This section provides a comprehensive overview of the essential components for a specific small engine model. Understanding the structure and organization of these elements is crucial for effective maintenance and repairs.

By delving into the various sections of this reference, users can identify and locate each part with ease. Whether for troubleshooting or replacement, having access to a clear visual representation is invaluable.

Equipped with this information, individuals can ensure their equipment operates efficiently and reliably, ultimately enhancing its longevity and performance. Regular upkeep and familiarity with the individual pieces play a significant role in overall functionality.

Understanding Jonsered 2150 Components

In this section, we will explore the various elements that make up a specific model of outdoor power equipment. Understanding these components is crucial for effective maintenance and repair, ensuring optimal performance and longevity.

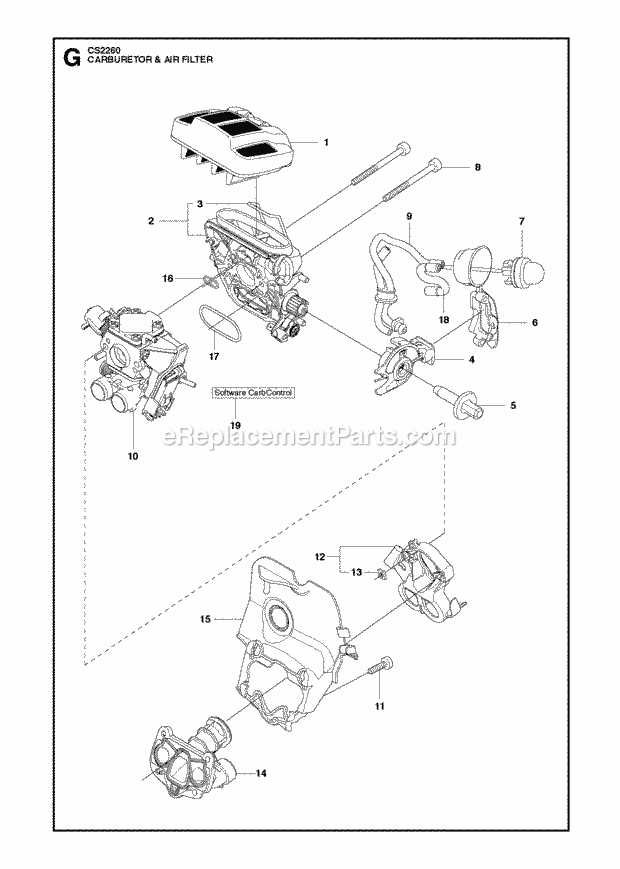

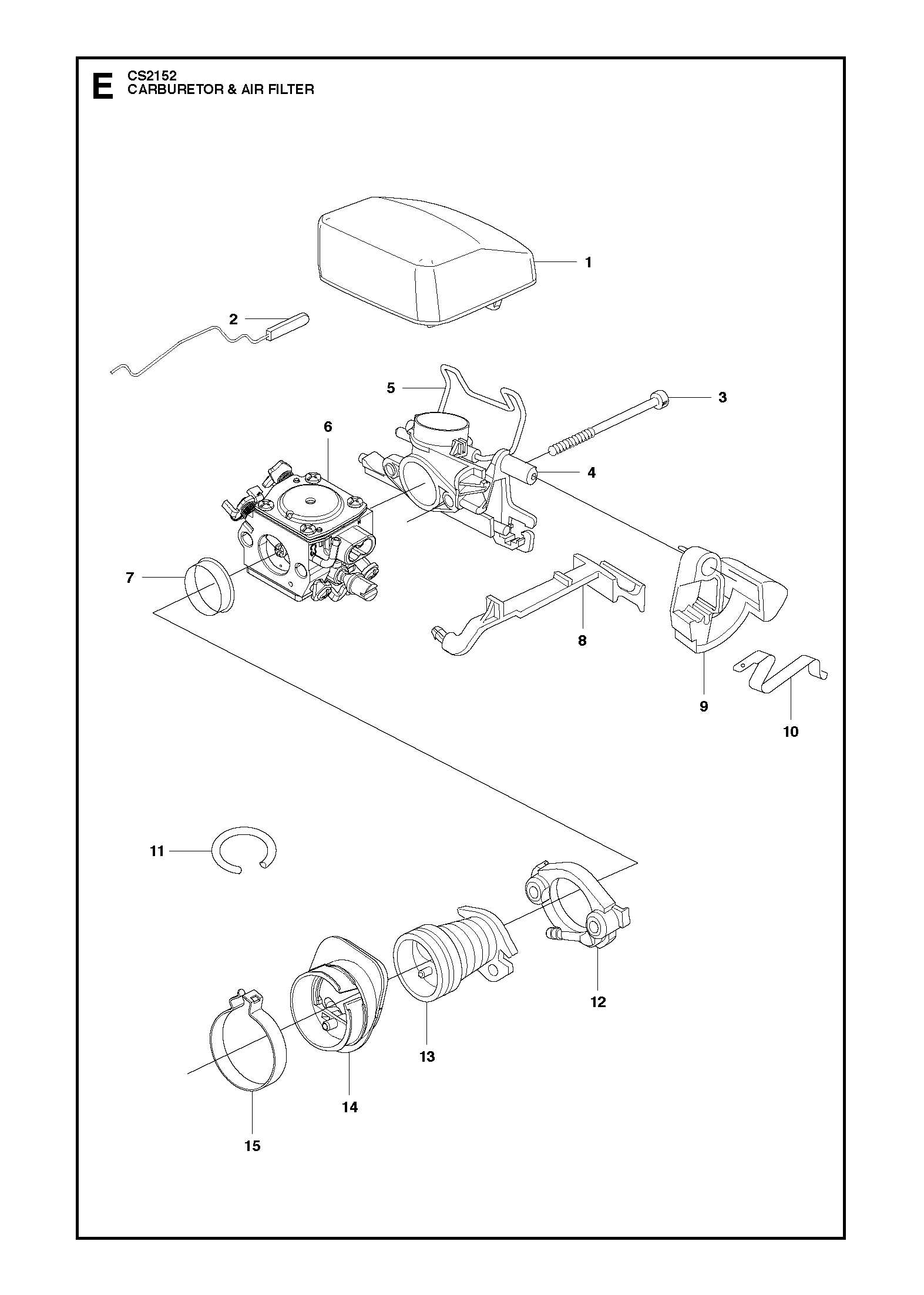

Each element plays a significant role in the overall function of the machine. For instance, the engine serves as the powerhouse, while the fuel system manages the energy supply. Additionally, the ignition system is essential for starting the engine efficiently.

By familiarizing yourself with these components, you can identify potential issues and address them promptly, enhancing the reliability and efficiency of your equipment.

Essential Parts of Jonsered 2150

This section highlights the critical components that contribute to the efficient operation of a popular chainsaw model. Understanding these elements is vital for maintenance and repair, ensuring longevity and optimal performance.

Power Unit: The engine serves as the powerhouse, driving the chainsaw’s performance. Regular checks on fuel intake and ignition systems can enhance functionality.

Guide Bar: This crucial element supports the cutting chain, allowing for precise cuts. Selecting the correct length and style can significantly impact cutting efficiency.

Chain: The cutting mechanism itself, made up of sharp teeth, requires regular sharpening to maintain effectiveness. Proper tensioning is equally important to prevent accidents.

Air Filter: Essential for maintaining clean airflow to the engine, this component should be regularly inspected and cleaned to avoid performance issues.

Starter Mechanism: This part is vital for initiating the engine. Ensuring it operates smoothly can prevent frustrating delays during use.

Fuel System: Comprising the tank and lines, this system is critical for efficient fuel delivery. Regular checks can help avoid clogs and ensure proper functioning.

How to Identify Each Component

Understanding the various elements of machinery is crucial for effective maintenance and repair. By familiarizing yourself with the components, you can troubleshoot issues more efficiently and ensure optimal performance.

Here are some common strategies to help you identify each part:

- Visual Inspection: Start with a thorough visual examination. Look for labels or markings that can indicate the component type.

- Consult Manuals: Reference user guides or technical manuals that provide detailed information about each element and its function.

- Online Resources: Utilize online forums or websites that specialize in machinery. Many have diagrams or lists that help in identifying parts.

- Ask Experts: If in doubt, consider reaching out to professionals or experienced users who can offer insights based on their knowledge.

By applying these techniques, you will enhance your ability to recognize and work with the individual parts of the equipment effectively.

Replacement Options for Worn Parts

When components of a tool become worn or damaged, it is crucial to explore effective alternatives to maintain functionality. Identifying suitable replacements can ensure the longevity and performance of the equipment.

| Original Component | Replacement Option | Notes |

|---|---|---|

| Handle | Ergonomic grip | Improves user comfort |

| Chain | High-performance chain | Enhances cutting efficiency |

| Fuel filter | Universal fuel filter | Compatible with multiple models |

| Bar | Heavy-duty replacement bar | Increases durability |

Tools Needed for Assembly and Repair

When engaging in the process of assembling and maintaining machinery, having the right tools is essential for efficient and effective work. Proper equipment not only ensures precision but also enhances safety during operations.

Essential Hand Tools

Basic hand tools such as screwdrivers, wrenches, and pliers are indispensable. These tools allow for precise adjustments and repairs. Additionally, socket sets can provide better leverage and accessibility in tight spaces.

Power Tools for Efficiency

Incorporating power tools can significantly speed up the assembly process. Tools like drills and impact wrenches enable faster and more secure fastening. Always ensure that power tools are suitable for the specific tasks at hand.

Common Issues with Jonsered 2150 Parts

When dealing with small engine machinery, certain complications frequently arise that can affect overall performance and functionality. Understanding these typical problems can assist users in effective maintenance and repairs.

Frequent Mechanical Failures

- Worn-out gaskets leading to leaks.

- Fuel delivery issues caused by clogged filters.

- Malfunctioning ignition components affecting starting efficiency.

Performance-Related Challenges

- Reduced power output due to improper air-fuel mixture.

- Overheating from blocked cooling fins.

- Inconsistent operation from a faulty spark plug.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and optimal performance of your equipment. Regular attention not only enhances efficiency but also prolongs its lifespan. Implementing effective maintenance practices can significantly reduce the likelihood of breakdowns and costly repairs.

Here are some key maintenance strategies:

| Tip | Description |

|---|---|

| Regular Cleaning | Keep the exterior and interior clean to prevent buildup that can affect performance. |

| Inspect Components | Frequently check all parts for signs of wear or damage to ensure everything is functioning correctly. |

| Lubrication | Apply appropriate lubricants to moving parts to minimize friction and wear. |

| Follow Manufacturer Guidelines | Adhere to recommended schedules for servicing and parts replacement as outlined in the user manual. |

Exploring Aftermarket Component Choices

When considering enhancements for your equipment, exploring aftermarket options can provide valuable alternatives to original components. These options often offer improved performance, durability, and cost-effectiveness, catering to various user needs.

Benefits of Aftermarket Options

- Enhanced performance and efficiency

- Broader selection of designs and features

- Potential cost savings compared to OEM parts

Factors to Consider

- Compatibility with existing equipment

- Quality and reputation of the manufacturer

- Warranty and support offered

Comparison of Original vs. Generic Parts

When considering components for machinery, the choice between original and generic options plays a crucial role in performance and reliability. Original parts are manufactured by the equipment’s brand, ensuring compatibility and adherence to quality standards. In contrast, generic alternatives can offer cost savings, but their reliability may vary.

| Aspect | Original Components | Generic Components |

|---|---|---|

| Quality | High-quality standards, consistent performance | Variable quality, may lack consistency |

| Price | Generally more expensive | Often more affordable |

| Compatibility | Designed specifically for the machinery | May fit but could have compatibility issues |

| Warranty | Typically includes warranty protection | Warranty varies, often limited |

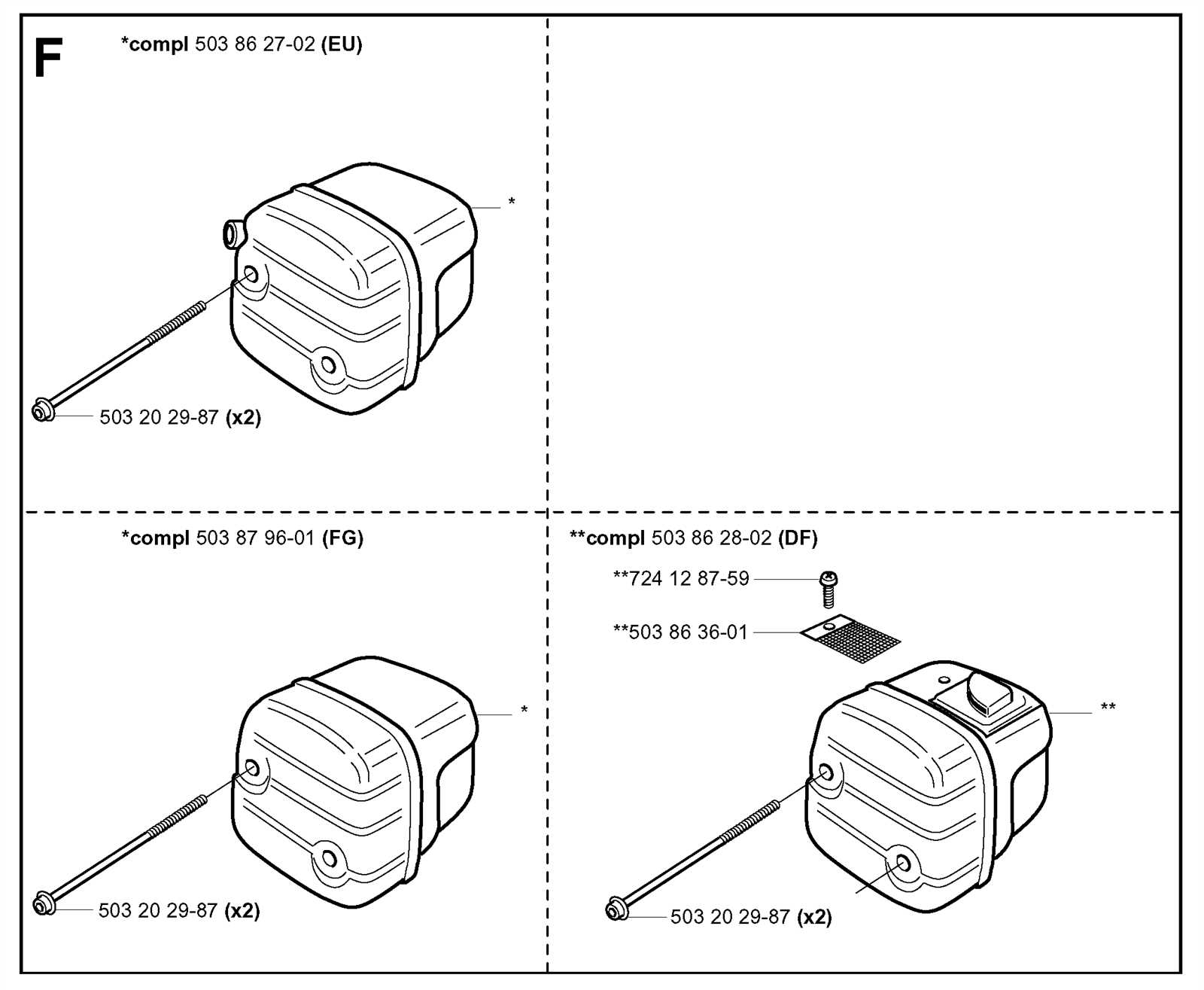

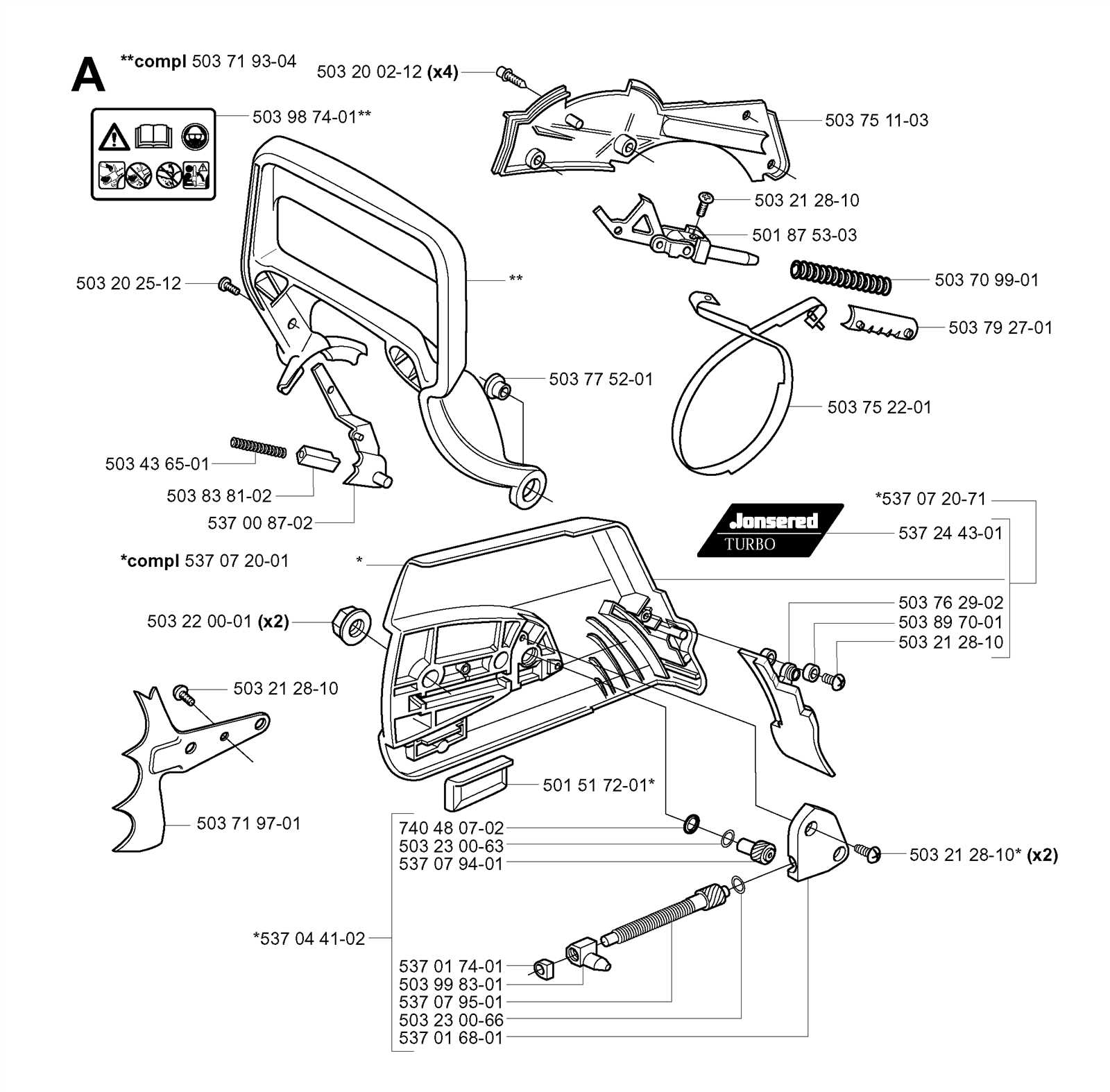

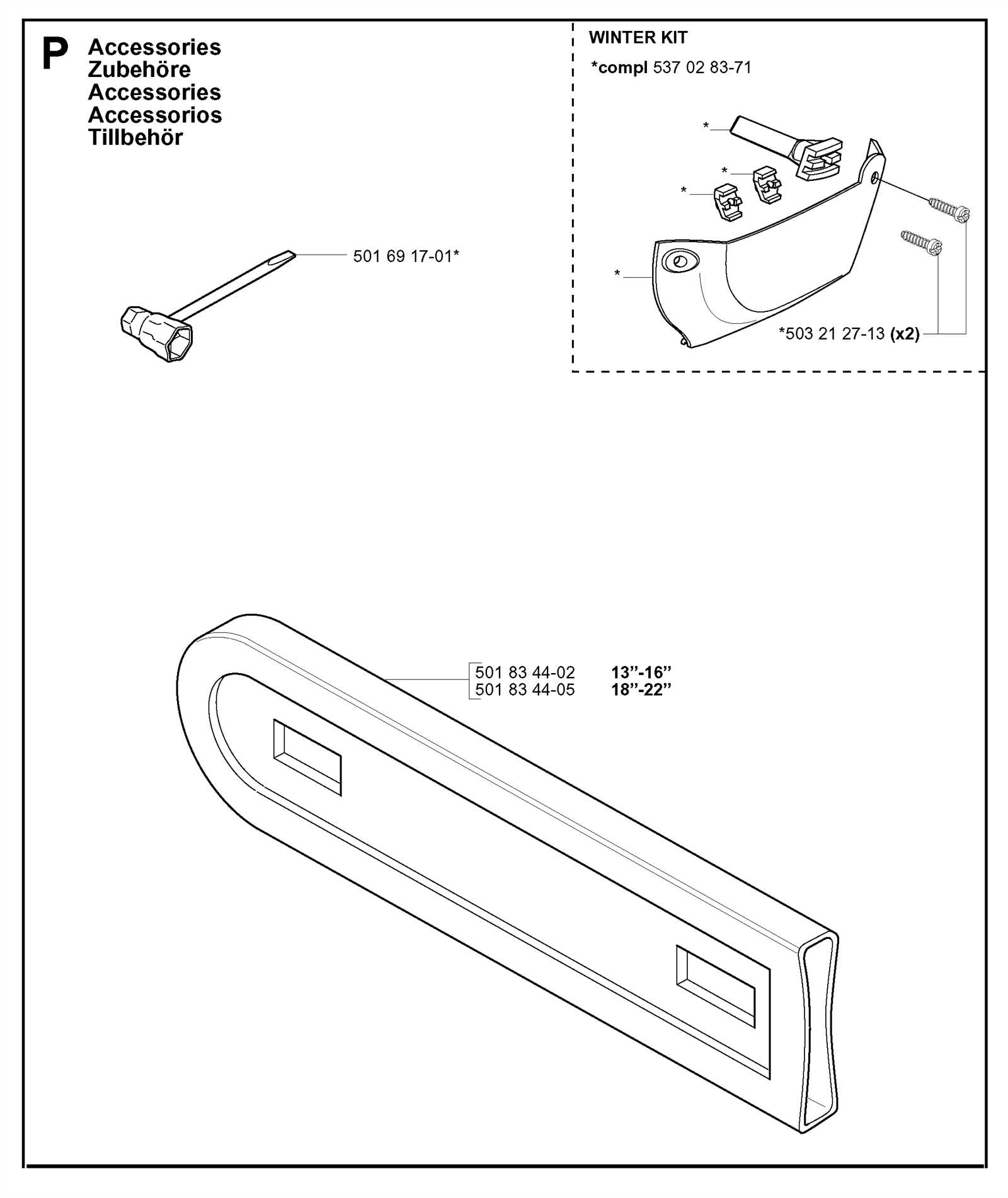

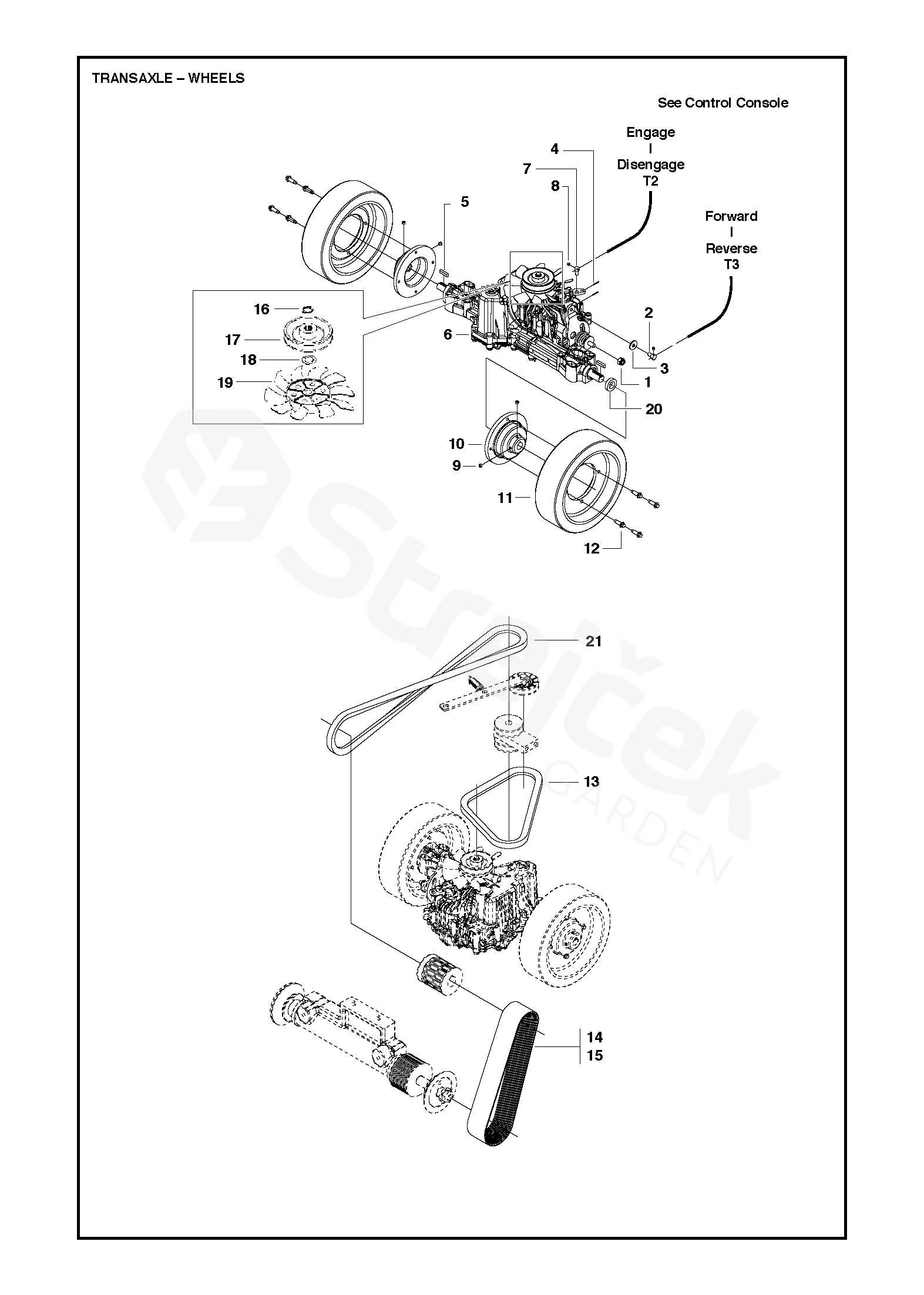

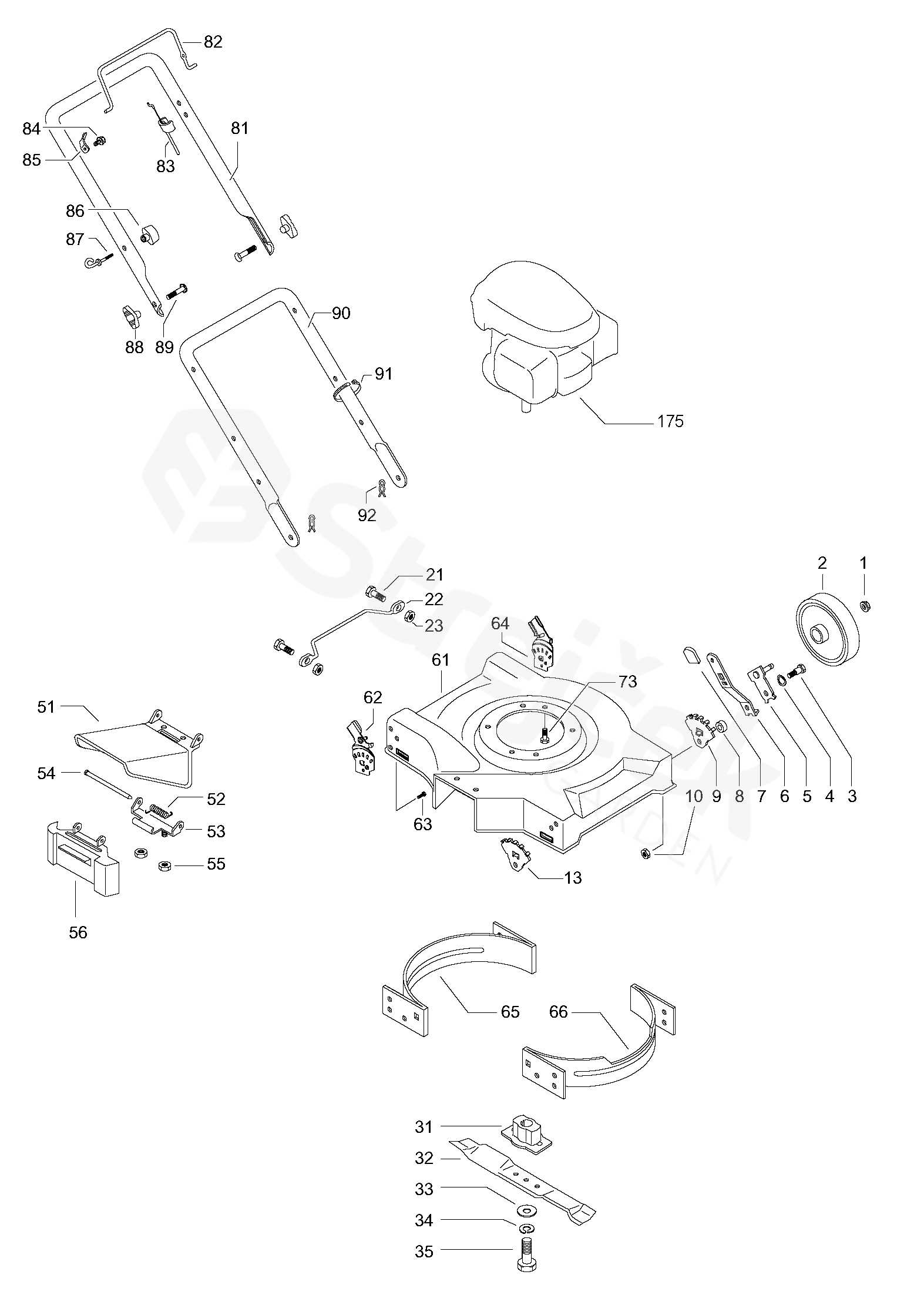

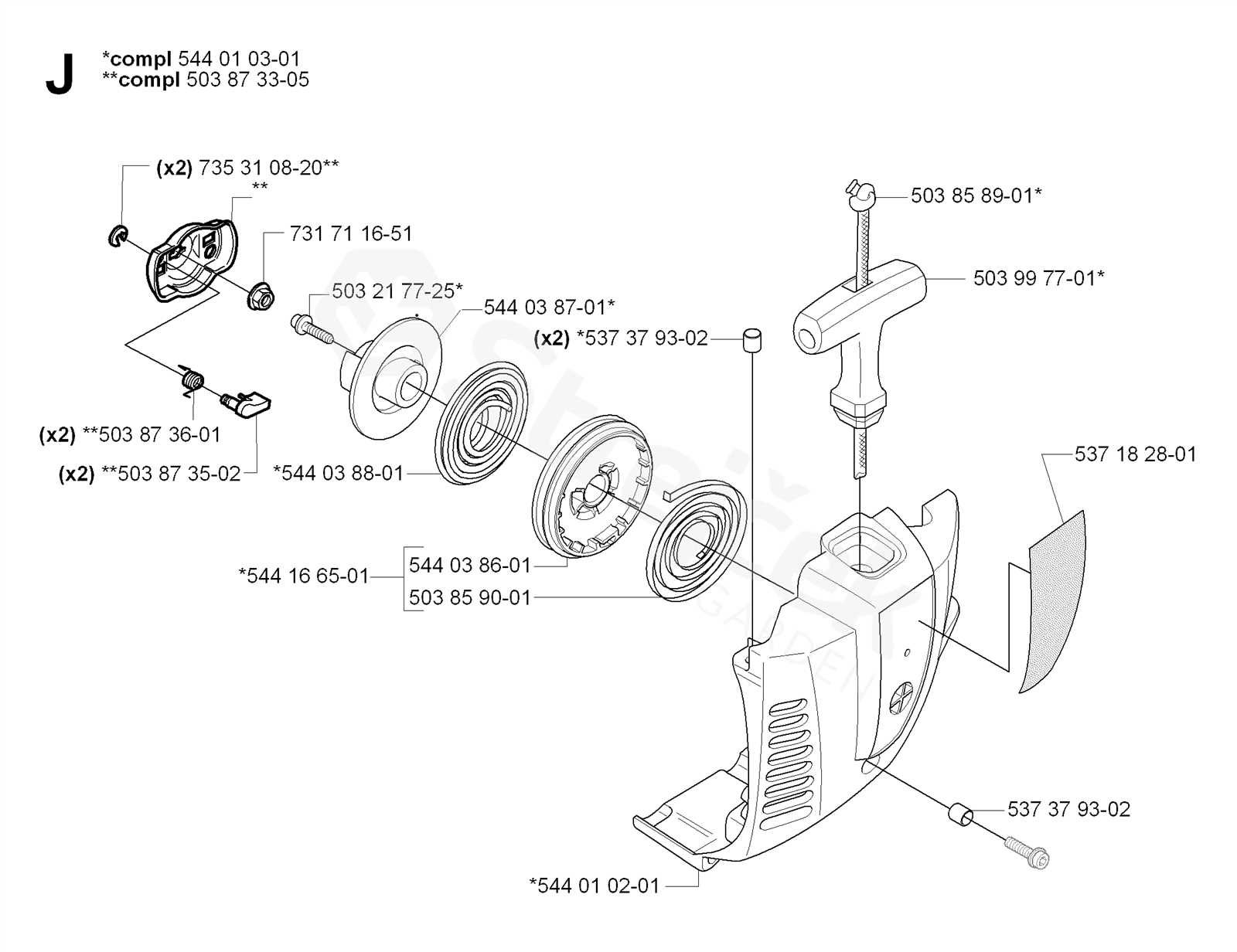

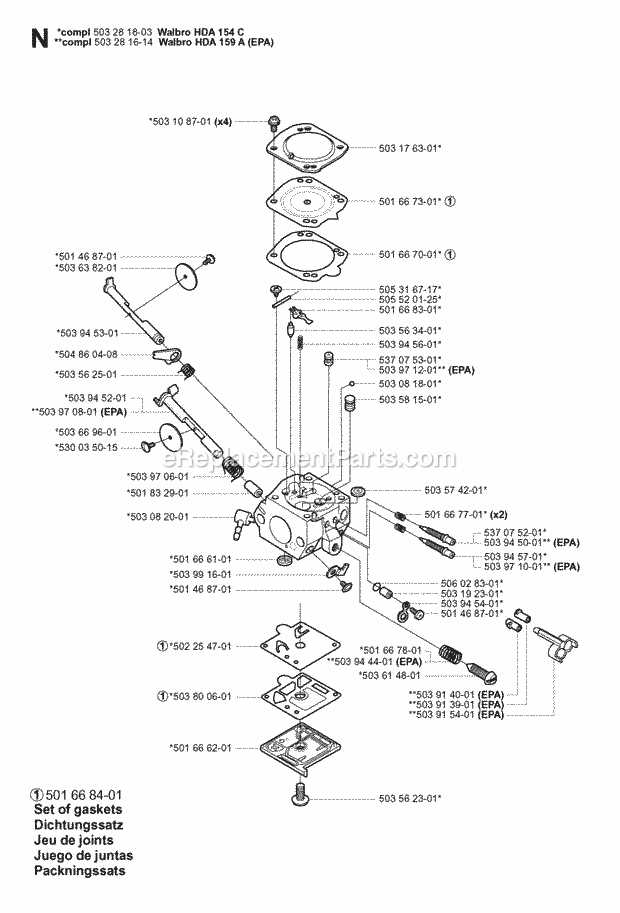

Diagrammatic Representation of Components

This section focuses on the visual layout of essential elements within a mechanical assembly, highlighting their interconnections and functions. Such representations serve as valuable tools for understanding the overall structure and operation of the machinery.

Understanding the Layout

The arrangement of components in a visual format allows for easier comprehension of their relationships. Each element’s position contributes to the functionality, ensuring that users can quickly identify how parts interact.

Benefits of Visual Guides

Utilizing graphic representations enhances the learning process for maintenance and repairs. Clear visuals simplify troubleshooting and assist users in locating specific elements within the assembly, promoting efficiency and accuracy.

Resources for Finding Spare Parts

Locating components for your equipment can be a straightforward process if you know where to look. Various resources are available that provide information on suppliers, distributors, and online platforms to help you acquire the necessary items for repairs or maintenance.

Online Marketplaces

Many websites specialize in offering a wide range of components for different machinery. These platforms allow users to search for specific items, compare prices, and read reviews from other customers.

Local Retailers and Service Centers

Your local shops and service centers can also be valuable resources. They often carry essential components or can order them for you, ensuring you receive the right fit for your needs.

| Resource Type | Examples | Notes |

|---|---|---|

| Online Marketplaces | eBay, Amazon, AliExpress | Wide selection, competitive pricing |

| Local Retailers | Hardware stores, Specialty shops | Immediate access, local support |

| Manufacturer’s Website | Official sites, Customer support | Genuine items, Technical assistance |