For anyone dealing with maintenance and repair, having access to a clear and detailed breakdown of individual elements of a machine can be extremely valuable. Such references serve as a guide to identifying specific units and understanding how they fit into the overall structure. This knowledge can make troubleshooting and upkeep far more efficient, ensuring that the right solutions are applied to the correct areas.

When dealing with complex equipment, these visual representations provide insight into the inner workings and allow for more informed decisions during both regular maintenance and emergency repairs. They also help pinpoint the exact piece that may require attention, streamlining the entire process of care and replacement.

Access to reliable documentation is essential, as it allows users to efficiently navigate through various sections, ensuring every component is properly understood. Whether you’re a seasoned professional or just beginning to explore the mechanics, having detailed illustrations at your disposal can significantly reduce the time spent on repairs and upgrades.

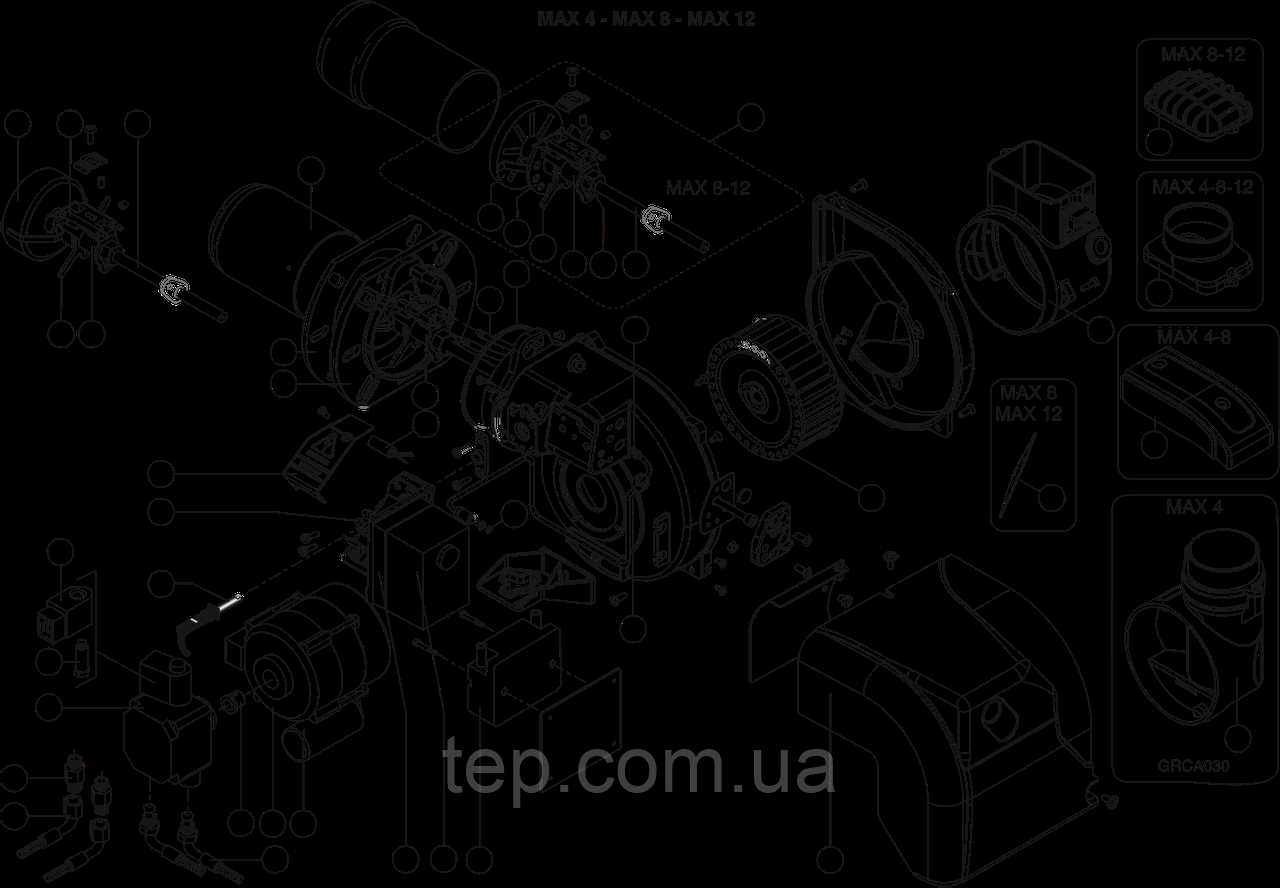

Karcher K4 Key Components Overview

This section provides a detailed look at the essential elements that make up the cleaning system, emphasizing their roles in ensuring optimal performance. Each part is carefully designed to work together, enhancing the overall functionality and efficiency of the device.

Main Structural Elements

- Motor Unit: The driving force behind the machine, delivering the necessary power for effective operation.

- Pump Mechanism: Responsible for generating the required water pressure to tackle dirt and grime on various surfaces.

- Cooling System: Ensures that the device maintains a consistent temperature, preventing overheating during extended use.

Key Functional Attachments

- Spray Lance: Allows the user to adjust the water pressure and flow depending on the cleaning task at hand.

- High-Pressure Hose: Transfers the pressurized water from the core mechanism to the cleaning attachment, ensuring effective delivery.

- Det

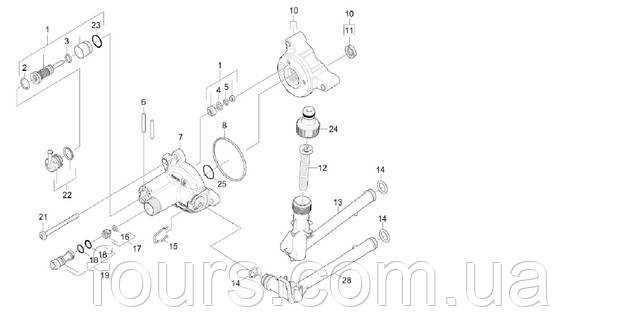

Understanding the Main Pump Unit

The central pump assembly is a crucial component of any high-pressure cleaning system. It is responsible for regulating the flow of water and maintaining the necessary pressure for efficient cleaning. A proper understanding of its structure and functionality is essential for ensuring optimal performance and longevity of the equipment.

- The pump assembly drives the water through the system, controlling both pressure and flow.

- It typically includes several key elements such as seals, pistons, and valves that work together to regulate water pressure.

- Proper maintenance of the pump is necessary to avoid wear and ensure smooth operation over time.

Understanding how each part of the pump functions within the system allows for easier troubleshooting and more efficient repairs when needed. Regular checks and upkeep are vital to prevent leaks or loss of pressure, ensuring reliable and consistent performance.

Hose and Nozzle Compatibility Guide

Understanding the compatibility between hoses and nozzles is crucial for ensuring optimal performance and longevity of your equipment. Different attachments serve specific functions, and choosing the right combination can enhance cleaning efficiency and ensure safe usage.

Types of Hoses and Their Applications

Hoses vary in length, flexibility, and material composition. Some are designed for higher pressure, while others prioritize ease of movement and maneuverability. It is important to select a hose that fits your intended cleaning tasks and equipment requirements.

Nozzle Selection Based on Cleaning Needs

Nozzles come in a range of spray patterns and pressure levels. Whether you’re targeting tough stains or large surface areas, there are specific nozzles that cater to each scenario. Using the appropriate nozzle helps achieve better results and reduces wear on both the hose and equipment.

Hose Type Recommended Nozzles Best Use High-Pressure Hose Narrow Spray Nozzles Heavy-duty cleaning tasks Flexible Hose Wide Spray Nozzles Light to medium cleaning tasks Pressure Regulator Functionality Explained

The pressure regulator is a key component in ensuring consistent water flow during cleaning. It plays a crucial role in maintaining balance by adjusting the water pressure to match the desired intensity for various tasks. This feature allows for safe and efficient operation across different surfaces without causing damage.

How It Works

A pressure regulator functions by controlling the flow of water through a valve. As the water moves through, the regulator adjusts the pressure level, ensuring that it stays within a predetermined range. This mechanism helps prevent sudden spikes in pressure, which could potentially harm the equipment or surface being cleaned.

Adjustable Settings

Most systems with pressure regulators offer adjustable settings, allowing users to fine-tune the water pressure according to their needs. By rotating a control knob or lever, the operator can increase or decrease the flow, making it suitable for delicate or heavy-duty cleaning tasks. The ability to modify pressure on the go enhances the versatility of the cleaning process.

Detergent System Assembly Breakdown

The detergent system plays a crucial role in efficient cleaning by ensuring the proper mix of cleaning solution and water. Understanding how this assembly functions and identifying the key components can help in maintaining and repairing the unit when needed. Each element works together to deliver a precise flow of detergent, ensuring optimal performance during the cleaning process.

The breakdown of this system includes various essential components such as the injection mechanism, valves, and tubing, all designed to handle specific volumes of cleaning fluid. Regular inspection and maintenance of these parts are vital to prevent clogs and ensure smooth operation. Familiarizing oneself with these elements simplifies troubleshooting and prolongs the lifespan of the system.

Water Inlet and Filter Maintenance

Proper upkeep of the water intake and filtration system is essential for ensuring optimal performance and longevity of your equipment. Regular checks and maintenance can prevent clogs and ensure a steady flow of clean water, which is crucial for effective operation.

Regular Inspection

Performing frequent inspections of the water inlet and filter can help identify potential issues before they escalate. Follow these steps:

- Check for any visible damage or wear on the filter.

- Ensure that the inlet is free of debris and blockages.

- Inspect hoses for leaks or cracks that may affect water flow.

Cleaning the Filter

A clean filter is vital for preventing contaminants from entering the system. Here’s how to maintain it:

- Remove the filter from the inlet.

- Rinse the filter under running water to remove dirt and buildup.

- Allow it to dry completely before reinserting it.

- Replace the filter if it shows signs of damage or excessive wear.

Trigger Gun and Connection Parts

This section focuses on the essential components that facilitate the operation and functionality of the spray mechanism. Understanding these elements is crucial for effective maintenance and optimal performance.

Key elements involved in the functioning of the spray gun include:

- Trigger Mechanism: Responsible for activating the flow of water, ensuring user control over the spray intensity.

- Connection Fittings: These parts ensure a secure link between the spray gun and the water source, preventing leaks and ensuring efficient operation.

- Sealings: Essential for maintaining pressure and preventing water from escaping at connection points.

- Nozzle Attachments: Various types can be fitted to adjust the spray pattern and pressure according to specific cleaning needs.

Proper inspection and maintenance of these components are vital to prolong the lifespan of the equipment and enhance cleaning efficiency. Regular checks for wear and tear, as well as ensuring that all connections are secure, will help in achieving optimal performance.

High-Pressure Hose Fittings and Adapters

High-pressure hoses play a crucial role in various applications, ensuring the safe and efficient transfer of water and cleaning agents. The fittings and adapters connected to these hoses are essential for maintaining pressure and preventing leaks. Understanding the types and functions of these components can enhance overall performance and reliability.

Different types of hose fittings and adapters are available, each serving unique purposes. Here are some common categories:

- Quick Connectors: These fittings allow for easy attachment and detachment, facilitating swift setup and storage.

- Threaded Fittings: Designed to create a secure connection, threaded fittings come in various sizes and types, including male and female threads.

- Barbed Fittings: These components feature ridges that grip the hose tightly, ensuring a leak-proof seal.

- Swivel Connectors: Providing flexibility, these fittings allow the hose to rotate without twisting, preventing kinks and pressure loss.

When selecting fittings and adapters, consider the following factors:

- Compatibility: Ensure that the fittings match the hose diameter and threading standards.

- Material: Choose materials resistant to corrosion and wear, such as brass or stainless steel, for durability.

- Pressure Rating: Select fittings designed to withstand the operating pressure of your system.

Proper installation and regular inspection of hose fittings and adapters are essential to maintain their performance and longevity. Regular maintenance can prevent unexpected failures and ensure efficient operation during cleaning tasks.

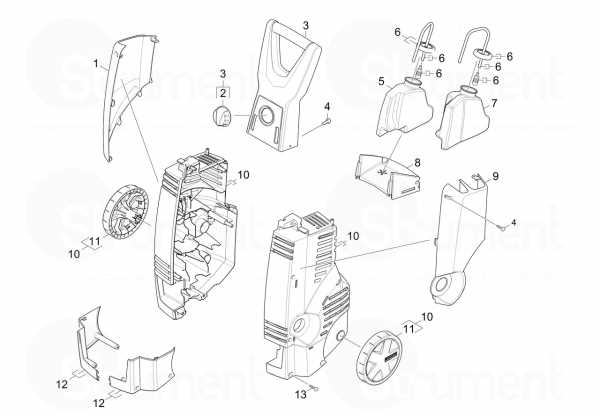

Motor Housing and Electrical Components

The housing that encloses the motor plays a crucial role in the overall functionality of the equipment. It is designed to provide structural integrity while ensuring that internal components are protected from external elements. Understanding the layout and assembly of this enclosure is essential for effective maintenance and repair.

Construction and Materials

The casing is typically made from robust materials that offer durability and resistance to wear. These materials help in shielding the internal electrical components from moisture and dust, which can significantly affect performance. The choice of material contributes to both the longevity of the equipment and the safety of its operation.

Electrical Components and Functions

Within the motor housing, various electrical parts work together to facilitate operation. These include wiring, connectors, and control modules that govern the motor’s performance. Understanding the function of each component is vital for troubleshooting and ensuring optimal functionality. Regular inspections can prevent potential failures and enhance the reliability of the unit.

Safety Valve and Pressure Control Details

The functionality of pressure devices is crucial for maintaining safe operation in various equipment. These components are designed to regulate and manage the flow of fluids, ensuring that pressure levels remain within acceptable limits. Proper understanding of these systems contributes to enhanced safety and performance, preventing potential failures or hazardous situations.

Functionality of the Safety Mechanism

The safety mechanism serves as a protective feature that activates when pressure exceeds predetermined thresholds. This action prevents damage to the equipment and minimizes the risk of leaks or explosions. By automatically releasing excess pressure, this component ensures optimal functioning and extends the lifespan of the machinery.

Pressure Control Features

Effective pressure regulation is achieved through a combination of adjustable settings and responsive design. The control system allows users to set desired pressure levels tailored to specific tasks. This flexibility not only enhances operational efficiency but also ensures user safety by adapting to varying conditions and requirements.

Replacement Parts and Service Tips

Maintaining and servicing your cleaning equipment is essential for optimal performance and longevity. This section provides valuable insights into acquiring necessary components and tips for efficient upkeep, ensuring your device operates smoothly and effectively. Understanding how to handle replacements can save you time and resources while enhancing the functionality of your machine.

Finding Compatible Components

When looking for suitable replacements, it’s important to identify compatible alternatives that match the specifications of your equipment. Local retailers and online marketplaces offer a variety of options. Always verify that the chosen items meet the required standards to avoid compromising performance.

Maintenance Suggestions

Regular maintenance plays a crucial role in the efficiency of your cleaning apparatus. Schedule periodic inspections to identify signs of wear and tear. Cleaning filters and checking hoses for blockages are simple yet effective practices. Following the manufacturer’s guidelines can significantly extend the lifespan of your device.

Accessories to Enhance K4 Performance

To optimize the functionality of your cleaning device, integrating additional components can significantly improve its efficiency and versatility. These enhancements can streamline various tasks, making your overall experience more productive and enjoyable.

Types of Enhancements

Various attachments are available to complement your cleaning equipment. For instance, specialized nozzles can alter water pressure and spray patterns, allowing for tailored cleaning based on the surface being treated. Similarly, surface cleaners can expedite large area cleaning, ensuring uniform results without the hassle of streaking.

Benefits of Upgrading

Utilizing supplementary tools not only boosts performance but also prolongs the lifespan of your equipment. By investing in these enhancements, users can tackle diverse cleaning challenges effectively, from delicate surfaces to heavy-duty tasks. Ultimately, the right accessories can transform your machine into a more powerful cleaning ally.