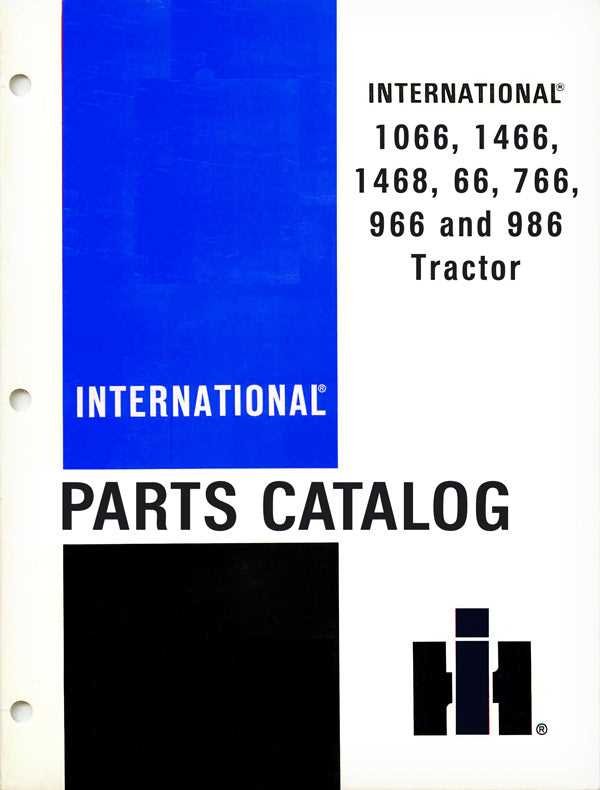

When working with any machinery, it is crucial to have a clear understanding of how various elements are connected and how they function together. The ability to identify and differentiate these elements ensures smooth maintenance and efficient repairs. With the right approach, comprehending how each piece fits into the larger system becomes much easier.

Efficient upkeep relies heavily on knowing which elements play a key role in the machine’s overall operation. Familiarizing oneself with the specific configurations can save time and prevent potential issues down the road. This section will help clarify the relationship between various elements, ensuring a more comprehensive understanding of their purpose.

From detailed overviews to step-by-step explanations, this guide provides a thorough examination of essential components and their interactions. Whether you’re troubleshooting or simply learning more, understanding these elements will improve your ability to keep things running smoothly.

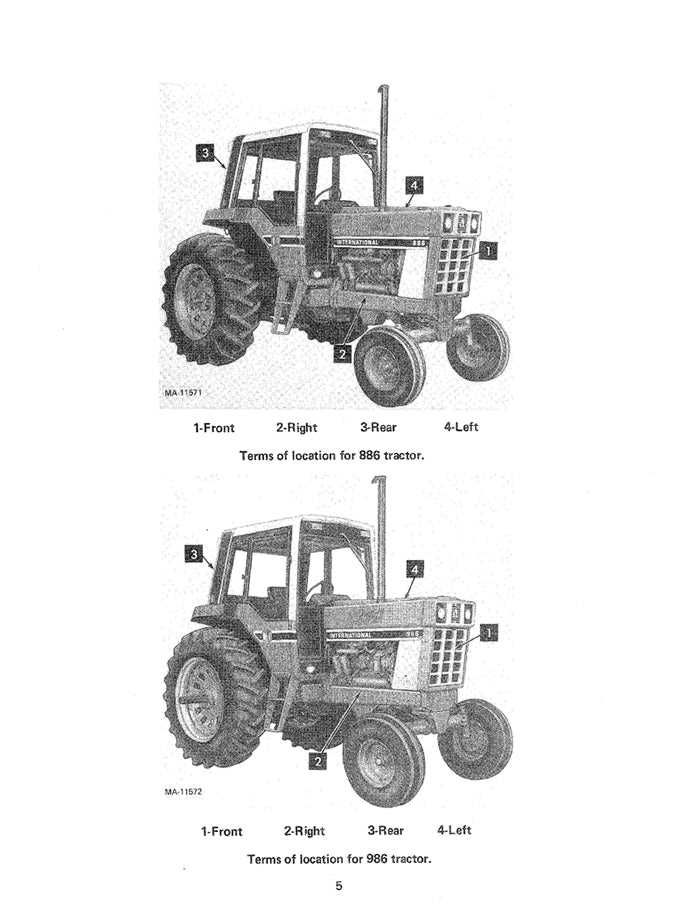

Understanding the IH 986 Components

Comprehending the various elements of this agricultural machinery is essential for ensuring its proper functionality. Each component plays a vital role in the smooth operation, contributing to the overall efficiency and durability of the equipment. By familiarizing yourself with these elements, you can maintain the machine more effectively and address potential issues before they escalate.

Key Mechanical Structures

The primary structures include essential mechanical systems designed for handling demanding tasks. These systems are constructed to withstand extensive use, ensuring reliable performance under various conditions. Regular maintenance of these structures will help prolong the lifespan of the equipment.

Supporting Systems

In addition to core mechanisms, supporting systems such as cooling, lubrication, and electrical networks are crucial for optimal operation. These systems ensure that the machinery continues to function smoothly, preventing overheating, wear, and other potential issues.

Key Engine Parts of IH 986

The core components of the IH engine are essential for ensuring reliable performance and smooth operation. Understanding the main elements is crucial for maintaining and servicing the machinery effectively. Below is a breakdown of the most important elements that play a vital role in the engine’s function.

Essential Engine Elements

- Cylinder Block: This forms the foundation of the engine, housing many critical components and providing structure to the entire system.

- Crankshaft: Responsible for converting linear energy into rotational force, driving the machinery’s power output.

- Pistons: Key in the combustion process, these elements move within the cylinder to generate power.

Additional Vital Components

- Camshaft: Regulates the timing of valve openings, ensuring precise intake and exhaust cycles.

- Valves: Manage the flow of air and fuel into the engine, and control the release of exhaust gases.

- Fuel Injector: Delivers the necessary fuel into the engine’s combustion chambers, enabling efficient energy conversion.

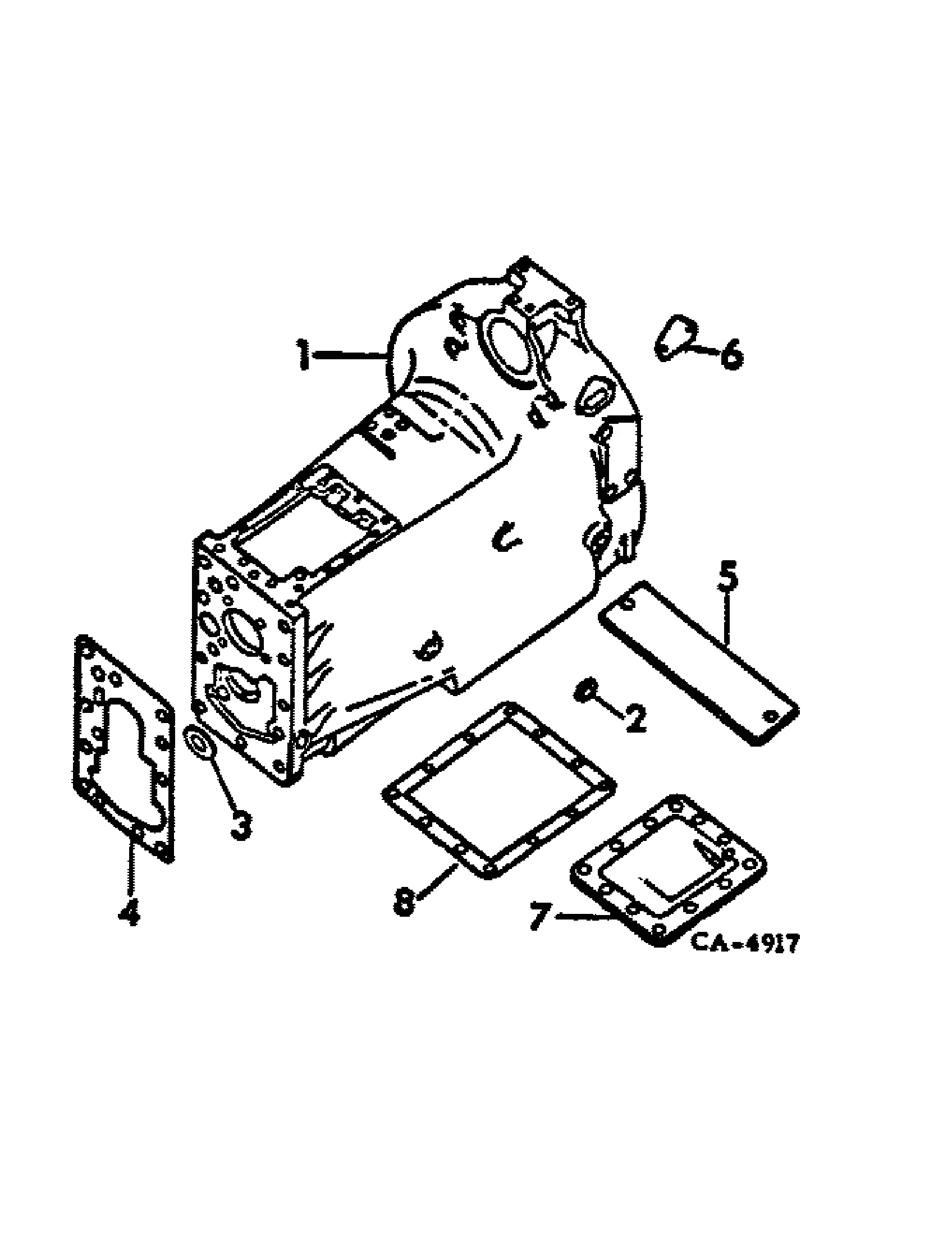

Transmission System Breakdown for IH 986

The transmission system is a critical component that ensures the smooth operation of the vehicle. It allows for efficient power distribution, ensuring that the machine can handle varying workloads and terrains. Understanding the internal structure of this system is essential for maintaining peak performance and diagnosing potential issues before they become problematic.

Main Components and Their Functions

Within the transmission assembly, multiple interconnected elements work together to regulate speed and torque. Key mechanisms include the gearbox, which adjusts the rotational force, and the clutch, responsible for engaging and disengaging power flow. Each of these elements plays a pivotal role in ensuring optimal control over the machine’s performance.

Maintenance and Common Issues

Regular maintenance of the transmission system is crucial to avoid disruptions. Lubrication of moving components and timely inspection of wear are necessary to prevent potential failures. Common problems include gear slippage, uneven power distribution, or abnormal noises, which often indicate underlying mechanical issues that require immediate attention.

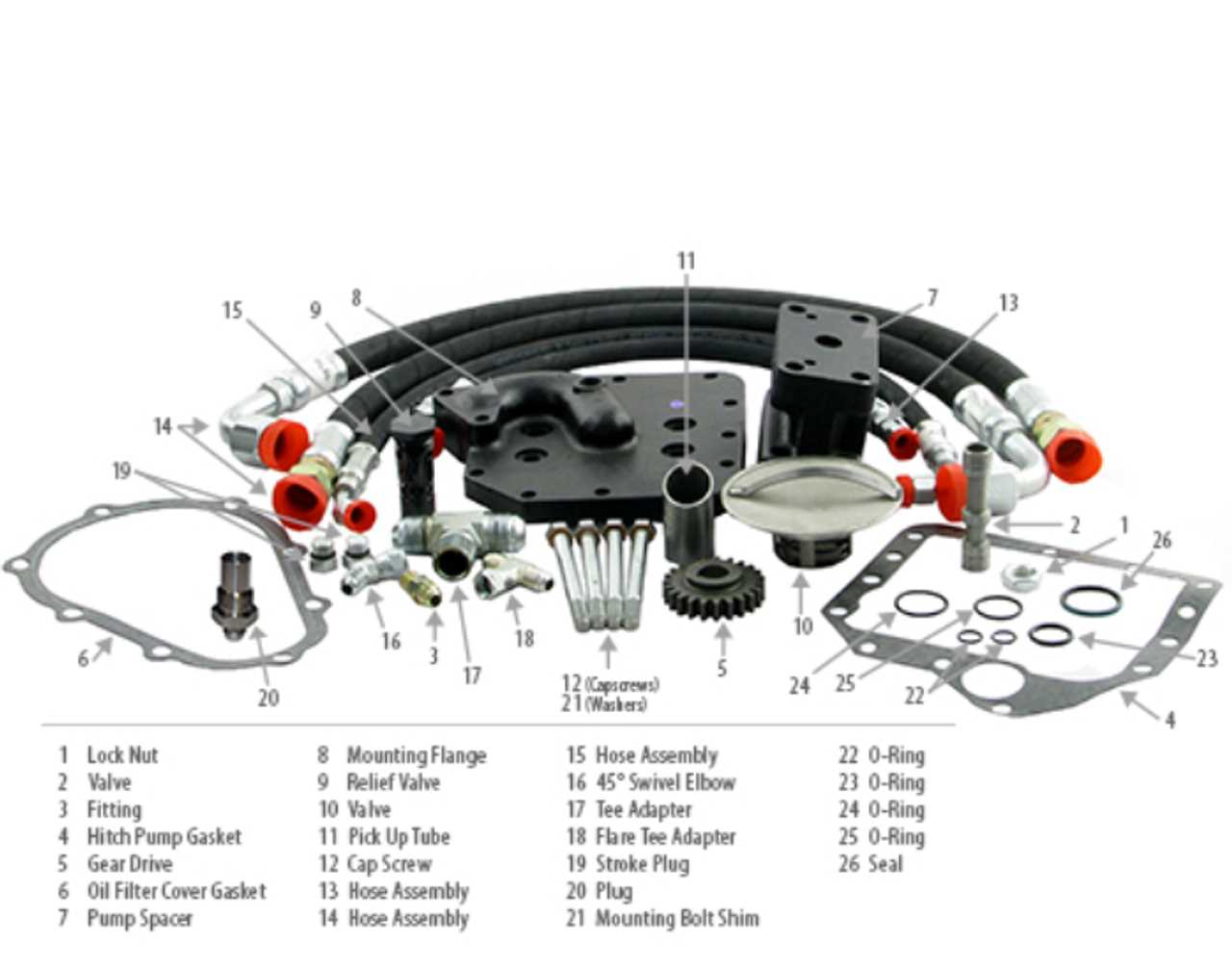

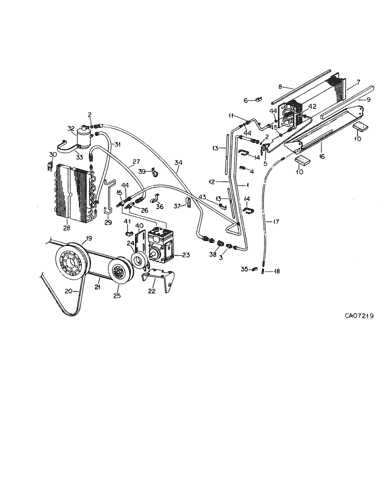

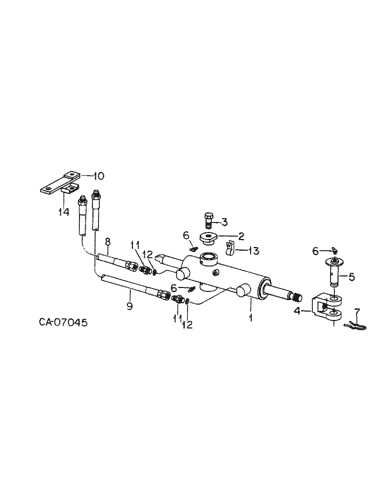

Detailed Overview of Hydraulic Components

Hydraulic systems play a crucial role in ensuring smooth and efficient operation of various machinery. By transmitting power through pressurized fluids, these systems enable precise control over mechanical functions, ensuring optimal performance. This section explores the key components involved in hydraulic systems, highlighting their roles and how they interact to create a reliable and durable setup.

| Component | Function | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pump | Generates the necessary fluid pressure to power the hydraulic system. | ||||||||||||||||||

| Valves | Control the flow and pressure of the fluid, ensuring the correct direction and force. | ||||||||||||||||||

| Cylinders | Convert hydraulic energy into mechanical movement, enabling tasks like lifting or pushing. | ||||||||||||||||||

| Hoses | Transport pressurized fluid between different parts of the system. | ||||||||||||||||||

| Reservoir | Stores

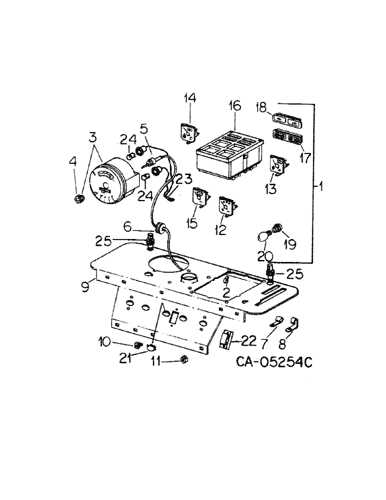

Exploring the Electrical Wiring Structure

The intricacies of an electrical system are vital for the seamless operation of machinery. Understanding the layout and connections within the wiring framework is crucial for maintenance and troubleshooting. This section delves into the essential components and their interrelations that contribute to the functionality of the overall electrical network. Each element plays a significant role in ensuring that power is effectively distributed throughout the system. Below is a detailed representation of the key components involved in the electrical structure:

Fuel System Layout in IH 986The arrangement of the fuel delivery components plays a crucial role in ensuring optimal performance and efficiency in agricultural machinery. Understanding how these elements interact can enhance maintenance and troubleshooting processes. Key Components: The fuel system typically consists of a fuel tank, lines, filters, and the injection mechanism. Each of these parts is designed to work in harmony, facilitating the smooth transfer of fuel from storage to the engine. Fuel Tank: The reservoir holds the necessary fuel, providing a steady supply for operation. It’s essential to regularly check for debris and ensure it remains free of contaminants. Fuel Lines: These conduits transport fuel to various components. Proper sealing and integrity are vital to prevent leaks that could compromise performance. Filters: Integral to maintaining the system’s cleanliness, filters trap impurities before they reach the engine. Regular replacement is recommended to avoid clogs and ensure efficient fuel flow. Injection Mechanism: This component atomizes the fuel for optimal combustion. Any issues here can significantly affect power output and engine responsiveness. Cooling Mechanism Parts and Functions

The cooling system plays a crucial role in maintaining optimal operating temperatures within machinery. By effectively regulating heat, it ensures that components function smoothly and efficiently. Understanding the various elements involved in this system helps in recognizing their individual contributions to overall performance. Key Components of the Cooling System

Functions of Each Element

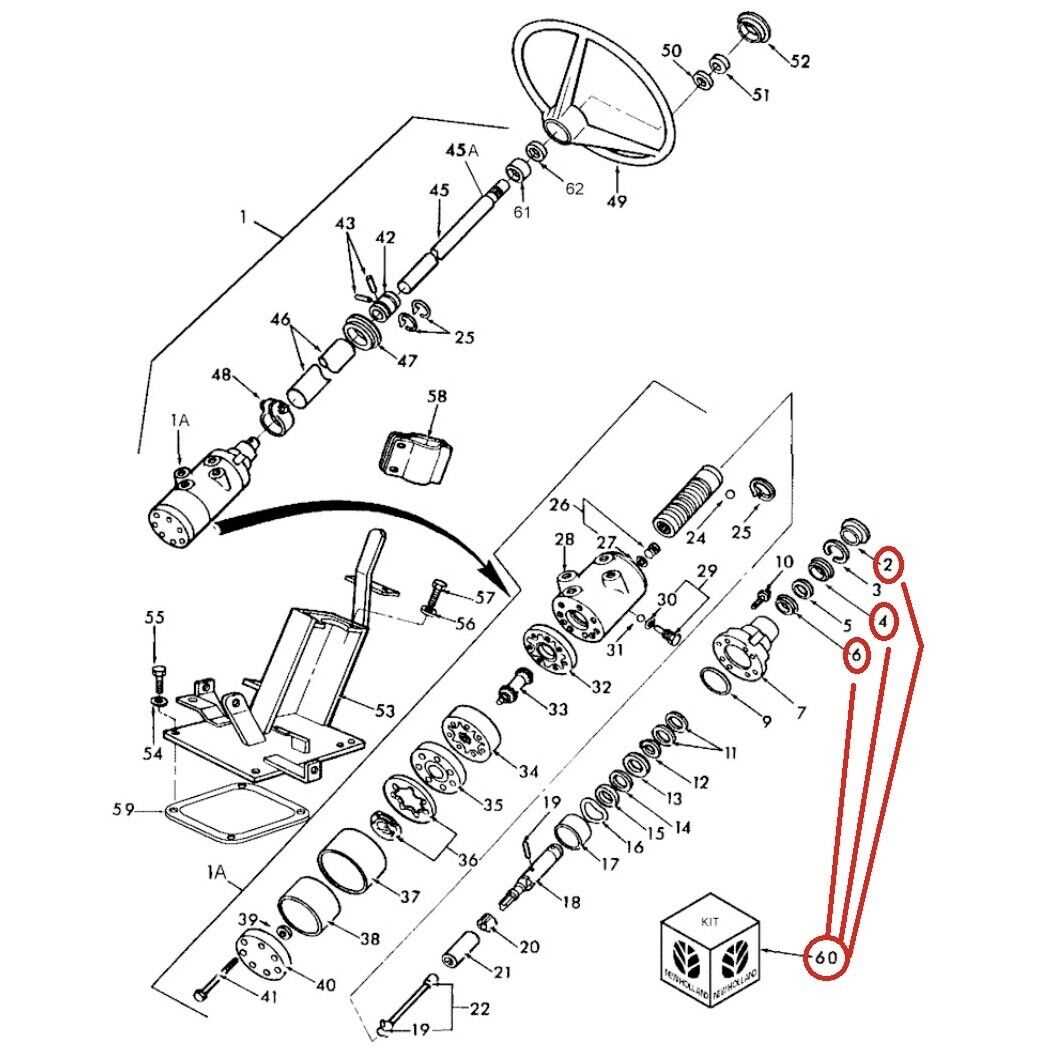

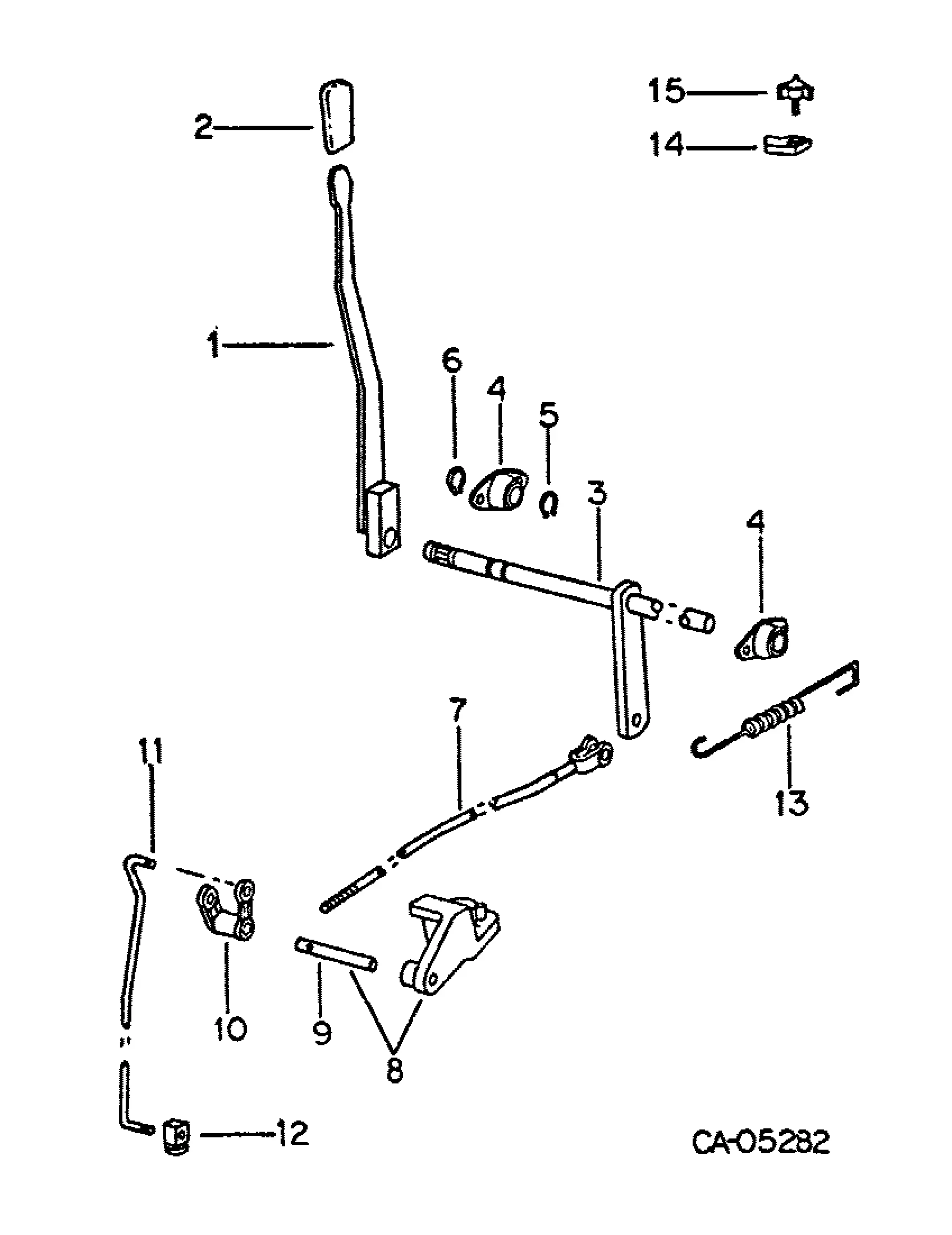

Clutch Assembly for IH 986 Tractor

The clutch mechanism is a crucial component in ensuring the efficient operation of agricultural machinery. It facilitates the connection and disconnection of the engine’s power to the drivetrain, allowing for smooth gear shifts and improved control during operation. Understanding the assembly of this system is essential for maintenance and repair tasks. This specific assembly consists of several vital elements, including the clutch plate, pressure plate, and release bearing. Each part plays a significant role in the overall functionality, ensuring that power is transferred effectively while minimizing wear and tear. Proper installation and adjustment of these components are necessary to maintain optimal performance and longevity. Steering and Control Elements ExplainedThe steering and control components of machinery play a crucial role in ensuring precise navigation and maneuverability. These elements are designed to facilitate operator control, enabling smooth operation and responsiveness to various driving conditions. Understanding how these mechanisms work together can enhance the overall efficiency and safety of the equipment. Fundamentals of Steering MechanismsThe steering mechanism serves as the primary interface between the operator and the vehicle’s direction. This system typically includes a series of linkages and joints that translate the operator’s input into actual movement. Components such as the steering wheel and hydraulic assist systems work in harmony to provide a seamless driving experience. Control Elements for Enhanced Performance

Control elements encompass various functionalities that contribute to the overall operation of the vehicle. These include throttle controls, brake systems, and transmission selectors. Each element must work efficiently to ensure optimal performance, allowing the operator to manage speed, direction, and stopping power effectively. A well-designed control system enhances both safety and responsiveness in demanding environments. Brake System and Its Components

The braking system is a crucial element of any vehicle, ensuring safety and control during operation. Its primary function is to slow down or halt the motion of the machine effectively, allowing for smooth handling and responsiveness under various conditions. Within this system, several key components work in harmony to achieve optimal performance. Brake pads are essential for creating the necessary friction against the rotors, while calipers play a vital role in applying pressure to these pads. Additionally, the master cylinder is responsible for generating hydraulic pressure, which is transmitted throughout the system to ensure that the brakes engage when needed. Moreover, the brake lines and hoses serve as conduits for the brake fluid, allowing for the transfer of force from the pedal to the braking mechanism. Regular maintenance of these components is essential to ensure the reliability and effectiveness of the braking system, promoting both performance and safety on the road. Maintenance Tips for Tractor Parts

Proper upkeep of agricultural machinery is crucial for ensuring longevity and optimal performance. Regular maintenance can prevent unexpected breakdowns and extend the lifespan of various components, allowing for a more efficient operation. This section will explore essential practices to keep your equipment in top condition. Regular Inspections

Conducting routine inspections is vital for identifying wear and tear before it leads to significant issues. Look for signs of damage, corrosion, or excessive wear on critical elements. Addressing minor problems promptly can save time and money in the long run. Lubrication and Cleaning

Keeping machinery well-lubricated is essential for smooth operation. Use appropriate lubricants on moving parts to reduce friction and prevent overheating. Additionally, regular cleaning of components helps to remove dirt and debris, which can interfere with performance and lead to premature deterioration. Remember, proactive maintenance practices are key to maximizing efficiency and reliability. By investing time and effort into the upkeep of your agricultural equipment, you ensure it remains a valuable asset for years to come. |