In the realm of machinery, grasping the intricate arrangement of various elements is crucial for effective maintenance and operation. This section delves into the structural organization of specific units, highlighting the relationships and functions of each individual component within the assembly. By examining this configuration, users can enhance their comprehension and ensure the longevity of their equipment.

Insight into Structural Composition is vital for troubleshooting and repairs. A well-organized layout not only aids in identifying potential issues but also streamlines the process of replacement and upgrading. With a clear visualization of how each segment interacts, users can approach their tasks with confidence and precision.

Furthermore, understanding the nuances of these assemblies fosters a deeper appreciation for engineering principles. The connection between components often reflects innovative solutions that optimize functionality and performance. By exploring this arrangement, one can gain insights into the design philosophy that drives the creation of such systems.

Key Features of Js63 Machinery

The machinery in question stands out for its innovative design and robust functionality, making it an ideal choice for various industrial applications. Built to enhance efficiency, this equipment integrates advanced technology with user-friendly features, ensuring optimal performance in demanding environments.

One of the most notable attributes is its powerful engine, which delivers exceptional torque and speed, allowing for quick execution of tasks. Additionally, the inclusion of a high-capacity hydraulic system facilitates precise control over operations, enhancing productivity and reducing downtime.

Moreover, the machinery is equipped with durable components that withstand rigorous use, ensuring longevity and reliability. The ergonomic design also prioritizes user comfort, featuring intuitive controls and a spacious cabin that reduces operator fatigue during extended periods of work.

Lastly, the emphasis on safety features cannot be overlooked. The incorporation of advanced monitoring systems and protective mechanisms ensures secure operation, making it a trustworthy choice for operators in the field.

Importance of Accurate Parts Diagrams

Having precise representations of components is crucial for efficient maintenance and repairs. These illustrations serve as invaluable tools that aid technicians and enthusiasts alike in understanding the structure and organization of assemblies. Without them, identifying individual elements and their relationships within a system can become a challenging task.

Clarity is one of the primary benefits provided by well-crafted representations. They simplify complex systems by breaking them down into understandable sections, allowing users to visualize how each piece interacts with others. This clear overview helps prevent confusion, especially when dealing with intricate machinery.

Moreover, accurate depictions facilitate effective communication among team members. When everyone refers to the same detailed images, it minimizes the chances of misinterpretation and ensures that all parties are on the same page during discussions regarding repairs or upgrades. This collaborative approach ultimately leads to better decision-making and more efficient workflow.

Additionally, having reliable illustrations can significantly reduce the risk of errors during assembly or disassembly. By following the provided layouts, users can ensure they are handling each component correctly, thus avoiding potential damage and minimizing costly mistakes. In turn, this promotes a safer working environment, as clarity in operations often leads to a reduction in accidents.

In summary, precise representations of components are essential for efficient operation and maintenance. They provide clarity, enhance communication, and reduce errors, making them invaluable resources in any technical field.

Common Issues with Js63 Parts

When working with various components in machinery, users often encounter several recurring problems that can impact performance and efficiency. Understanding these issues can help in troubleshooting and maintenance, ensuring smooth operation and longevity of the equipment.

Frequent Challenges

Several common challenges may arise when dealing with the components of a particular model. These issues can stem from manufacturing defects, wear and tear, or improper installation. Addressing these problems promptly is essential to avoid more significant disruptions in functionality.

Impact on Performance

These recurring issues can lead to a decline in overall efficiency, resulting in higher operational costs and reduced productivity. Regular maintenance and inspections are crucial to identify and resolve these problems before they escalate.

| Issue | Potential Cause | Recommended Solution |

|---|---|---|

| Overheating | Poor ventilation | Ensure adequate airflow and clean cooling systems |

| Unusual noises | Worn bearings | Replace bearings and lubricate moving parts |

| Inconsistent performance | Misalignment | Check and adjust alignment of components |

| Leakage | Damaged seals | Inspect and replace seals as necessary |

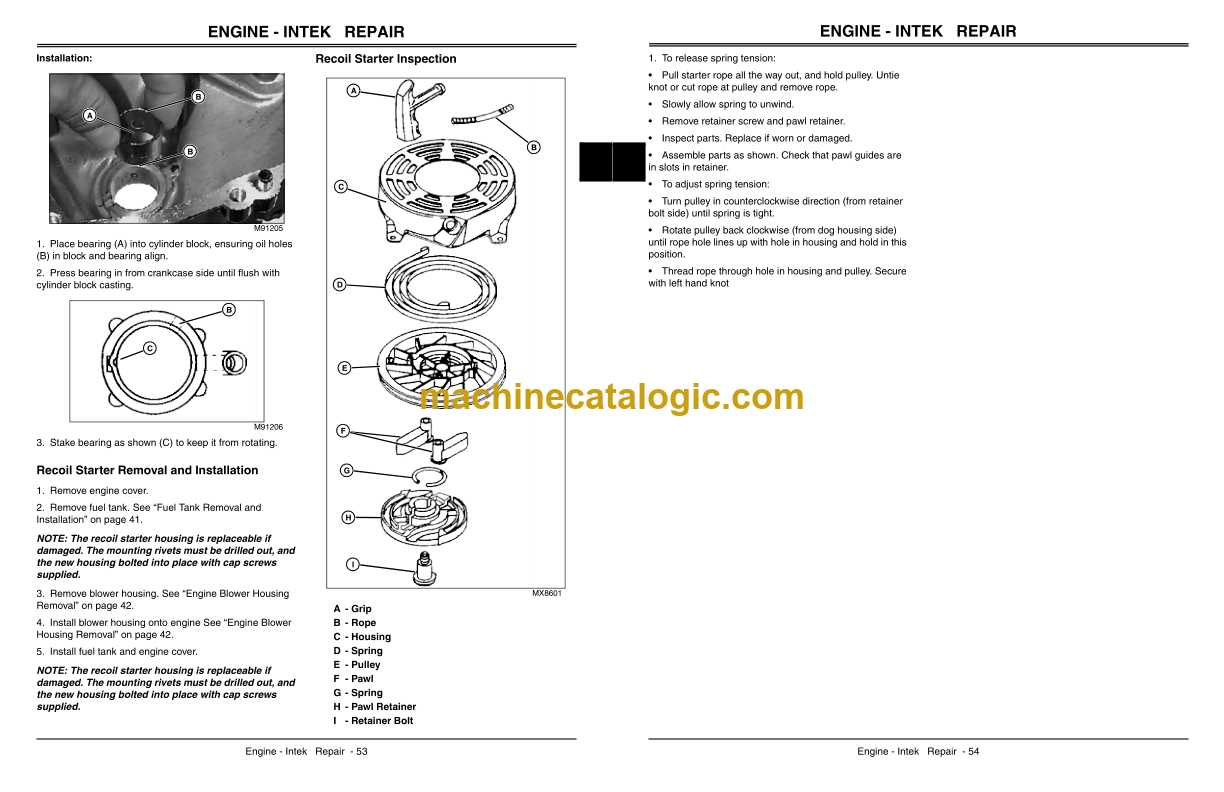

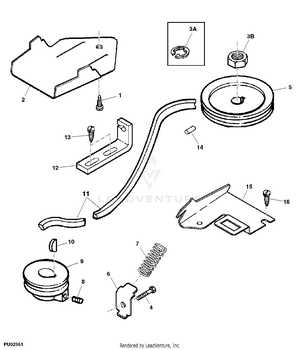

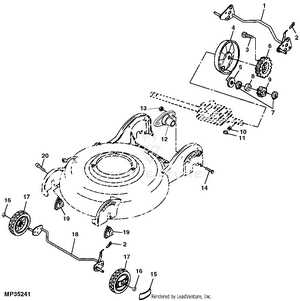

How to Interpret Parts Diagrams

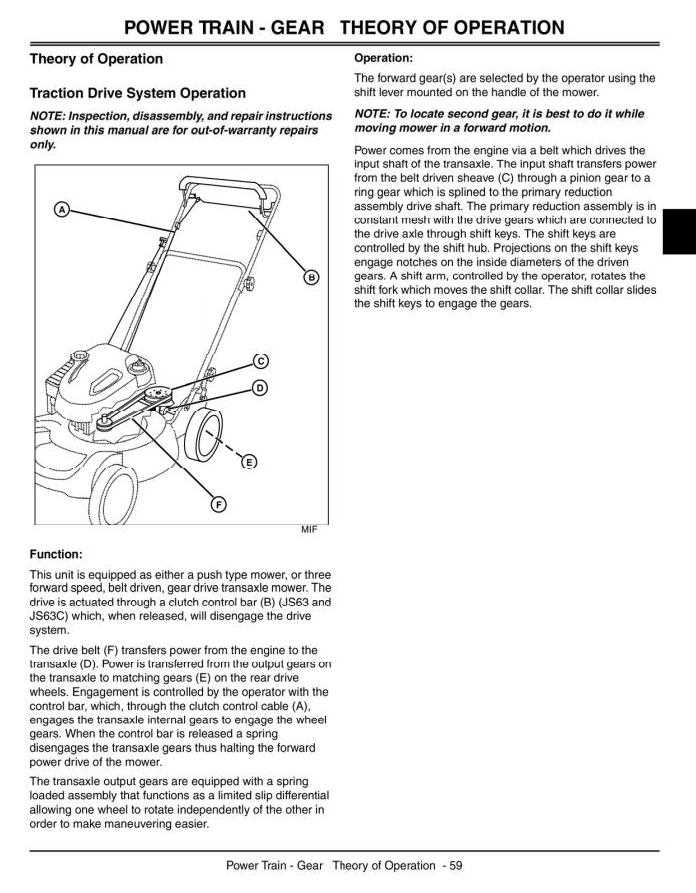

Understanding the layout of components within a mechanical system is essential for effective maintenance and repairs. This visual representation provides a clear overview of the various elements and their relationships, allowing users to identify and troubleshoot issues efficiently.

Key Elements to Consider

- Labels: Each component is usually accompanied by a label that describes its function or part number. Familiarizing yourself with these labels can help you quickly locate the necessary pieces.

- Connections: Pay attention to how parts are interconnected. This information is crucial for understanding how to disassemble or reassemble the system correctly.

- References: Many visuals include reference numbers that correspond to a list of components. This can be helpful for ordering replacements or verifying compatibility.

Steps to Effectively Use the Visual Representation

- Start by reviewing the overall layout to get a sense of the arrangement and organization.

- Identify and make note of any key components that you need to address or replace.

- Refer to the accompanying list or legend to understand the specifics of each item.

- When disassembling, keep track of the order in which parts are removed to simplify reassembly.

By following these guidelines, you can confidently navigate through complex mechanical visuals, ensuring that repairs and maintenance are performed accurately and efficiently.

Maintenance Tips for Js63 Equipment

Proper upkeep of machinery is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns. Here are some essential practices to ensure your equipment remains in top condition.

- Regular Inspections: Conduct routine checks to identify any signs of wear or damage. This proactive approach helps in addressing issues before they escalate.

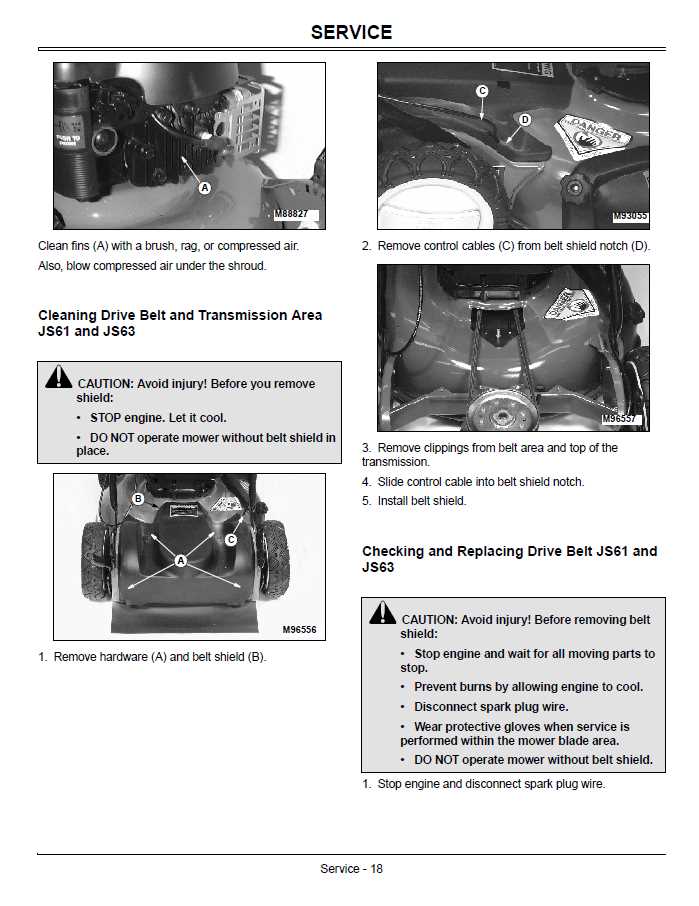

- Cleanliness: Keep the equipment clean by removing dirt and debris. Regular cleaning can prevent buildup that may affect performance.

- Lubrication: Ensure that all moving parts are properly lubricated. This reduces friction and minimizes wear over time.

- Replacement of Worn Parts: Replace any components that show signs of excessive wear. Using original or compatible replacements ensures reliability.

- Adhere to Manufacturer Guidelines: Follow the manufacturer’s recommendations for maintenance schedules and procedures. These guidelines are designed to maximize performance.

By following these tips, you can enhance the reliability and efficiency of your machinery, ensuring it operates smoothly for years to come.

Identifying Wear and Tear

Recognizing signs of degradation is essential for maintaining equipment efficiency and longevity. Regular inspections can help spot potential issues before they escalate, ensuring smooth operation and safety.

Common Indicators of Wear

- Visual Inspection: Look for discoloration, cracks, or abnormal surface textures.

- Movement and Alignment: Check for unusual noises or vibrations during operation.

- Functional Performance: Note any decrease in efficiency or performance metrics.

Assessment and Action

- Conduct routine checks based on usage frequency.

- Document any findings for future reference.

- Replace or repair components as necessary to avoid further damage.

By staying proactive in identifying wear and tear, you can extend the lifespan of your equipment and enhance overall performance.

Replacement Parts Availability

When maintaining any machinery, ensuring access to suitable components is crucial for optimal performance and longevity. The availability of these items can significantly impact repair timelines and overall operational efficiency. Understanding where to source high-quality replacements is essential for anyone looking to keep their equipment running smoothly.

Numerous suppliers specialize in offering a wide array of replacement components, catering to various models and specifications. Online marketplaces, authorized dealers, and local distributors provide convenient avenues for acquiring necessary items. It is vital to verify the compatibility of each component with your specific machinery to avoid potential issues during installation.

In addition, exploring forums and community resources can yield valuable insights into reliable vendors and alternative sourcing options. Engaging with fellow users often leads to recommendations for trustworthy suppliers, ensuring that you have access to the right components when needed. Maintaining a list of preferred vendors can streamline the procurement process and minimize downtime during repairs.

Guidelines for Assembly and Disassembly

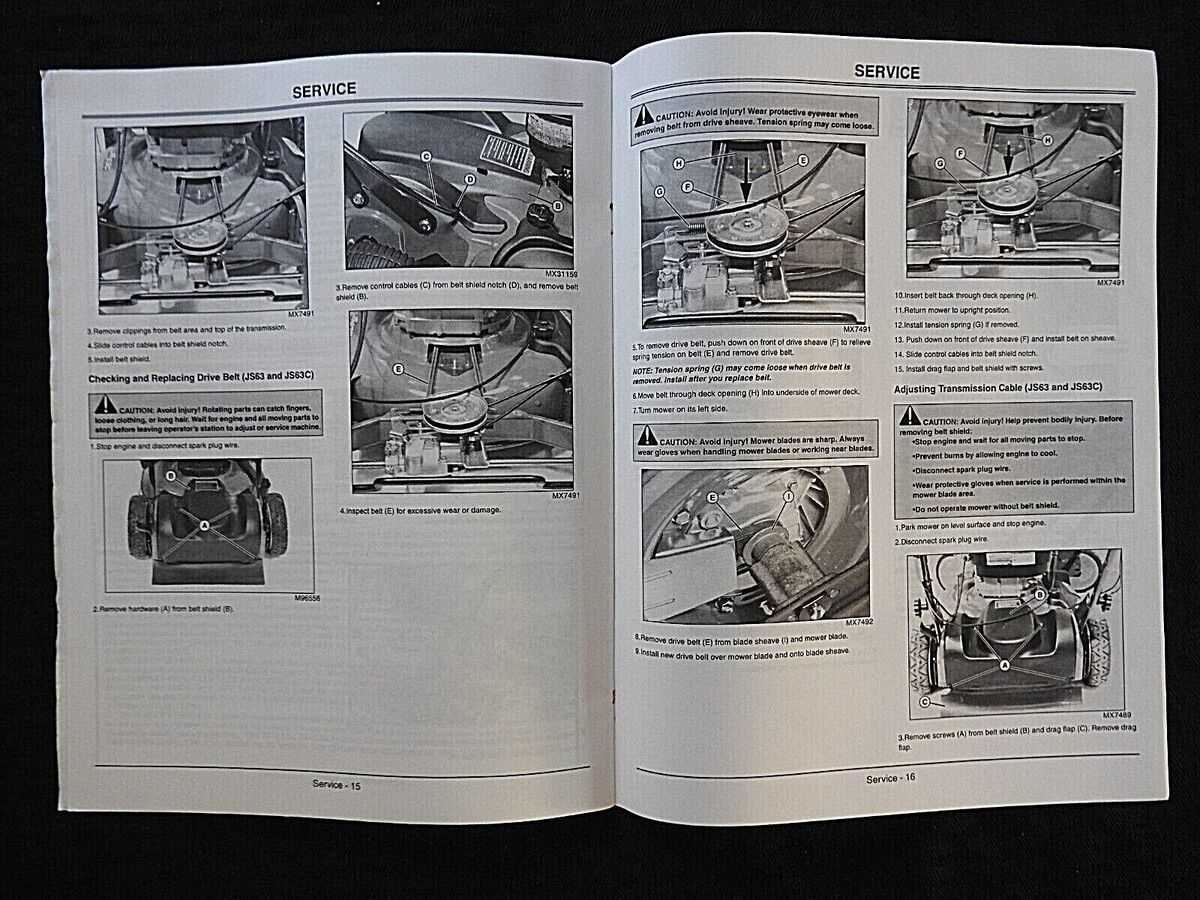

Understanding the correct methods for assembling and disassembling components is essential for maintaining efficiency and ensuring the longevity of the equipment. Proper techniques not only facilitate smoother operations but also minimize the risk of damage to parts during the process. This section outlines the key practices that should be followed to achieve successful assembly and disassembly.

Preparation Steps

Before initiating the process, gather all necessary tools and ensure that the workspace is clean and organized. Familiarize yourself with the specific components involved, as this knowledge will aid in identifying any potential challenges. Additionally, reviewing any available documentation or manuals can provide valuable insights into the required steps and best practices.

Best Practices

When assembling, begin by aligning the components carefully to avoid misalignment, which can lead to operational issues. Use gentle pressure to secure the pieces together, and avoid forcing them, as this may cause damage. During disassembly, proceed with caution; remove screws and fasteners in the reverse order of assembly to prevent any confusion. Always keep track of small parts to ensure they do not get lost.

Safety Precautions When Working

Ensuring a safe working environment is essential to prevent accidents and injuries during any task. By following specific guidelines and implementing proper practices, individuals can minimize risks associated with their activities. The following precautions should be considered to maintain safety and efficiency.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and masks.

- Ensure the workspace is clean and organized to avoid tripping hazards.

- Use tools and equipment according to the manufacturer’s instructions and guidelines.

- Keep emergency contact information readily available in case of accidents.

- Perform a risk assessment before starting any task to identify potential hazards.

Additionally, it is crucial to stay focused and avoid distractions while working. Regular breaks can help maintain concentration and reduce fatigue, which may lead to mistakes or oversights.

- Plan the task ahead of time, including the steps involved and the resources required.

- Ensure all tools are in good working condition before use.

- Never work alone, especially when performing complex or dangerous tasks.

By adhering to these guidelines, individuals can create a safer working atmosphere and reduce the likelihood of accidents and injuries.

Resources for Js63 Owners

For enthusiasts and owners of this specific model, having access to comprehensive resources is essential for maintenance and upgrades. Whether you are looking for replacement components, repair guides, or community support, numerous platforms can provide valuable information and assistance.

Online Forums and Communities

- Join dedicated online forums where fellow owners share their experiences, tips, and troubleshooting advice.

- Participate in social media groups focused on this model to connect with others and exchange knowledge.

- Explore dedicated subreddits for discussions and resources related to this vehicle.

Official Manuals and Guides

- Access the manufacturer’s official manuals for detailed specifications and maintenance procedures.

- Look for online repositories that host repair and service guides, which can be invaluable for DIY repairs.

- Consider purchasing a comprehensive service manual that covers all aspects of ownership, including troubleshooting and upgrades.

By utilizing these resources, owners can enhance their understanding of their vehicle and ensure it remains in optimal condition for years to come.