In the world of heavy-duty vehicles, comprehending the individual elements that contribute to the overall functionality is essential. This section focuses on the intricate network of components that make up these powerful machines, offering insights into their arrangement and interconnections. By familiarizing oneself with these parts, one can enhance maintenance practices and improve operational efficiency.

Each truck consists of numerous vital elements, including the engine, transmission, suspension, and electrical systems. Recognizing how these components interact is crucial for anyone involved in the maintenance or operation of such vehicles. Knowledge of these intricate relationships allows for more informed decisions when it comes to repairs and upgrades, ultimately leading to enhanced performance.

In this exploration, we will delve into various schematics that illustrate how each element fits within the broader system. This understanding not only aids in troubleshooting issues but also empowers operators to make better choices regarding their vehicle’s care. With a comprehensive grasp of these essential components, one can ensure optimal performance and longevity.

Overview of Kenworth T680 Components

This section provides a comprehensive understanding of the various elements that contribute to the functionality and performance of a heavy-duty truck. Each component plays a crucial role in ensuring efficiency, safety, and durability, ultimately affecting the overall driving experience.

The following table outlines the essential features and functions of different parts found in these trucks:

| Component | Description | Function |

|---|---|---|

| Chassis | The main framework of the vehicle. | Supports all other components and provides structural integrity. |

| Engine | The power unit that drives the vehicle. | Generates the necessary horsepower and torque for movement. |

| Transmission | The system that transfers power from the engine to the wheels. | Facilitates gear shifting and speed control. |

| Suspension | The system that absorbs shocks and maintains stability. | Ensures a smooth ride by minimizing bumps and vibrations. |

| Braking System | The mechanism responsible for slowing or stopping the vehicle. | Enhances safety by providing reliable stopping power. |

Engine Specifications and Details

This section provides an overview of the specifications and characteristics of the engine used in heavy-duty trucks, emphasizing performance, efficiency, and reliability. Understanding these details is crucial for optimizing operation and ensuring longevity.

The engine’s design incorporates advanced technology that enhances fuel efficiency and reduces emissions. Key features include a robust turbocharger system, which improves power output while maintaining optimal fuel consumption rates. The engine is engineered to deliver impressive torque, facilitating heavy loads and challenging terrains.

Specifications include:

- Displacement: Varies based on configuration, ensuring adaptability to different applications.

- Horsepower: Typically ranges from 400 to 600, depending on tuning and design.

- Torque: Achieves high torque values, crucial for heavy-duty hauling.

- Fuel Type: Compatible with diesel fuel, designed for maximum performance and efficiency.

Regular maintenance is essential to uphold engine performance and reliability. Proper monitoring of fluid levels and timely replacement of filters will extend the engine’s lifespan and enhance overall vehicle efficiency.

Transmission System Breakdown

The transmission system is a critical component in any heavy-duty vehicle, responsible for converting engine power into usable torque for movement. Understanding the intricacies of this system is essential for effective maintenance and performance optimization. This section delves into the various elements that comprise the transmission system, highlighting their functions and interconnections.

| Component | Description | Function |

|---|---|---|

| Transmission Housing | The outer shell that encloses the transmission components. | Provides protection and structural integrity to the internal parts. |

| Torque Converter | A fluid coupling device that connects the engine to the transmission. | Transfers engine power to the transmission while allowing for slippage during acceleration. |

| Planetary Gear Set | A gear arrangement that enables various gear ratios. | Facilitates smooth shifting and power distribution to the wheels. |

| Clutch Assembly | A mechanism that engages and disengages the engine from the transmission. | Allows for gear changes without stalling the engine. |

| Shift Control Module | A control unit that manages gear selection. | Ensures timely and accurate gear shifts based on driving conditions. |

Each component plays a vital role in ensuring the efficiency and reliability of the transmission system. Regular inspection and maintenance of these elements are crucial for prolonging vehicle lifespan and enhancing performance.

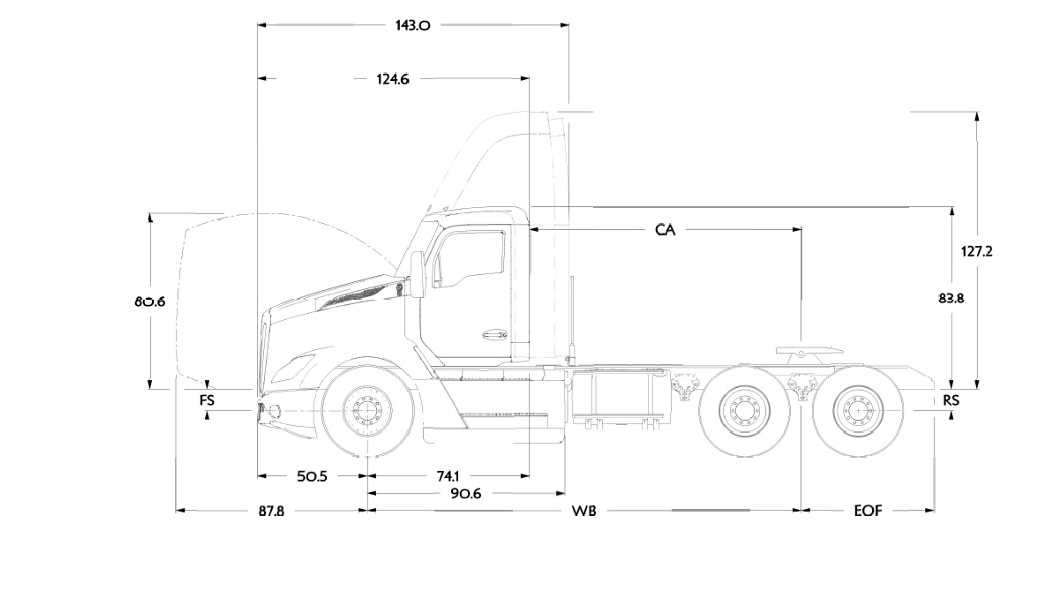

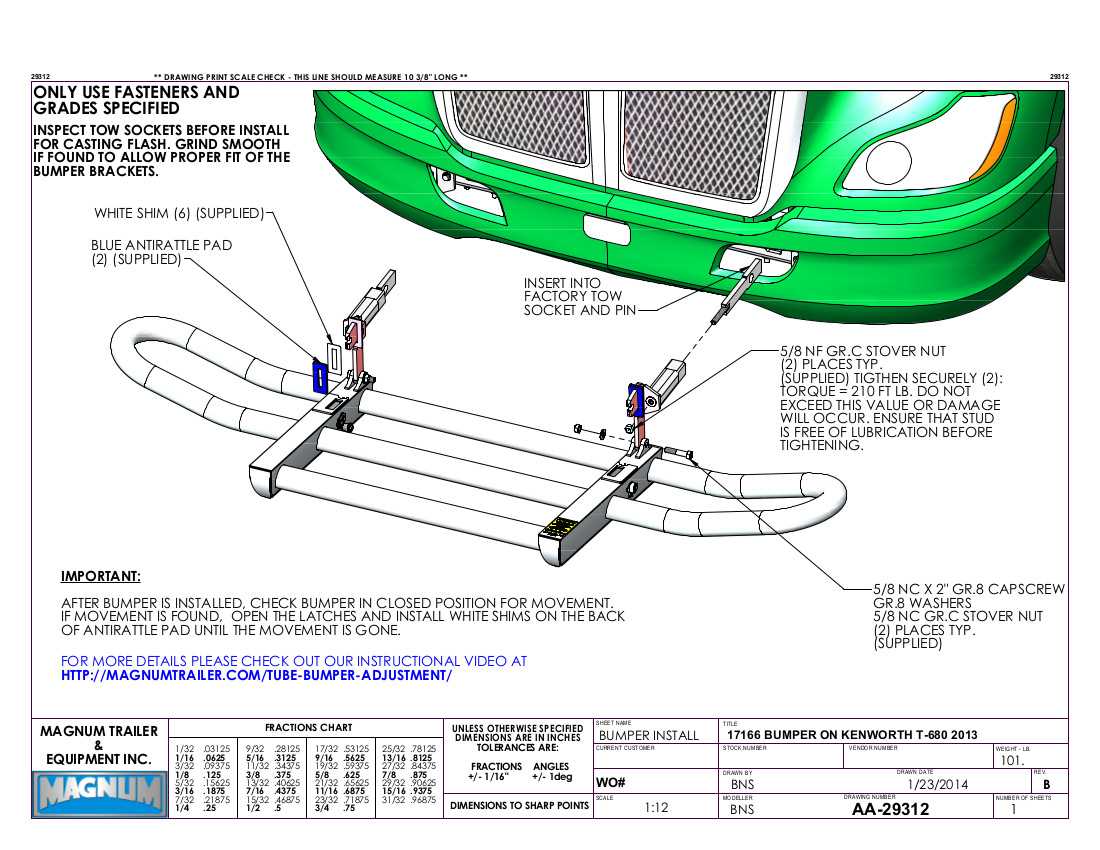

Chassis and Frame Elements

The structural framework of a vehicle plays a crucial role in ensuring stability, strength, and overall performance. This section delves into the fundamental components that comprise the chassis and frame, highlighting their significance in the design and functionality of heavy-duty vehicles.

Key Components of the Chassis

- Frame Rails: The primary structural elements that provide the necessary strength and support for the entire vehicle.

- Crossmembers: Reinforcing elements that connect the frame rails and enhance rigidity.

- Suspension Mounts: Attachments that house the suspension system, ensuring proper vehicle handling and ride comfort.

- Axle Seats: Locations where axles are mounted, crucial for load distribution and stability.

Importance of a Robust Chassis

A well-engineered framework is essential for optimal performance. It not only supports the vehicle’s weight but also absorbs impacts and vibrations, contributing to a smoother ride. Furthermore, a durable chassis is vital for safety, as it ensures that all components remain securely in place during operation.

- Weight Distribution: Properly designed frames aid in even load distribution, enhancing maneuverability.

- Longevity: Sturdy construction materials ensure a longer lifespan, reducing the need for frequent repairs.

- Adaptability: A flexible chassis design allows for modifications and upgrades as necessary.

Electrical System Layout

The electrical system of a vehicle plays a crucial role in ensuring all components function effectively. Understanding the configuration of this system is essential for diagnosing issues, performing maintenance, and ensuring optimal performance. This section will provide a comprehensive overview of the layout, highlighting the connections and components involved in the electrical network.

Component Overview

The electrical architecture includes various elements such as the battery, alternator, fuses, and wiring harnesses. Each of these components has a specific function, working in harmony to deliver power where it’s needed. For instance, the battery serves as the primary power source, while the alternator recharges it during operation. Fuses are crucial for protecting the electrical system from overloads, ensuring safety and reliability.

Wiring Connections

The arrangement of wiring is integral to the efficiency of the electrical layout. Proper routing of cables minimizes interference and potential damage. Color coding is often used to simplify identification and maintenance tasks. Understanding the connections between the components can help in troubleshooting and ensuring that repairs are executed correctly, maintaining the vehicle’s functionality.

Braking System Configuration

The braking system plays a crucial role in ensuring safety and performance in heavy-duty vehicles. This section focuses on the configuration of braking components, highlighting their functions and how they interact to provide optimal stopping power. A well-designed system enhances control and reduces wear, contributing to overall vehicle efficiency.

Various elements contribute to the effectiveness of the braking mechanism. Each component must work in harmony to ensure reliable performance under diverse driving conditions. The following table outlines the key components involved in this system, their descriptions, and their significance in maintaining braking efficiency.

| Component | Description | Importance |

|---|---|---|

| Brake Pads | Friction materials that press against the brake rotor to create stopping power. | Essential for converting kinetic energy into heat, thus slowing the vehicle. |

| Brake Rotors | Discs that the brake pads clamp down on during braking. | Vital for dissipating heat and maintaining consistent braking performance. |

| Calipers | Mechanisms that house the brake pads and apply pressure to the rotors. | Crucial for controlling the force applied to the pads for effective stopping. |

| Brake Lines | Hoses that transmit hydraulic fluid from the master cylinder to the calipers. | Important for ensuring proper fluid transfer and response during braking. |

| Master Cylinder | The component that generates hydraulic pressure when the brake pedal is pressed. | Central to the braking system’s operation, as it initiates the braking process. |

Suspension Features Explained

The suspension system of heavy-duty vehicles plays a crucial role in ensuring stability, comfort, and safety during operation. By effectively managing the impact of road conditions, it enhances the overall driving experience and protects the vehicle’s structure. Understanding the various components and their functions is essential for maintaining optimal performance and longevity.

Key Components of the Suspension System

- Shock Absorbers: These devices dampen the oscillations caused by road irregularities, providing a smoother ride.

- Springs: They support the vehicle’s weight and absorb shocks from the road, maintaining the correct ride height.

- Control Arms: These link the chassis to the wheels, allowing for controlled movement and alignment.

- Sway Bars: These components reduce body roll during turns, enhancing stability.

Benefits of an Efficient Suspension System

- Improved Handling: A well-designed suspension enhances the vehicle’s responsiveness and steering accuracy.

- Increased Load Capacity: The right suspension components allow for better weight distribution and load management.

- Enhanced Comfort: Effective shock absorption contributes to a more pleasant driving experience for operators and passengers.

- Reduced Wear: Proper suspension reduces stress on other vehicle parts, leading to lower maintenance costs.

Cooling System Components

The cooling system is a critical aspect of any heavy-duty vehicle, ensuring optimal engine performance by regulating temperature. This system comprises various elements that work together to maintain the engine’s ideal operating conditions and prevent overheating, which can lead to severe damage.

Radiator

The radiator plays a vital role in dissipating heat generated by the engine. It circulates coolant through its core, allowing airflow to cool the fluid before it re-enters the engine. A properly functioning radiator is essential for maintaining engine efficiency and longevity.

Water Pump

The water pump is responsible for circulating the coolant throughout the engine and radiator. This component ensures that the fluid reaches all necessary areas, facilitating efficient heat exchange. A malfunctioning water pump can lead to inadequate cooling, resulting in overheating and potential engine failure.

Understanding these components and their functions is crucial for effective maintenance and troubleshooting of the cooling system, ultimately enhancing the vehicle’s reliability and performance.

Fuel System Components Overview

The efficiency and performance of a vehicle heavily rely on its fuel delivery system. This system is responsible for managing the flow and quality of fuel, ensuring that the engine receives the necessary resources for optimal operation. Understanding the essential elements of this system can help in maintaining and troubleshooting issues effectively.

Key Elements of the Fuel Delivery System

At the core of the fuel delivery system are several critical components. The fuel tank serves as the storage unit, holding the necessary fuel until it is needed. The fuel pump plays a vital role by transferring the fuel from the tank to the engine, while the fuel filter ensures that impurities are removed, preventing damage to the engine components. Together, these parts work harmoniously to facilitate smooth operation.

Importance of Proper Maintenance

Regular maintenance of the fuel system is crucial for longevity and efficiency. Neglecting this can lead to issues such as poor fuel economy, engine misfires, or even complete engine failure. Employing routine inspections and replacements of the fuel filter and checking the fuel pump functionality can significantly enhance performance and reliability.

Interior and Cabin Layout

The interior space of modern heavy-duty vehicles is designed to enhance comfort and functionality for long hauls. This section explores the various elements that contribute to an optimized driver and passenger experience, focusing on ergonomic design, accessibility, and the integration of advanced technology.

Comfort Features

Cabins are equipped with numerous comfort-enhancing features, including adjustable seating, climate control systems, and sound insulation. These elements work together to create a serene environment that minimizes fatigue during extended journeys. The careful arrangement of controls and displays ensures that drivers can operate the vehicle effortlessly while maintaining focus on the road.

Technology Integration

Modern vehicles often come with a range of technological advancements. Navigation systems, entertainment options, and connectivity features are seamlessly integrated into the cabin layout. This connectivity allows for real-time updates and communication, keeping drivers informed and engaged throughout their travels. The thoughtful placement of these systems further enhances usability and safety.

Wheel and Tire Specifications

This section provides crucial information regarding the specifications of wheels and tires essential for optimal vehicle performance. Understanding the correct dimensions and types can significantly influence handling, safety, and efficiency.

The following are key specifications to consider:

- Wheel Diameter: The diameter of the wheel is vital for compatibility with tire sizes. It affects the overall ride quality and vehicle handling.

- Tire Width: This measurement indicates the width of the tire tread. A wider tire can provide better traction, while a narrower tire can enhance fuel efficiency.

- Aspect Ratio: This ratio reflects the height of the tire’s sidewall relative to its width. A lower aspect ratio generally improves cornering stability.

- Load Rating: This rating indicates the maximum weight the tire can support. It’s critical to choose tires that can handle the weight of the vehicle and its load.

- Speed Rating: This specification defines the maximum speed at which a tire can safely operate. Selecting the appropriate rating is crucial for maintaining safety during high-speed travel.

Properly matched wheels and tires are essential for maximizing performance and ensuring the vehicle operates efficiently. Regular checks and adherence to specified dimensions contribute to overall vehicle longevity and safety.

Maintenance Tips for Parts

Regular upkeep is essential to ensure optimal performance and longevity of your vehicle’s components. Implementing a routine maintenance schedule can prevent unexpected breakdowns and enhance the overall efficiency of the machine.

Here are some practical suggestions to keep your vehicle’s components in excellent condition:

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Fluid Checks | Monthly | Inspect and top off fluids to ensure proper operation. |

| Filter Replacements | Every 10,000 miles | Replace air, oil, and fuel filters to maintain cleanliness. |

| Tire Inspection | Bi-weekly | Check for wear and proper inflation to ensure safety and efficiency. |

| Brake System Review | Every 6 months | Examine pads and rotors for wear to ensure reliable stopping power. |

| Belt and Hose Checks | Every 5,000 miles | Look for cracks or wear and replace as necessary. |

By adhering to these maintenance recommendations, you can prolong the life of your vehicle’s systems, reduce repair costs, and improve its overall reliability.