The intricate design of machinery often requires a thorough exploration of its individual elements. Each segment plays a crucial role in the overall functionality, making it essential to comprehend how they interconnect and operate together.

By examining the assembly of various components, one can appreciate the meticulous engineering involved. This exploration not only enhances understanding but also aids in effective maintenance and troubleshooting.

Ultimately, having a clear visual representation of these elements fosters greater insight into the machine’s performance. This knowledge can empower users to make informed decisions about repairs and enhancements.

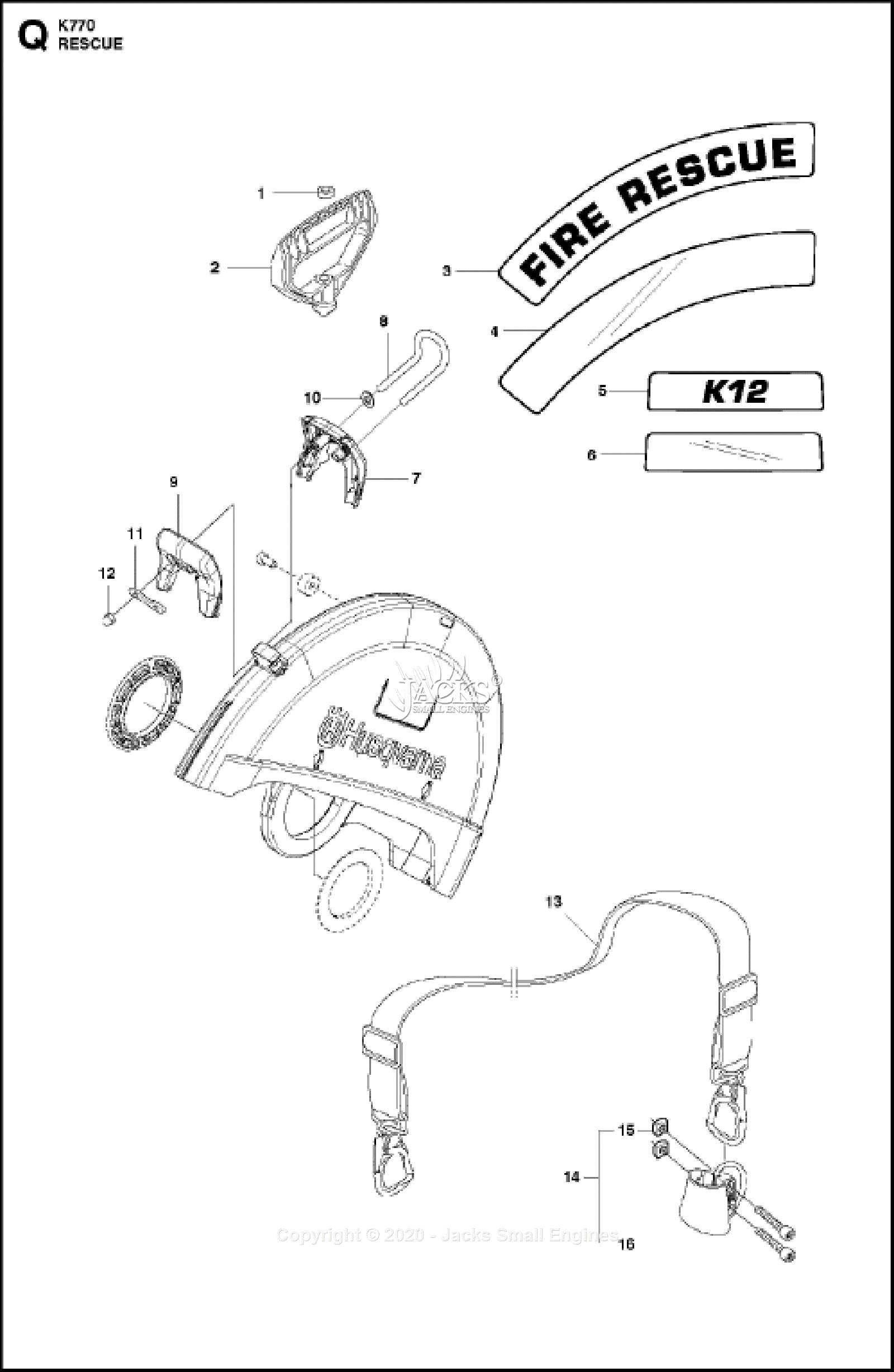

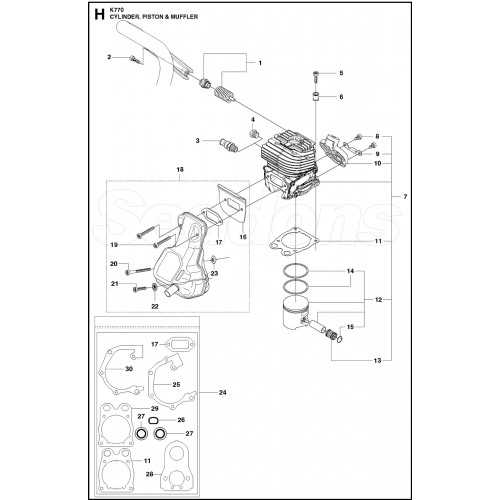

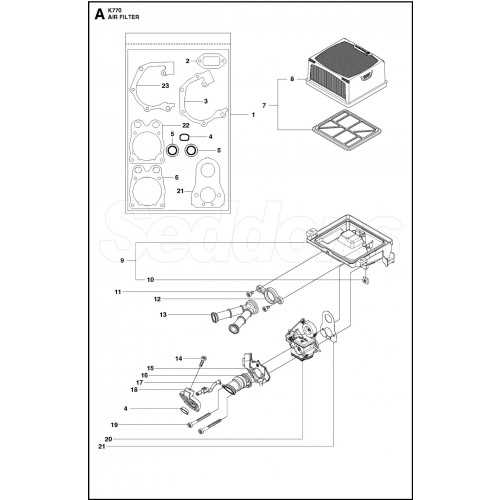

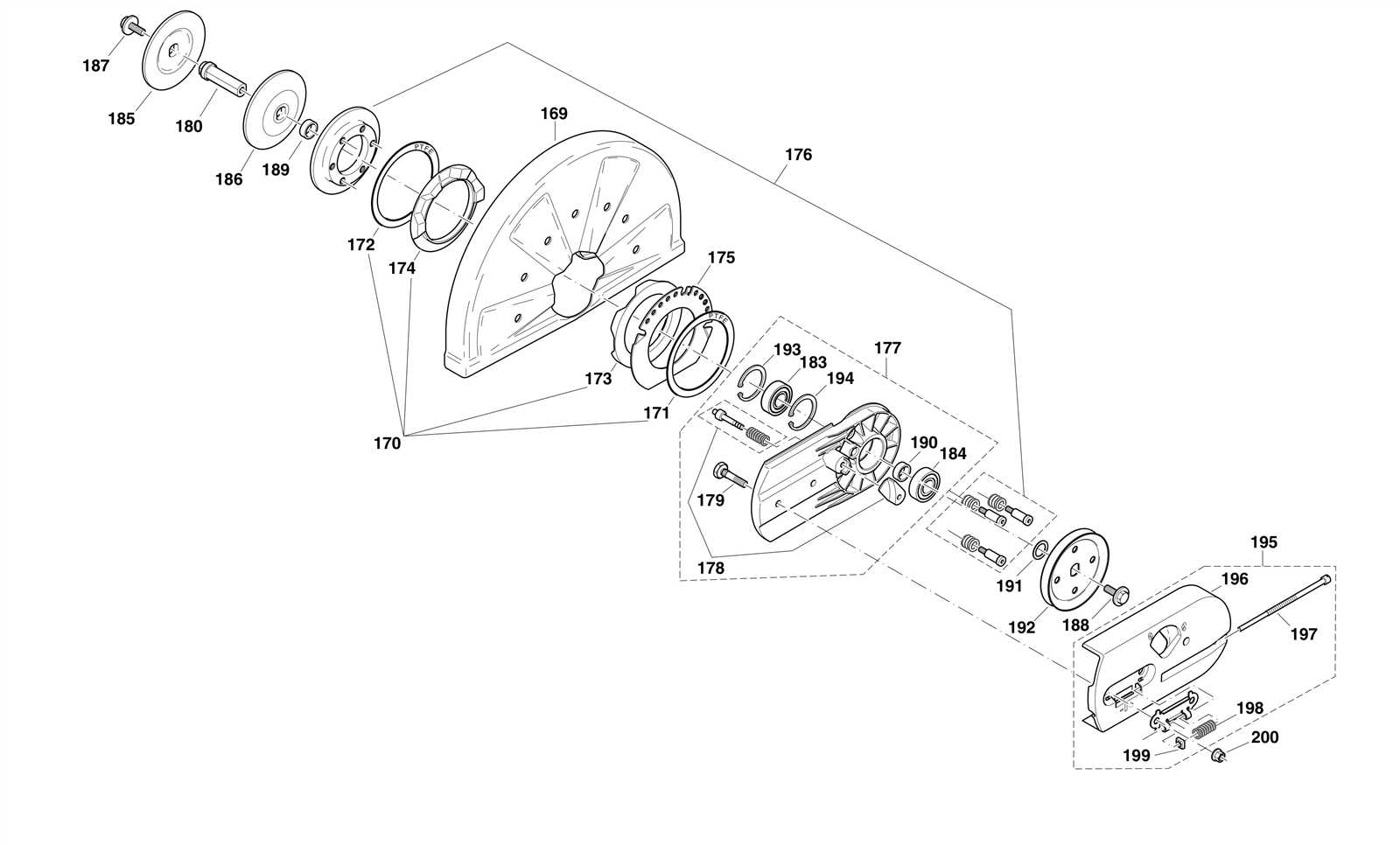

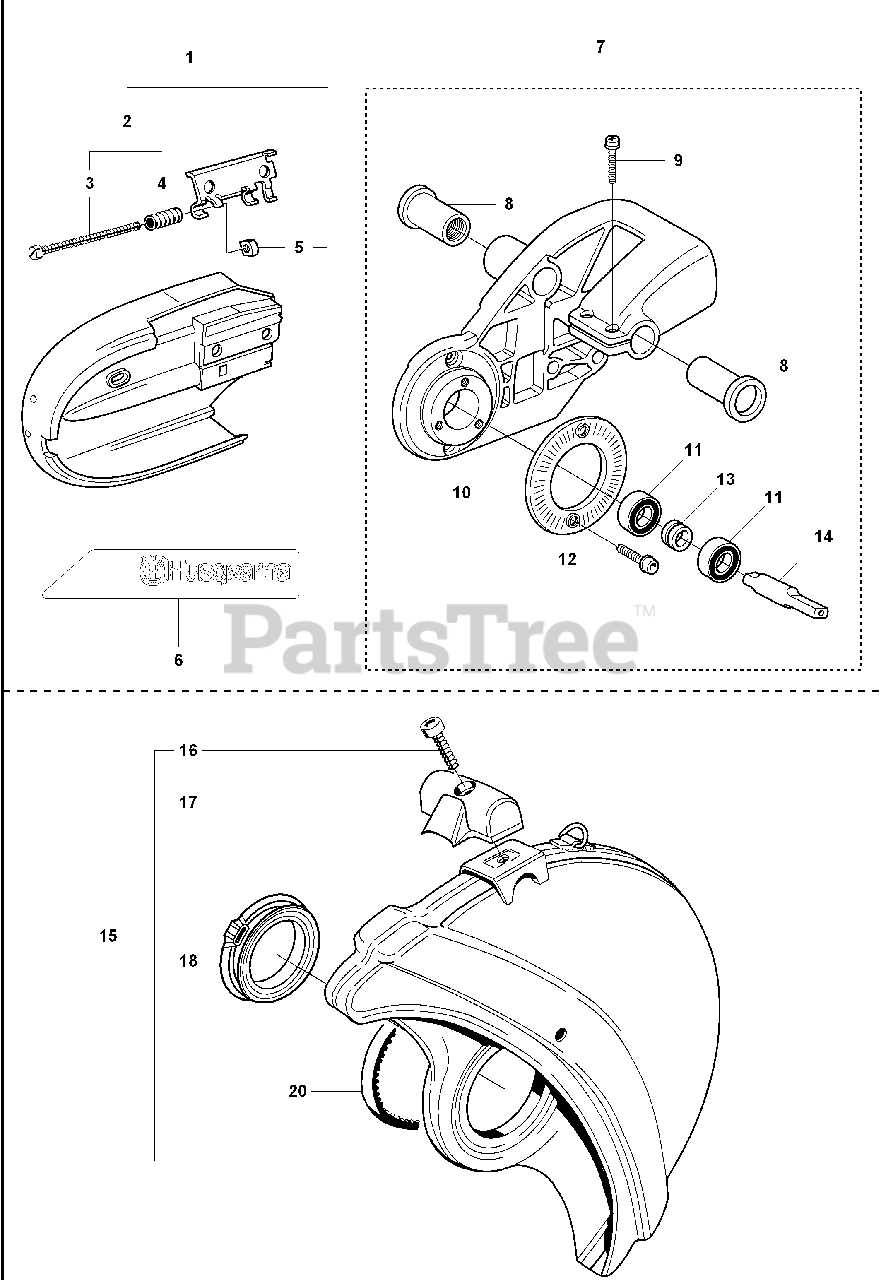

Understanding K770 Parts Diagram

This section aims to clarify the components and their interrelations within a specific mechanical unit. A visual representation serves as a crucial tool for anyone seeking to grasp how various elements work together to achieve optimal performance.

Key Components Overview

Each element plays a vital role in the overall functionality, influencing efficiency and durability. Familiarity with these components allows for better maintenance and troubleshooting.

| Component | Description |

|---|---|

| Engine | Powers the machinery and ensures operational efficiency. |

| Frame | Provides structural integrity and support for all parts. |

| Fuel System | Manages the supply and regulation of fuel. |

| Transmission | Transmits power from the engine to the wheels. |

Importance of Visualization

Understanding how these elements connect is essential for effective troubleshooting and repair. A well-structured visual aid enhances comprehension and facilitates informed decision-making.

Key Components of K770

This section provides an overview of the essential elements that contribute to the functionality and efficiency of the machinery. Understanding these components is crucial for maintenance and optimal performance.

- Engine: The heart of the machine, responsible for providing the necessary power to operate various functions.

- Cooling System: Essential for maintaining optimal temperature levels, preventing overheating during operation.

- Fuel System: Manages the delivery and efficiency of fuel to ensure smooth operation.

- Transmission: Facilitates the transfer of power from the engine to the working components, enabling effective movement.

- Frame: The structural backbone that supports all other components and maintains stability during operation.

In addition to these core elements, several auxiliary systems enhance overall performance:

- Electrical System: Powers all electronic components and ensures reliable operation.

- Hydraulic System: Provides the necessary force for various functions, allowing for precise control and movement.

- Exhaust System: Responsible for directing exhaust gases away from the engine, promoting cleaner operation.

Each of these components plays a vital role, and understanding their functions can help users make informed decisions regarding maintenance and repairs.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that guide technicians and engineers in their work, ensuring accuracy and efficiency in tasks.

Key reasons for utilizing such illustrations include:

- Clarity: These visuals break down complex systems into manageable segments, making it easier to identify each element.

- Efficiency: Quick reference aids streamline the repair process, reducing downtime and improving productivity.

- Accuracy: Detailed visuals help prevent errors by providing precise information on component placement and connections.

- Training: New technicians benefit from clear representations, enhancing their understanding of equipment and promoting safety.

- Documentation: Visual aids serve as valuable records for future reference, aiding in troubleshooting and routine checks.

Incorporating these visual tools into maintenance practices not only enhances operational effectiveness but also extends the lifespan of the machinery, ultimately leading to cost savings and improved performance.

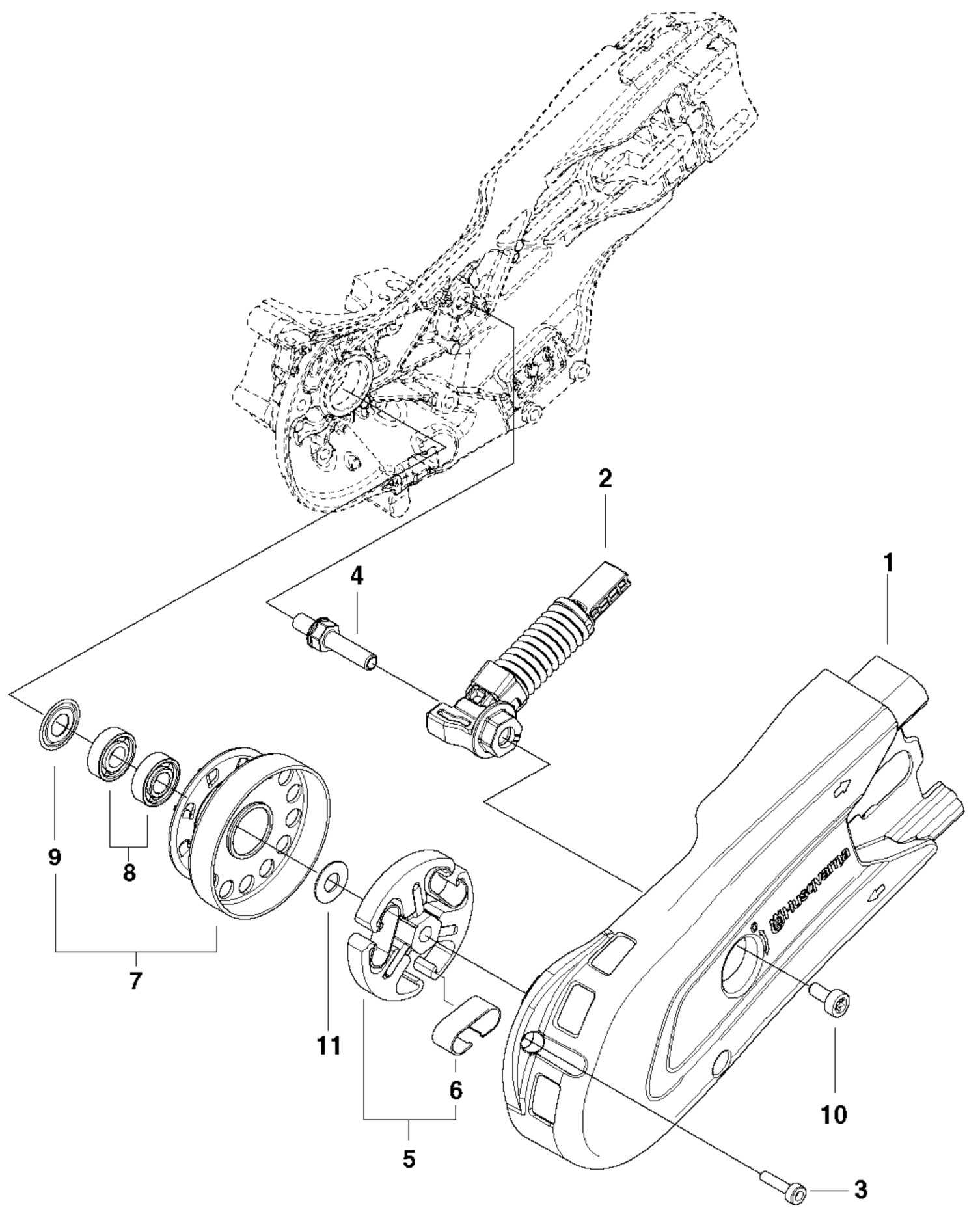

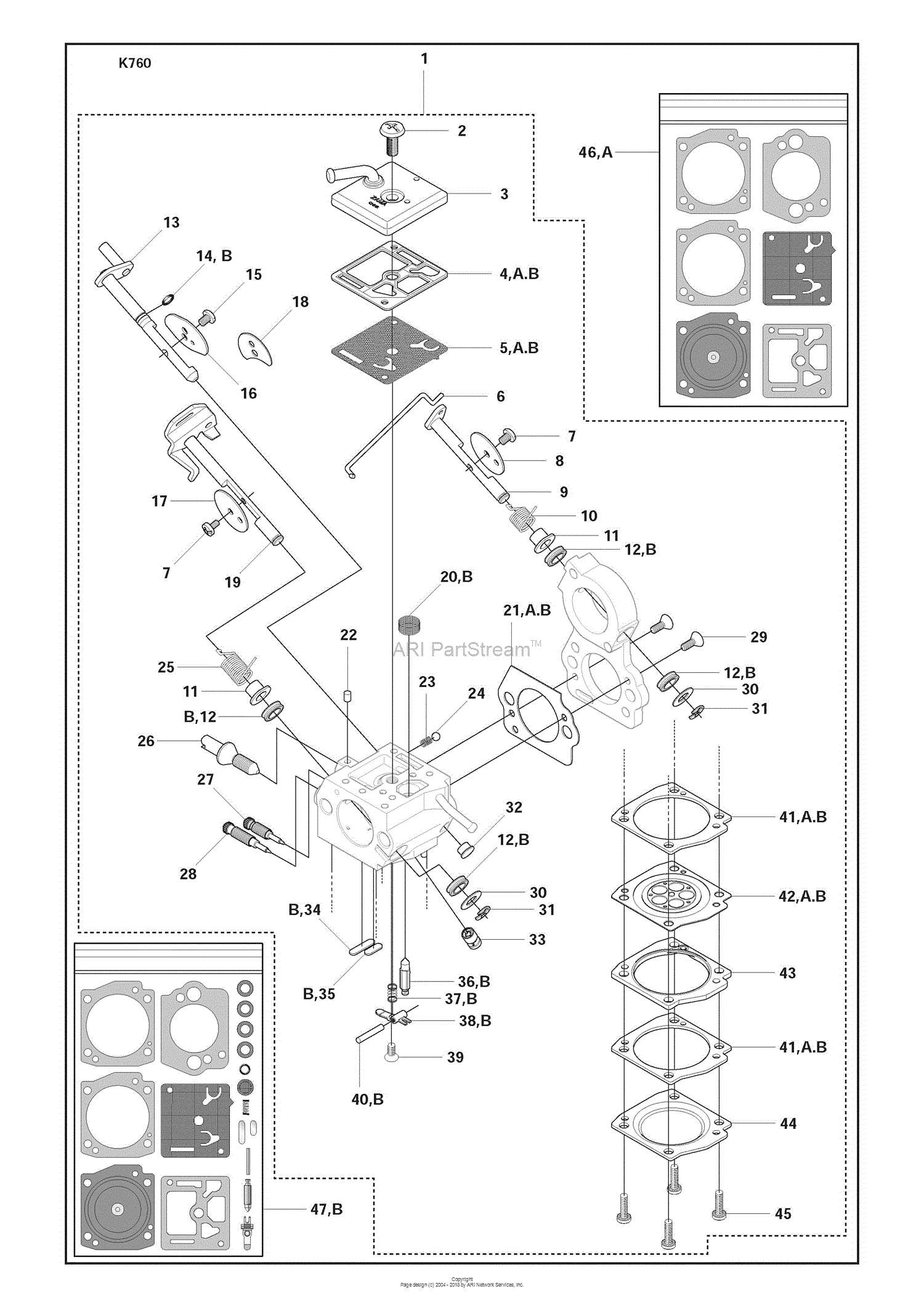

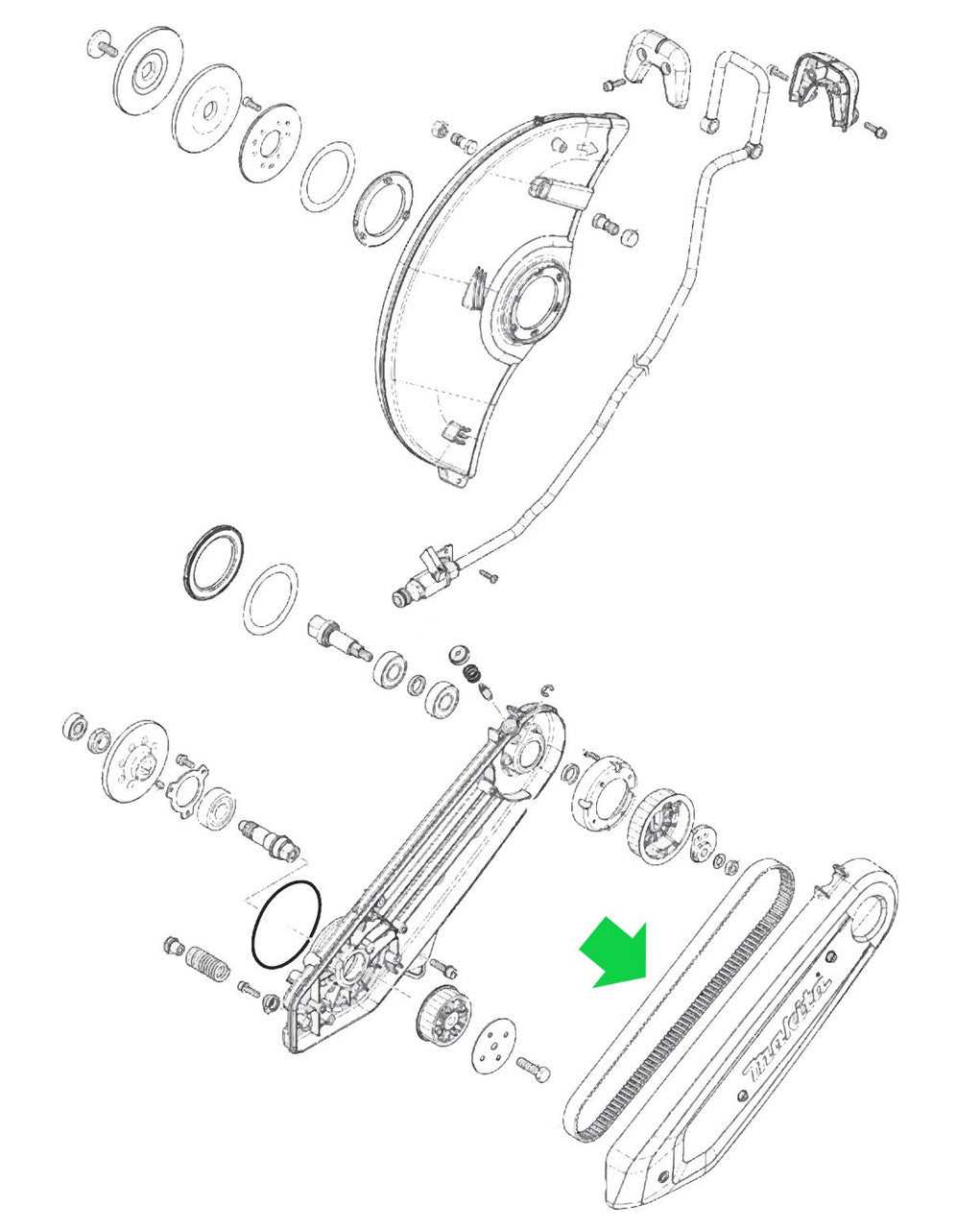

How to Read the Diagram

Understanding a visual representation of components is essential for efficient maintenance and repair. These illustrations provide a clear overview of each element and how they fit together, enabling users to identify and address issues effectively.

Key Elements to Focus On

When examining the visual layout, pay attention to the following aspects:

- Labels: Each section is typically marked, guiding you to the specific parts.

- Connections: Observe how different pieces link, as this reveals the assembly process.

- Numbering: Items may be numbered to correspond with a list, ensuring clarity in identification.

Interpreting the Information

To utilize the illustration effectively, follow these steps:

- Identify the components you need to inspect or replace.

- Cross-reference the labels with the accompanying list for detailed specifications.

- Check the connections to understand the assembly and disassembly process.

| Element | Purpose |

|---|---|

| Labeling | Indicates specific components and their locations. |

| Numbering | Facilitates easy reference to parts in documentation. |

| Connections | Shows how parts interact, aiding in troubleshooting. |

By following these guidelines, you can navigate the visual representation with confidence, ensuring accurate repairs and efficient maintenance.

Common Issues and Solutions

In any mechanical system, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their solutions can help ensure optimal functionality and extend the lifespan of the equipment. Below are some frequently observed issues along with practical remedies.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Overheating | Poor ventilation, excessive load | Check air filters, reduce workload, ensure proper airflow |

| Unusual noises | Loose components, wear and tear | Tighten screws, inspect for damaged parts, lubricate moving elements |

| Loss of power | Clogged filters, fuel issues | Clean or replace filters, check fuel levels and quality |

| Vibrations | Imbalance, misalignment | Inspect for balanced weight distribution, realign components |

| Difficulty starting | Battery issues, ignition faults | Test battery voltage, check ignition system, clean terminals |

Replacing Parts in K770

Maintaining and restoring functionality in machinery often requires the careful substitution of components. Understanding how to effectively execute these replacements is essential for optimal performance and longevity. Each element plays a crucial role, and ensuring compatibility and quality in replacements is vital.

Assessing the Situation: Before initiating any replacement process, it’s important to evaluate the condition of the equipment. Identifying worn-out or malfunctioning elements can help in planning the necessary interventions. Regular inspections can prevent unexpected breakdowns and enhance overall efficiency.

Choosing Quality Components: Selecting high-quality replacements is critical. Inferior parts can lead to further complications and diminish the reliability of the machinery. It is advisable to source components from reputable suppliers who guarantee compatibility and durability.

Step-by-Step Replacement: Once the appropriate components are acquired, follow a systematic approach for replacement. Documenting each step can aid in maintaining clarity and ensuring that every part is correctly installed. Always refer to the manufacturer’s guidelines for specific instructions to avoid errors.

Final Checks: After completing the replacement, conduct a thorough inspection and testing. This ensures that the new elements are functioning as intended and that the overall system operates smoothly. Regular maintenance following replacements can further extend the lifespan of the equipment.

Maintenance Tips for K770

Proper upkeep is essential for optimal performance and longevity of any machinery. Regular attention to various components can prevent costly repairs and ensure smooth operation over time. Here are some key practices to consider.

1. Regular Inspections: Frequently examine all critical elements for wear and tear. Pay close attention to any signs of damage or unusual noise during operation.

2. Cleaning: Keep the equipment free from dust, debris, and contaminants. This helps maintain efficiency and reduces the risk of malfunction.

3. Lubrication: Ensure that moving parts are adequately lubricated. This minimizes friction and extends the life of the equipment.

4. Filter Replacement: Change filters as needed to ensure optimal airflow and performance. Clogged filters can lead to overheating and reduced efficiency.

5. Calibration: Regularly check and calibrate settings to maintain accuracy and effectiveness. Proper calibration is key to achieving desired outcomes.

6. Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommendations for maintenance schedules and procedures. This ensures compliance and maximizes performance.

By implementing these practices, you can enhance the functionality and durability of your equipment, ultimately leading to more reliable service.

Finding OEM vs Aftermarket Parts

When it comes to sourcing components for machinery, understanding the difference between original equipment manufacturer options and alternatives is crucial. Each category presents its own set of benefits and challenges, impacting performance, longevity, and cost. This knowledge empowers users to make informed decisions that align with their specific needs and preferences.

Original components are crafted by the same manufacturer that produced the equipment, ensuring compatibility and adherence to industry standards. These items often come with warranties and are regarded as reliable choices for those prioritizing quality and performance. However, they can come with a higher price tag, which may not always align with budgetary constraints.

On the other hand, alternative options are produced by third-party manufacturers. While they can offer significant savings, the trade-off may involve variations in quality and compatibility. Buyers should carefully assess the reputation of these manufacturers and the experiences of other users to gauge reliability. In some cases, these alternatives may meet or even exceed the performance of the original options, making them an appealing choice for cost-conscious consumers.

Ultimately, the decision between original and alternative items should be guided by individual priorities–be it performance, cost, or availability. Evaluating both options will help ensure that the right components are chosen for the task at hand, enhancing overall satisfaction and efficiency.

Tools Needed for Repairs

When it comes to maintaining and fixing machinery, having the right instruments at your disposal is crucial. A well-equipped toolkit not only streamlines the repair process but also ensures that tasks are completed safely and efficiently. Below is a list of essential tools that will aid in various repair tasks.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts. |

| Screwdrivers | For driving screws of various types and sizes. |

| Wrenches | For gripping and turning fasteners. |

| Pliers | For gripping, twisting, and cutting wire. |

| Hammer | For driving nails or breaking apart components. |

| Torque Wrench | For applying a specific torque to fasteners. |

| Utility Knife | For cutting materials and insulation. |

| Multimeter | For measuring voltage, current, and resistance. |

Equipping yourself with these tools will significantly enhance your ability to perform repairs effectively. Proper maintenance not only extends the life of equipment but also enhances performance and safety.

Upgrades and Modifications Available

Enhancing the performance and functionality of your equipment can significantly improve its efficiency and longevity. Numerous options exist for those looking to customize their machinery, catering to specific needs and preferences.

- Engine Enhancements: Consider performance kits that boost power and fuel efficiency.

- Ergonomic Features: Upgrade handles and grips for improved comfort during use.

- Safety Modifications: Install advanced safety guards and emergency shut-off switches.

- Custom Attachments: Explore various tools and accessories to expand capabilities.

- Technology Integration: Incorporate smart systems for monitoring and diagnostics.

By carefully selecting upgrades, users can delve into the ultimate potential of their machinery, tailoring it to meet specific demands and enhancing overall productivity.

Resources for K770 Owners

For enthusiasts and users of specific models, having access to reliable information and materials is essential for optimal maintenance and enhancement. This section provides valuable tools, guides, and references that can support owners in ensuring their equipment operates efficiently and remains in excellent condition.

One of the primary resources is the official manufacturer’s website, where detailed manuals and user guides are available. These documents often include troubleshooting tips, maintenance schedules, and safety instructions, which are crucial for preserving performance over time.

In addition, online forums and communities dedicated to these models serve as a platform for users to exchange experiences, ask questions, and share solutions. Engaging with fellow owners can lead to valuable insights and recommendations for upgrades or repairs.

Moreover, there are numerous third-party websites that offer aftermarket components and accessories. These resources can be beneficial for those looking to customize or enhance their machinery, providing alternatives that may suit individual preferences or specific needs.

Lastly, instructional videos on platforms like YouTube can be incredibly helpful for visual learners. Many creators produce step-by-step guides that demonstrate various maintenance tasks or repairs, making complex processes more accessible to everyone.