In the realm of machinery maintenance and repair, comprehending the layout of various components is crucial for efficiency and effectiveness. This understanding not only aids technicians in troubleshooting issues but also ensures that the machinery operates at its peak performance. By exploring the intricate relationships between different parts, one can enhance their ability to address challenges swiftly.

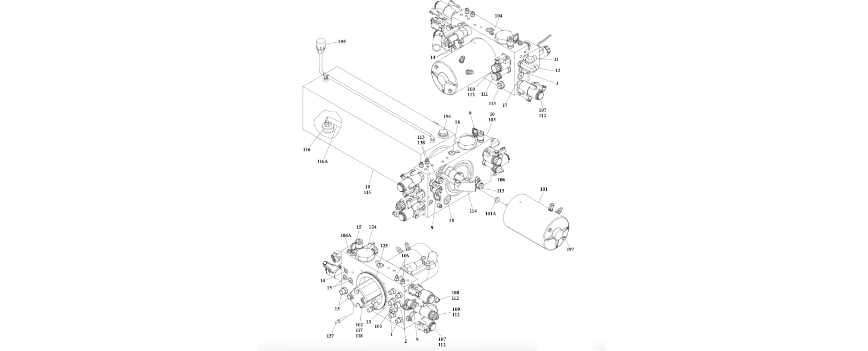

Visual representations of these assemblies serve as invaluable resources, allowing users to identify specific elements and their functions. Such illustrations provide clarity and guidance, transforming complex systems into comprehensible formats. This fosters a deeper appreciation of the equipment’s design and functionality.

Additionally, familiarity with these layouts empowers users to make informed decisions regarding repairs and replacements. Whether you are a seasoned professional or a newcomer, understanding the interconnectedness of components can lead to more effective maintenance practices and ultimately prolong the life of the machinery.

Understanding JLG T350 Components

In the realm of aerial work platforms, a thorough grasp of the various elements that contribute to functionality is essential. Each component plays a vital role in ensuring efficiency, safety, and reliability during operations. This section will explore key parts, highlighting their significance and interconnections.

Main Components Overview

- Platform: The working area where operators perform tasks.

- Chassis: The framework that supports the entire structure and provides stability.

- Hydraulic System: Powers the lifting and maneuvering functions, crucial for elevating the platform.

- Controls: The interface that allows operators to manage movement and height adjustments.

Importance of Each Element

- Safety: Each part is designed with safety mechanisms to prevent accidents.

- Performance: The efficiency of the machine relies on the seamless interaction of all components.

- Maintenance: Understanding the individual functions aids in proper upkeep and repairs.

By familiarizing oneself with these components, operators can enhance their operational effectiveness and ensure safe usage of the equipment.

Overview of JLG T350 Features

This section explores the remarkable attributes of a compact aerial lift designed for efficiency and versatility in various applications. With an emphasis on ease of use and adaptability, this machine is ideal for both indoor and outdoor tasks, enhancing productivity in challenging environments.

Compact Design: The equipment boasts a sleek profile, allowing it to navigate through tight spaces effortlessly.

Height Capability: Engineered to reach impressive elevations, it empowers operators to tackle high-access jobs with confidence.

Stability: Featuring a robust base, this lift provides excellent stability, ensuring safety during operation.

Operator Comfort: The cockpit is designed for user-friendly controls, allowing for smooth maneuvering and increased comfort during extended use.

Versatile Functionality: Ideal for various tasks, from maintenance to construction, it offers the ultimate flexibility needed in diverse work environments.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repairs. Visual representations provide clarity, enabling technicians to identify each element and its function within the whole system. This knowledge not only facilitates troubleshooting but also ensures that repairs are conducted efficiently, minimizing downtime.

Moreover, these illustrations serve as valuable references during assembly or disassembly, reducing the likelihood of errors. Technicians can quickly locate required components and understand how they interact with one another.

| Benefit | Description |

|---|---|

| Clarity | Enhances understanding of individual components and their roles. |

| Efficiency | Streamlines the repair process, saving time and resources. |

| Reference | Acts as a guide during assembly or disassembly tasks. |

Common Issues with JLG T350

Understanding the frequent challenges encountered with aerial work platforms can enhance maintenance and operational efficiency. Identifying these concerns helps operators prepare for potential setbacks and ensures smoother project execution.

- Hydraulic System Failures

- Electrical Component Malfunctions

- Wear and Tear on Mobility Parts

- Stability Issues on Uneven Surfaces

Addressing these common problems proactively can significantly reduce downtime and enhance safety during operations. Regular inspections and maintenance are crucial in mitigating these issues.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations provide a detailed overview of individual elements, their relationships, and assembly instructions. Mastering the interpretation of these visuals can significantly enhance your troubleshooting efficiency and repair accuracy.

Identifying Key Components

Begin by familiarizing yourself with the main elements depicted in the illustration. Look for labels and reference numbers, which often correspond to a list of items or a catalog. Recognizing the symbols and their meanings will help you pinpoint specific parts and their functions within the overall system.

Understanding Relationships and Assembly

Next, analyze how components interact with one another. Pay attention to connecting lines, arrows, and other indicators that demonstrate how pieces fit together. This will aid in comprehending the assembly process and ensure that you can correctly reassemble everything after any modifications or replacements. Remember that attention to detail is crucial in avoiding potential errors during reinstallation.

Key Maintenance Tips for T350

Regular upkeep is essential for ensuring the longevity and efficient operation of your equipment. By following a few fundamental practices, you can minimize downtime and enhance performance, leading to a smoother experience in your projects.

Routine Inspections

Conducting regular inspections is vital. Check all components for wear and tear, ensuring that everything functions correctly. Pay special attention to hydraulic systems and electrical connections.

Lubrication and Cleaning

Proper lubrication reduces friction and wear on moving parts. Additionally, keeping the machine clean from debris and contaminants prevents unnecessary damage and promotes optimal functionality.

Finding Replacement Parts Easily

Locating suitable components for your machinery can be a straightforward process with the right approach. Understanding where to look and how to search effectively can save time and ensure you get the right items quickly.

| Source | Description |

|---|---|

| Authorized Dealers | Official suppliers who offer genuine components, ensuring quality and compatibility. |

| Online Marketplaces | Websites where various sellers list components, often providing competitive pricing. |

| Local Hardware Stores | Physical shops that may carry common items or can order specific components for you. |

| Manufacturer’s Website | Direct access to the manufacturer’s catalog and resources for identifying specific needs. |

Utilizing these resources allows you to navigate the replacement component landscape more efficiently, ultimately leading to successful repairs and maintenance.

Comparative Analysis with Other Models

This section aims to explore the distinctions and similarities among various lifting equipment available in the market. By examining their specifications, functionalities, and applications, we can better understand how different models cater to specific operational needs.

Key Features Comparison

When assessing different models, it’s essential to highlight the following attributes:

- Load Capacity: The maximum weight each model can safely handle.

- Height Reach: The vertical distance each unit can extend.

- Stability: The design aspects that ensure secure operation under varying conditions.

- Mobility: How easily the equipment can be maneuvered on-site.

Application Suitability

Different models serve unique purposes depending on the work environment. Consider the following scenarios:

- Construction Sites: Models designed for heavy lifting and rugged terrain.

- Warehousing: Equipment that excels in narrow aisles and requires high maneuverability.

- Outdoor Projects: Units with enhanced weather resistance and stability.

By evaluating these characteristics, users can make informed decisions that align with their operational requirements and ensure optimal performance.

Safety Precautions When Repairing

When undertaking maintenance or repair tasks, it is crucial to prioritize safety to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly reduce risks associated with mechanical work. Ensuring a safe environment not only protects the technician but also extends the lifespan of the equipment being serviced.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes items such as gloves, safety goggles, and steel-toed boots. Each piece of equipment serves a specific purpose, helping to shield against sharp edges, chemical exposure, and heavy objects. Ensure that all protective gear is in good condition and suitable for the specific tasks at hand.

Work Environment Safety

Maintaining a clean and organized workspace can greatly enhance safety. Remove any unnecessary tools or materials that could cause tripping hazards. Additionally, ensure proper lighting to avoid accidents when working in tight or poorly lit areas. It is also advisable to keep fire extinguishers accessible and regularly check for proper functioning of emergency equipment.

Resources for Technical Support

Accessing reliable support resources is essential for effective maintenance and repair of machinery. These tools and references can significantly enhance your understanding and troubleshooting capabilities.

Manufacturer Websites: Official sites often provide valuable documentation, including manuals and troubleshooting guides. Always start here for the most accurate information.

User Forums: Engaging with communities of fellow operators can yield practical advice and firsthand experiences. These platforms are rich with knowledge and tips that may not be found in official resources.

Technical Support Hotlines: Many manufacturers offer dedicated support lines. These services can provide immediate assistance and expert guidance tailored to your specific needs.

Online Video Tutorials: Visual demonstrations can simplify complex procedures. Platforms like YouTube often feature experienced technicians sharing their insights and techniques.

Local Dealers: Authorized dealers can be a great resource for parts and services. They often have trained personnel who can assist with inquiries and repairs.

Utilizing these resources can ultimately empower users to maintain their equipment effectively and troubleshoot issues with confidence.

Upgrading Your JLG T350

Enhancing your aerial work platform can significantly improve its efficiency, performance, and safety. With the right modifications, you can ensure that your equipment meets the evolving demands of your projects. Below are several key areas to consider when looking to elevate your machine’s capabilities.

Here are some effective upgrade options:

- Power Source: Consider upgrading to a more efficient engine or battery system to increase runtime and reduce emissions.

- Lift Capacity: Evaluate the possibility of reinforcing the structure to allow for a higher load capacity.

- Control Systems: Implement advanced control technologies for better maneuverability and precision.

Additionally, focus on the following components:

- Hydraulics: Upgrading hydraulic components can lead to faster lift times and improved overall performance.

- Safety Features: Integrate modern safety systems, including emergency stop functions and enhanced stability controls.

- Platform Enhancements: Expanding the working platform can provide more space and improve worker comfort.

Incorporating these enhancements not only boosts productivity but also prolongs the life of your equipment, making it a worthwhile investment for any operator.