Understanding the configuration of key elements within modern chlorine production devices is essential for both maintenance and optimization. These units rely on a blend of precision-engineered elements that work together to deliver efficient water treatment solutions. By familiarizing oneself with the layout and connections of these components, users can effectively troubleshoot and maintain their equipment.

The systematic arrangement of various parts ensures seamless operation, allowing users to achieve consistent and reliable performance. Each element is designed to play a specific role, from controlling the flow to monitoring the production process. Recognizing how these pieces fit together can lead to a more comprehensive understanding of the overall system.

For those seeking detailed insights, exploring the layout of these systems can reveal essential information about maintenance practices, replacement procedures, and performance enhancements. This knowledge aids in extending the lifespan of the device, minimizing downtime, and ensuring water quality remains at optimal levels.

Understanding Intellichlor System Components

Exploring the key elements of this system allows users to gain insights into how each unit functions together to deliver effective water treatment. Recognizing the purpose and role of each element is essential for maintaining optimal performance and ensuring smooth operation.

The system is built from several interconnected units, each playing a vital role in the overall functionality. From monitoring tools to essential processing units, every component has a specific task that contributes to the efficient handling of water care tasks. Understanding the purpose of these elements can help in troubleshooting and regular upkeep.

Learning how these units interact provides a clear view of the operational flow, which is crucial for efficient management. Proper knowledge of each unit’s role and maintenance needs can also aid in extending the system’s lifespan, ensuring reliable and long-lasting performance.

Key Parts of the Intellichlor System

The system is composed of several essential components that work together to maintain water clarity and cleanliness. Each element plays a specific role in ensuring the effective operation of the unit, contributing to a balanced and safe aquatic environment. Understanding these elements and their functions is crucial for optimal maintenance and troubleshooting.

One of the main elements is the control unit, which manages the entire operation, monitoring and adjusting performance based on the pool’s needs. This central hub allows users to customize settings and ensures consistent operation.

Another crucial part is the cell, responsible for the actual process of water treatment. Through an advanced mechanism, it converts essential chemicals, aiding in maintaining proper water balance. Regular checks and maintenance of this element are vital for continuous efficiency.

Additional smaller components, including cables, connectors, and sensors, provide necessary support, ensuring smooth communication between the system’s various parts. They help in monitoring conditions and make adjustments as needed to preserve water quality.

Detailed Look at the Control Unit

The control unit serves as the core element responsible for managing various operations. This section provides an in-depth exploration of its essential features, mechanisms, and how it integrates with other components. Understanding the functions of this unit is crucial for efficient and seamless system performance.

At the heart of the control unit is a sophisticated microprocessor that regulates all commands and signals. It ensures precise adjustments and smooth operation by constantly monitoring and adjusting parameters as needed. Additionally, this unit is equipped with safety protocols to prevent malfunctions and extend the overall lifespan of the system.

Another key aspect of the control unit is its user interface. Designed for straightforward navigation, it allows users to easily access various settings and make adjustments as required. With intuitive controls, the interface simplifies the process of managing essential tasks, making it accessible even for those with minimal technical experience.

The integration capability of the control unit is also notable. It connects seamlessly with other modules,

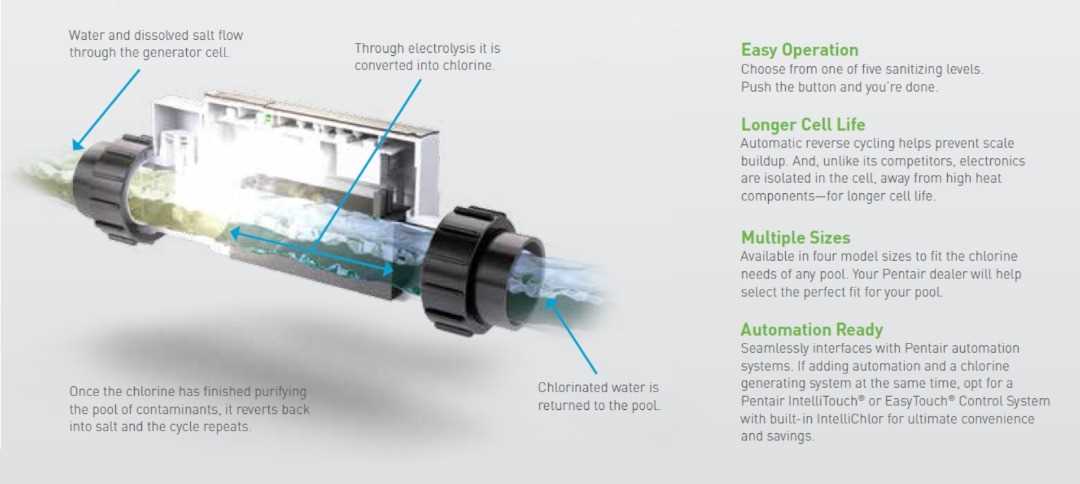

How the Cell Assembly Works

The cell assembly is a crucial component that facilitates the conversion process needed for effective water treatment. It operates by generating a chemical reaction that helps to maintain optimal water quality. The assembly consists of multiple elements working in tandem to achieve this process, ensuring consistent and efficient performance.

At the core of the assembly are a series of metallic plates arranged strategically to interact with the surrounding fluid. When activated, these plates induce a transformation that aids in breaking down unwanted elements, keeping the water clean and clear. The design of the cell allows for a continuous flow, which maximizes the exposure of water to the reactive surfaces, ensuring thorough treatment.

Additionally, the structure includes protective mechanisms that monitor and adjust the flow, preventing potential issues and extending the lifespan of the device. Regular maintenance ensures that the assembly remains in peak condition, contributing to the overall effectiveness of the system.

Exploring the Flow Sensor Mechanism

The flow sensor is a critical element in monitoring the movement of liquid through a system. It ensures that the device operates efficiently by detecting the presence and rate of fluid movement. By providing accurate data, it allows the system to respond appropriately to varying conditions.

How It Works: The sensor uses a combination of electrical signals and mechanical components to gauge the flow rate. When liquid passes through, the sensor captures the changes in speed and pressure, transmitting this information to the control unit.

Key Benefits: Implementing this mechanism enhances the system’s efficiency and reliability. It ensures safety by preventing operation under inappropriate conditions, helping maintain consistent performance and prolonging the lifespan of the equipment.

Power Supply Features and Functions

The power supply unit serves as a crucial component within a system, providing the necessary energy for its optimal operation. This essential device converts electrical energy from a source into usable power, ensuring that all connected elements function seamlessly. Understanding its characteristics and roles is vital for maintaining the overall efficiency of the system.

Key Characteristics

One of the primary features of a power supply is its ability to regulate voltage levels. This regulation is essential to protect sensitive components from voltage fluctuations that could lead to malfunction or damage. Moreover, a reliable power source is designed to offer consistent performance, enabling devices to operate under varying load conditions without interruption.

Functional Role

In addition to voltage regulation, the power supply unit typically incorporates various safety mechanisms, such as overcurrent protection and thermal shutdown features. These functions not only safeguard the equipment but also enhance the longevity of the entire system. By ensuring stable and secure power delivery, the unit contributes significantly to the overall reliability and functionality of the installation.

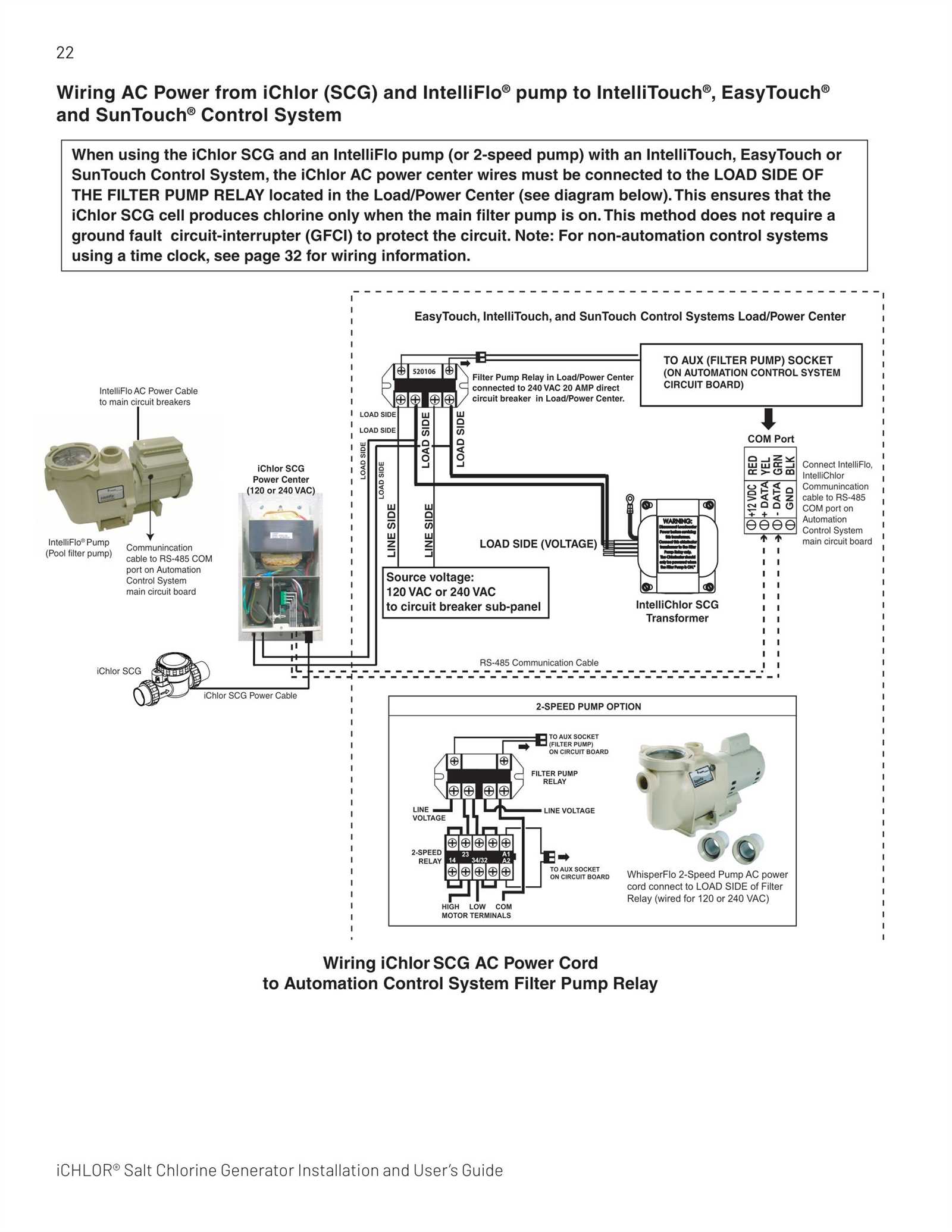

Importance of Proper Wiring Connections

Establishing accurate electrical linkages is crucial for the optimal performance and longevity of any electrical system. When components are connected correctly, the overall functionality improves, reducing the risk of malfunctions and enhancing safety. Conversely, improper connections can lead to various issues, including inefficiencies and potential hazards.

Reliability is one of the primary benefits of ensuring correct electrical connections. Well-established links minimize the chances of unexpected interruptions, allowing systems to operate smoothly. This reliability is essential, particularly in environments where consistent performance is expected.

Additionally, proper connections contribute significantly to safety. Faulty wiring can lead to overheating or even electrical fires, posing serious risks to users and property. By adhering to proper connection standards, one can significantly mitigate these dangers and ensure a secure operational environment.

Finally, well-executed electrical connections can lead to cost savings over time. By preventing issues that require repair or replacement, individuals can avoid unnecessary expenses. Therefore, investing time and effort in ensuring correct wiring is a wise decision for anyone looking to maintain an effective and safe electrical system.

Chlorine Production: Core Elements

The process of generating chlorine involves several fundamental components that work in harmony to ensure efficient and safe production. Understanding these essential elements is crucial for optimizing the overall functionality of the system.

Key Components

- Electrolytic Cell: The heart of the operation, where the transformation of raw materials into chlorine occurs through electrolysis.

- Power Supply: Provides the necessary electrical energy to facilitate the electrochemical reactions within the electrolytic cell.

- Electrodes: These conductive elements are immersed in the electrolyte and play a vital role in the chemical reactions, allowing for chlorine to be generated effectively.

- Electrolyte Solution: A mixture that facilitates the conduction of electricity, often consisting of saltwater, which is critical for the process.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and ensuring the longevity of the equipment.

Safety Measures

- Pressure Relief Valves: These devices are essential for preventing excessive pressure buildup, which can lead to dangerous situations.

- Leak Detection Systems: Early identification of any leaks is vital to maintain safety and prevent environmental contamination.

- Protective Gear: Operators must be equipped with appropriate safety equipment to minimize exposure to harmful substances during operation.

Installation Guide for Replacement Parts

This section provides essential information for successfully replacing essential components in your system. Proper installation is crucial to ensure optimal performance and longevity of the unit. Following the outlined steps will help facilitate a smooth transition during the replacement process.

Step 1: Prepare the Area

Before starting the replacement, ensure the workspace is clean and well-lit. Gather all necessary tools and new components to avoid interruptions during the procedure. Disconnect power to the device to ensure safety while working.

Step 2: Remove the Old Component

Carefully detach the existing unit by following the specific instructions for removal. Take note of how the old piece is installed, as this will serve as a reference for positioning the new item correctly.

Step 3: Install the New Component

Align the replacement unit with the designated slots and gently secure it in place. Ensure that all connections are tight and that the new part is seated correctly to avoid any future issues.

Step 4: Test the Installation

Once everything is installed, restore power and test the system to verify that it operates smoothly. Monitor the unit for a short period to ensure that the installation was successful and that there are no leaks or malfunctions.

By following these steps, you can effectively replace the necessary elements in your system, ensuring it continues to operate efficiently.

Common Issues with System Components

When dealing with various system elements, users may encounter a range of frequent challenges that can impact overall functionality. Understanding these issues can facilitate smoother operation and maintenance, ensuring that the system performs optimally.

- Inconsistent Performance: Variability in performance levels can often stem from underlying component malfunctions or environmental factors.

- Frequent Malfunctions: Regular breakdowns can indicate a need for component replacement or adjustment, which can be critical for maintaining system efficiency.

- Inadequate Calibration: Poor calibration may lead to imprecise functioning, resulting in less effective operation.

Additionally, it is essential to recognize specific signs that may indicate underlying problems:

- Unusual Noises: Sounds such as grinding or rattling can suggest that parts are misaligned or damaged.

- Increased Energy Consumption: A sudden spike in energy usage may be a clear indication of malfunctioning components requiring immediate attention.

- Unexpected Shutdowns: If the system frequently powers down without warning, this could signify a serious issue with the electrical elements.

Addressing these concerns promptly can significantly enhance the longevity and reliability of the overall system.

Maintenance Tips for Long-Lasting Performance

Ensuring the longevity of your equipment requires regular care and attention. By implementing a few simple practices, you can enhance its efficiency and extend its operational life. This section will provide you with essential advice to keep your device functioning optimally over time.

Regular Cleaning

Cleaning your system periodically is crucial for preventing buildup and maintaining performance. Make it a habit to inspect and clean the internal components regularly. Use appropriate tools and solutions to avoid damaging sensitive parts, ensuring that all surfaces are free from debris and contaminants.

Routine Checks

Conduct routine inspections to identify any potential issues before they escalate. Pay close attention to wear and tear on components and connections. Regular monitoring can help you detect anomalies early, allowing for timely repairs or replacements, ultimately saving you time and money.

Efficient Upgrades for Better Functionality

Enhancing the performance and reliability of your equipment can significantly improve its efficiency and longevity. By investing in modern enhancements, you can optimize various features, ensuring they operate at their best. This section explores some effective strategies to upgrade your system, making it more efficient and capable of meeting your needs.

Upgrading key components can lead to noticeable improvements. Consider the following options that can help in maximizing the functionality of your system:

| Upgrade Option | Description | Benefits |

|---|---|---|

| Advanced Sensors | Installing new sensors to monitor performance and optimize operations. | Increased accuracy and real-time data feedback. |

| Enhanced Control Systems | Implementing updated control interfaces for better user interaction. | Improved usability and more intuitive controls. |

| High-Quality Filters | Upgrading filtration systems to capture more impurities. | Better water quality and system protection. |

| Energy-Efficient Pumps | Replacing pumps with energy-efficient models. | Lower energy consumption and cost savings. |

By focusing on these enhancement areas, you can create a more efficient and durable system that meets the demands of modern usage.