In the realm of mechanical devices, comprehending the various elements and their interrelationships is essential for efficient operation and maintenance. Each unit comprises distinct segments that work harmoniously to achieve optimal performance. Analyzing these segments can provide valuable insights for both enthusiasts and professionals alike.

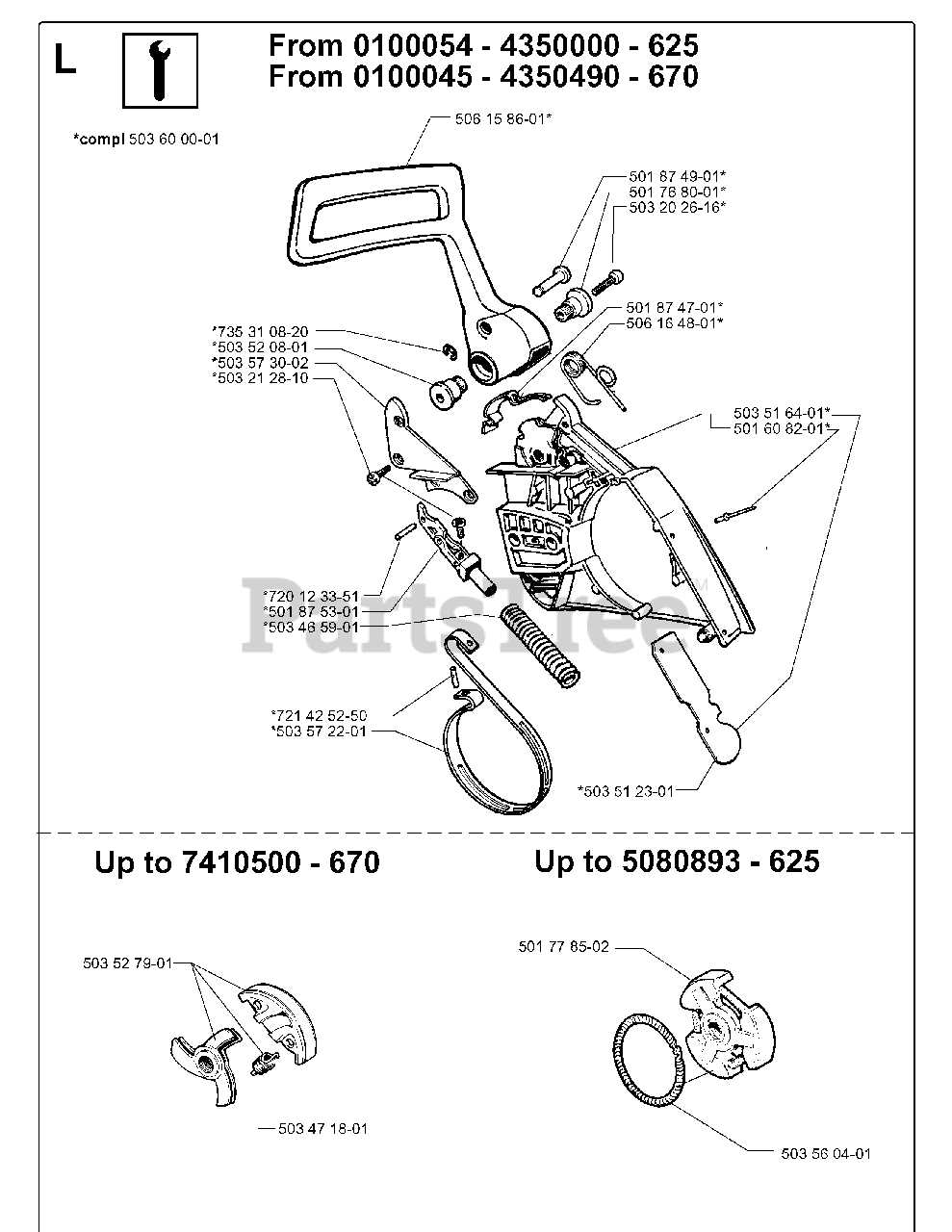

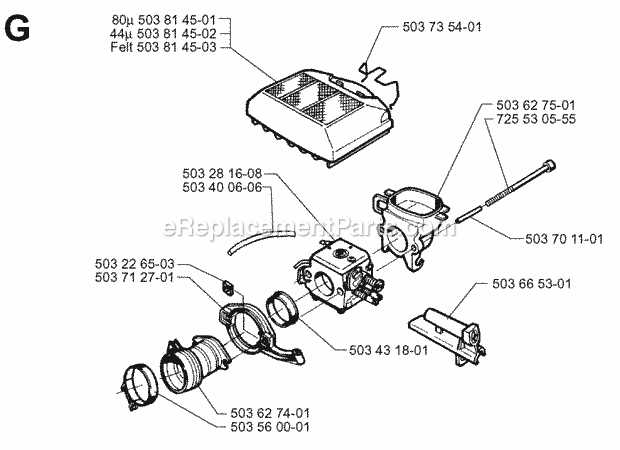

Detailed visual representations can greatly enhance one’s understanding of how these components fit together. By studying these illustrations, users can identify individual elements, grasp their functions, and recognize how they contribute to the overall efficiency of the machinery. Such knowledge is crucial for effective troubleshooting, repair, and enhancement of performance.

Whether you are a seasoned expert or a newcomer to the field, familiarizing yourself with these layouts will empower you to make informed decisions regarding maintenance and upgrades. With a clearer grasp of the structure, you can ensure the longevity and reliability of your equipment, leading to improved outcomes in various applications.

Understanding the Parts Layout

The arrangement of components within a mechanical assembly is crucial for efficient operation and maintenance. By comprehending how these elements interact and are positioned, one can ensure optimal functionality and troubleshoot issues more effectively.

Each component serves a specific purpose, contributing to the overall performance of the system. Recognizing the location and role of each part can greatly enhance the ability to diagnose problems and perform repairs. The layout is designed to facilitate accessibility while ensuring that all components function harmoniously.

Visualizing the structure allows for a deeper understanding of the intricate relationships between elements. It is essential to familiarize oneself with this arrangement, as it can significantly impact the efficiency and longevity of the equipment. Proper knowledge leads to better care and the ability to identify potential areas for improvement.

Essential Features of the Jonsered 70e

This segment delves into the fundamental attributes of a well-known outdoor power tool, highlighting its performance, durability, and user-friendly design. Understanding these key aspects can enhance the experience for operators, ensuring they can maximize its potential in various applications.

Robust Construction: The tool boasts a sturdy design, making it resilient against wear and tear during demanding tasks. This durability not only extends the lifespan of the device but also ensures consistent performance under challenging conditions.

Powerful Engine: Equipped with a high-performance engine, this model delivers impressive power output, enabling it to tackle tough jobs efficiently. The engine’s efficiency contributes to reduced fuel consumption, making it a cost-effective choice for users.

User-Centric Features: The thoughtful engineering incorporates ergonomic handles and intuitive controls, enhancing comfort and ease of use. Operators can work for extended periods without discomfort, increasing productivity and satisfaction.

Maintenance Accessibility: The design facilitates straightforward maintenance procedures, allowing users to keep the tool in optimal condition with minimal effort. Easy access to essential components simplifies routine checks and repairs.

Common Repairs for the Jonsered Model

Regular maintenance and timely fixes are crucial for ensuring the longevity and efficiency of outdoor power equipment. Addressing common issues can enhance performance and prevent more significant problems down the line. Familiarity with prevalent repairs can empower users to take proactive measures and keep their machinery in optimal condition.

Engine Performance Issues

One of the most frequent concerns involves the engine’s functionality. Symptoms such as difficulty starting or stalling during operation often indicate problems with the fuel system. Cleaning or replacing the fuel filter and ensuring proper fuel delivery can restore the engine’s performance.

Chain and Bar Maintenance

Another area requiring attention is the chain and bar assembly. Over time, wear and tear can lead to decreased cutting efficiency. Regularly checking the tension of the chain, lubricating it adequately, and replacing worn-out components are essential steps to maintain effective cutting performance. Neglecting these tasks can result in more extensive repairs or decreased productivity.

Identifying Each Component’s Function

Understanding the various elements of a mechanical assembly is crucial for effective maintenance and troubleshooting. Each individual part plays a specific role, contributing to the overall functionality and performance of the system. By familiarizing oneself with these components, one can ensure efficient operation and address issues more effectively.

The following list outlines some common elements found within such assemblies, along with their primary functions:

- Power Source: Provides the necessary energy to operate the system.

- Drive Mechanism: Transmits power from the source to the operational parts.

- Control Unit: Regulates the operation, allowing for adjustments in performance.

- Cooling System: Prevents overheating by dissipating excess heat generated during operation.

- Housing: Protects internal components from external elements and provides structural integrity.

By identifying these key components and understanding their functions, users can improve their ability to maintain and repair the equipment effectively.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Adhering to a systematic maintenance routine can significantly enhance performance, prevent potential issues, and reduce the need for costly repairs. Understanding the critical components and their functions is the first step toward achieving optimal operation.

1. Routine Cleaning: Keep the exterior and interior of the machinery clean from dirt and debris. Regularly check filters and air intakes to prevent clogging, which can hinder airflow and cause overheating.

2. Lubrication: Ensure that all moving parts are properly lubricated. This reduces friction, minimizes wear and tear, and extends the life of the equipment. Refer to the manufacturer’s guidelines for recommended lubricants and intervals.

3. Inspection: Conduct periodic inspections of critical components, including belts, chains, and connections. Look for signs of wear, looseness, or damage, and address any issues promptly to maintain safe and efficient operation.

4. Seasonal Checkups: Schedule seasonal maintenance checks to prepare your machinery for varying conditions. This includes examining fuel lines, spark plugs, and battery connections to ensure reliability throughout the year.

5. Proper Storage: When not in use, store your equipment in a clean, dry place. Protect it from harsh weather conditions that may lead to corrosion or deterioration of materials.

By implementing these simple yet effective maintenance strategies, you can ensure that your machinery remains in peak condition, ultimately enhancing its performance and reliability.

Where to Find Replacement Parts

Locating suitable components for your equipment can be straightforward if you know where to look. Various resources are available, ranging from local shops to online retailers. Each option has its advantages, depending on your specific needs and preferences.

Here are some effective methods to consider:

- Authorized Dealers: Start by checking with official distributors who specialize in your equipment brand. They often carry a full range of compatible components.

- Online Retailers: Websites dedicated to machinery and equipment often have extensive catalogs. Be sure to compare prices and availability.

- Local Hardware Stores: Many local stores may stock common components or be able to order them for you, providing a quick solution.

- Second-hand Markets: Consider searching through online marketplaces or local classifieds for used components, which can be a cost-effective option.

- Forums and Community Groups: Engaging with enthusiasts and experts in online forums can provide valuable leads on where to find specific items.

By exploring these avenues, you can increase your chances of finding the right components to keep your equipment running smoothly.

Safety Guidelines During Repairs

When undertaking maintenance or fixing equipment, prioritizing safety is essential to prevent accidents and injuries. Adhering to specific precautions ensures a secure environment for both the individual performing the work and those nearby. Understanding potential hazards and taking appropriate measures can significantly reduce risks associated with mechanical repairs.

Before starting any repair task, it is vital to wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear. This gear helps shield against potential injuries from sharp objects, chemicals, or flying debris. Additionally, ensure that the workspace is well-lit and free of clutter to avoid tripping hazards and allow for a clear view of the task at hand.

Always disconnect the power source before beginning any work on machinery to prevent accidental start-up. If applicable, confirm that the equipment is properly grounded. It is also important to familiarize oneself with the specific tools required for the job and to use them as intended, ensuring that they are in good condition to avoid malfunctions.

Maintaining a clean and organized workspace contributes to overall safety. Dispose of any waste materials or broken components properly and keep tools stored in designated areas. If at any point during the repair process you feel uncertain or unsafe, seek assistance or consult the equipment manual for guidance. Being proactive about safety can lead to successful and injury-free maintenance experiences.

Upgrading Your Jonsered Equipment

Enhancing your outdoor machinery can significantly improve performance and extend its lifespan. Whether you are a casual user or a professional, upgrading certain components can lead to better efficiency and reliability in your tasks. A thorough understanding of available enhancements will empower you to make informed decisions tailored to your specific needs.

Key areas for improvement often include the engine, cutting mechanisms, and safety features. By selecting high-quality replacements or upgrades, you can ensure that your equipment meets current standards and performs optimally under various conditions.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | High-performance air filters, spark plugs | Increased power output, improved fuel efficiency |

| Cutting Mechanism | Enhanced blades, wider bars | Faster cutting speed, smoother operation |

| Safety Features | Advanced braking systems, vibration dampeners | Reduced risk of accidents, improved user comfort |

By considering these aspects, you can make meaningful upgrades to your equipment that enhance both performance and safety, ultimately leading to a more enjoyable experience.