In the world of outdoor equipment, having a reliable and efficient tool is crucial for various activities. This section explores the essential elements that contribute to the overall functionality of a portable drilling device. By examining the various components, users can gain a deeper understanding of how each part works together to enhance performance.

Knowing the individual elements involved allows for better maintenance and troubleshooting. Each segment plays a vital role in ensuring smooth operation, whether in a recreational or professional setting. With this knowledge, users can optimize their experience and make informed decisions regarding repairs and upgrades.

Furthermore, this exploration aids in recognizing common issues and understanding how to address them effectively. Familiarity with the construction of this tool not only empowers users but also enriches their overall engagement with outdoor pursuits.

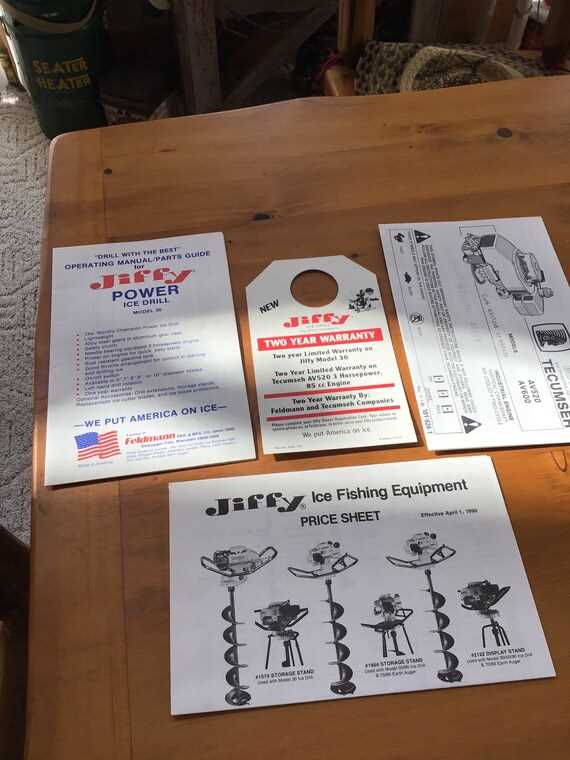

Understanding Jiffy Ice Augers

When it comes to winter fishing, having the right equipment is essential for an efficient and enjoyable experience. Familiarity with your tools can significantly enhance your performance on the ice, ensuring you’re well-prepared for the cold conditions. This section delves into the various components and their functions, offering insights that will help you maximize the use of your drilling machinery.

- Functionality: Each element plays a crucial role in the overall operation, from the power source to the cutting mechanism.

- Maintenance: Regular upkeep is vital to prolong the life of your equipment and maintain optimal performance.

- Upgrades: Understanding available enhancements can improve efficiency and ease of use.

By gaining knowledge about these essential features, users can make informed decisions, ensuring they select the best options for their specific needs and preferences.

Components of Jiffy Ice Augers

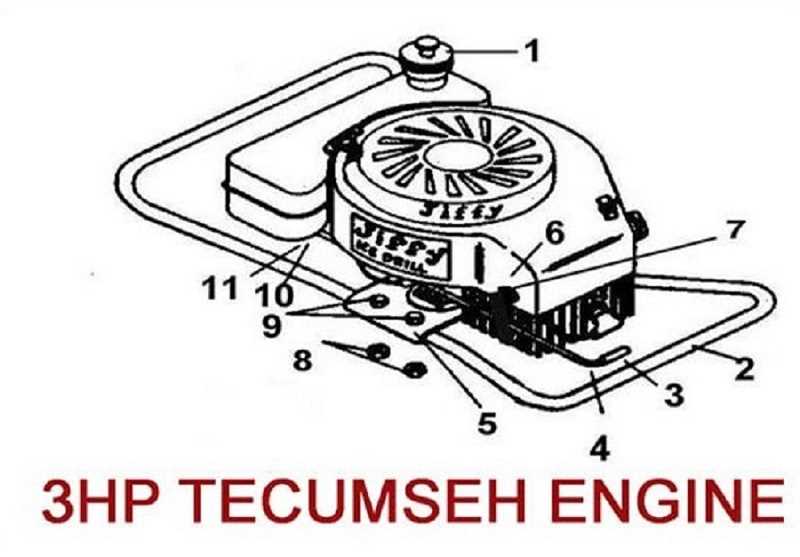

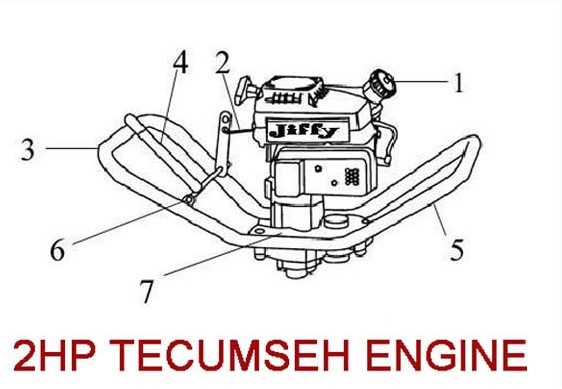

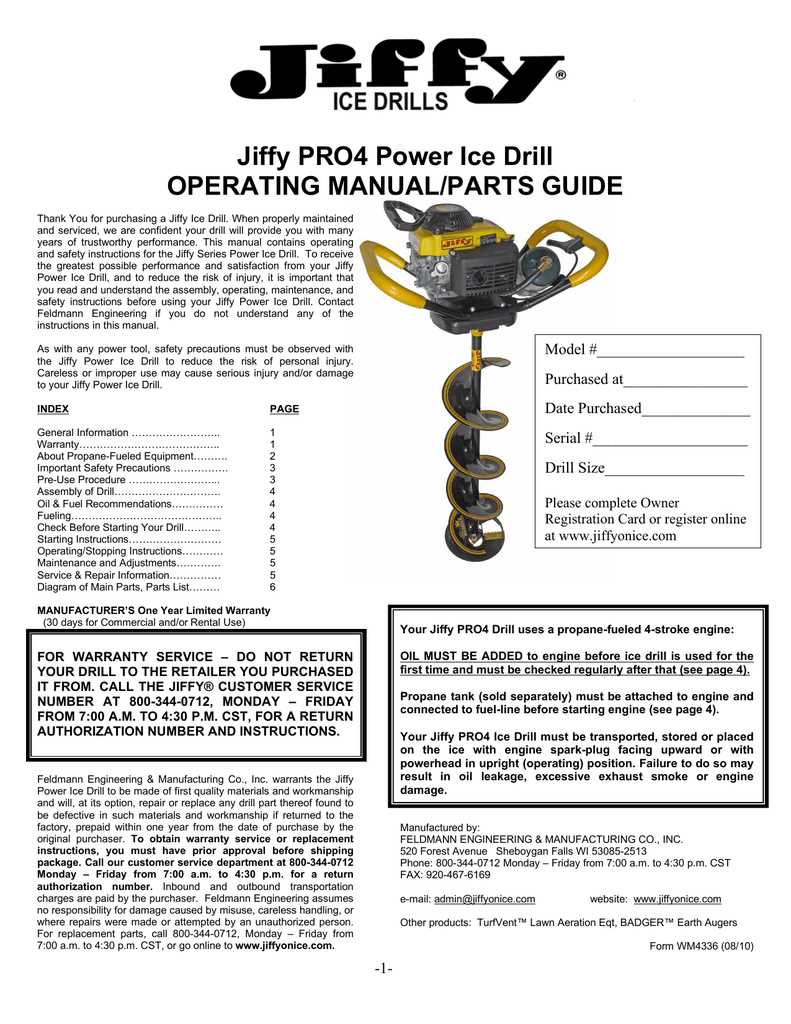

Understanding the essential elements that make up a drilling machine is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficiency and effectiveness during operation. From the motor to the cutting mechanism, the interplay between these elements determines the overall functionality of the device.

Key Elements of the Mechanism

The driving force behind the operation is typically a robust engine that provides the necessary power. This is connected to a transmission system that transfers energy to the drill bit, allowing for smooth and controlled movements. Additionally, a handle system is designed for user comfort and stability, making the experience more manageable during use.

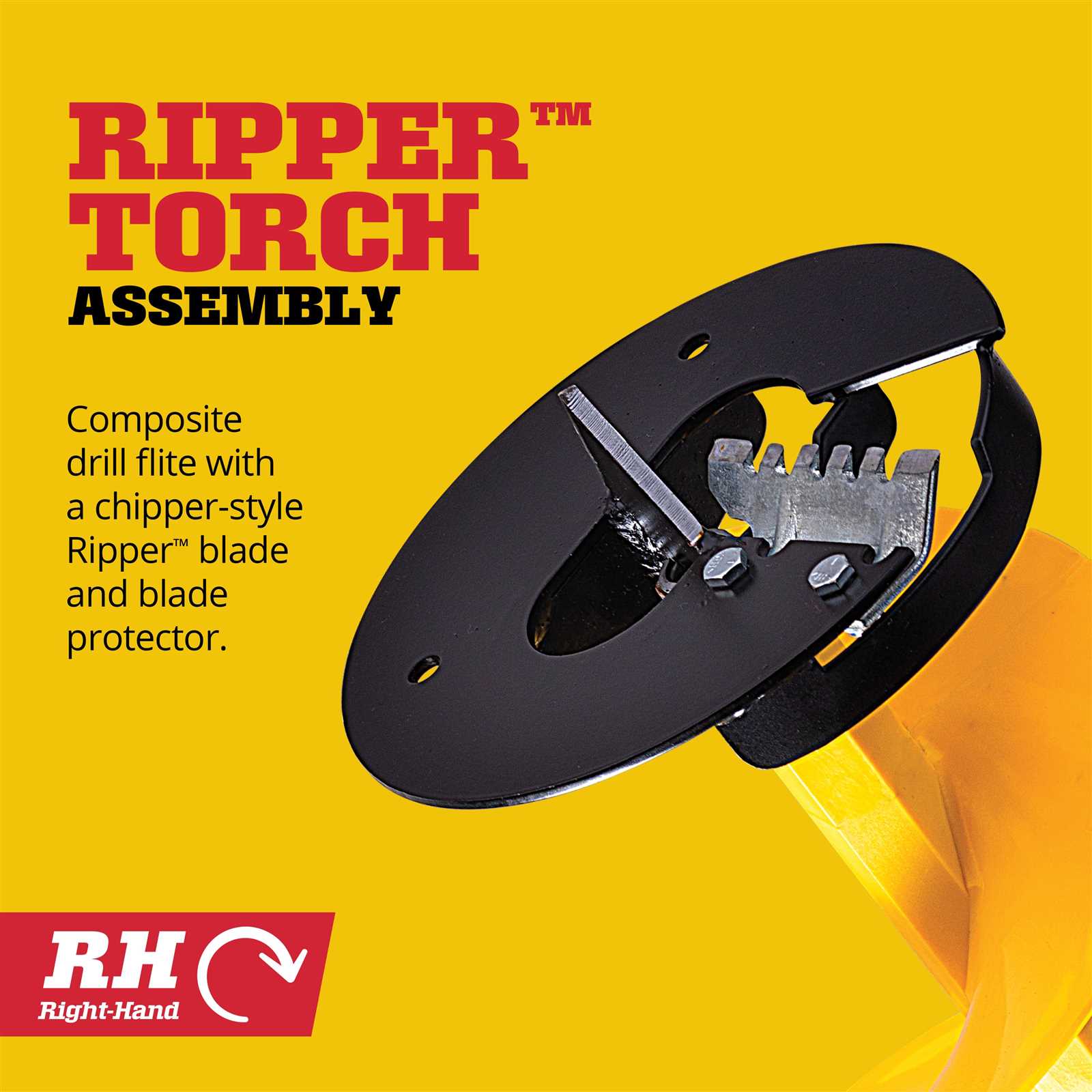

Cutting and Support Systems

At the forefront of any drilling apparatus is the cutting mechanism, crafted to penetrate various surfaces with precision. The design of the blades is crucial, as it impacts the efficiency of the drilling process. Furthermore, support components ensure that the machine remains stable and aligned, minimizing the risk of misalignment during operation.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of your equipment requires regular attention and care. Proper upkeep not only enhances performance but also prevents unexpected breakdowns, ultimately saving time and money. Implementing a consistent maintenance routine can significantly extend the life of your tools and ensure they function optimally when needed.

Benefits of Regular Upkeep

Routine maintenance provides numerous advantages, including:

- Increased reliability

- Improved performance

- Enhanced safety

- Cost savings over time

Key Maintenance Practices

Implementing the following practices can help maintain your equipment:

| Task | Frequency | Description |

|---|---|---|

| Inspection | Monthly | Check for wear and tear, ensuring all components are functioning correctly. |

| Lubrication | Every season | Apply lubricant to moving parts to reduce friction and wear. |

| Cleaning | After each use | Remove debris and dirt to prevent corrosion and damage. |

| Storage | Off-season | Store in a dry, protected environment to avoid deterioration. |

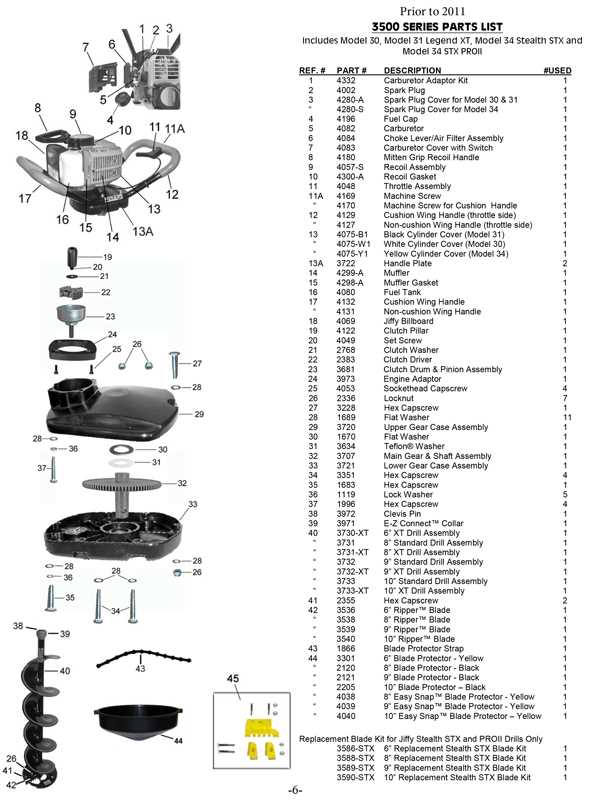

Common Replacement Parts Overview

Understanding essential components for maintenance can significantly enhance the longevity and efficiency of your equipment. Recognizing the key elements that may require substitution can ensure optimal performance during use.

Key Components

Several critical items are frequently replaced to maintain operational excellence. These include elements that contribute to functionality, safety, and overall efficiency.

| Component Name | Description |

|---|---|

| Blades | Sharp elements crucial for cutting through thick materials. |

| Drive Shaft | Connects the motor to the cutting mechanism, transferring power effectively. |

| Fuel Filter | Ensures clean fuel supply to the engine, enhancing performance. |

| Spark Plug | Ignites the fuel-air mixture for engine operation, vital for starting. |

Maintenance Tips

Regular inspection and timely replacement of these components can prevent failures and ensure seamless operation. Keeping an inventory of these essentials can minimize downtime during usage.

Identifying Auger Model Variations

Recognizing the differences among various drill models is essential for effective maintenance and optimal performance. Each version may feature distinct characteristics that can affect functionality and compatibility with accessories.

Key Features to Examine

- Handle Design: Variations in the shape and material can influence user comfort and control.

- Drill Bit Size: Different models may accommodate varying diameters, affecting cutting efficiency.

- Power Source: Check if the equipment is powered by gas, electric, or manual mechanisms.

Common Model Types

- Standard Model: Typically lightweight and easy to maneuver, suitable for casual use.

- Heavy-Duty Model: Designed for professional applications, often featuring more robust construction and advanced features.

- Compact Model: Smaller in size for enhanced portability, ideal for those with limited storage space.

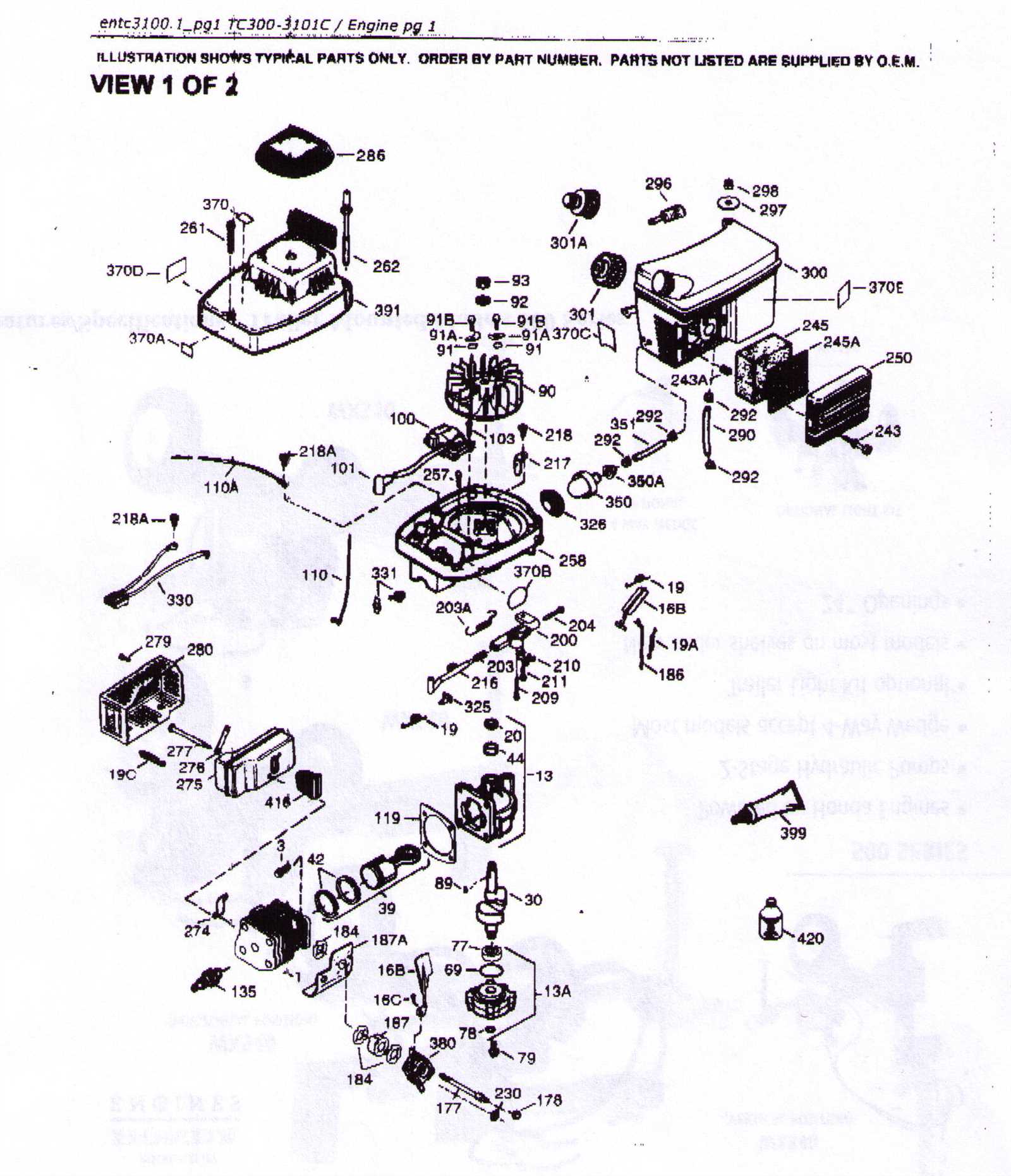

How to Read Parts Diagrams

Understanding component illustrations is essential for effective maintenance and repair of machinery. These visual representations provide a clear view of how various elements fit together, making it easier to identify and address issues. By familiarizing yourself with the symbols and layouts, you can streamline your repair processes and ensure accurate assembly.

Key Elements to Consider

When analyzing a component illustration, pay attention to the following aspects:

| Element | Description |

|---|---|

| Labels | Indicate the names or codes of the individual items. |

| Connections | Show how different parts link or interact with one another. |

| Numbering | Helps to identify specific pieces for easy reference. |

Interpreting the Visuals

Take time to study the layout and identify the function of each component. Look for grouped elements, as they often represent assemblies or sub-units. This comprehensive approach enables you to grasp the overall mechanism and enhances your ability to troubleshoot effectively.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right tools on hand is essential for a successful outcome. Proper tools not only expedite the process but also ensure that repairs are conducted safely and effectively. Below is a list of essential implements that should be considered before beginning any repair tasks.

Essential Implements

- Wrenches: Various sizes for loosening and tightening nuts and bolts.

- Screwdrivers: Both flat-head and Phillips for accessing different types of fasteners.

- Pliers: Useful for gripping and twisting components.

- Socket Set: For easier handling of fasteners in tight spaces.

- Torque Wrench: Ensures that bolts are tightened to the specified torque settings.

Additional Items

- Lubricants: To reduce friction and wear on moving parts.

- Cleaning Supplies: Brushes and rags to keep surfaces free of debris.

- Protective Gear: Gloves and safety glasses to protect against injuries.

- Work Light: To illuminate dark areas for better visibility.

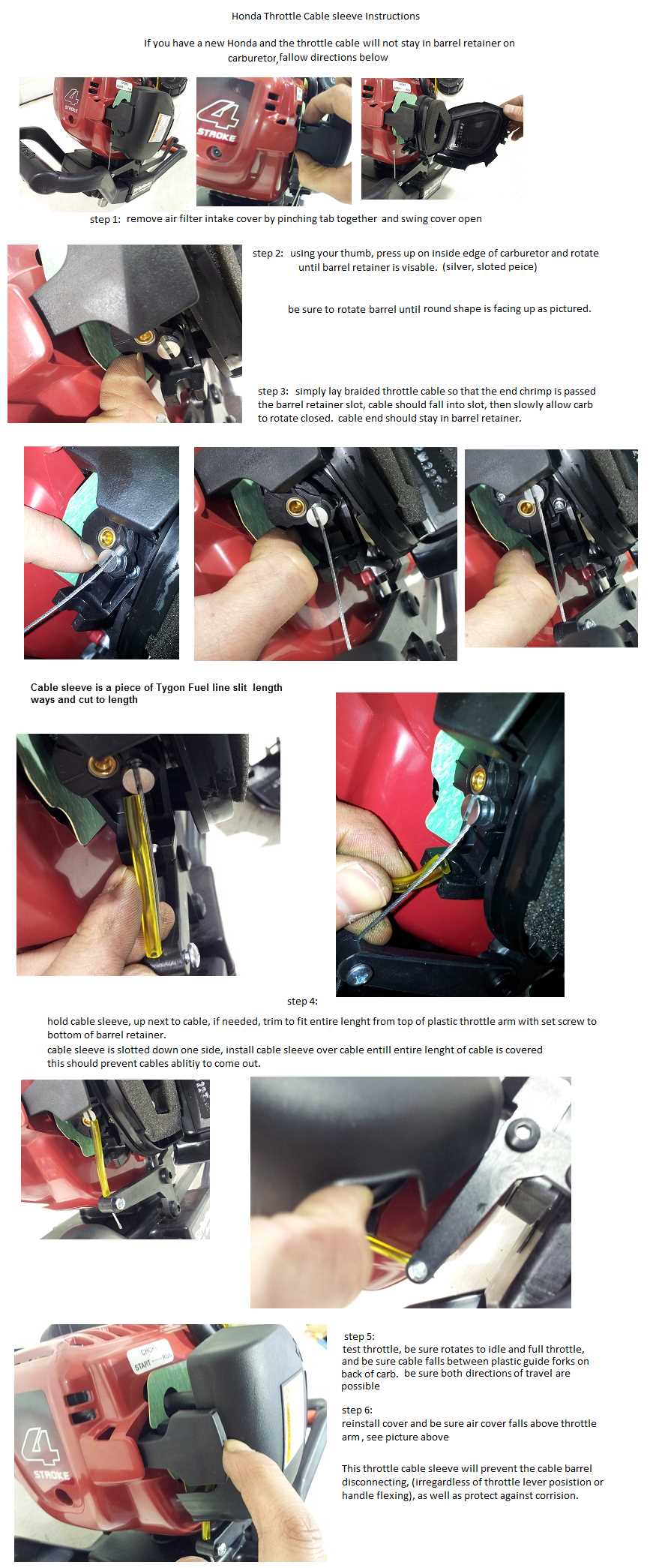

Step-by-Step Repair Instructions

This section provides a comprehensive guide to fixing common issues that may arise with your equipment. By following these detailed steps, you can effectively restore functionality and ensure optimal performance.

| Step | Action | Description |

|---|---|---|

| 1 | Inspection | Carefully examine the unit for any visible damage or wear that may be causing issues. |

| 2 | Disassembly | Using appropriate tools, carefully disassemble the components to access the internal mechanisms. |

| 3 | Cleaning | Thoroughly clean all parts to remove debris or corrosion that may affect operation. |

| 4 | Replacement | Identify any worn or broken components and replace them with new or refurbished items. |

| 5 | Reassembly | Carefully reassemble the unit, ensuring that all parts are secured properly to avoid future issues. |

| 6 | Testing | Once reassembled, test the equipment to confirm that it operates as intended. |

Upgrading Your Ice Auger

Enhancing your drilling tool can significantly improve your overall performance and efficiency. Whether you’re looking for increased power, better durability, or advanced features, a thoughtful upgrade can transform your experience on the frozen terrain. Consider various aspects such as motor performance, blade quality, and ergonomic design to achieve the ultimate results.

Choosing the Right Components

When considering improvements, focus on high-quality components that match your specific needs. Upgrading to a more powerful motor can increase drilling speed and efficiency. Additionally, selecting sharper and more durable cutting blades can ensure smoother operation, minimizing effort and maximizing productivity.

Ergonomics and Handling

Don’t overlook the importance of comfort and usability. An ergonomic handle can greatly enhance your control and reduce fatigue during extended use. Exploring models with adjustable features can provide a tailored experience, allowing for easier handling in various conditions.

Safety Tips for Ice Fishing

Engaging in winter fishing activities can be thrilling, yet it is essential to prioritize safety while enjoying the experience. Proper precautions can help prevent accidents and ensure a fun outing on the frozen landscape.

Evaluate Ice Conditions

Before venturing out, always assess the thickness and stability of the frozen surface. A minimum thickness of four inches is generally recommended for safe traversal. Be cautious of changes in temperature and local conditions that may weaken the ice.

Wear Appropriate Gear

Dress in layers to maintain warmth and flexibility. Ensure that your footwear provides good traction to avoid slipping. A personal flotation device is advisable, as it can be a lifesaver should an unexpected fall occur.

Remember: Preparation and vigilance are key components to enjoying your time on the frozen waters safely. Stay alert and informed about your surroundings.

Where to Buy Replacement Parts

Finding components for your equipment can be a straightforward process when you know where to look. Several options are available that cater to various preferences and needs, ensuring you can quickly restore functionality.

- Online Retailers: Websites specializing in outdoor and recreational gear often carry a wide selection of components. Popular platforms like Amazon or eBay provide a convenient way to compare prices and find specific items.

- Manufacturer’s Website: Directly visiting the official site of the manufacturer is a reliable choice. They usually have an extensive catalog of available components along with detailed information about compatibility.

- Local Sporting Goods Stores: Many local shops carry essential components for outdoor equipment. It’s advisable to call ahead to check availability or ask if they can order specific items for you.

- Specialty Repair Shops: Some businesses focus on repairing outdoor gear and may have the necessary components in stock. They can also provide expert advice on which items you need.

Before making a purchase, always verify compatibility with your existing equipment to ensure the best performance.

Frequently Asked Questions

This section addresses common inquiries related to equipment components and their functionality. Understanding these elements can enhance your overall experience and efficiency while utilizing your tools.

| Question | Answer |

|---|---|

| What should I do if a component is not functioning properly? | Check for loose connections and ensure all parts are correctly installed. If issues persist, consider replacing the affected item. |

| Where can I find replacement items? | Replacement components are typically available through authorized dealers or online retailers specializing in outdoor equipment. |

| How can I maintain my equipment for longevity? | Regular cleaning and lubrication of moving parts, along with proper storage, can significantly extend the lifespan of your tools. |

| Is there a warranty for the components? | Most manufacturers offer a warranty that covers defects in materials and workmanship. Be sure to check the warranty details upon purchase. |

Customer Reviews and Feedback

This section highlights the experiences and insights shared by users regarding their recent purchases. Understanding customer opinions can guide potential buyers in making informed decisions and enhance overall satisfaction.

Positive Experiences

- Many users praised the reliability and efficiency of the equipment.

- Customers often mention the ease of use, especially for beginners.

- Several reviews highlight the durability of the components, which ensures longevity.

Constructive Criticism

- Some users reported challenges with assembly, suggesting clearer instructions would be beneficial.

- A few customers noted that certain components could be improved for better performance.

- Some feedback indicated a desire for more color options and accessories.