The efficiency and longevity of drilling equipment largely depend on understanding the design and arrangement of its essential elements. By gaining a clear vision of the internal structure and how each element contributes to the overall performance, users can ensure optimal functionality and easier maintenance.

In this section, we will explore the major elements involved in the operation of this specialized tool, along with their respective positions within the equipment. Having a visual understanding of these interconnected elements can significantly aid in troubleshooting and regular upkeep, ensuring the equipment runs smoothly for extended periods.

Additionally, familiarity with the layout of internal mechanisms allows users to easily identify areas that may require repair or replacement. This knowledge not only enhances the user’s ability to maintain the equipment but also extends its operational life, reducing the need for frequent servicing.

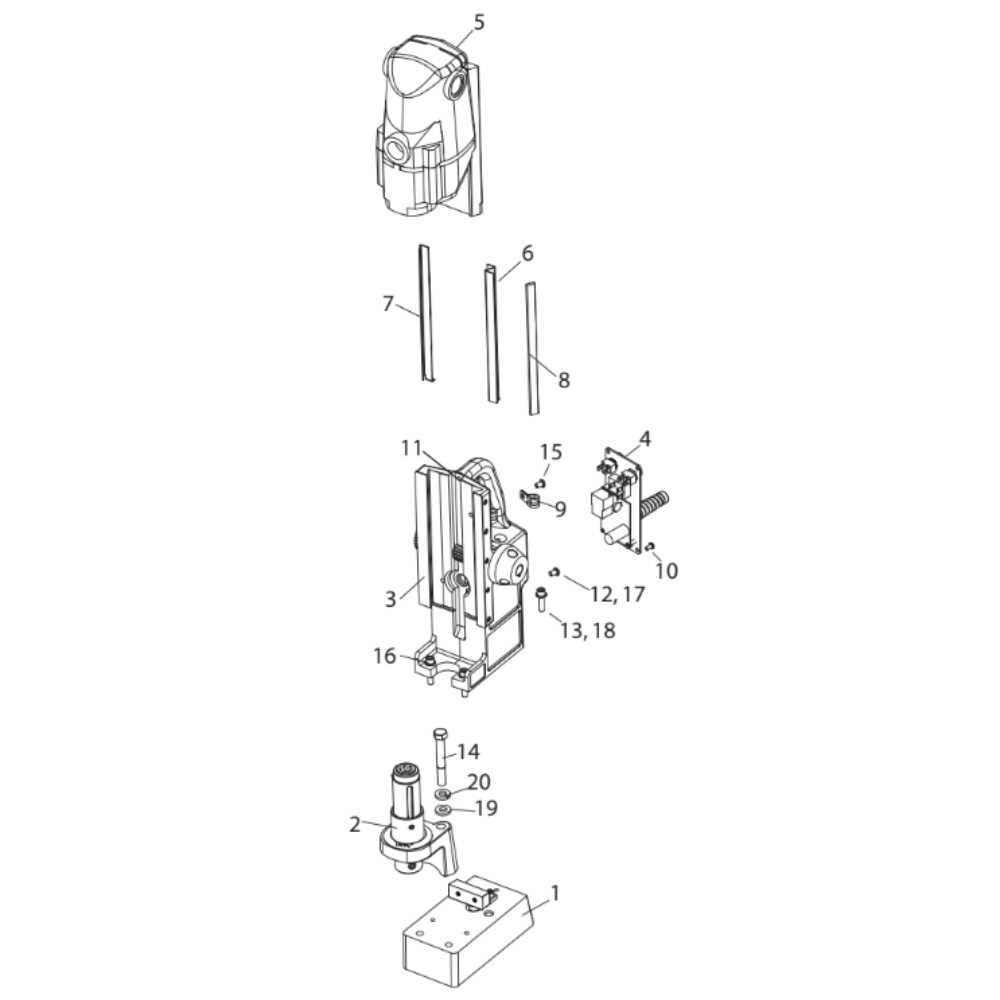

Hougen HMD904 Parts Diagram

The detailed representation of this drilling tool’s components allows users to easily identify each element necessary for maintenance and replacement. A clear illustration is essential for understanding the relationship between different sections and how they interact during operation.

Component identification becomes more efficient when users are provided with a visual breakdown of each part’s function. This assists in troubleshooting and ensures that repairs or upgrades are done accurately. Without a clear layout, understanding the internal mechanics can become a challenge.

When examining each element, it’s

Main Components Overview

In this section, we will explore the essential elements of a magnetic drilling tool, emphasizing the major components that ensure efficient operation. Each element plays a crucial role in the overall functionality and performance of the device, contributing to its reliability in various applications.

Magnetic Base

The foundation of the machine is a strong magnetic base, which provides stability during operation. This feature allows the tool to securely attach to metallic surfaces, ensuring precise and safe drilling, even in vertical or overhead positions.

Drilling Motor

The core of the system is the high-performance drilling motor, which powers the cutting tool. The

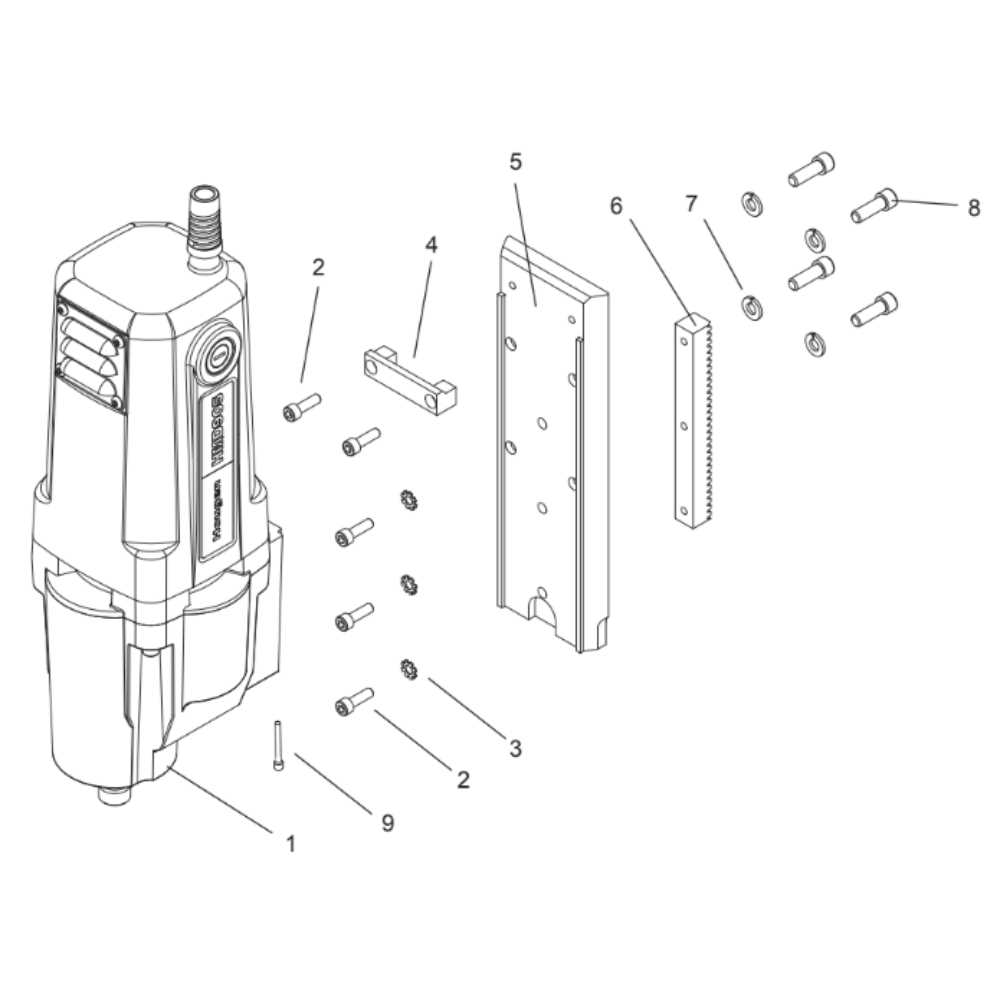

Drilling Mechanism Breakdown

The drilling system consists of several interdependent components that work together to ensure precise and efficient material penetration. Each element plays a crucial role in the overall operation, ensuring accuracy, stability, and durability during the drilling process. Understanding the interaction of these elements helps in maintaining and troubleshooting the tool effectively.

Main Drive Component

The central drive is responsible for transferring power from the motor to the cutting tool. This component converts electrical energy into rotational motion, ensuring the cutting edge rotates at optimal speeds for drilling various materials. Regular maintenance is required to prevent wear and ensure smooth performance.

Depth Control System

The depth control mechanism allows the operator to adjust how deep the cutting edge penetrates the surface. It ensures precision in each drilling operation, providing consistent results across different applications. Adjustments can be made manually or through automated settings, depending on the model and configuration.

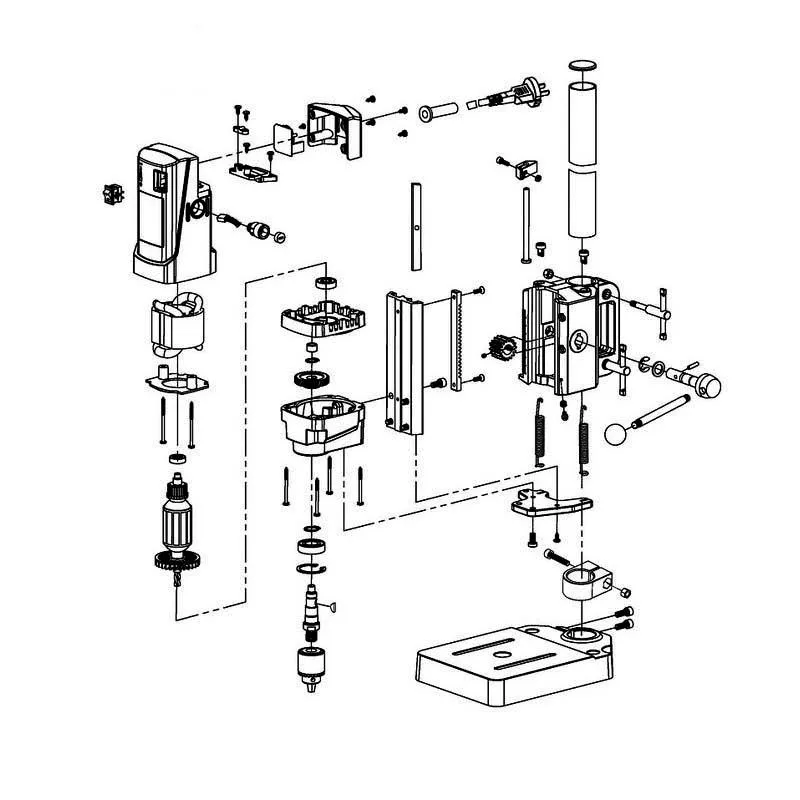

Motor Assembly and Function

The motor unit plays a crucial role in powering the entire tool, ensuring efficient operation and seamless performance. The assembly of this component involves several integral parts that work in harmony to convert electrical energy into mechanical force, which drives the cutting process.

Core Components: The motor system includes a stator, rotor, and bearings. The stator remains stationary, while the rotor rotates to generate motion. High-quality bearings ensure smooth and stable movement of the rotating parts.

Operational Efficiency: Proper alignment and maintenance of the motor assembly are essential to its efficiency. The system is designed to handle high loads, providing consistent

Handle and Control Features

The structure is designed with user convenience in mind, allowing for seamless operation and effective manipulation. The system integrates various elements that enhance usability, ensuring precision and control during operation. These components contribute to the overall efficiency, providing intuitive handling for both beginners and experienced users.

Handle Design: The handle offers a secure and comfortable grip, minimizing fatigue during extended use. It is strategically placed to allow optimal control, ensuring stability and accuracy. The ergonomic design aids in reducing strain, even when managing complex tasks.

Control Elements: The interface includes essential controls for easy access and

Spindle and Arbor Setup

The correct configuration of the spindle and arbor is essential for achieving optimal performance and accuracy in drilling applications. This section outlines the fundamental principles and steps necessary for setting up these components effectively. Proper alignment and adjustment ensure that the drilling tool operates smoothly and efficiently, minimizing wear and enhancing precision.

When preparing to set up the spindle and arbor, it is crucial to follow a systematic approach. The components should be checked for any signs of damage or wear before assembly. Ensuring that both the spindle and arbor are clean and free of debris is vital to facilitate a secure fit and prevent operational issues.

| Component | Description | Key Considerations |

|---|---|---|

| Spindle | The rotating shaft that drives the tool. | Ensure proper alignment and secure attachment. |

| Arbor | A device that connects the tool to the spindle. | Check compatibility with the tool and spindle size. |

| Alignment | The process of ensuring the spindle and arbor are correctly positioned. | Use precision tools to verify alignment. |

| Maintenance | Regular checks and servicing of components. | Inspect for wear and lubricate as needed. |

In conclusion, setting up the spindle and arbor requires careful attention to detail and adherence to best practices. Regular maintenance and checks will contribute to the longevity of the equipment and ensure consistent performance throughout its use.

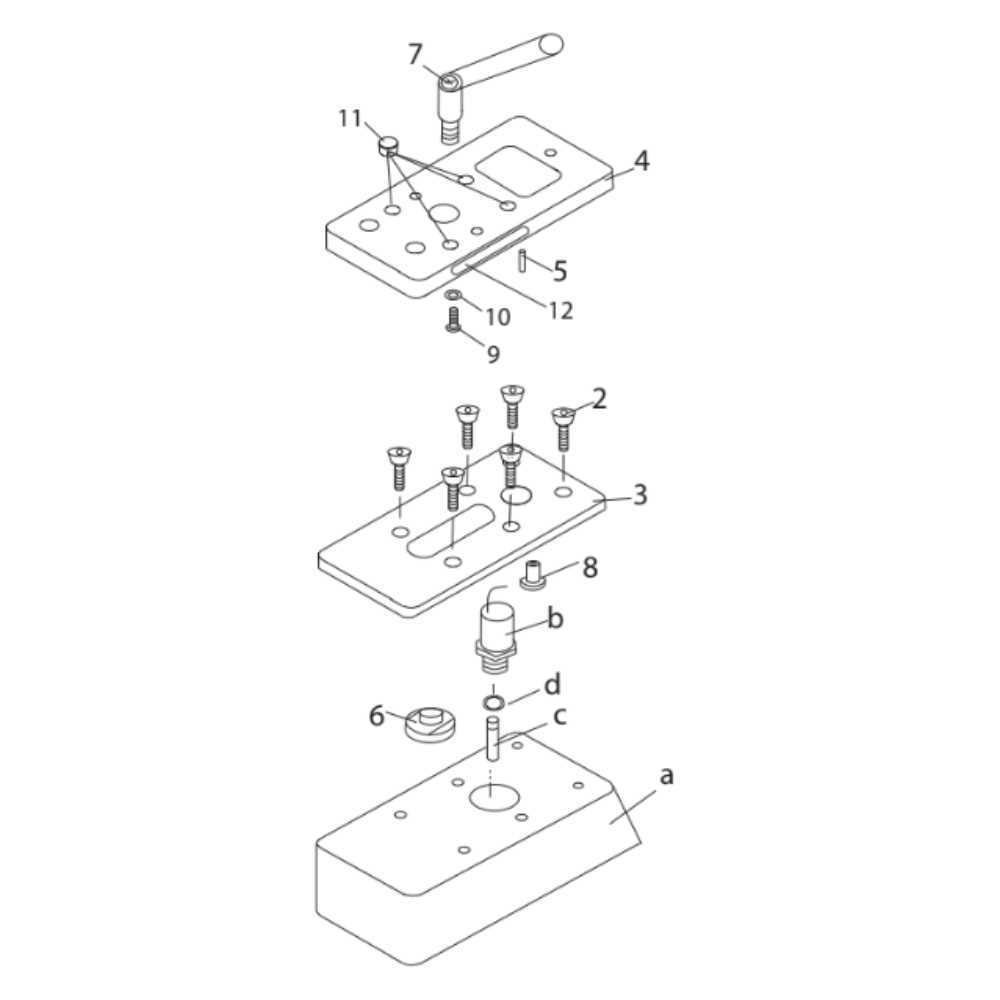

Magnetic Base Structure

The magnetic base serves as a fundamental component in various industrial applications, providing a stable and secure attachment point for tools and equipment. Its design is crucial for ensuring precise operations, especially in environments where mobility and positioning are key factors.

This structure typically comprises several essential elements that work in harmony to deliver optimal performance:

- Magnetic Foot: This component generates a strong magnetic field, allowing for firm adhesion to metal surfaces.

- Adjustment Mechanism: Enables fine-tuning of the tool’s position, ensuring accuracy during operation.

- Base Plate: Provides a solid foundation for mounting equipment and enhances overall stability.

- Locking System: Secures the position of the magnetic base, preventing any unintended movement during use.

Understanding the configuration and functionality of these elements can greatly enhance the effectiveness of magnetic bases in various applications. Proper maintenance and handling of these components are essential for prolonging their lifespan and ensuring reliability in demanding work environments.

Cooling System Configuration

The configuration of a cooling system is essential for maintaining optimal performance in various machines and devices. It ensures that the internal components remain within safe temperature limits, thus enhancing efficiency and prolonging the lifespan of the equipment. A well-designed cooling system not only facilitates heat dissipation but also contributes to the overall stability of operations.

Key elements in the setup of an effective cooling mechanism include:

- Cooling Medium: The choice of cooling fluid or gas plays a crucial role in the heat transfer process.

- Heat Exchanger: This component is vital for transferring heat from the internal environment to the cooling medium.

- Pumps and Fans: These devices are responsible for circulating the cooling medium efficiently throughout the system.

- Thermostatic Control: This feature allows for the regulation of temperature by adjusting the flow of the cooling medium based on real-time requirements.

When configuring the cooling system, several factors must be considered to optimize performance:

- Flow Rate: It is critical to determine the appropriate flow rate for the cooling medium to ensure effective heat removal.

- System Layout: The physical arrangement of components can influence the efficiency of heat transfer.

- Environmental Conditions: External temperatures and conditions should be taken into account to design a robust cooling solution.

Ultimately, a carefully planned cooling system configuration is integral to the reliable operation of machinery, preventing overheating and enhancing performance.

Gearbox and Transmission System

The gearbox and transmission mechanism play a crucial role in the performance and efficiency of various machinery. This system is designed to transmit power from the engine to the operational components, enabling effective movement and functionality. By converting torque and speed, it ensures optimal operation under varying conditions.

Typically, this assembly consists of various gears, shafts, and bearings that work in unison. The arrangement of these elements determines the gear ratio, which significantly affects the overall torque output and speed. A well-designed transmission system allows for smooth shifting between different speed levels, enhancing both control and stability.

Regular maintenance of the gearbox is essential for sustaining its longevity and performance. Inspections should include checking for signs of wear and ensuring adequate lubrication. Proper care can prevent costly repairs and extend the life of the entire mechanism.

In summary, understanding the intricacies of the gearbox and transmission system is vital for anyone involved in the operation or maintenance of machinery. Its efficient performance directly influences the overall effectiveness of the equipment.

Electrical Wiring Layout

This section outlines the essential components and arrangements involved in the electrical wiring of drilling equipment. A well-structured layout ensures safe operation, efficient power distribution, and ease of maintenance. Proper planning of the wiring system is crucial for optimal performance and longevity of the machinery.

Understanding the wiring configuration helps technicians diagnose issues quickly and facilitates modifications when necessary. The layout typically consists of various elements, including power sources, switches, and connectors, all integrated to work seamlessly together.

| Component | Description | Function |

|---|---|---|

| Power Source | Main supply unit | Provides electrical energy to the system |

| Switches | Control devices | Regulate the flow of electricity |

| Connectors | Linking devices | Join various sections of the wiring together |

| Wires | Conductive materials | Transmit electrical current between components |

By adhering to a well-defined electrical wiring layout, users can enhance the safety and functionality of their drilling operations. Regular inspections and adherence to safety standards are recommended to prevent malfunctions and ensure optimal performance.

Key Maintenance Components

Regular upkeep of equipment is essential for optimal performance and longevity. Understanding the vital elements that require attention can significantly enhance functionality and reliability. Below are the crucial components that should be monitored and maintained periodically.

- Drilling Head: Ensures precision and efficiency in drilling operations. Regular inspection for wear and tear is essential.

- Cooling System: Prevents overheating during extended use. Check coolant levels and inspect for leaks to maintain proper operation.

- Power Supply: A stable energy source is vital for smooth operation. Inspect connections and replace faulty components as needed.

- Drive Mechanism: Transmits power to the drilling head. Lubrication and inspection for alignment issues can prolong its lifespan.

- Safety Guards: Essential for user protection. Regular checks to ensure they are intact and functioning properly are crucial.

By focusing on these key elements, users can ensure that their equipment remains in top condition, minimizing downtime and maximizing efficiency.

Safety Features and Parts

Ensuring a secure operation is paramount in any machinery. Various mechanisms are integrated to enhance user safety and minimize the risk of accidents. Understanding these components and their functions is essential for maintaining optimal performance and preventing potential hazards.

Key Safety Mechanisms

The following are crucial elements that contribute to the safety of the equipment:

| Component | Function |

|---|---|

| Emergency Stop Switch | Allows immediate shutdown of the equipment in case of emergencies. |

| Overload Protection | Prevents the machine from operating beyond its designed capacity, reducing the risk of failure. |

| Guarding Systems | Physical barriers that protect the operator from moving parts, enhancing safety during operation. |

Importance of Regular Maintenance

Regular inspection and maintenance of these safety features are vital. Ensuring all components function correctly not only enhances the lifespan of the equipment but also guarantees a safe working environment for users. Neglecting maintenance can lead to unforeseen malfunctions, increasing the risk of accidents.

Assembly and Disassembly Tips

Proper assembly and disassembly techniques are essential for maintaining equipment efficiency and longevity. Understanding the steps involved can prevent damage and ensure that all components fit together seamlessly.

Here are some key suggestions to keep in mind:

- Preparation: Gather all necessary tools and components before starting. This will help streamline the process and reduce interruptions.

- Clean Work Area: Ensure the workspace is clean and organized. A clutter-free environment minimizes the risk of losing parts and helps maintain focus.

- Follow Instructions: Always refer to the manufacturer’s guidelines for specific assembly and disassembly procedures. These instructions provide valuable insights and safety measures.

When taking apart the equipment:

- Document Each Step: Take notes or photographs during disassembly to serve as a reference for reassembly.

- Handle with Care: Be cautious with delicate components to prevent breakage or wear.

- Label Parts: Use labels or containers to keep small parts organized, which will simplify the reassembly process.

During assembly:

- Align Components: Ensure that all pieces are properly aligned before fastening them together to avoid misalignment issues.

- Tighten Fasteners: Gradually tighten bolts and screws to the recommended torque settings to ensure a secure fit without over-tightening.

- Final Check: Once assembled, inspect the equipment thoroughly to ensure everything is correctly in place and functioning properly.

Following these tips will not only make the process smoother but also extend the life of the equipment.