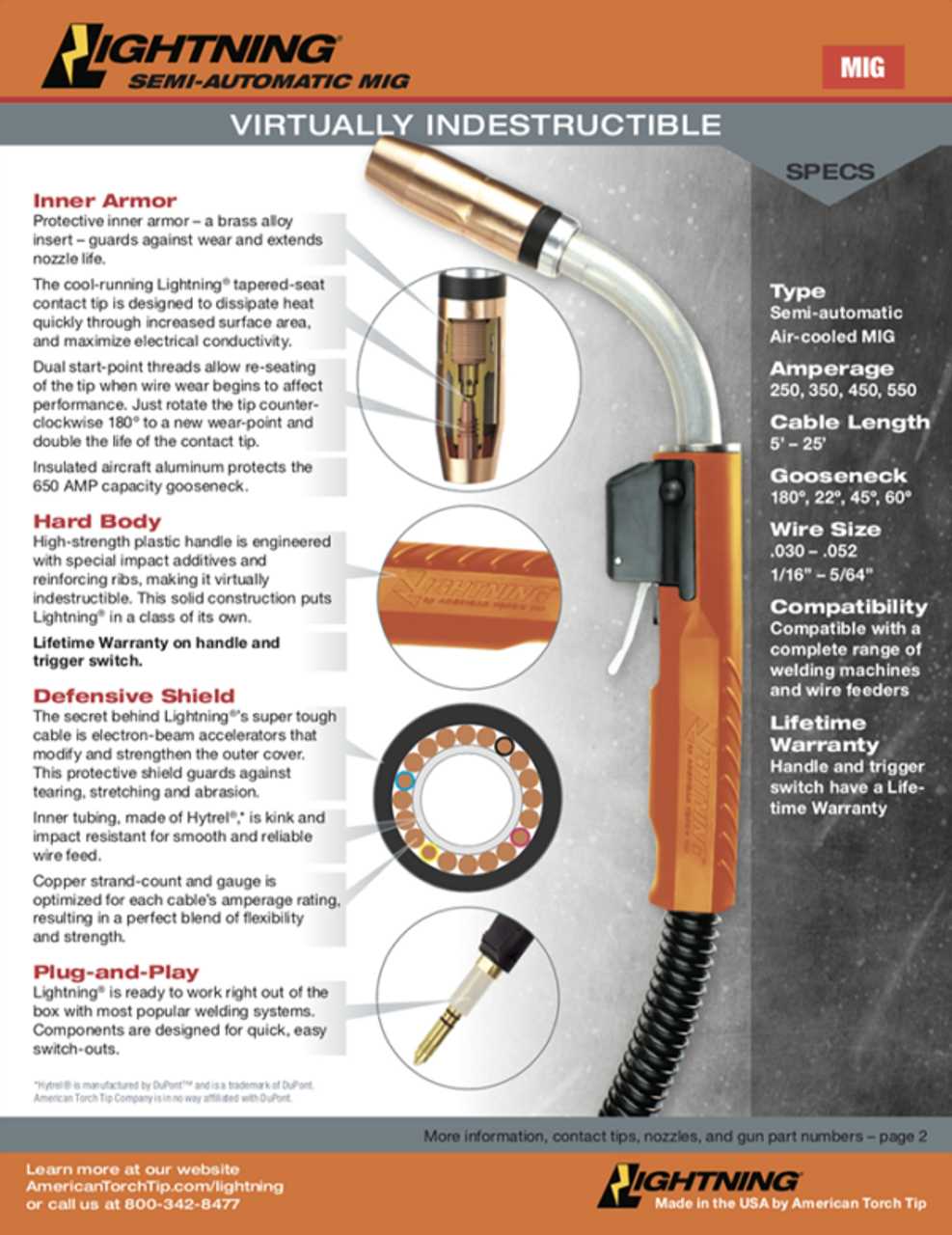

Using Genuine Hobart Parts

Opting for authentic components is essential for ensuring optimal performance and longevity of your equipment. These original elements are specifically designed to fit seamlessly, promoting reliability and efficiency in operation. By choosing genuine items, you minimize the risk of malfunction and enhance overall safety during usage.

Benefits of Authentic Components

Utilizing original elements significantly improves the durability of your machinery. They undergo rigorous testing and quality control processes, ensuring that they meet the highest industry standards. Moreover, using these components often leads to better warranties and support, providing peace of mind for users.

Maintaining Performance and Safety

Authentic items contribute to the consistent performance of your equipment. They are engineered to work harmoniously with existing systems, reducing wear and tear. Additionally, safety is greatly enhanced, as these elements are designed to withstand operational stresses, decreasing the likelihood of accidents or failures.

Upgrading Your Welding Equipment

Enhancing your equipment is crucial for improving performance and efficiency. By investing in better tools and accessories, you can achieve superior results in your projects while also extending the lifespan of your setup.

Benefits of Upgrading

- Improved efficiency in your tasks

- Enhanced safety features

- Better energy consumption

- Access to advanced technology

Key Considerations

- Assess your current equipment’s limitations.

- Research available upgrades that suit your needs.

- Consider compatibility with existing tools.

- Budget for both initial costs and long-term benefits.

Customer Support for Hobart Products

Quality assistance is essential for ensuring optimal performance and longevity of equipment. Customers can rely on various support channels to address their queries and receive guidance on their tools. Access to knowledgeable representatives enhances the user experience and fosters confidence in the brand.

| Support Channel | Availability | Contact Method |

|---|---|---|

| Phone Support | Weekdays, 8 AM – 5 PM | 1-800-XXX-XXXX |

| Email Support | 24/7 | [email protected] |

| Online Chat | Weekdays, 9 AM – 6 PM | Available on website |

| FAQs | Always Available | Website Resource |

Utilizing these resources ensures users can effectively manage their equipment and access the ultimate support when needed.

Where to Find Diagrams Online

Locating detailed visual references online can significantly enhance your understanding of various equipment. Numerous resources are available for enthusiasts and professionals alike, making it easier to access essential information.

Online Resources

Several websites specialize in providing comprehensive schematics and instructional guides. These platforms cater to users looking for specific information about machinery and tools.

Community Forums

Engaging in community forums can also be beneficial. Members often share valuable insights and links to useful resources, which can aid in your search for particular visuals.

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official sites typically offer user manuals and schematics. |

| Online Retailers | Many e-commerce platforms provide links to product documentation. |

| DIY Websites | Dedicated sites often feature guides created by fellow users. |

DIY Repair Tips for Hobart Welders

Maintaining and fixing your equipment can significantly extend its lifespan and enhance performance. Whether you’re facing minor issues or more complex challenges, a few handy tips can empower you to tackle repairs confidently.

- Consult the Manual: Always start by reviewing the user manual. It contains crucial information regarding common issues and maintenance routines.

- Gather the Right Tools: Ensure you have the necessary tools on hand. Common items include wrenches, screwdrivers, and multimeters for electrical diagnostics.

- Inspect Regularly: Make it a habit to inspect your equipment for wear and tear. Look for signs of damage, such as frayed wires or loose connections.

- Check Connections: Loose or corroded connections can lead to performance problems. Tighten all connections and clean any corrosion to ensure optimal conductivity.

For more intricate repairs, consider the following steps:

- Identify the Problem: Take note of any unusual sounds, smells, or performance issues. Understanding the symptoms can help narrow down potential causes.

- Replace Consumables: Regularly replacing tips and nozzles is crucial. Ensure you use compatible replacements to maintain efficiency.

- Seek Online Resources: Leverage online forums and videos. Many users share their repair experiences and solutions, which can provide valuable insights.

- Document Your Repairs: Keep a record of repairs made, including parts replaced and any adjustments. This can be useful for future maintenance.

By following these tips, you can effectively address issues, ensuring your equipment remains reliable and efficient for all your projects.