In the world of refrigeration technology, comprehending the arrangement and functionality of various elements is crucial for efficient operation. A clear visualization of these components aids technicians and enthusiasts alike in grasping how each part interacts within the system, ensuring optimal performance.

Whether you’re troubleshooting an issue or performing routine maintenance, familiarity with the specific structure can significantly enhance your understanding. This knowledge not only facilitates repair processes but also promotes a deeper appreciation of the machinery’s design and engineering.

Furthermore, having a detailed representation allows for easier identification of each segment, helping users to navigate through complex assemblies with confidence. By analyzing these layouts, one can develop a more profound expertise that empowers better decision-making and problem-solving in everyday scenarios.

Understanding Ice-O-Matic Machines

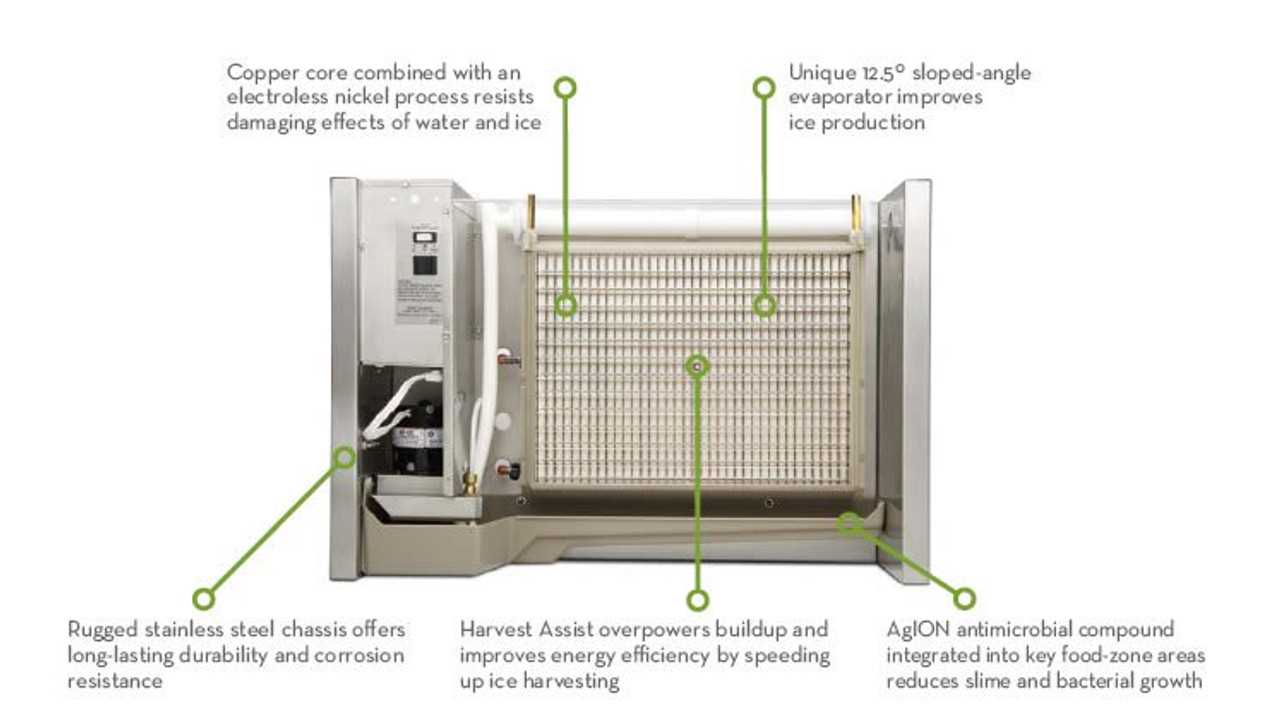

These innovative refrigeration units play a crucial role in various settings, from restaurants to convenience stores, by providing essential frozen commodities. Their efficient design allows for rapid production, ensuring that users have access to a steady supply of ice or frozen items.

Components of these machines are intricately designed to work together, making the overall system more reliable. Each segment, from the cooling elements to the dispensing mechanisms, contributes to the ultimate functionality of the unit.

By delving into the specifics of how these devices operate, one can appreciate the engineering behind their efficiency. Understanding the interactions among different elements helps in troubleshooting and maintaining optimal performance.

Overview of Ice-O-Matic Components

This section provides a comprehensive look at the essential elements that contribute to the efficient operation of these machines. Understanding the various components is crucial for effective maintenance and troubleshooting, ensuring optimal performance and longevity.

Key Functional Elements

Each unit comprises multiple vital components, including the compressor, evaporator, and control system. These parts work in synergy to produce and manage the freezing process, with each playing a specific role in maintaining temperature and quality.

Maintenance and Care

Regular inspection of the critical elements is important for preventing issues. Identifying wear or damage early can lead to timely repairs, ultimately enhancing the unit’s reliability and efficiency.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for efficient operation and maintenance. Visual representations serve as essential tools, providing clarity and insight into the structure and functionality of equipment. They not only facilitate comprehension but also enhance problem-solving abilities when issues arise.

Benefits of Visual Representations

- Enhanced Understanding: Clear visuals help users grasp the relationships and functions of various elements within a system.

- Streamlined Maintenance: Identifying specific elements becomes easier, allowing for quicker repairs and servicing.

- Effective Training: New users can learn more rapidly when provided with detailed illustrations that depict complex systems.

Applications in Various Fields

- Manufacturing: Visual guides assist technicians in assembling and maintaining machinery efficiently.

- Education: Learners benefit from diagrams that simplify complex concepts, making them more accessible.

- Repair Services: Service professionals rely on these visuals to diagnose and resolve issues effectively.

In conclusion, these visual aids are invaluable in multiple contexts, promoting better understanding, efficiency, and effective communication among users and technicians alike.

Common Parts in Ice Machines

Understanding the essential components of ice-making equipment is crucial for efficient operation and maintenance. Each element plays a significant role in the production and delivery of ice, ensuring optimal performance and longevity.

Key Components

Ice-making machines typically consist of several critical elements that work together seamlessly. These components include the condenser, evaporator, and water reservoir, among others. Each part contributes uniquely to the ice generation process.

Functional Overview

| Component | Function |

|---|---|

| Condenser | Removes heat from refrigerant, allowing it to cool and condense. |

| Evaporator | Facilitates the freezing of water into ice through refrigeration. |

| Water Reservoir | Holds water that is used to create ice. |

| Compressor | Pumps refrigerant and maintains pressure in the system. |

How to Read a Parts Diagram

Understanding a schematic representation of components is crucial for effective maintenance and repair. It provides a visual guide that simplifies complex assemblies, allowing users to identify each element and its relationship to others. This knowledge empowers technicians to work more efficiently and accurately.

Familiarizing with Symbols and Labels

Each illustration employs specific symbols and annotations. Recognizing these is the first step to comprehension. Here are some common features to note:

- Symbols: Different shapes represent various components. Familiarize yourself with their meanings.

- Labels: Names or numbers often accompany symbols to provide clarity on each element’s function.

- Connections: Lines or arrows indicate how parts are linked, revealing their operational flow.

Step-by-Step Analysis

To navigate the visual representation effectively, follow these steps:

- Start at the Source: Identify the main component or entry point of the system.

- Follow the Flow: Trace the connections to understand how components interact with one another.

- Cross-reference: Utilize accompanying manuals or documents for additional context and explanations.

- Take Notes: Jot down any critical observations or questions that arise during your review.

With practice, interpreting these visual guides will become an intuitive skill, enhancing both troubleshooting and repair processes.

Identifying Key Components

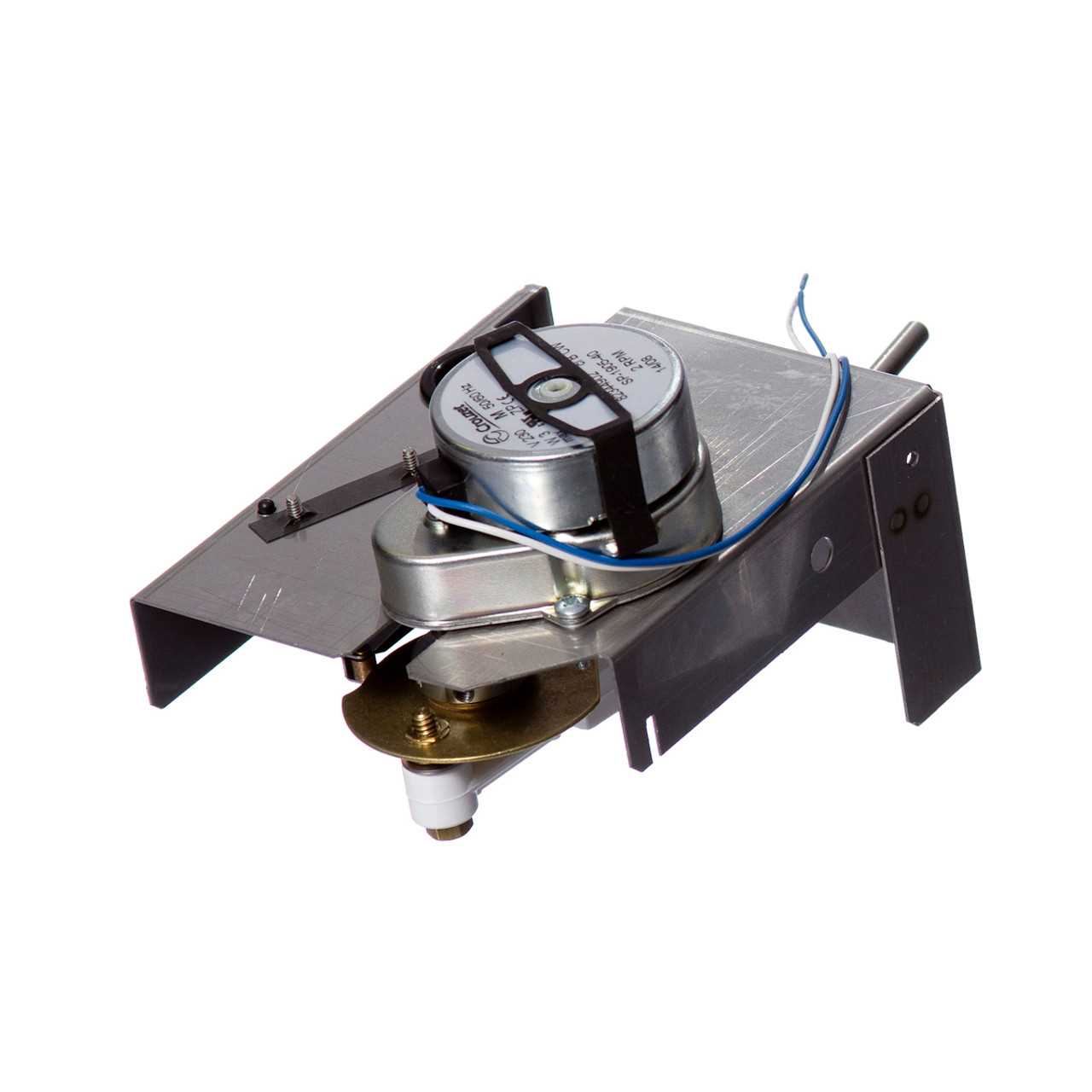

Understanding the essential elements of any equipment is crucial for effective maintenance and troubleshooting. Recognizing these parts helps users operate the machinery efficiently, ensuring optimal performance and longevity. This section will explore the main components that play a vital role in the functioning of the device.

Main Functional Elements

- Compressor: Responsible for pressurizing the refrigerant, facilitating the cooling process.

- Condenser: Allows the refrigerant to release heat, transitioning it from gas to liquid.

- Evaporator: Absorbs heat from the surroundings, turning the refrigerant back into gas.

- Expansion Valve: Regulates the flow of refrigerant, maintaining appropriate pressure levels.

Supporting Components

- Fan: Circulates air, enhancing heat exchange efficiency.

- Controls: Manage operation settings and monitor system performance.

- Hoses and Fittings: Facilitate the movement of refrigerant throughout the system.

- Base: Provides structural support and stability to the entire assembly.

Maintenance Tips for Ice-O-Matic

Regular upkeep is essential for ensuring optimal performance and longevity of your ice-making equipment. By implementing effective maintenance strategies, you can minimize downtime and enhance the efficiency of your machine.

Routine Cleaning

Keeping the unit clean is vital for its functionality. Here are some steps to follow:

- Unplug the machine before cleaning.

- Use a soft cloth and mild detergent to wipe down the exterior.

- Clean the ice bin regularly to prevent buildup and contamination.

- Remove any ice clogs or debris from the water reservoir and drain.

Check and Replace Components

Regularly inspecting and replacing worn-out parts can help maintain efficiency. Consider the following:

- Inspect water filters and replace them as needed to ensure clean water supply.

- Check seals and gaskets for wear; replace if damaged.

- Monitor the condition of electrical connections and components.

- Schedule professional servicing at least once a year for comprehensive checks.

Common Issues and Solutions

In the world of refrigeration equipment, various challenges can arise that affect performance and efficiency. Identifying these issues promptly is crucial for maintaining smooth operations. This section explores prevalent problems encountered, along with effective remedies to restore functionality.

Frequent Problems

One of the most common dilemmas is inadequate cooling. This can stem from several factors, such as blocked air vents or insufficient refrigerant levels. Regular inspections can help in early detection and prevention of further complications.

Effective Remedies

For low cooling output, start by checking for obstructions in airflow. Clear any debris around the unit and ensure that all vents are free from blockage. If the refrigerant levels are low, it’s advisable to consult a professional to recharge the system safely.

Replacement Parts Availability

Ensuring that essential components are readily accessible is crucial for maintaining optimal performance and longevity of equipment. Timely access to these elements minimizes downtime and supports efficient operations.

Sources for Components

- Authorized distributors

- Online marketplaces

- Local service centers

Considerations When Purchasing

- Verify compatibility with existing models

- Check warranty options

- Evaluate customer reviews

Staying informed about availability can significantly enhance the reliability of your machinery.

Benefits of Using Genuine Parts

Utilizing authentic components in your equipment can significantly enhance performance and longevity. These original elements are designed specifically to meet the exact specifications of your machinery, ensuring optimal functionality.

Quality Assurance: Genuine components are rigorously tested for durability and reliability, which means they are less likely to fail prematurely compared to substitutes.

Compatibility: Authentic elements guarantee seamless integration, reducing the risk of malfunctions caused by mismatched specifications.

Warranty Protection: Many manufacturers offer warranty coverage when genuine parts are used, providing peace of mind and financial protection.

Resale Value: Equipment maintained with original components typically retains higher resale value, appealing to potential buyers.

In conclusion, investing in original elements not only safeguards your machinery but also enhances its overall efficiency and reliability.

Finding Technical Manuals Online

Locating comprehensive guides for equipment maintenance can significantly enhance troubleshooting and repair efficiency. With a wealth of resources available on the internet, users can quickly access the information they need to ensure optimal performance of their machinery.

Utilizing Manufacturer Websites

Many manufacturers provide downloadable documentation directly on their official websites. These resources often include installation instructions, maintenance tips, and troubleshooting guidelines. Always verify that the document corresponds to your specific model for accurate information.

Exploring Online Databases

Several online platforms aggregate manuals from various manufacturers. These databases allow users to search by model number or type of equipment. Using advanced search filters can streamline the process, ensuring you find the right guide swiftly.

Upgrades for Enhanced Performance

To achieve optimal functionality and efficiency, enhancing the existing systems is crucial. Various upgrades can significantly improve the overall output, leading to better results and prolonged equipment lifespan.

Key Areas for Enhancement

- Cooling Efficiency

- Power Consumption

- Durability of Components

Recommended Upgrades

- Install advanced thermal management systems for improved cooling.

- Utilize energy-efficient motors to reduce electricity usage.

- Incorporate high-grade materials to increase component longevity.

Frequently Asked Questions

This section addresses common inquiries related to the components and assembly of our equipment. It aims to provide clarity on various aspects, ensuring users have the information they need for effective operation and maintenance.

What are the common issues encountered with the unit?

Users often face problems such as inadequate performance or unusual noises. Identifying these symptoms can help in troubleshooting effectively.

How can I obtain replacement components?

Replacement items can typically be ordered through authorized suppliers or directly from manufacturers. It’s advisable to check compatibility before making a purchase.