When maintaining outdoor power equipment, having a clear overview of its individual elements is essential. This understanding not only aids in effective repairs but also enhances the overall functionality and longevity of the device. Each component plays a crucial role in the operation and efficiency of the machinery.

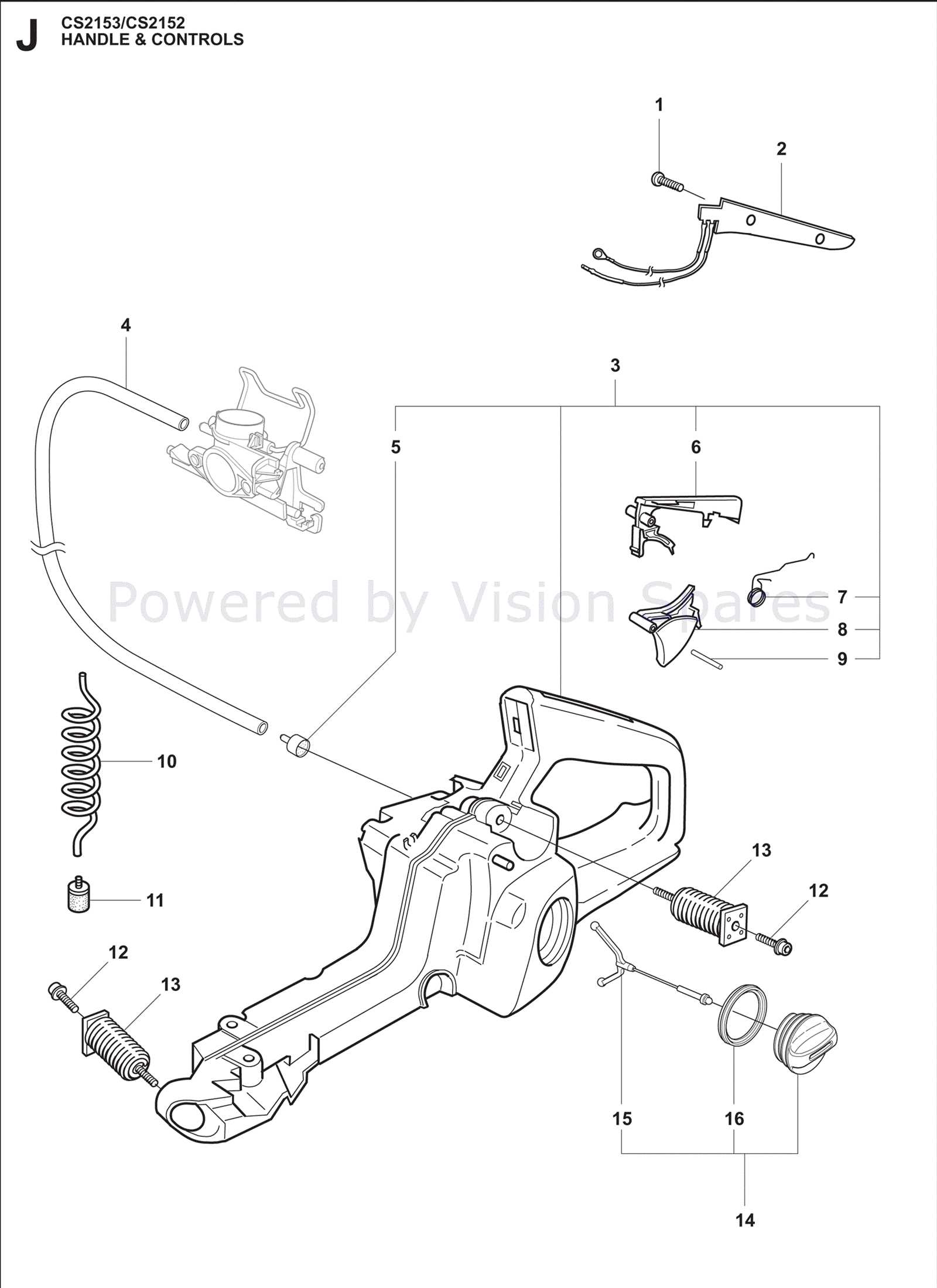

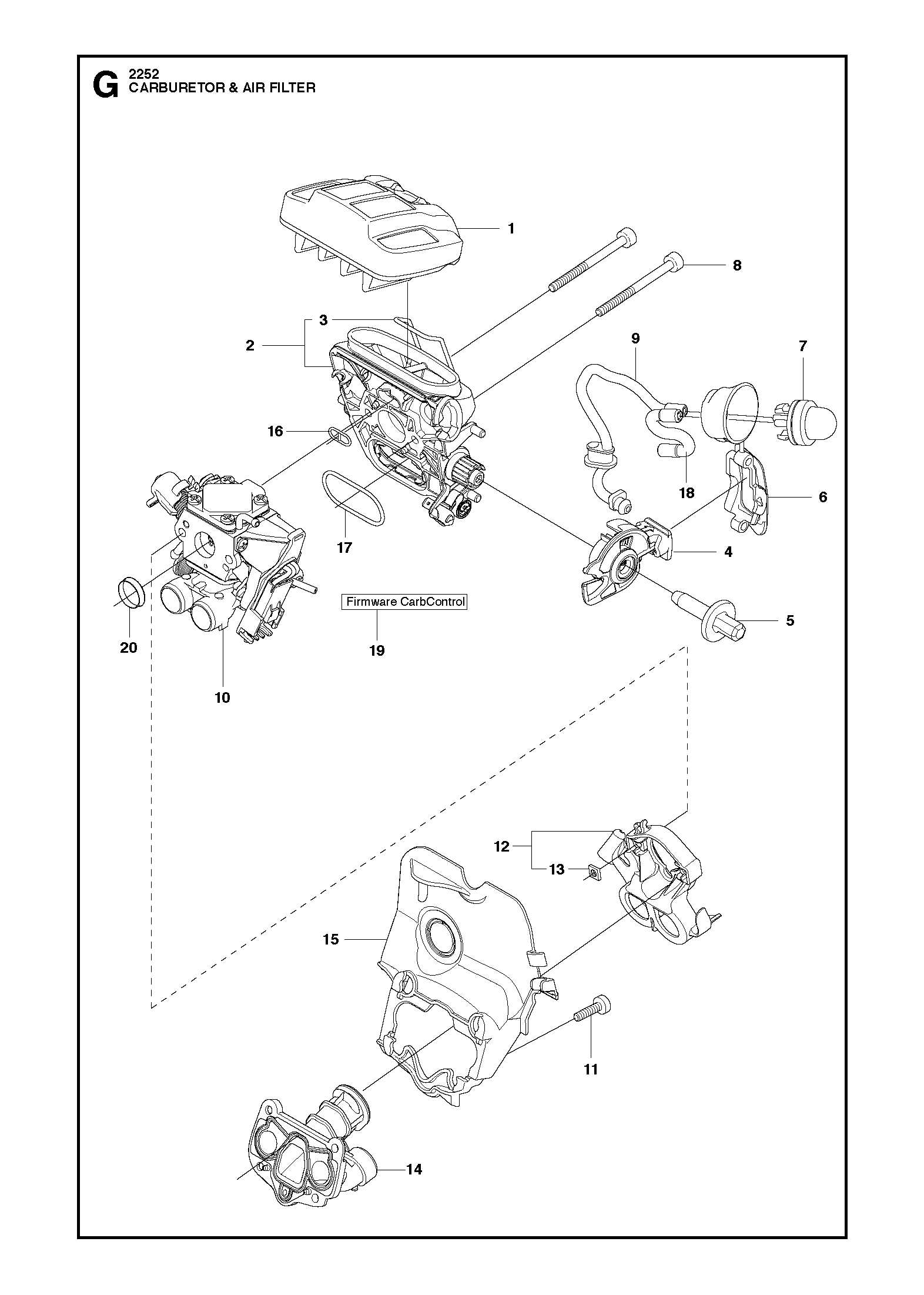

In this section, we will explore a detailed representation of a specific chainsaw model, focusing on its essential components and their arrangements. By breaking down the various parts, users can easily identify and address any issues that may arise during operation.

Familiarity with the machinery’s layout will empower users to perform maintenance tasks with confidence. Moreover, knowing how each element interacts within the system is vital for troubleshooting and optimizing performance.

Key Components of the Chainsaw

A chainsaw is a powerful tool designed for cutting wood and other materials efficiently. Understanding its essential elements can enhance user safety and maintenance, ensuring optimal performance. Below are the primary components that contribute to the functionality of this machine.

- Engine: The heart of the chainsaw, responsible for generating the power needed to drive the cutting mechanism.

- Guide Bar: This elongated component serves as a track for the chain, allowing for precise cutting.

- Chain: A series of interconnected links with sharp teeth that do the actual cutting.

- Chain Brake: A safety feature that stops the chain quickly to prevent accidents.

- Fuel System: Comprises the fuel tank and lines, delivering power to the engine.

- Air Filter: Essential for keeping the engine clean by preventing dust and debris from entering.

- Starter Mechanism: Facilitates the ignition of the engine, typically involving a pull cord.

- Handle: Provides grip and control, allowing for maneuverability during operation.

Each of these components plays a crucial role in the overall effectiveness of the chainsaw, and understanding their functions can aid in proper maintenance and safe usage.

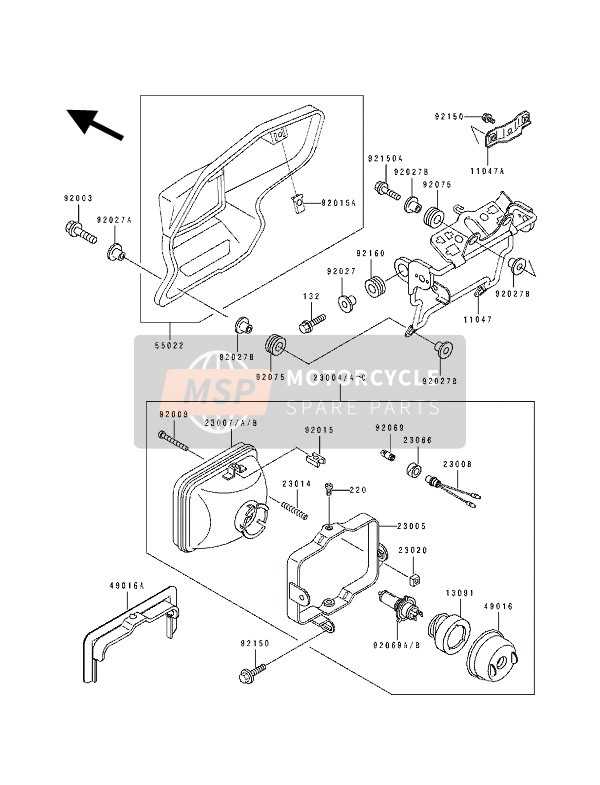

Understanding the Parts Diagram

The visual representation of components plays a crucial role in comprehending the assembly and functionality of machinery. It serves as a guide for users to identify each element and its relation to the overall system. By analyzing this illustration, individuals can gain insights into how various pieces interact and contribute to optimal performance.

Familiarity with each component is essential for maintenance and troubleshooting. Recognizing the function of each part aids in efficient repairs and enhancements. When users understand the layout, they can swiftly locate any specific section that requires attention, leading to better upkeep of the equipment.

Additionally, this representation is invaluable for new users seeking to familiarize themselves with the equipment. It demystifies the complexity of the machinery, allowing for a smoother learning curve. By engaging with this visual aid, individuals can build confidence in operating and caring for their tools effectively.

Common Issues and Solutions

Every machine may encounter challenges during its operation. Understanding these issues and their solutions can enhance the efficiency and longevity of the equipment. This section explores frequent problems users face and offers practical resolutions to ensure smooth performance.

Frequent Problems

- Difficulty starting the engine

- Loss of power during use

- Excessive vibrations

- Fuel leaks

- Chain not moving properly

Proposed Solutions

- Ensure the fuel tank is filled and the fuel is fresh.

- Check the air filter for clogs and replace if necessary.

- Inspect the spark plug for wear; clean or replace if needed.

- Tighten any loose bolts and screws to minimize vibrations.

- Examine the chain tension and lubricate it regularly for optimal performance.

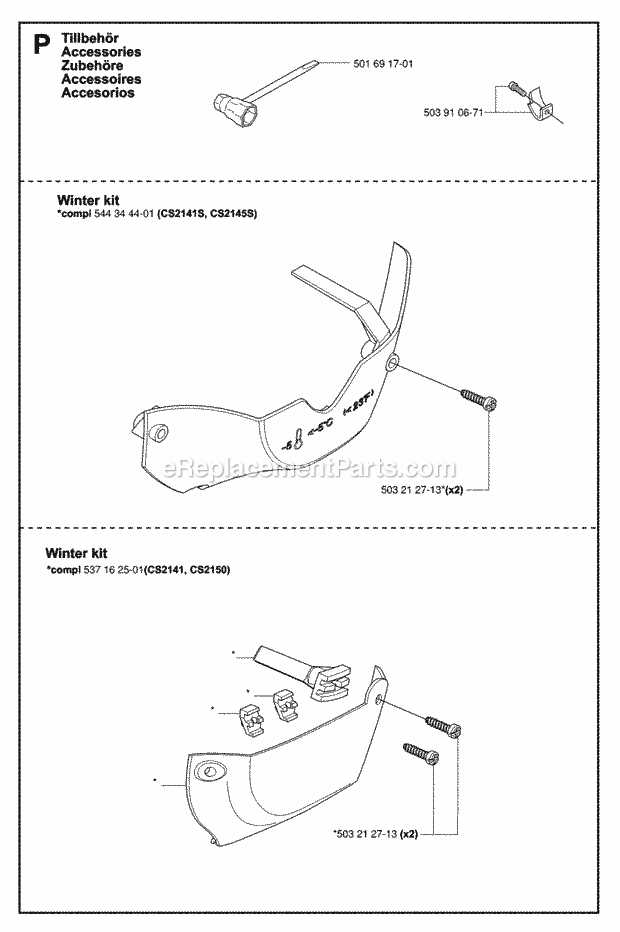

Replacement Parts and Compatibility

When maintaining and repairing outdoor power equipment, understanding the available components and their compatibility is crucial. Ensuring that the right elements are selected not only enhances performance but also extends the lifespan of the machinery. In this section, we will explore essential aspects of component replacement and the importance of selecting appropriate substitutes.

Finding Suitable Components

Identifying compatible components for your equipment involves considering several factors, including specifications, quality, and availability. Various manufacturers produce similar items that can be utilized interchangeably. Researching compatibility helps in making informed decisions and ensures optimal functioning.

Aftermarket Options

Aftermarket alternatives are often available, providing cost-effective solutions without compromising quality. These options may vary in design and manufacturing, but many meet or exceed the original specifications. Always check user reviews and ratings to gauge reliability before making a purchase.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. By following a few key practices, you can maintain optimal performance and reduce the likelihood of breakdowns.

- Regular Cleaning: Keep the device free from debris and contaminants to prevent wear and tear.

- Inspect Components: Frequently check essential parts for signs of damage or wear.

- Lubrication: Apply appropriate lubricants to moving parts to ensure smooth operation and minimize friction.

- Fuel Quality: Use high-quality fuel to avoid engine issues and enhance performance.

- Storage Practices: Store the equipment in a dry, sheltered environment to protect it from the elements.

Implementing these simple yet effective maintenance strategies can significantly prolong the functionality and reliability of your equipment.

Tools Needed for Disassembly

When undertaking the task of disassembling a machine, having the right tools is crucial for ensuring a smooth and efficient process. Proper equipment not only aids in the removal of components but also minimizes the risk of damage to both the parts and the user. Below is a list of essential tools that will facilitate the disassembly procedure.

Essential Hand Tools

To begin, a selection of hand tools is necessary. These tools provide the leverage and grip needed to safely detach various components. The following table outlines the basic hand tools required for disassembly:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws |

| Socket Wrench | For removing bolts and nuts |

| Plier Set | For gripping and manipulating small parts |

| Torque Wrench | To ensure bolts are tightened to the correct specifications |

Safety Equipment

In addition to hand tools, safety equipment is equally important to protect the individual during the disassembly process. The following items should be considered:

- Safety goggles to protect the eyes

- Gloves to ensure a firm grip and protect hands

- Dust mask to avoid inhaling debris

Assembly Instructions for Repaired Parts

When reassembling components that have undergone repairs, it’s essential to follow a systematic approach to ensure proper functionality. This section provides a clear outline of the assembly process, highlighting key steps and considerations for successful reassembly.

Begin by organizing all the components involved in the reassembly. Having a clean workspace helps prevent misplacing any items. Review any notes or instructions you may have related to the repairs performed. This can provide valuable insights into the assembly order and any specific adjustments needed.

Start with the main body of the device, ensuring that any seals or gaskets are in place. Align the repaired components carefully, making sure that all connection points fit snugly without forcing them together. Use appropriate tools to secure each part, following the recommended torque specifications where applicable.

After the initial assembly, perform a visual inspection to confirm that everything is correctly positioned. Finally, test the functionality of the assembled unit to ensure that the repairs have been successful and that the device operates as intended.

Comparative Analysis with Other Models

When evaluating various saw models, it is essential to consider their features, performance, and user-friendliness. Each model offers distinct advantages that cater to different user needs, ranging from hobbyists to professional users. This section explores the similarities and differences among competing products in the market, highlighting key attributes that influence consumer choice.

Performance and Power

In terms of cutting efficiency, some models outperform others due to their engine power and design. For instance, while certain saws prioritize lightweight construction for easy handling, others focus on delivering high torque and faster cutting speeds. Analyzing these attributes allows users to select a tool that best fits their operational requirements.

Durability and Maintenance

Durability is another critical factor when comparing models. Some designs incorporate robust materials that enhance longevity, while others may require more frequent maintenance. Understanding the maintenance needs of each model is vital for ensuring long-term performance and reliability.

User Experience

The ergonomics of various saws significantly affect user experience. Features such as handle design, weight distribution, and vibration reduction technologies contribute to overall comfort during prolonged use. Comparing these elements can provide insights into which models are better suited for extensive tasks or less experienced users.

Where to Purchase Genuine Parts

For maintaining or repairing your equipment, it is crucial to find reliable sources that offer original components. This ensures durability, compatibility, and long-term performance. Knowing where to acquire authentic items is the first step towards a successful repair process.

- Authorized Dealers: The most trustworthy option is to visit certified sellers, as they guarantee the authenticity of all items offered. These suppliers often provide warranties and customer support for peace of mind.

- Online Marketplaces: Reputable online platforms can be a convenient option for finding a wide range of original components. Look for sellers with high ratings and verified reviews to ensure quality.

- Specialized Retailers: Many stores focus specifically

Frequently Asked Questions About Parts

This section aims to address common concerns related to various components and their compatibility, performance, and replacement process. Below are answers to the most frequent inquiries, which can help clarify some of the uncertainties you might encounter during maintenance or assembly.

- What are the most critical elements to check during maintenance?

Focus on inspecting the essential mechanical and electrical elements, as these are most prone to wear. Proper examination will ensure optimal operation and

- What are the most critical elements to check during maintenance?