In the realm of machinery and technical assemblies, comprehending the intricate arrangements of individual elements is essential for effective maintenance and repair. This section aims to explore the essential framework that guides users through the configuration of various components, enhancing both efficiency and functionality.

By delving into detailed visual representations, users can gain valuable insights into the relationships between different units. Such understanding is pivotal for troubleshooting and ensuring optimal performance in diverse applications.

Ultimately, having access to clear and concise illustrations allows for a more profound appreciation of the assembly process, equipping technicians with the knowledge needed to navigate complex systems effortlessly. With this foundation, we can explore the specifics of these configurations in greater detail.

Understanding the Jx75 Parts Diagram

Grasping the intricacies of a mechanical blueprint is essential for effective maintenance and repair. This visual representation allows users to identify individual components and their relationships within a system, facilitating a comprehensive understanding of how everything fits together.

Key Elements to Note

- Component Labels: Clearly marked identifiers help locate specific pieces.

- Connection Points: Understanding where parts link is crucial for assembly and disassembly.

- Scale and Measurements: Accurate dimensions ensure proper fitting and compatibility.

Benefits of Familiarity

- Enhanced Troubleshooting: Quick identification of faulty elements streamlines repairs.

- Improved Efficiency: Knowing where each part resides reduces time spent searching.

- Better Upgrades: Understanding existing components allows for informed enhancements.

Essential Components of the Jx75

This section focuses on the key elements that contribute to the functionality and performance of this specific model. Understanding these components is crucial for maintenance and optimal operation.

Key Functional Parts

Each crucial element plays a significant role in the overall efficiency and effectiveness of the unit. From power systems to control mechanisms, every part is designed to work in harmony.

| Component | Function |

|---|---|

| Engine | Provides the necessary power for operation. |

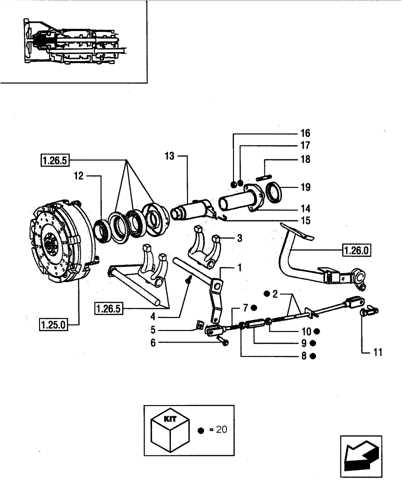

| Transmission | Facilitates the transfer of power to the wheels. |

| Chassis | Offers structural support and stability. |

| Control System | Enables user interaction and adjustments. |

Maintenance Considerations

Regular checks and servicing of these essential components are vital for prolonging the lifespan and enhancing the performance of the machine. Proper attention to each element ensures reliability and efficiency.

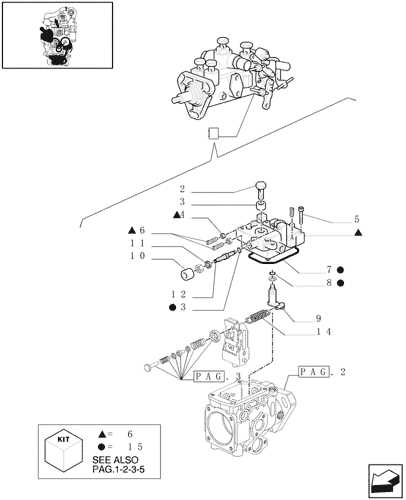

How to Read the Diagram Effectively

Understanding complex visual representations is essential for efficient maintenance and repair. Grasping the layout and interrelationships of components can significantly enhance your ability to troubleshoot and assemble machinery. Familiarizing yourself with the symbols and notations used is the first step toward gaining confidence in navigating these illustrations.

Begin by identifying the key sections of the illustration. Often, these are categorized based on functionality or location within the system. Pay attention to labels, as they provide crucial information about each element, including its purpose and specifications. Use a systematic approach, reviewing each part individually before considering their interactions with others.

Color coding is frequently employed to distinguish between different categories or functions. Take note of these distinctions, as they can provide insights into which components work together or require simultaneous attention. Additionally, refer to any accompanying legends or keys that clarify symbols and terminology, ensuring a comprehensive understanding of the entire schematic.

Lastly, practice makes perfect. Regularly working with these illustrations will help you become more comfortable with their structure and language. Over time, you will find that your ability to interpret these visuals will improve, leading to more effective diagnostics and repairs.

Common Issues with Jx75 Parts

When dealing with machinery components, various challenges can arise that impact performance and longevity. Understanding these common problems can help in troubleshooting and ensuring optimal functionality.

Frequent Challenges

One of the primary issues encountered involves wear and tear, which can lead to decreased efficiency. Additionally, improper installation can result in misalignment, causing further complications in operation.

Prevention and Solutions

Regular maintenance and timely replacements are crucial for mitigating these problems. Ensuring correct installation practices can also significantly enhance the lifespan of these components.

| Issue | Description | Solution |

|---|---|---|

| Wear and Tear | Degradation over time affecting performance. | Routine inspections and timely replacements. |

| Misalignment | Improper setup leading to operational issues. | Ensure correct installation and adjustments. |

| Contamination | Foreign substances causing malfunctions. | Regular cleaning and protective measures. |

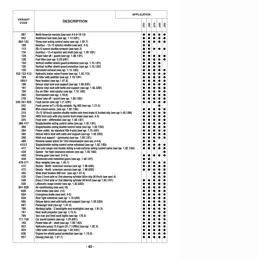

Identifying Replacement Parts Easily

Finding the correct components for your equipment can be a straightforward task when you know where to look. Understanding how to navigate resources and tools available can significantly simplify the replacement process.

Here are some effective strategies to aid in identification:

- Consult manufacturer manuals for specifications and codes.

- Utilize online resources and forums for community support and shared experiences.

- Employ visual aids, such as photographs and charts, to recognize the required items.

In addition, consider these tips:

- Cross-reference similar models to ensure compatibility.

- Keep a record of previous replacements for future reference.

- Contact customer service for expert guidance when in doubt.

By using these methods, you can confidently pinpoint what you need, making your repair or upgrade tasks much smoother.

Maintenance Tips for Jx75 Users

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By adhering to a structured maintenance routine, users can prevent potential issues and enhance overall efficiency. This section outlines key strategies that will aid in the proper care and maintenance of your device.

Routine Inspection

Conducting frequent checks is crucial. Look for any signs of wear and tear, including loose components or unusual noises during operation. Addressing minor issues promptly can save time and resources in the long run.

Cleaning Procedures

Maintaining cleanliness is vital for the smooth operation of machinery. Ensure that all surfaces are free from debris and buildup. Use appropriate cleaning agents to avoid damaging sensitive parts. Regular cleaning helps in preventing malfunctions and enhances the lifespan of your equipment.

Differences Between Jx75 Models

This section explores the variations among different iterations of a specific series, highlighting their unique features and specifications. Understanding these distinctions is crucial for selecting the appropriate model for various applications.

Key Variations

- Performance Levels

- Design Specifications

- Compatibility with Accessories

Model Comparisons

- Base Model: Basic functionalities suitable for entry-level users.

- Enhanced Model: Improved features for advanced performance.

- Premium Model: Ultimate capabilities designed for professional use.

Where to Find Jx75 Parts

Locating essential components for machinery can be a daunting task, yet various avenues can streamline this process. Knowing where to search can save time and ensure you obtain quality items that enhance functionality.

Online Retailers: Numerous e-commerce platforms specialize in machinery accessories. Websites dedicated to tools often provide a wide range of options, complete with customer reviews and competitive pricing.

Local Dealers: Visiting nearby suppliers can be beneficial. These establishments may offer valuable expertise and the advantage of immediate availability, allowing for quicker repairs.

Forums and Community Groups: Engaging with online communities can lead to recommendations and second-hand options. Enthusiasts often share insights and may have leads on where to find rare items.

Manufacturer Resources: Directly contacting the original manufacturer can yield official recommendations for purchasing components, ensuring compatibility and quality assurance.

Auctions and Clearance Sales: Keeping an eye on local auctions and clearance events can uncover hidden gems at reduced prices, making them worth exploring for budget-conscious buyers.

Tools Needed for Jx75 Repairs

Effective maintenance and restoration of machinery require a specific set of instruments to ensure optimal performance and longevity. Having the right tools on hand can significantly streamline the repair process and enhance efficiency.

Basic Hand Tools: Essential items such as wrenches, screwdrivers, and pliers form the foundation for any repair task. These tools facilitate the removal and tightening of various components.

Specialty Equipment: Depending on the complexity of the job, specialized devices like torque wrenches and impact drivers may be necessary. These instruments provide precision and power for more demanding tasks.

Measuring Tools: Accurate measurements are crucial. Calipers and tape measures help ensure that parts fit perfectly, which is vital for maintaining performance.

Safety Gear: Personal protection is paramount. Gloves, goggles, and ear protection safeguard against potential hazards during repairs.

By gathering these essential instruments, you will be well-prepared to tackle any challenges that arise during maintenance tasks.

DIY Repairs Using the Diagram

Engaging in self-repairs can be a rewarding experience, allowing individuals to save costs and enhance their technical skills. By utilizing a detailed layout of components, anyone can navigate the intricacies of their device with confidence. This approach empowers users to understand each element’s function, making it easier to identify issues and apply effective solutions.

To begin your repair journey, familiarize yourself with the layout. Understanding where each element is located simplifies troubleshooting and minimizes guesswork. This foundational knowledge is crucial for effective repairs and ensures that you’re not overlooking any crucial components.

Moreover, having a clear reference aids in organizing your tools and workspace, making the process more efficient. By meticulously following the visual guide, you can ensure that every part is handled correctly, ultimately leading to a successful repair.

In conclusion, armed with a comprehensive overview, even the most complex repairs can become manageable. Embrace the challenge and take pride in restoring your device to its optimal condition.

Expert Advice on Jx75 Maintenance

Proper upkeep of machinery is crucial for ensuring optimal performance and longevity. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency, making it essential for operators to familiarize themselves with best practices and recommendations.

Regular Inspections: Conduct routine checks on critical components. This helps in identifying wear and tear early, allowing for timely replacements or repairs. Pay close attention to moving parts, as they are often the most susceptible to damage.

Fluid Levels: Keeping an eye on lubricants and other fluids is vital. Ensure that all necessary liquids are at the recommended levels and replace them according to the manufacturer’s guidelines. This helps to minimize friction and overheating.

Cleaning: Maintain cleanliness by removing dirt and debris from the equipment. A clean machine operates more efficiently and reduces the risk of component failure due to accumulated grime.

Calibration: Regularly calibrate your equipment to ensure it operates within specified parameters. This not only improves performance but also extends the lifespan of various elements.

Documentation: Keep a detailed log of all maintenance activities, including dates, findings, and actions taken. This record can be invaluable for future reference and helps in identifying patterns that may indicate larger issues.

By adhering to these expert recommendations, operators can significantly improve the reliability and efficiency of their machinery, ultimately leading to enhanced productivity and reduced costs.