Understanding the internal structure of a coffee machine can be essential for both maintenance and troubleshooting. This guide will walk you through the arrangement of various elements inside the machine, focusing on how each piece contributes to the overall functionality. Without diving into complex technical terms, it’s important to grasp the basic setup and interconnections of its mechanical and electronic components.

Each section of the machine works together seamlessly, and being familiar with their placement allows for a smoother experience when it comes to repairs or upgrades. Knowing the layout of key elements can help you pinpoint specific areas that might need attention, enhancing the longevity and efficiency of your device.

In this article, we will explore the arrangement of critical features and their roles in ensuring a perfect coffee-making process. From water flow to grinding mechanisms, every part plays a role in delivering a rich a

Overview of Jura E8 Coffee Machine Components

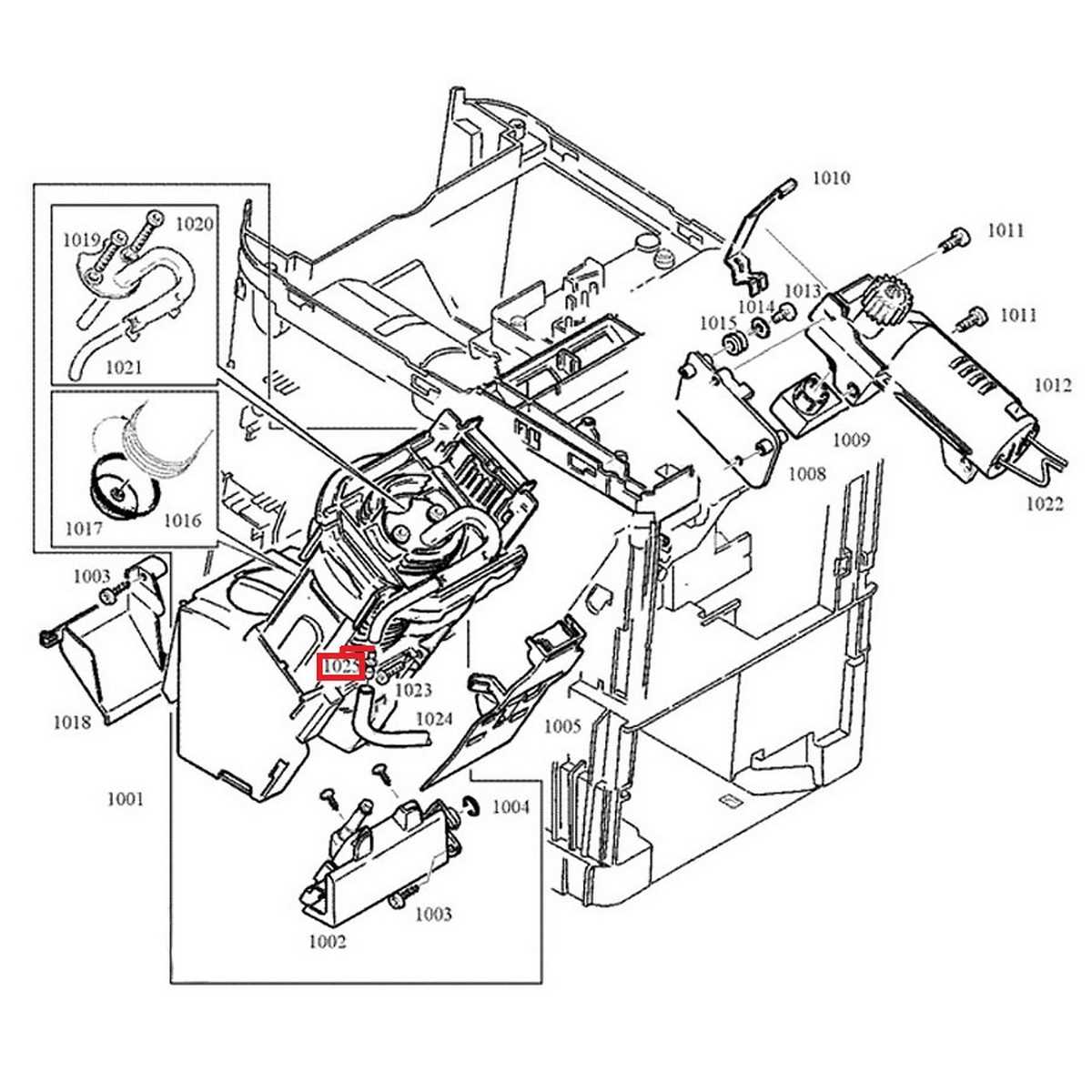

The coffee machine in question is a sophisticated system made up of various interconnected elements that ensure its high functionality. Each of these elements plays a crucial role in delivering a seamless experience, from brewing to maintenance. Understanding the core components is essential for efficient use and upkeep.

At the heart of the system, you will find the brewing mechanism, responsible for processing and delivering the perfect cup. Supporting this, other essential elements, like the water heating system and grinder, work in unison to ensure the quality and consistency of the final product. Additional features include the milk frothing unit and intuitive control interface, designed for ease of use and customization.

Maintaining these key elements is critical for prolonging the lifespan of the machine and ensuring it operates at peak performance. Regular cleaning and maintenance of specific components will keep everything running smoothly.

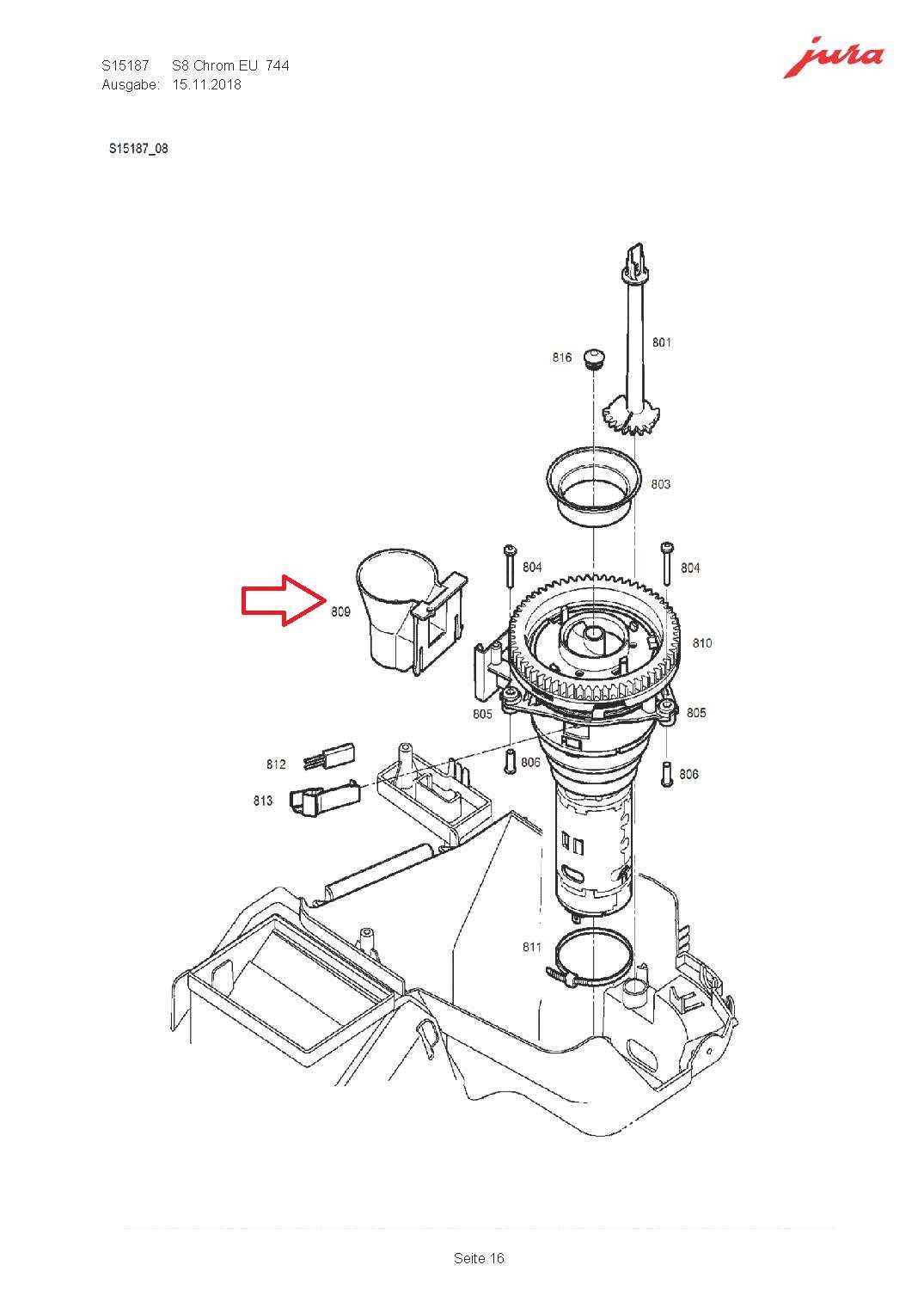

Main Internal Parts of the Jura E8

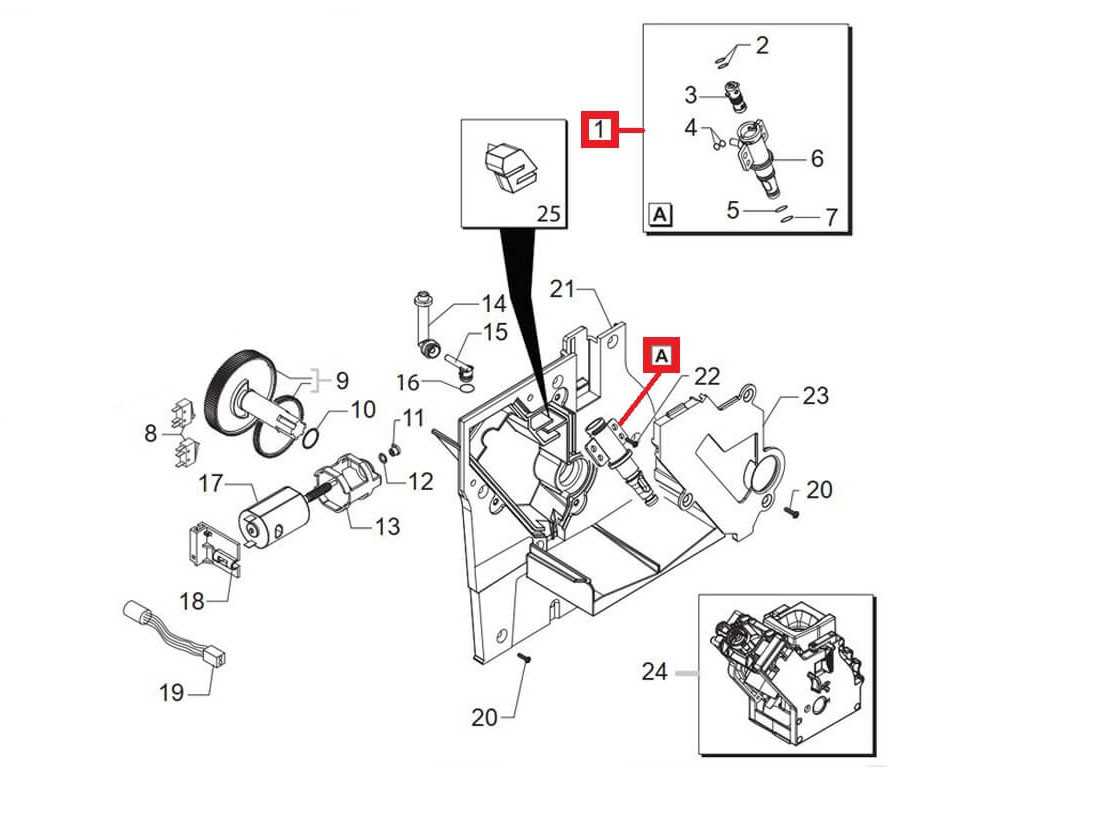

The advanced coffee machine model is composed of several key components that work together to ensure smooth operation and deliver high-quality beverages. These elements are carefully designed and placed to enhance performance and longevity.

- Brewing Unit: This essential component handles the extraction process, ensuring each cup of coffee is brewed to perfection.

- Water Pump: Responsible for maintaining water pressure, it ensures the optimal flow for creating your desired drink.

- Heating System: This element heats water to the precise temperature necessary for brewing and steaming.

- Grinder Mechanism: Designed to grind coffee beans to a consistent size, ensuring flavor extraction and freshness.

- Milk Frother: This unit mixes air with milk to create a creamy foam, ideal for cappuccinos and lattes.

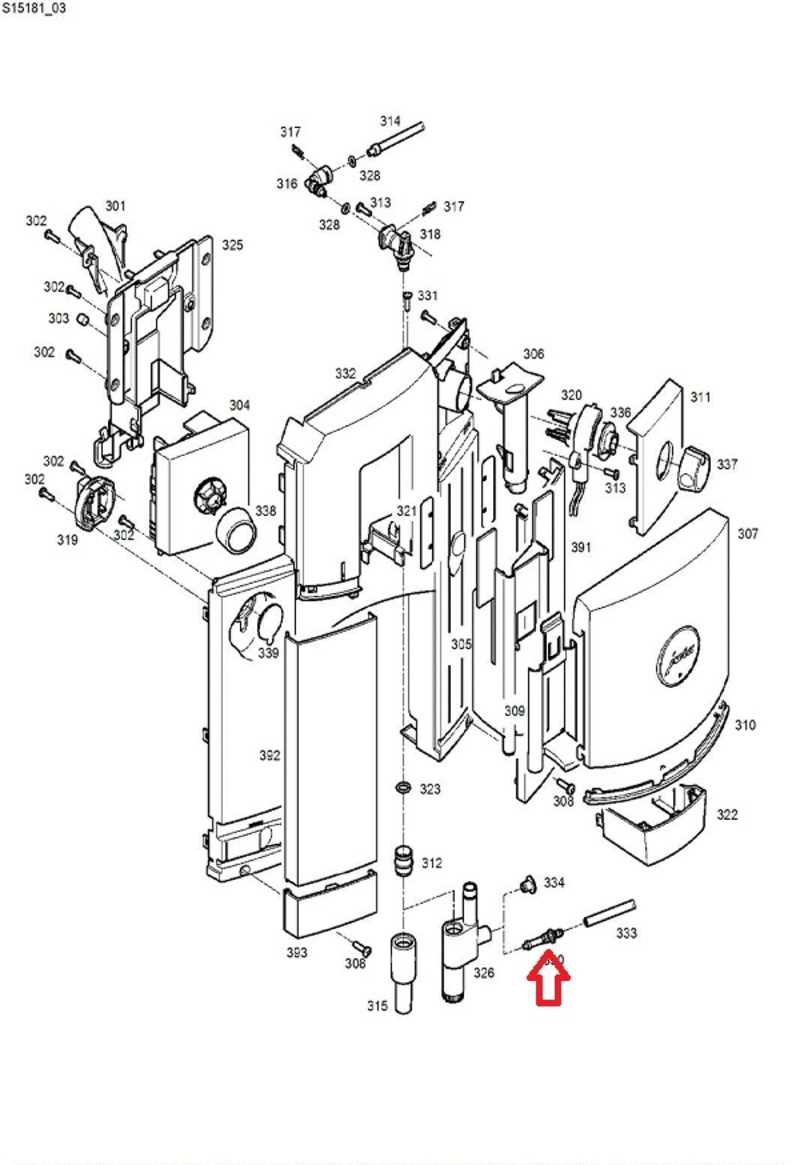

Water System Parts for Jura E8

The fluid management components in this advanced coffee machine ensure precise operation of the brewing process. These elements work together to regulate the flow and purity of water, which is crucial for achieving optimal results in beverage preparation. Understanding the role of each component allows for better maintenance and long-term performance.

Key elements of the fluid system include the mechanisms responsible for filtering water, regulating temperature, and managing pressure during the brewing cycle. Regular upkeep of these components ensures that the quality of water used remains at its peak, contributing directly to the flavor and consistency of the beverages produced.

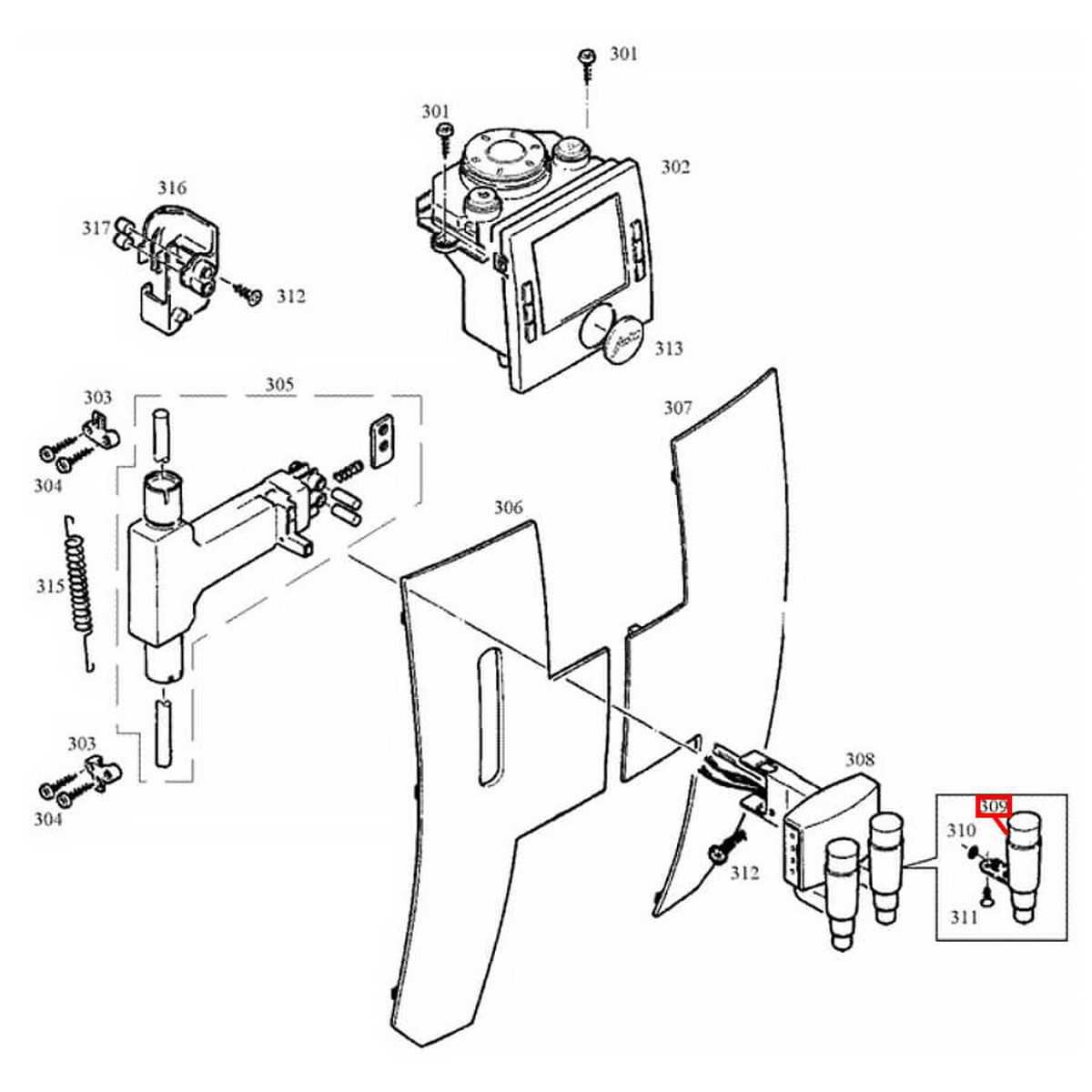

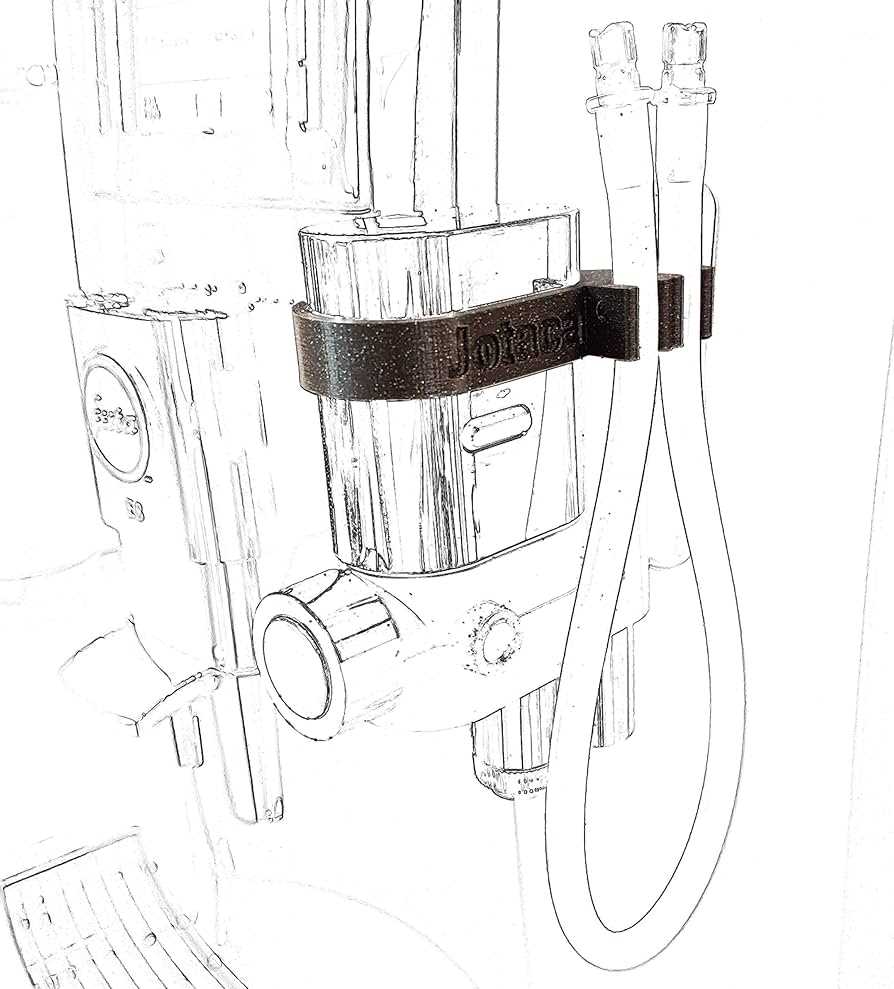

Understanding the Grinder Mechanism

The grinder system plays a crucial role in transforming coffee beans into the fine texture needed for brewing. Its design allows for consistent grinding, which significantly impacts the quality of the final beverage. The process involves precise control over the coarseness of the beans, ensuring a balanced extraction of flavors.

At the core of this mechanism, there are sharp, durable blades that rotate at high speeds, cutting through the beans with precision. The grind size can be adjusted depending on the desired result, providing flexibility in brewing different types of coffee. The structure is engineered for efficiency and longevity, minimizing wear over time.

Maintenance of the grinder is essential to keep it functioning optimally. Regular cleaning prevents residue buildup, ensuring the machine continues to operate smoothly and delivers consistent results. Proper care also extends the lifespan of the components involved in the grinding process.

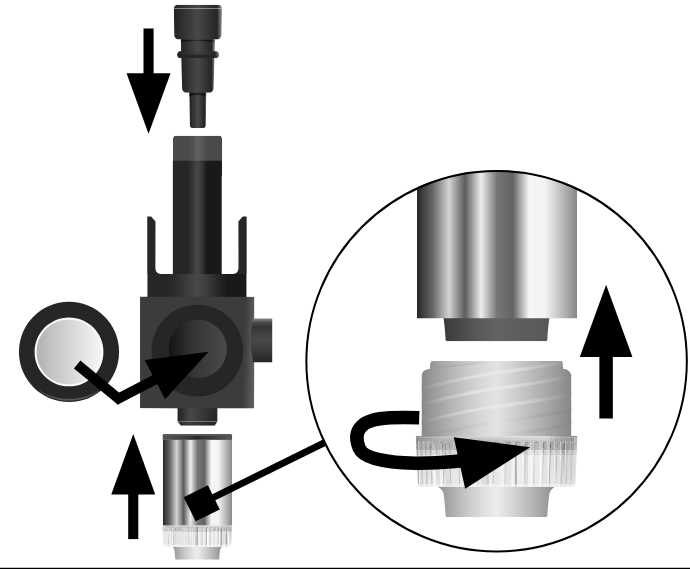

Milk Frother System Components

The milk frothing mechanism consists of several interconnected elements designed to create smooth, creamy foam. Each component plays a specific role in ensuring that milk is efficiently aerated to achieve the desired texture for various beverages. The system is engineered to handle both warm and cold frothing, providing versatility for different drink preferences.

| Component | Function |

|---|---|

| Steam Wand | Directs steam into the milk, heating and frothing it simultaneously. |

| Frothing Nozzle | Controls the flow of air and steam, ensuring a consistent foam texture. |

| Milk Intake Tube | Draws milk into the frothing chamber for aeration. |

| Component | Function |

|---|---|

| Filter Cartridge | Removes chlorine, sediments, and other contaminants from water. |

| Water Reservoir | Stores the filtered water before it is used for brewing. |

| Flow Control Valve | Regulates the water flow through the filtration system. |

| Bypass Valve | Allows water to bypass the filter during maintenance or when not in use. |

Importance of Regular Maintenance

Regular maintenance of the filtration components is essential to ensure they function effectively. This includes timely replacement of the filter cartridge and cleaning of the water reservoir to prevent buildup of bacteria and other unwanted substances.

How the Heating System Works

The heating mechanism in these machines plays a crucial role in ensuring optimal beverage preparation. It is designed to heat water to precise temperatures, which is essential for extracting the best flavors from coffee grounds or tea leaves. Understanding the operation of this system helps in appreciating the intricate engineering that goes into crafting the perfect cup.

At its core, the heating system consists of several key components that work together harmoniously. The water is initially drawn from the reservoir, passing through various filters before entering the heating unit. This unit is responsible for raising the temperature of the water to the desired level, which is determined by the specific beverage settings chosen by the user.

| Component | Function |

|---|---|

| Heating Element | Increases water temperature to desired level. |

| Thermostat | Regulates temperature for consistent heating. |

| Water Pump | Controls water flow through the heating unit. |

| Temperature Sensor | Monitors water temperature for accuracy. |

Once the water reaches the appropriate temperature, it is pushed through the coffee grounds or tea leaves at a controlled pressure. This process is vital for extracting flavors, resulting in a rich and aromatic beverage. Overall, the heating system is a vital aspect of these machines, ensuring that every cup is brewed to perfection.

Cleaning System Parts for Maintenance

Regular upkeep of a coffee brewing apparatus is essential for optimal performance and longevity. The components responsible for the cleaning mechanism play a crucial role in ensuring that the device operates smoothly and efficiently. Understanding these elements can significantly enhance the maintenance process, leading to a consistently great coffee experience.

Key Components of the Cleaning Mechanism

The cleaning system comprises several integral components that work together to facilitate the maintenance process. Each element is designed to tackle specific tasks, such as descaling, residue removal, and overall sanitation. Familiarizing oneself with these components helps users appreciate their importance in prolonging the lifespan of the machine.

Importance of Regular Inspection

Frequent examination of the cleaning elements is vital to prevent malfunctions and ensure that the system functions as intended. Neglecting these components can lead to buildup and operational inefficiencies, adversely affecting the quality of the brewed beverages. Adopting a proactive approach to maintenance will yield long-term benefits.