Exploring the intricate assembly of engine mechanisms is essential for anyone involved in maintenance or repair tasks. A thorough grasp of how various elements interact enhances efficiency and prolongs the lifespan of machinery. This knowledge is crucial for both professionals and hobbyists alike.

In the world of mechanical engineering, visual aids serve as invaluable resources. They help in identifying each individual component, simplifying the complex relationships within the system. By breaking down the construction into manageable sections, one can navigate repairs with greater confidence and accuracy.

To achieve optimal performance, it is vital to understand the specifications and roles of each part. Recognizing where every piece fits within the larger framework allows for precise troubleshooting and effective replacement strategies. This foundational insight ultimately leads to improved functionality and reliability.

Kohler CV740 Overview

This section provides a comprehensive understanding of a robust engine model widely recognized for its performance and reliability. It serves various applications, primarily in outdoor power equipment, showcasing versatility and efficiency in challenging environments.

The key features of this engine include:

- High torque output, enabling powerful performance.

- Durable construction designed to withstand demanding conditions.

- Efficient fuel consumption for extended operation time.

- Easy maintenance, facilitating user convenience.

Engine specifications typically encompass:

- Cylinder configuration for optimal power delivery.

- Cooling system designed to maintain performance stability.

- Ignition system ensuring reliable starts.

- Lubrication system that promotes engine longevity.

Applications of this engine are varied, including:

- Lawn care equipment such as mowers and tractors.

- Utility vehicles for both commercial and residential use.

- Generators providing backup power in emergencies.

Understanding the specifications and features of this engine allows users to appreciate its capabilities and select appropriate applications for optimal performance.

Key Features of the CV740 Engine

This section explores the remarkable characteristics of a robust engine designed for superior performance and reliability. It encompasses innovative technologies and engineering advancements that enhance functionality and efficiency, making it a preferred choice for various applications.

Performance and Efficiency

The engine boasts impressive power output while maintaining fuel efficiency, allowing users to accomplish tasks without frequent refueling. Its design minimizes emissions, contributing to a cleaner environment.

Durability and Maintenance

Constructed with high-quality materials, this engine is built to withstand rigorous use. Routine maintenance is simplified, ensuring longevity and reducing downtime for users.

| Feature | Description |

|---|---|

| Power Output | Delivers high horsepower for demanding tasks. |

| Fuel Efficiency | Optimized consumption for extended operation. |

| Emission Control | Advanced technology for reduced environmental impact. |

| Durable Construction | Engineered for longevity under tough conditions. |

| Easy Maintenance | User-friendly design for hassle-free upkeep. |

Common Applications for CV740

The engine in question is widely utilized in various equipment due to its reliability and performance. Its robust design makes it suitable for numerous applications across different industries.

- Residential lawn mowers: Ideal for maintaining home gardens and lawns.

- Commercial landscaping equipment: Frequently found in professional-grade machines for large-scale projects.

- Utility vehicles: Powers various models designed for transportation and labor in diverse settings.

- Garden tractors: Enhances the efficiency of tilling and other gardening tasks.

Each of these applications benefits from the engine’s durability and efficiency, making it a preferred choice for both personal and commercial use.

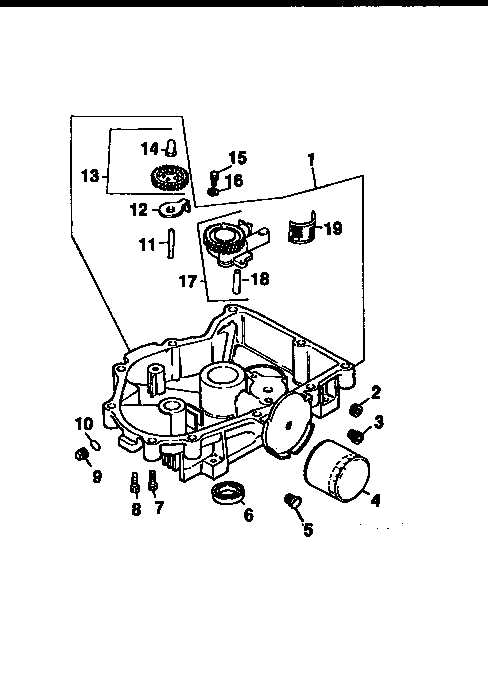

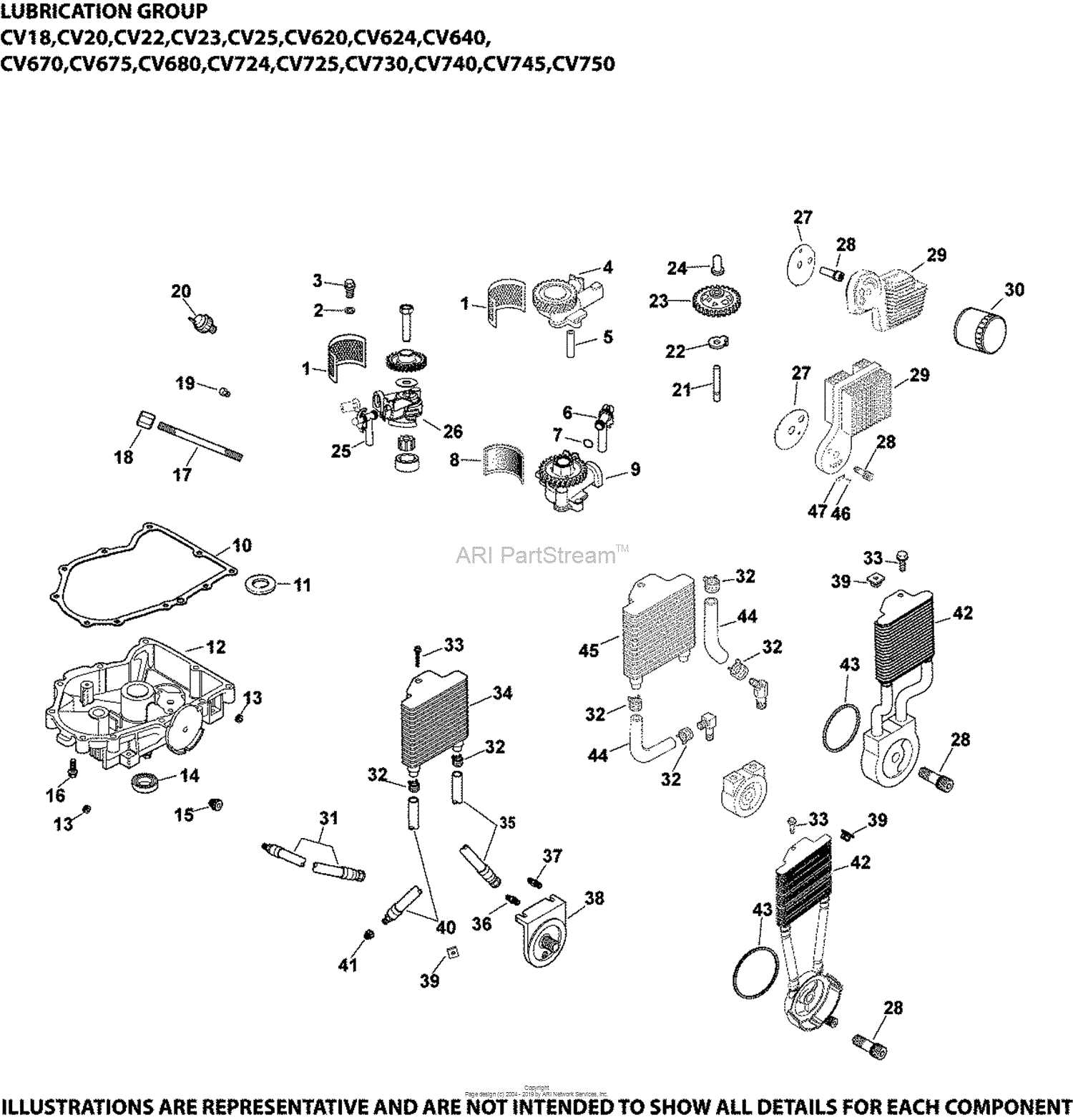

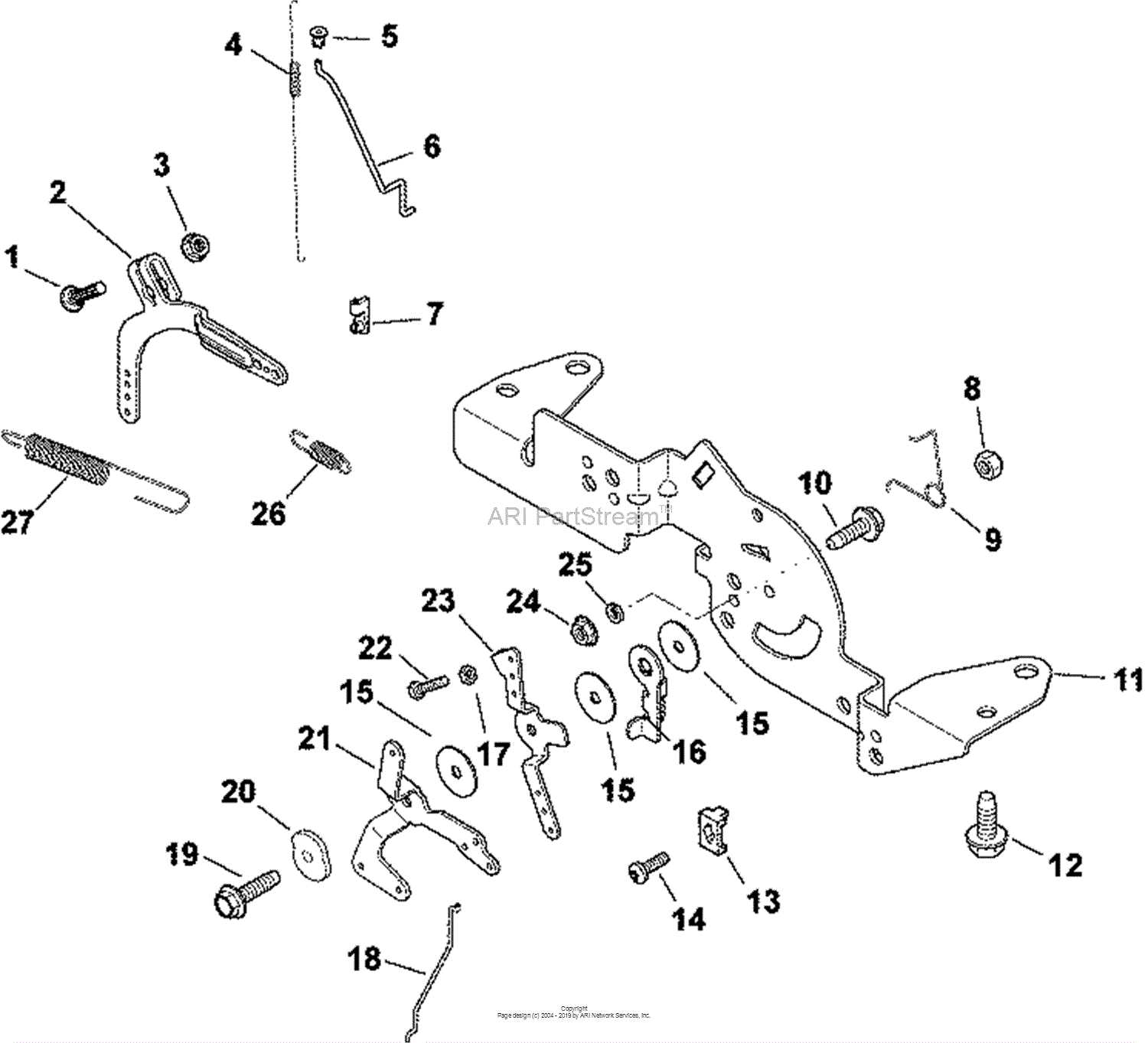

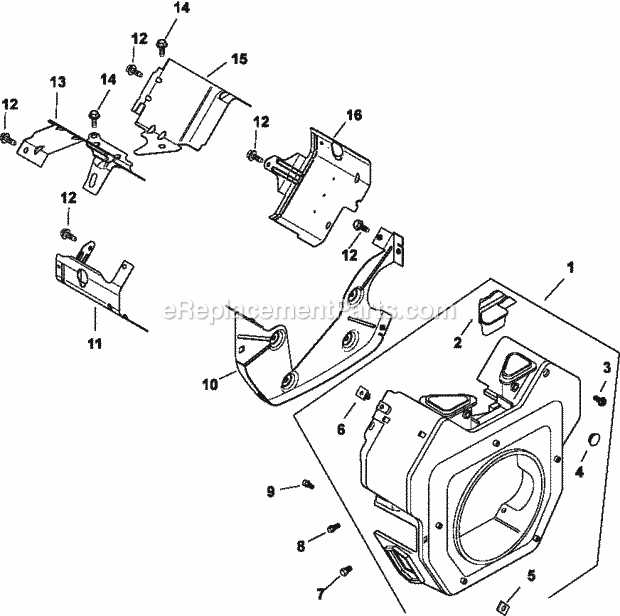

Understanding Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair. They offer a clear overview of individual elements, enabling users to identify and locate each item easily. These illustrations simplify complex systems, making it easier to grasp how everything fits together and functions cohesively.

Benefits of Visual Guides

Utilizing these visual tools enhances efficiency during troubleshooting. Technicians can quickly reference the layout, reducing downtime and improving accuracy. Moreover, they help in understanding the interrelationships between different components, which is essential for effective repairs.

Key Features to Look For

When exploring these representations, focus on the clarity of labels and the detail of each component. Color coding and numbering can further aid in distinguishing parts, making it easier to follow along during assembly or disassembly tasks.

Importance of OEM Parts

Using original equipment manufacturer components is crucial for maintaining the performance and longevity of machinery. These items are specifically designed to fit and function seamlessly within the systems they support. By opting for genuine replacements, users can ensure compatibility, reliability, and optimal operation.

One of the primary advantages of utilizing original components lies in their superior quality. Manufacturers adhere to strict standards, ensuring that each part meets precise specifications. This attention to detail minimizes the risk of premature wear or failure, ultimately saving time and costs associated with repairs.

Additionally, OEM components often come with warranties that provide added peace of mind. In the event of any issues, customers can rely on support from the manufacturer, ensuring that they receive the necessary assistance and replacement if needed. This level of backing is typically not available with generic alternatives.

Furthermore, choosing authentic items helps to preserve the value of equipment. Well-maintained machinery with original components is often more attractive in resale markets, as buyers are assured of its quality and reliability. Investing in genuine items not only benefits current operations but also supports long-term financial interests.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. Such illustrations provide a clear overview of the various elements, their arrangement, and how they interact with one another. Familiarity with these graphics can streamline troubleshooting and enhance the efficiency of replacement procedures.

Identify the Key Sections: Begin by locating the main areas depicted in the illustration. Each segment often corresponds to specific functionalities or assemblies. Recognizing these sections will help you navigate the layout with ease.

Familiarize Yourself with Symbols: Various icons and markings are used to denote different parts and their connections. Take time to review any accompanying legend or key that explains these symbols. This understanding will clarify the roles of each element.

Check the Numbering System: Many visual guides utilize a numbering scheme to identify individual components. These numbers are crucial for locating specific items when searching for replacements or when consulting additional resources.

Review Assembly Sequence: Often, these representations illustrate the order in which parts should be assembled or disassembled. Pay attention to any directional arrows or sequential numbering that indicates the correct procedure.

Cross-reference with Documentation: Finally, it’s beneficial to compare the visual representation with any manuals or technical documents available. This practice ensures that you fully grasp the context and specifics of the components involved.

Essential Tools for Maintenance

Proper upkeep of machinery and equipment requires a selection of fundamental implements that ensure efficiency and longevity. Having the right tools at hand not only simplifies the maintenance process but also enhances the overall performance of the devices being serviced. This section outlines the indispensable tools needed for effective care.

Basic Hand Tools

Among the most crucial instruments are basic hand tools. Wrenches, screwdrivers, and pliers form the foundation of any maintenance toolkit. These versatile items allow for adjustments and repairs, making them essential for addressing minor issues that may arise over time. A well-stocked toolbox should include both metric and standard sizes to accommodate various fasteners.

Diagnostic Instruments

In addition to hand tools, diagnostic instruments play a significant role in maintenance. Tools such as multimeters and pressure gauges provide critical data that can help identify underlying problems before they escalate. Regular use of these devices can prevent costly repairs and downtime, ensuring that machinery operates smoothly.

Identifying Common Issues

Understanding frequent problems associated with small engine machinery can significantly enhance maintenance and repair efforts. Recognizing symptoms early can prevent more extensive damage and ensure optimal performance.

Here are some typical issues you might encounter:

- Starting Difficulties: Engines that refuse to start can be caused by a variety of factors, such as fuel supply issues or electrical faults.

- Excessive Vibrations: Unusual vibrations may indicate misalignment or wear in components, leading to further complications if not addressed.

- Poor Performance: A noticeable drop in power or efficiency can often be traced back to clogged filters or worn-out spark plugs.

- Overheating: Engines running hotter than normal may suffer from cooling system failures or insufficient lubrication.

To effectively troubleshoot these issues, consider the following steps:

- Inspect fuel levels and quality.

- Check electrical connections and battery condition.

- Examine belts and hoses for signs of wear or damage.

- Clean or replace air and fuel filters as necessary.

Regular inspections and maintenance can help mitigate these problems and extend the life of the equipment.

Finding Replacement Parts

Locating the necessary components for your equipment can often be a daunting task. Understanding where to search and what to look for can simplify the process significantly. Here are some effective strategies to assist you in finding the right items for your machine.

- Manufacturer’s Website: Start by visiting the official site of the maker. They often provide detailed catalogs and resources to help you identify the components you need.

- Authorized Dealers: Reach out to authorized sellers. These businesses usually have access to a wide range of inventory and can offer expert advice on compatible options.

- Online Marketplaces: Websites dedicated to selling equipment accessories can be invaluable. Search for the specific model or type to find various options.

Additionally, consider the following resources:

- Repair Manuals: Consult manuals specific to your model. These documents typically contain illustrations and part numbers that are crucial for identification.

- Forums and Communities: Join online forums or social media groups. Engaging with fellow users can provide insights and recommendations based on personal experiences.

- Local Repair Shops: Visit nearby repair shops that specialize in your equipment. Their expertise can guide you to the correct parts and may even offer installation services.

By utilizing these approaches, you can streamline the search for the correct components, ensuring your equipment operates smoothly once again.

Maintenance Tips for Longevity

Ensuring the extended life of your engine requires consistent care and attention. By implementing a few essential practices, you can enhance performance and reduce the likelihood of premature wear and tear.

Regularly check and change the oil to keep internal components lubricated and functioning smoothly. Clean or replace air filters to maintain optimal airflow, preventing debris buildup that can hinder performance. Additionally, inspect spark plugs periodically, as they play a crucial role in efficient combustion.

Keep the cooling system in good shape by regularly checking coolant levels and inspecting hoses for any signs of wear. Tighten any loose fittings to prevent leaks. Lastly, store the engine in a dry, clean environment when not in use, protecting it from moisture and contaminants.

Upgrading Your CV740 Engine

Enhancing the performance of your engine can lead to significant improvements in efficiency and power. Whether you’re aiming for increased torque, better fuel economy, or reduced emissions, there are various modifications available to elevate your machine’s capabilities. Understanding the components that contribute to overall performance is essential for a successful upgrade.

One effective method to boost power output is by upgrading the air intake system. A more efficient intake allows for better airflow, which can enhance combustion efficiency. Additionally, consider investing in a high-performance exhaust system. This upgrade can improve exhaust flow, reducing back pressure and further increasing engine performance.

Fuel delivery is another critical aspect. Replacing the fuel system with higher-flow components can ensure that your engine receives the optimal amount of fuel for combustion. Pairing this with an advanced ignition system can result in improved ignition timing and enhanced overall performance.

Finally, regular maintenance and tuning can also contribute significantly to engine performance. Keeping components like spark plugs, filters, and fluids in optimal condition ensures that your engine runs smoothly and efficiently. By focusing on these areas, you can maximize the potential of your engine and enjoy a more powerful and efficient machine.

Resources for Technical Support

Access to reliable assistance is crucial for maintaining equipment efficiency and longevity. Users often seek comprehensive resources that provide guidance, troubleshooting steps, and essential information to resolve issues effectively. A variety of platforms exist to support users in their quest for knowledge and solutions.

Online Forums and Communities

Engaging with fellow users can be invaluable. Online forums offer a space to share experiences, ask questions, and gain insights from a diverse group of enthusiasts and experts.

Official Documentation

Manufacturer-provided manuals and guides serve as primary resources for understanding the intricacies of your equipment. These documents typically include detailed instructions, specifications, and troubleshooting tips.

| Resource Type | Description |

|---|---|

| Forums | Peer support and shared experiences. |

| User Manuals | Official guides and specifications. |

| Videos | Tutorials demonstrating repairs and maintenance. |

| Customer Support | Direct assistance from the manufacturer. |

Frequently Asked Questions

This section addresses common inquiries regarding the components and assembly of small engine models. Here, you’ll find clarifications on maintenance, replacement options, and troubleshooting techniques to enhance your understanding and facilitate efficient repairs.

What should I do if a part is missing?

If you discover that a component is absent, it’s advisable to consult the manufacturer’s official resources or seek assistance from a certified dealer to ensure you acquire the correct item.

How often should I replace engine components?

Replacement frequency can vary based on usage. Regular inspections are recommended, and any signs of wear should prompt immediate attention to avoid further damage.

Where can I find reliable replacement components?

Trusted suppliers, including authorized dealers and reputable online retailers, offer a wide selection of high-quality replacements to ensure compatibility and performance.

What are the signs that a part needs replacement?

Indicators include unusual noises, decreased performance, or visible damage. Monitoring these signs can help maintain optimal functioning and prolong the life of your equipment.

Can I perform repairs myself?

Many individuals opt for DIY repairs. However, it’s crucial to have a good understanding of the assembly and access to the right tools to ensure a safe and effective process.