In the realm of mechanical systems, comprehending the intricate assembly of various elements is crucial for efficient operation and maintenance. This section aims to explore the layout of essential components, highlighting their functions and interrelationships. A clear visualization of these parts can significantly enhance the understanding of the overall functionality of the system.

Every mechanical apparatus comprises numerous elements that work in harmony to achieve optimal performance. By examining the arrangement and interaction of these parts, users can identify potential areas for improvement or maintenance. A well-structured representation serves as a valuable tool for both novice and experienced technicians, facilitating a deeper insight into the operational principles of the equipment.

Moreover, having a detailed overview of the configurations allows for more effective troubleshooting and repair processes. This comprehensive examination enables users to grasp how each element contributes to the system’s efficiency and longevity. Engaging with this information empowers individuals to maintain and optimize their equipment effectively.

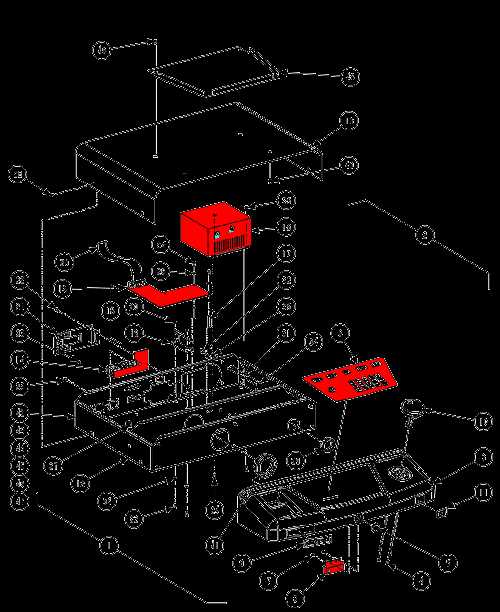

Overview of Hunter TCX51 Components

The intricate assembly of this equipment comprises various elements, each contributing to its overall functionality and performance. Understanding the relationship and purpose of these components is essential for effective operation and maintenance. This section delves into the fundamental parts, emphasizing their roles within the system.

Key Elements and Their Functions

Among the vital components, the drive mechanism plays a crucial role in ensuring smooth operation. This part transfers energy from the motor to other sections, facilitating movement and efficiency. Additionally, the control unit serves as the brain of the system, managing signals and commands to optimize performance based on user input.

Maintenance and Care

Regular inspection and maintenance of these essential elements are paramount for longevity. Keeping the drive mechanism clean and free of debris can prevent operational issues, while ensuring the control unit is updated with the latest firmware can enhance functionality. Adhering to proper care protocols significantly contributes to the equipment’s reliability.

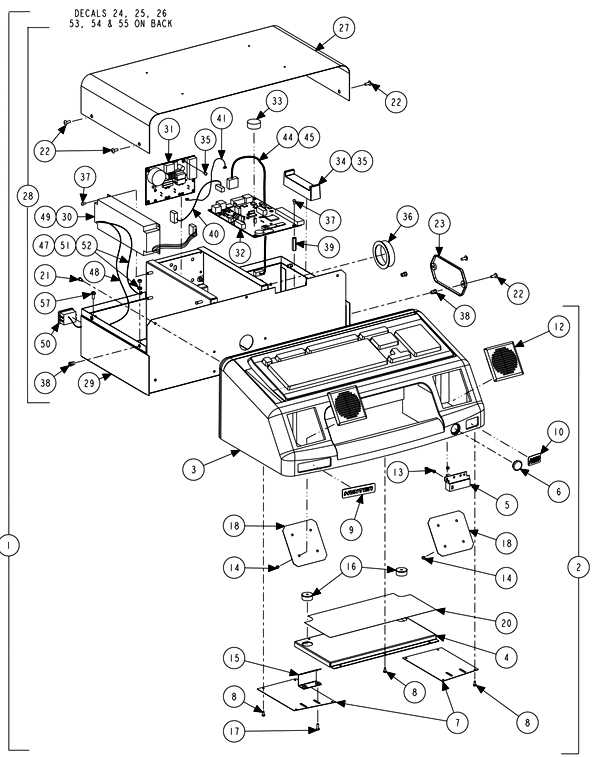

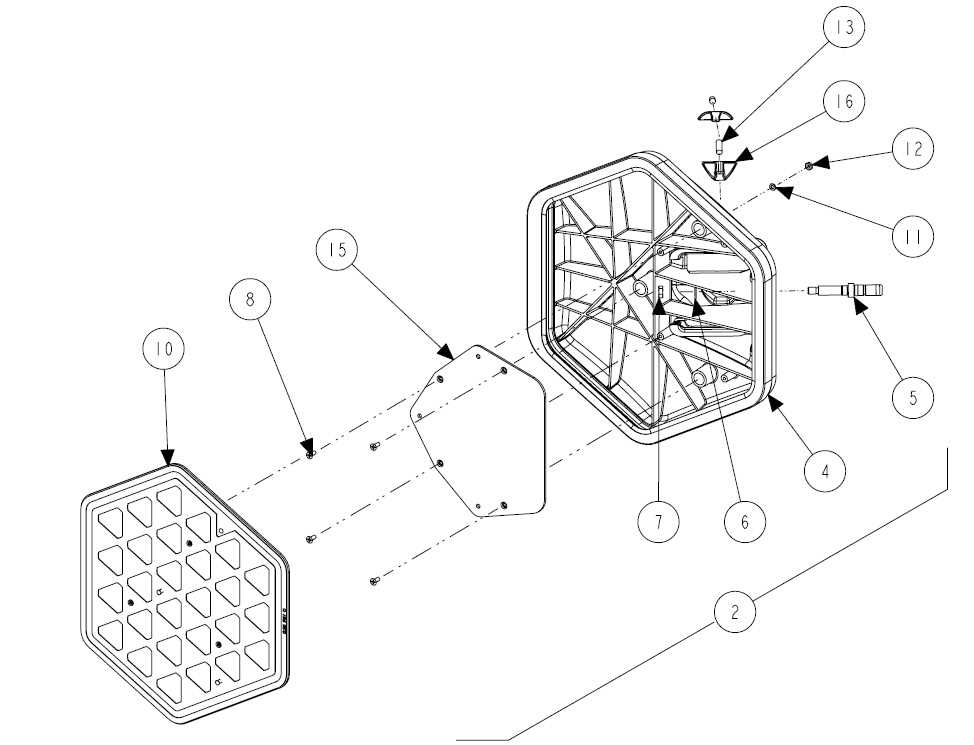

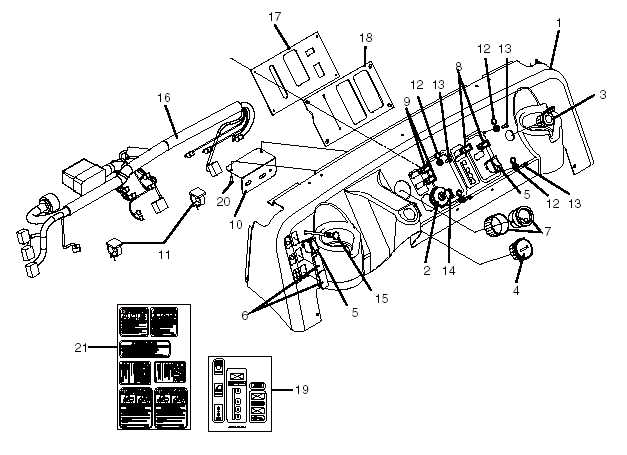

Understanding the Parts Diagram

Analyzing an assembly illustration is essential for grasping the various components involved in a specific system. These visual representations serve as valuable tools for technicians and enthusiasts alike, aiding in the identification and comprehension of individual elements within a machine. By interpreting these graphics, users can gain insights into the relationships between different parts and their roles in the overall functionality.

The Importance of Component Identification

Recognizing each element’s function is crucial for effective maintenance and troubleshooting. A well-structured illustration helps in pinpointing issues and simplifies the repair process. Understanding how each piece fits into the larger system allows for more efficient diagnostics and enhances the longevity of the equipment.

Key Features of Assembly Illustrations

These visual aids often include labels, numbers, and legends that correspond to specific components, providing a clearer understanding of their locations and functions. The following table summarizes common features found in such illustrations:

| Feature | Description |

|---|---|

| Labeling | Identification tags for each component, facilitating easy reference. |

| Numbering | Sequential numbers that correspond to a list of parts, aiding in organization. |

| Legends | Explanatory notes that clarify symbols or color codes used in the illustration. |

| Orientation Arrows | Directional indicators showing the arrangement or connection of components. |

Identifying Key Components

Understanding the essential elements of a mechanical system is crucial for effective maintenance and troubleshooting. This section highlights the significant parts involved in the operation of a specific machinery model, enabling users to recognize their functions and importance within the assembly.

Primary Elements to Note

- Motor: This component serves as the driving force, converting electrical energy into mechanical power to initiate movement.

- Control Module: A vital part that regulates the performance and functionality of the machinery, allowing for user interaction and settings adjustments.

- Frame: The structural backbone that supports all other components, ensuring stability and durability during operation.

- Drive System: This mechanism transfers power from the motor to the working components, facilitating movement and functionality.

Auxiliary Parts

- Connectors: Essential for linking various components, ensuring efficient communication and energy transfer.

- Cooling System: Prevents overheating by dissipating excess heat generated during operation, prolonging the life of the machinery.

- Safety Features: Integrated mechanisms designed to protect users and the equipment from potential hazards.

By familiarizing oneself with these critical elements, operators can enhance their understanding of the equipment, leading to improved maintenance practices and overall performance.

Assembly and Disassembly Procedures

The process of putting together or taking apart mechanical systems is crucial for maintenance and repair tasks. Understanding the correct sequence of steps can enhance efficiency and prevent damage to components. This section outlines essential methods and considerations to ensure smooth assembly and disassembly, ultimately aiding in the longevity and performance of the equipment.

When disassembling, start by ensuring that the workspace is clean and well-organized. Gather all necessary tools and documentation to assist in the procedure. Carefully remove any covers or housing that may obstruct access to the internal components. It is advisable to keep track of all fasteners and small parts, potentially using labeled containers to avoid misplacement.

During assembly, follow the reverse order of disassembly, paying close attention to alignment and fit of each component. Utilize torque specifications where applicable to secure fasteners properly. It is beneficial to inspect each piece for wear or damage before reassembly, ensuring that all parts function optimally together. Finally, conduct a thorough test of the assembled system to confirm proper operation.

Common Issues and Solutions

In any mechanical system, certain problems can frequently arise, affecting performance and functionality. Understanding these issues and their remedies is crucial for maintaining efficiency and prolonging the lifespan of the equipment. This section outlines common challenges faced by users and provides practical solutions to address them effectively.

Frequent Challenges

- Inconsistent operation due to wear and tear on components.

- Electrical malfunctions causing system failures.

- Blockages in airflow leading to overheating.

- Leakages from connection points affecting overall efficiency.

Effective Remedies

- Regular Maintenance: Schedule routine checks to identify and replace worn parts before they lead to further issues.

- Electrical Inspections: Conduct thorough inspections of wiring and connections to prevent short circuits and ensure optimal operation.

- Clear Airflow: Regularly clean filters and ducts to avoid obstructions that can lead to overheating.

- Seal Connections: Use appropriate sealants to prevent leakages at connection points, ensuring a tight fit and efficient operation.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan and optimal performance of any equipment. By adhering to a few straightforward maintenance practices, you can enhance reliability and minimize the likelihood of unexpected failures. Regular attention to key components not only preserves functionality but also contributes to overall efficiency.

1. Regular Inspections: Conduct frequent evaluations of your device to identify signs of wear or damage. Early detection of potential issues can save time and costs associated with more significant repairs later.

2. Cleanliness: Keep all surfaces free from dust, dirt, and debris. Accumulation of particles can hinder performance and lead to malfunctions. Regular cleaning should be part of your maintenance routine.

3. Lubrication: Ensure moving parts are adequately lubricated to prevent friction-related wear. Using the right lubricant can significantly enhance performance and reduce the risk of breakdowns.

4. Follow Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for maintenance practices. Adhering to specific protocols can ensure that your equipment operates efficiently and safely.

5. Store Properly: When not in use, store your device in a clean, dry environment to protect it from environmental factors that could cause deterioration. Proper storage can greatly extend its useful life.

Implementing these practices can lead to improved functionality and a longer operational period for your equipment, ultimately providing better value and performance over time.

Replacement Parts and Compatibility

When it comes to maintaining and repairing outdoor equipment, ensuring the availability of suitable components is crucial for optimal performance. Understanding the options for replacements and their compatibility with various models can significantly enhance the longevity and efficiency of your machinery.

Identifying Suitable Components

Finding the right replacements requires careful consideration of specific requirements. Here are some factors to keep in mind:

- Model Specifications: Always check the model number to ensure compatibility.

- Manufacturer Recommendations: Consult the manufacturer’s guidelines for suggested components.

- Quality Standards: Opt for high-quality replacements to avoid premature wear and tear.

Compatibility Considerations

Ensuring that replacement components work seamlessly with your equipment involves several key aspects:

- Size and Fit: Verify that the dimensions of the new part match the original.

- Functional Requirements: Ensure that the replacement meets the same operational standards as the original.

- Warranty Implications: Be aware that using non-approved components may void any existing warranties.

By understanding the essential factors of replacements and their compatibility, you can make informed decisions that promote the effective use of your outdoor equipment.

Tools Required for Repairs

Effective maintenance and repair work relies heavily on having the right set of tools. This section highlights the essential instruments and equipment needed to carry out repairs efficiently and safely. Proper preparation with the necessary tools can significantly enhance the quality of the work and ensure a smoother process.

Essential Hand Tools

Among the most important items in any repair kit are hand tools. These typically include screwdrivers, wrenches, and pliers. Each of these tools plays a vital role in loosening, tightening, or adjusting components. Having a variety of sizes ensures that users can handle different types of fasteners and fittings effectively.

Power Tools and Accessories

For more extensive repairs, power tools can save significant time and effort. Drills and impact drivers are particularly useful for tasks that require greater force or precision. Additionally, accessories such as saw blades and drill bits should be chosen based on the materials being worked on to optimize performance.

Safety Precautions During Maintenance

Ensuring a safe working environment is crucial when performing upkeep on machinery. Proper procedures and guidelines can significantly reduce the risk of accidents and injuries, allowing for a smoother maintenance process. Adhering to safety measures is essential for both the operator and the equipment being serviced.

Proper Personal Protective Equipment

Wearing the appropriate personal protective equipment (PPE) is a fundamental aspect of maintaining safety during maintenance tasks. This includes items such as gloves, safety goggles, and hearing protection. Each piece of equipment serves to shield the worker from potential hazards, such as sharp edges or loud noises, and should be worn at all times when working on machinery.

Equipment Lockout Procedures

Implementing lockout/tagout procedures is vital to prevent accidental startup of machinery during servicing. Before beginning any maintenance work, ensure that the equipment is fully powered down and securely locked to prevent unintended operation. Using a lock and tag system helps to communicate to others that maintenance is in progress, thereby reducing the risk of injury.

Where to Find Original Parts

Locating authentic components for your machinery is essential for maintaining optimal performance and reliability. Whether you are repairing or upgrading, sourcing genuine items ensures compatibility and quality, which are crucial for longevity and efficient operation.

Authorized Distributors

One of the most reliable methods to obtain genuine components is through authorized distributors. These suppliers have direct access to the manufacturer’s inventory and are trained to provide assistance specific to your needs. Visiting their websites or physical locations can yield a wide array of options tailored to your requirements.

Manufacturer’s Website

Another excellent resource is the manufacturer’s official website. Here, you can find a catalog of available components, along with detailed specifications. Many manufacturers offer online purchasing options, ensuring that you receive the correct items directly from the source.

FAQs About Hunter TCX51 Parts

This section addresses common inquiries regarding components and their maintenance. Understanding these elements is essential for ensuring optimal functionality and longevity of the equipment.

- What should I consider when replacing components?

When replacing any component, it is crucial to check compatibility, quality, and warranty options. Ensure that the new item meets the specifications required for your equipment.

- How can I identify a faulty component?

Signs of malfunction may include unusual noises, inconsistent performance, or visible wear and tear. Regular inspections can help catch issues early.

- Where can I find quality replacements?

Quality replacements can be sourced from authorized dealers, reputable online retailers, or specialized stores. Always verify the seller’s credibility.

- What maintenance practices should I follow?

Regular cleaning, timely lubrication, and periodic inspections are vital. Follow the manufacturer’s guidelines for optimal upkeep.

- Are there any warranties on new components?

Many replacements come with warranties, which vary by manufacturer and retailer. Always inquire about warranty details before purchasing.

Upgrades and Modifications Available

Enhancing the performance and functionality of your equipment can significantly improve its efficiency and user experience. Various options exist for upgrades that can tailor your system to meet specific needs, whether it’s for increased power, improved aesthetics, or additional features. These enhancements not only elevate the overall performance but also allow for greater customization based on individual preferences.

Performance Enhancements: One of the most popular modifications includes upgrading components to boost performance metrics. Consider replacing standard parts with high-performance alternatives that offer improved durability and efficiency. These upgrades can lead to better speed, increased reliability, and enhanced overall output.

Cosmetic Changes: Aesthetic upgrades can also play a vital role in personalizing your setup. Upgrading the exterior with custom finishes, decals, or even new housing can significantly change the look of your unit, making it stand out while still maintaining functionality.

Additional Features: Implementing new features, such as advanced control systems or connectivity options, can greatly enhance the user experience. These modifications can facilitate easier operation, provide greater flexibility, and integrate seamlessly with other systems.

Exploring the available upgrades and modifications allows users to create a unique setup that not only meets their functional requirements but also reflects their personal style and preferences.

Expert Recommendations for Users

To enhance the performance and longevity of your equipment, it’s essential to follow expert guidance. Implementing best practices not only optimizes functionality but also minimizes potential issues that may arise during use. Here are some valuable insights to consider.

Firstly, regular maintenance is crucial. Ensure that all components are routinely inspected and serviced according to the manufacturer’s recommendations. This proactive approach helps identify wear and tear before it escalates into more significant problems.

Additionally, using high-quality replacement elements can make a substantial difference in operational efficiency. Investing in reliable substitutes guarantees better compatibility and performance, ultimately extending the lifespan of the equipment.

Moreover, keeping a detailed log of maintenance activities and replacements aids in tracking performance trends over time. This information can be invaluable for troubleshooting and optimizing functionality.

| Tip | Description |

|---|---|

| Regular Inspection | Conduct periodic checks to identify and address potential issues early. |

| Quality Replacements | Opt for top-tier substitutes to ensure optimal performance and longevity. |

| Maintenance Log | Maintain a record of all maintenance tasks for effective tracking and analysis. |