The intricate mechanisms that power modern heating and cooling systems are pivotal for maintaining comfort in our environments. A comprehensive grasp of these crucial elements is necessary for effective maintenance and troubleshooting. This section aims to explore the various components involved, shedding light on their roles and interconnections.

By dissecting the functionalities and relationships of these integral pieces, users can enhance their understanding and operational efficiency. An in-depth look at these mechanisms will empower individuals to make informed decisions, ensuring longevity and reliability in their systems.

As we delve into the specifics, the focus will be on identifying key features and the ultimate significance of each component. Whether for DIY enthusiasts or professionals, this knowledge serves as a valuable resource in the journey toward optimal system performance.

Understanding Honeywell Gas Valves

This section explores the intricacies of control mechanisms utilized in heating and energy systems. These components play a crucial role in regulating flow and ensuring safety in various applications.

Key Features

- Precision control for optimal performance

- Safety mechanisms to prevent accidents

- Durability and reliability in demanding environments

Applications

- Residential heating systems

- Commercial energy solutions

- Industrial applications requiring efficient flow management

Understanding these elements is essential for effective maintenance and troubleshooting, ultimately enhancing system efficiency and safety.

Components of Honeywell Gas Valves

This section explores the essential elements that contribute to the functionality and reliability of these essential mechanisms in controlling fuel flow. Understanding these components is crucial for effective maintenance and troubleshooting.

| Component | Description |

|---|---|

| Actuator | The device responsible for opening and closing the flow path based on signals received. |

| Sensor | Monitors pressure and temperature to ensure optimal performance and safety. |

| Sealing Mechanism | Prevents leaks and ensures a secure closure when the system is not in operation. |

| Control Module | Processes inputs from sensors and sends commands to the actuator for precise control. |

| Body | The main structure that houses all components and withstands operational pressures. |

Common Issues with Gas Valve Parts

When dealing with heating systems, several components can experience malfunctions that lead to operational inefficiencies. Understanding these common challenges can help in diagnosing problems and ensuring safe and effective performance. Familiarity with these issues is crucial for maintenance and repair processes.

Frequent Malfunctions

One of the most prevalent issues involves leaks, which can compromise safety and efficiency. These leaks often result from wear and tear or improper installation. Additionally, blockages within the mechanism can prevent proper flow, leading to inadequate heating. Another significant problem is electrical failures, where faulty wiring or connections can disrupt functionality.

Signs of Trouble

Identifying signs of malfunction early can save time and resources. Unusual noises during operation, fluctuating temperatures, or inconsistent performance are often indicative of underlying issues. Regular inspection and prompt attention to these symptoms can help maintain optimal operation and extend the lifespan of the equipment.

Importance of Proper Installation

Ensuring the correct setup of crucial components in any system is vital for optimal performance and safety. Misalignment or improper assembly can lead to inefficiencies, potential hazards, and premature failures. Understanding the significance of meticulous installation practices is essential for both functionality and longevity.

First and foremost, accurate placement of these components minimizes the risk of leaks and malfunctions. Each piece is designed to work harmoniously within the system, and any deviations can disrupt this balance. Furthermore, a well-executed installation process helps to maintain manufacturer warranties and ensures compliance with industry regulations.

Additionally, following the correct procedures fosters better operational efficiency. Properly installed components contribute to reduced energy consumption and enhance overall system performance. This not only translates to lower operational costs but also promotes a more sustainable approach to energy use.

Finally, investing time and effort into correct installation pays off in the long run. It enhances the reliability of the system, reducing the need for frequent repairs and replacements. In conclusion, prioritizing proper installation is not just a technical requirement; it is a fundamental practice that safeguards both the integrity of the system and the well-being of its users.

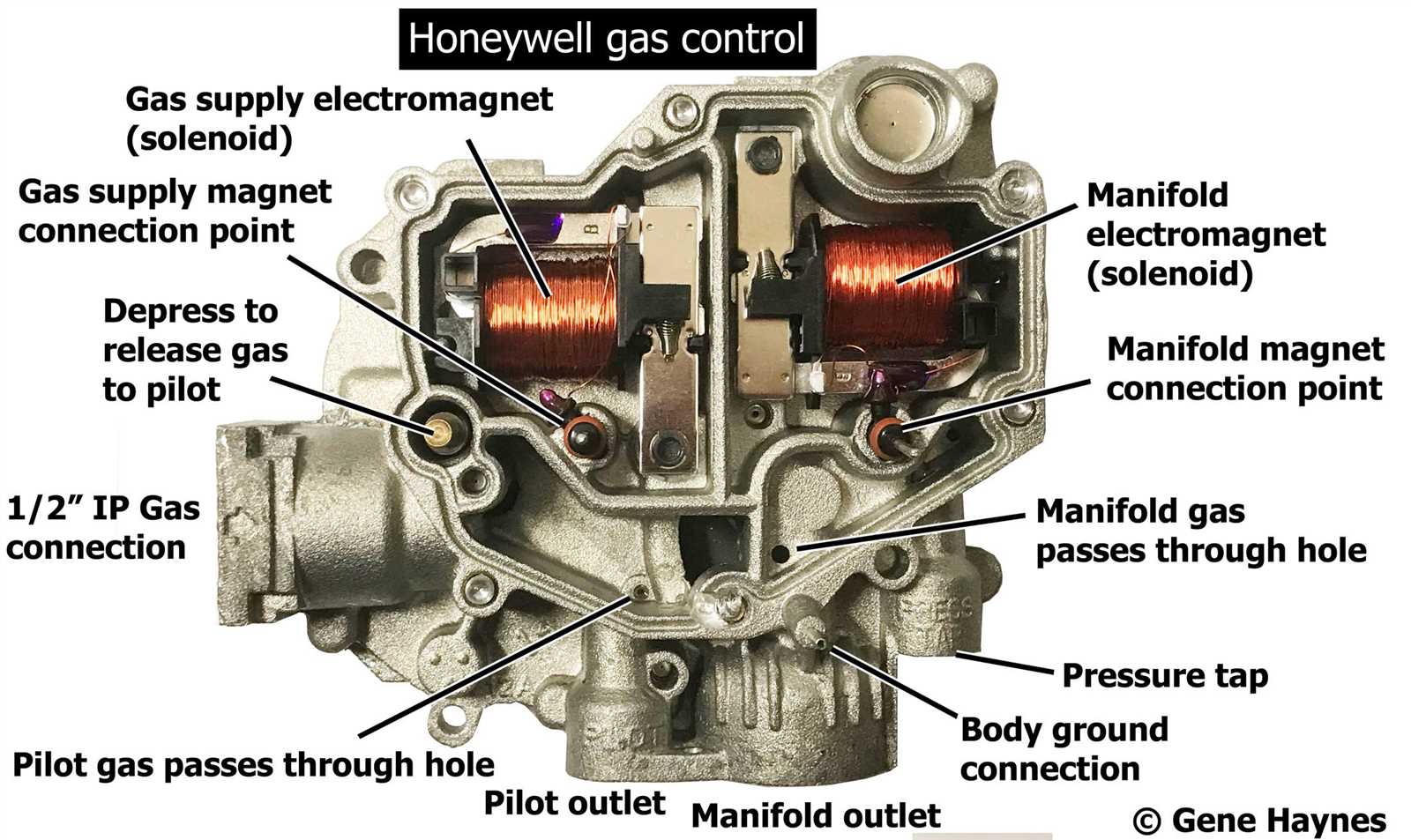

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective troubleshooting and maintenance. These visual guides serve as a roadmap, illustrating the relationships and functions of various elements within a system. Familiarity with reading these illustrations can enhance efficiency and accuracy in repairs and replacements.

Identifying Components

Begin by examining the symbols and labels that denote different elements. Each shape or icon corresponds to a specific component, often accompanied by a reference number or name. Pay close attention to any annotations that provide additional information about the role of each part. This knowledge will help you pinpoint areas requiring focus during service tasks.

Understanding Connections

Next, focus on the lines and arrows that depict the interactions between components. These connections illustrate how parts communicate and work together to achieve the overall functionality. Recognizing these relationships is crucial for diagnosing issues or planning modifications, ensuring a comprehensive grasp of the system’s operation.

Maintenance Tips for Gas Valves

Regular upkeep is essential for ensuring the longevity and safety of crucial components in your system. Neglecting maintenance can lead to performance issues and potential hazards. Here are some key practices to consider for optimal functionality.

1. Routine Inspection: Frequently check the components for any signs of wear, corrosion, or damage. Early detection can prevent more serious problems down the line.

2. Cleaning: Keep all areas free from dirt and debris. A clean environment helps maintain efficient operation and extends the life of the components.

3. Tight Connections: Ensure that all connections are secure. Loose fittings can lead to leaks, compromising safety and performance.

4. Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. This helps maintain smooth operation and prevents seizing.

5. Professional Servicing: Schedule regular checks with a qualified technician. Professional insights can uncover issues that may not be visible during routine inspections.

Following these maintenance tips can help ensure your system operates efficiently and safely for years to come.

Identifying Gas Valve Models

Understanding the various types of control mechanisms is essential for effective management and troubleshooting. Different models can exhibit unique features, making it crucial to recognize specific characteristics that distinguish one from another.

First, familiarize yourself with the markings and labels typically found on the units. These identifiers often include model numbers, which can provide a wealth of information about the design and function.

Second, consider the operational specifications, such as the pressure rating and compatibility with different systems. These factors can help narrow down the possible models and ensure the correct application.

Lastly, consulting manufacturer documentation can be invaluable. Manuals and guides often include detailed descriptions, aiding in the precise identification of the mechanism you are working with.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a secure environment is paramount. Proper precautions help prevent accidents and protect both the technician and the equipment involved. Being aware of potential hazards and taking the necessary steps can significantly mitigate risks.

Always wear appropriate personal protective equipment, such as gloves and goggles, to shield against possible injuries. Additionally, ensure that the work area is well-ventilated to avoid the accumulation of harmful fumes. Before starting any repairs, turn off the main supply and disconnect any power sources to eliminate electrical risks.

Furthermore, familiarize yourself with the specific components being handled. Review relevant manuals and guidelines to understand the proper procedures. If uncertainty arises, seek assistance from a qualified professional to avoid mishaps.

Lastly, keep the workspace organized and free from clutter to enhance safety and efficiency. By following these essential steps, the repair process can be executed with greater confidence and reduced risk.

Replacing Faulty Gas Valve Parts

When components in a heating or control system begin to malfunction, it is crucial to address the issue promptly to ensure safe and efficient operation. Identifying the specific elements that require replacement is the first step in restoring functionality. This process not only involves assessing the condition of the components but also understanding the impact of their failure on the overall system.

Identifying Issues

Before proceeding with replacements, it is essential to conduct a thorough examination. Look for signs of wear, corrosion, or damage. Often, symptoms such as irregular functioning or unusual noises indicate that certain elements may be compromised. Documenting these findings can assist in making informed decisions during the replacement process.

Replacement Steps

Once faulty components have been identified, follow these steps for a successful replacement:

- Power Down: Ensure the system is completely powered off to avoid any safety hazards.

- Access the Components: Remove any covers or enclosures to gain access to the affected parts.

- Careful Removal: Detach the damaged elements with appropriate tools, taking care not to damage surrounding parts.

- Install New Components: Securely install the new elements, ensuring proper alignment and connections.

- Test Functionality: Restore power and conduct tests to confirm that the system operates smoothly.

Following these guidelines will help maintain the integrity of your system and prolong its lifespan. Regular inspections and timely replacements are key to ensuring optimal performance.

Tools Required for Maintenance

Regular upkeep of your system is crucial for optimal performance and longevity. Having the right equipment on hand ensures that maintenance tasks are executed efficiently and effectively. This section outlines the essential tools that will aid in the care of your unit.

Essential Equipment

- Wrenches: A variety of sizes will help in loosening or tightening components.

- Screwdrivers: Both flat-head and Phillips types are necessary for accessing different screws.

- Multimeter: Essential for electrical diagnostics and ensuring proper functioning of components.

- Manifold Gauge Set: Useful for checking pressure levels, which is critical for safe operation.

- Safety Gear: Gloves, goggles, and masks to protect against hazards during maintenance.

Additional Supplies

- Lubricants: To keep moving parts functioning smoothly.

- Cleansing Agents: For removing dust and debris from sensitive areas.

- Replacement Components: Always have a few spare parts for quick replacements.

- Measuring Tools: To ensure precise adjustments are made where needed.

Equipping yourself with these tools not only simplifies the maintenance process but also enhances the safety and reliability of your system. Regular checks and prompt repairs will contribute to its overall efficiency.

Best Practices for Gas System Efficiency

Optimizing performance in a combustion system is crucial for maintaining energy efficiency and safety. Implementing effective strategies can lead to significant reductions in operational costs and environmental impact. This section outlines essential practices to enhance the overall functionality and longevity of your setup.

Regular Maintenance and Inspection

Consistent upkeep of your installation is vital. Schedule routine inspections to identify any wear or malfunctioning components. This proactive approach can prevent minor issues from escalating into costly repairs. Additionally, ensure that all elements are clean and free from debris, which can hinder performance.

Utilization of Advanced Technology

Incorporating modern monitoring systems can greatly improve efficiency. These technologies provide real-time data, enabling you to adjust settings dynamically based on usage patterns. This capability not only enhances performance but also supports better fuel management, ultimately leading to lower emissions and operational costs.

Where to Source Replacement Parts

Finding reliable sources for essential components is crucial for maintaining the efficiency and safety of your systems. Whether you’re dealing with repairs or upgrades, knowing where to look can save time and ensure quality.

Here are some effective options for sourcing the necessary items:

- Authorized Dealers: Contact authorized distributors who specialize in the brand’s equipment. They often carry a complete range of components and can provide expert advice.

- Online Retailers: Websites such as Amazon and eBay offer a wide selection of items. Always check seller ratings and reviews before making a purchase.

- Local Supply Stores: Many communities have hardware or specialty stores that stock a variety of essential components. Visiting in person can allow you to ask questions and get recommendations.

- Manufacturer’s Website: Visit the official website for direct access to products, manuals, and sometimes exclusive offers on components.

- Industry Trade Shows: Attending relevant trade shows can provide opportunities to meet suppliers and discover new products that might not be available elsewhere.

By exploring these options, you can find the right components to ensure your systems operate smoothly and efficiently.