The efficient movement of goods relies heavily on the intricate design and functionality of specialized transportation vehicles. Understanding the various elements that comprise these vehicles is essential for maintaining their performance and ensuring reliability during transit. This section provides a comprehensive overview of the essential components involved in the operation of such vehicles.

Each element plays a pivotal role in facilitating smooth operations, from the loading mechanisms to the stability features. Recognizing how these components interact and support the overall functionality can enhance our appreciation of the engineering behind them. The following discussion will delve into the key features, offering insights into their significance and operational mechanics.

In addition to understanding individual components, it is crucial to explore how they collectively contribute to the efficiency and safety of transportation systems. This knowledge not only aids in troubleshooting potential issues but also assists in making informed decisions regarding upgrades and maintenance. Join us as we dissect these vital elements and uncover their impact on freight logistics.

This section presents an overview of specialized transportation vehicles designed for bulk material handling. These vehicles are essential for efficient loading and unloading processes in various industries, particularly in the movement of commodities such as grains, coal, and minerals. Understanding the different components of these vehicles helps to enhance their functionality and maintenance practices.

- Introduction to Specialized Vehicles

- Definition and purpose

- Importance in transportation

- Structure and Design Features

- Overview of design elements

- Significance of aerodynamics

- Loading Mechanisms

- Types of loading systems

- Efficiency in bulk handling

- Unloading Techniques

- Gravity discharge methods

- Pneumatic unloading systems

- Wheel and Axle Configuration

- Importance of wheel design

- Impact on stability

- Brake Systems

- Types of braking mechanisms

- Safety considerations

- Frame Construction

- Material selection

- Durability aspects

- Maintenance Practices

- Routine inspections

- Common repairs

- Regulatory Standards

- Compliance with safety regulations

- Industry best practices

- Advancements in Technology

- Smart vehicle features

- Automation in operations

- Environmental Considerations

- Impact on sustainability

- Innovations for reduced emissions

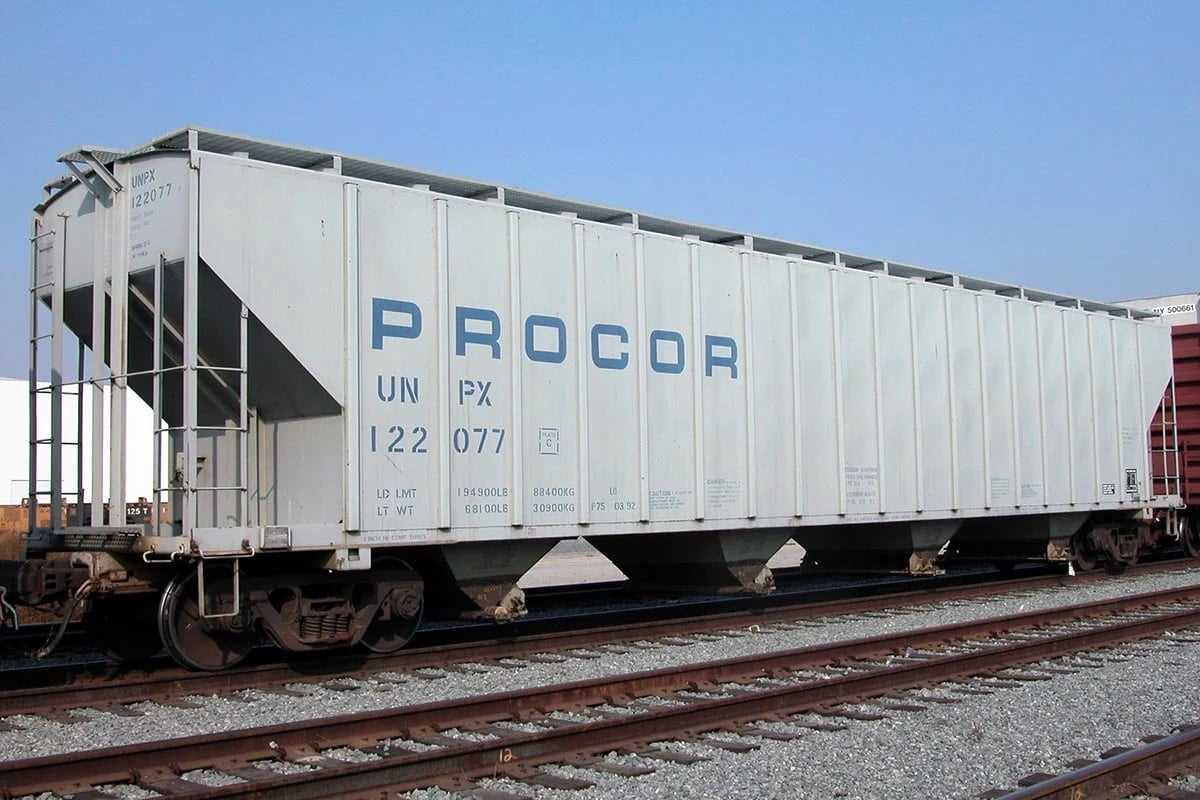

Key Components of Hopper Railcars

Understanding the essential elements of bulk transport vehicles is crucial for appreciating their functionality and efficiency. These vehicles are specifically designed to handle the transportation of various materials, often featuring a unique structure that supports effective loading and unloading processes.

One of the main structural features includes a wide base, which allows for stable loading and ensures balance during transit. The conical shape of the vehicle’s body is tailored to facilitate the easy discharge of contents, while its robust frame contributes to durability against harsh conditions.

The loading mechanisms are designed for quick and efficient filling, ensuring that operations remain timely. Additionally, various coupling systems enable secure connections with other transport units, enhancing the overall efficiency of the transport chain.

Furthermore, specialized braking systems are integral to maintaining safety during movement, providing reliable stopping power when needed. The combination of these features illustrates how this type of vehicle is engineered for optimal performance in transporting bulk materials.

Functionality of Hopper Doors

The doors of bulk transport containers play a crucial role in the efficient handling and release of materials. Their design and operation are essential for ensuring that contents can be safely loaded and unloaded, optimizing the overall performance of the transportation process.

These openings are typically designed to provide a tight seal when closed, preventing spillage during transit. When activated, they allow for the controlled discharge of the contents, facilitating precise management of material flow. The mechanism often includes features that ensure the doors can be opened quickly and securely, which is vital for operations in busy loading and unloading environments.

Moreover, the construction of these doors must withstand significant stress and varying environmental conditions, ensuring durability and reliability. Regular maintenance is required to keep the mechanisms functioning properly, ensuring that the containers can operate effectively over time.

In summary, the functionality of these access points is central to the efficiency and safety of transporting bulk materials, making them an integral aspect of modern logistics.

Types of Hopper Railcars Explained

In the realm of freight transport, various designs cater to different cargo requirements. Each model is tailored to efficiently handle specific materials, ensuring safe and effective transportation. Understanding these variations is essential for industry professionals and enthusiasts alike.

One common design is the covered version, which protects sensitive goods from environmental elements. This type is often used for transporting grains, chemicals, and other products that require safeguarding against moisture and contamination.

Another significant category is the open model, primarily utilized for bulk materials such as coal, gravel, and ore. This design facilitates quick loading and unloading, maximizing efficiency for heavy industries.

Additionally, there are specialized variations equipped for specific commodities, like those designed for transporting aggregates or those fitted with advanced unloading mechanisms. These innovations enhance the versatility and utility of freight transport systems, meeting the diverse demands of the market.

Overall, recognizing the different configurations and their respective applications can greatly improve operational effectiveness and resource management in the logistics sector.

Importance of Proper Maintenance

Regular upkeep of transport vehicles is crucial for ensuring their efficiency and longevity. Neglecting maintenance can lead to various issues, ranging from minor operational disruptions to significant safety hazards. By adhering to a consistent maintenance schedule, operators can minimize downtime, enhance performance, and extend the service life of their equipment.

Benefits of Consistent Upkeep

Implementing a routine maintenance plan provides numerous advantages, including increased reliability and reduced repair costs. Regular inspections allow for the early detection of potential problems, enabling timely interventions that prevent more extensive damage. Additionally, well-maintained vehicles tend to perform better, resulting in improved fuel efficiency and overall productivity.

Safety Considerations

Safety is paramount in any transportation system. Proper maintenance plays a vital role in ensuring that all components function correctly, thereby reducing the risk of accidents. Regular checks help to confirm that safety features are operational, providing peace of mind to operators and users alike. Ultimately, prioritizing maintenance contributes to a safer and more efficient transport environment.

Identifying Common Parts and Functions

Understanding the essential components and their roles is crucial for effective maintenance and operation. Each element contributes to the overall functionality, ensuring that the system operates smoothly and efficiently.

One of the most significant elements is the container, which serves as the primary holding area for the materials. Its design varies based on the type of cargo it is intended to carry, influencing its structural integrity and capacity.

Another key component is the undercarriage, which supports the entire assembly and provides stability during movement. This structure includes wheel sets and axles that facilitate motion, crucial for transportation.

Braking systems are also vital, ensuring safety during operation. These mechanisms allow for controlled stopping, preventing accidents and ensuring compliance with safety regulations.

Lastly, monitoring devices play an essential role in tracking performance and conditions. These tools help operators assess efficiency and identify potential issues before they escalate.

Materials Used in Hopper Construction

The construction of bulk transport vehicles involves various materials that enhance their durability and functionality. The choice of materials plays a crucial role in ensuring efficiency and safety during operation. Below are some commonly utilized substances in the assembly of these vehicles.

- Steel: This is the primary material used for the framework due to its strength and resistance to wear. Different grades of steel may be employed to meet specific load requirements.

- Aluminum: Lightweight and corrosion-resistant, aluminum is often used in components where weight reduction is essential, contributing to improved fuel efficiency.

- Polymer Coatings: Protective coatings made from polymers are applied to surfaces to prevent rust and enhance the lifespan of metallic parts.

- Reinforced Plastics: These composites are utilized in certain sections to provide flexibility and reduce weight without sacrificing strength.

Each material serves a distinct purpose, ensuring that the vehicle can withstand various environmental conditions while maintaining operational efficiency.

Understanding the Loading Mechanism

The loading mechanism is a critical component in the transportation of bulk materials. It plays a vital role in ensuring efficient and effective transfer of cargo from the source to the storage unit. Understanding its functionality allows for better operation and maintenance, which ultimately enhances productivity and reduces downtime.

Typically, this mechanism involves various elements that work together to facilitate the smooth transition of materials. The process begins with the positioning of the container, followed by the activation of systems that enable the filling of materials. Efficient loading minimizes the risk of spillage and ensures that the container is utilized to its full capacity.

Moreover, the design of the loading mechanism is tailored to accommodate different types of materials, ranging from granular substances to more cohesive products. This adaptability is essential for various industries, as it allows for versatile applications in transportation and logistics. Proper understanding of the loading mechanism not only enhances operational efficiency but also contributes to the overall safety of the handling process.

Impact of Design on Performance

The structure and configuration of a transportation vessel significantly influence its operational efficiency and effectiveness. Thoughtful design elements contribute to the overall functionality, enabling the vehicle to achieve optimal performance under various conditions.

Streamlined shapes enhance aerodynamics, minimizing resistance during movement. This can lead to reduced fuel consumption and increased speed. Additionally, material selection plays a crucial role; lightweight yet durable materials can improve handling and longevity while reducing wear and tear.

Ergonomics also affect usability, ensuring that operators can manage the vehicle effectively. A well-designed interface allows for seamless interaction, enhancing control and responsiveness. Ultimately, the interplay between various design factors determines how well the vehicle performs in its intended applications.

Safety Features in Hopper Railcars

Ensuring the protection of personnel and cargo during transport is a fundamental aspect of rail vehicle design. These vehicles incorporate various safety mechanisms aimed at preventing accidents and enhancing operational security. Understanding these features is crucial for maintaining a safe working environment and ensuring the integrity of the transported materials.

One of the key elements in safeguarding these vehicles is the inclusion of robust braking systems. These systems are designed to deliver reliable stopping power under various conditions, thereby minimizing the risk of derailments. Additionally, the incorporation of advanced monitoring systems allows for real-time assessments of vehicle performance, alerting operators to potential issues before they escalate.

Another significant feature is the structural integrity of the vehicle. Reinforced frames and durable materials help withstand the stresses of transport, protecting both the cargo and the vehicle itself. Furthermore, the design includes safety barriers and proper ventilation to prevent the buildup of hazardous materials or gases.

| Safety Feature | Description |

|---|---|

| Braking System | Advanced mechanisms providing reliable stopping power. |

| Monitoring Systems | Real-time performance assessments for early issue detection. |

| Reinforced Structure | Durable materials and design enhancing overall safety. |

| Safety Barriers | Preventing the escape of hazardous materials during transit. |

| Ventilation Systems | Ensuring air circulation to mitigate gas buildup. |

Collectively, these features contribute significantly to the overall safety and reliability of transport vehicles, highlighting the importance of ongoing innovation and adherence to safety standards in the industry.

Repair Techniques for Common Issues

Understanding the various methods to address frequent malfunctions is essential for maintaining operational efficiency. By employing the right strategies, one can significantly extend the lifespan of essential components and enhance performance. This section explores effective techniques for resolving typical challenges encountered during usage.

Preventive Maintenance

Implementing regular inspections and upkeep routines can prevent many issues before they escalate. By checking for signs of wear and ensuring all systems are functioning correctly, operators can reduce the risk of sudden breakdowns.

Repair Approaches

In case of a malfunction, specific approaches can be taken to address the problem efficiently. Here are some common repair techniques:

| Issue | Technique | Description |

|---|---|---|

| Wear and Tear | Replacement | Replacing worn components with new parts to ensure optimal functionality. |

| Sealing Problems | Sealing Compound Application | Applying appropriate sealing materials to eliminate leaks and enhance integrity. |

| Structural Integrity | Reinforcement | Reinforcing critical areas to improve strength and durability under stress. |

| Alignment Issues | Realignment | Adjusting components to ensure proper alignment, reducing friction and wear. |

Future Innovations in Railcar Design

The advancement of freight transportation technology is paving the way for new concepts that enhance efficiency, sustainability, and safety. These innovations aim to transform traditional designs into more effective solutions for moving goods across vast distances.

Emerging trends in the industry include:

- Smart Technologies: Integration of IoT devices enables real-time monitoring of vehicles, enhancing operational efficiency.

- Lightweight Materials: Utilizing advanced composites reduces weight, improving fuel efficiency and increasing cargo capacity.

- Modular Designs: Flexible configurations allow for easy adaptation to different freight types and varying load requirements.

- Enhanced Safety Features: Advanced braking systems and collision avoidance technologies significantly reduce the risk of accidents.

- Eco-friendly Solutions: Implementation of energy-efficient designs and sustainable materials promotes environmentally conscious operations.

These advancements signify a shift towards a more intelligent and responsible freight transportation system, promising improved performance and a reduced ecological footprint.