When it comes to small engine machinery, having a clear overview of its various elements is essential for maintenance and repair. This section aims to provide insight into the intricate parts that make up these engines, highlighting their roles and interconnections. Familiarity with these components can greatly enhance the understanding of engine functionality.

For those looking to troubleshoot or upgrade their equipment, a detailed representation of the engine’s elements is invaluable. Recognizing each piece’s specific function aids in diagnosing issues and ensures that repairs are carried out effectively. By exploring these intricate details, users can gain confidence in handling their machinery.

Furthermore, having access to comprehensive information about engine components can facilitate informed decision-making when it comes to replacements and upgrades. This knowledge empowers users to choose compatible parts that will enhance performance and longevity, ultimately contributing to a smoother operation of their equipment.

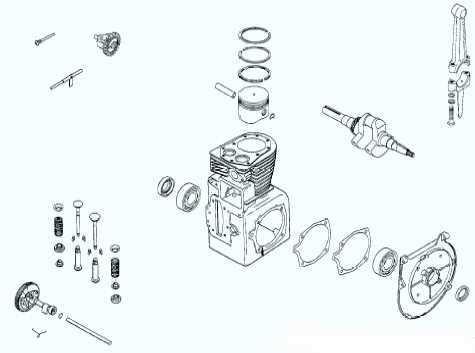

Kohler K341 Parts Diagram

This section provides an overview of the essential components for a specific engine model. Understanding the various elements involved is crucial for maintenance and repairs. Each part plays a vital role in the overall functionality of the system.

Key Components Overview

The following list highlights significant components that contribute to the performance of the engine:

- Crankshaft: Responsible for converting linear motion into rotational motion.

- Piston: Moves up and down within the cylinder, facilitating the combustion process.

- Valves: Regulate the intake of air and fuel, as well as the exhaust of gases.

- Cylinder Head: Houses the combustion chamber and contains various integral components.

- Flywheel: Helps stabilize the engine’s speed and smoothens operation.

Maintenance Tips

Regular maintenance is essential for optimal performance. Consider the following suggestions:

- Inspect components for wear and tear regularly.

- Replace any damaged or worn parts promptly to avoid further issues.

- Keep the engine clean and free from debris to ensure proper airflow.

- Consult the manufacturer’s guidelines for specific maintenance intervals.

Understanding Kohler K341 Engine Components

The engine in question consists of various elements that work together to ensure optimal performance and reliability. Familiarity with these components is essential for effective maintenance and troubleshooting. This section aims to elucidate the key parts and their functions, enabling users to gain a deeper understanding of the engine’s operation.

- Cylinder: The primary chamber where fuel and air mix to generate power.

- Piston: A cylindrical component that moves up and down within the cylinder, converting energy into mechanical work.

- Crankshaft: A shaft that translates the linear motion of the piston into rotational motion, driving the engine’s output.

- Valves: Mechanisms that regulate the intake of air-fuel mixture and the expulsion of exhaust gases.

- Flywheel: A heavy disc that stabilizes the engine’s speed and helps store rotational energy.

Understanding these components and their interactions is crucial for anyone involved in maintenance or repair tasks. Each part plays a vital role in ensuring the engine operates smoothly and efficiently.

- Ignition System: This includes the spark plug and associated components that create the spark necessary for combustion.

- Fuel System: Comprises the fuel tank, lines, and carburetor, which deliver the fuel-air mixture to the engine.

- Cooling System: Helps maintain optimal operating temperatures, preventing overheating and ensuring longevity.

By grasping the function of these essential parts, users can better troubleshoot issues, perform repairs, and ensure the engine remains in peak condition.

Key Parts of the Kohler K341

The engine consists of several crucial components that work together to ensure efficient operation and reliability. Understanding these elements can aid in maintenance and repair, enhancing the longevity and performance of the machinery.

Essential Components

Crankshaft: This vital piece converts linear motion into rotational motion, enabling the engine to function smoothly.

Cylinder: The cylinder houses the combustion process, playing a critical role in generating power.

Supporting Elements

Ignition System: This system is responsible for starting the engine by creating a spark that ignites the fuel-air mixture.

Fuel System: This component ensures that the appropriate fuel mixture reaches the combustion chamber, promoting efficient operation.

Visual Reference for K341 Parts

This section aims to provide a comprehensive visual guide to the components of the engine in question. By illustrating various elements, users can better understand the assembly and maintenance processes.

Understanding the layout and functionality of the engine’s elements can significantly enhance repair efficiency. Below are key categories of components that are typically included:

- Fuel System:

- Carburetor

- Fuel tank

- Fuel lines

- Ignition System:

- Spark plug

- Ignition coil

- Flywheel

- Cooling System:

- Cooling fins

- Fan blade

- Shroud

- Lubrication System:

- Oil filter

- Oil pump

- Oil pan

For effective troubleshooting, it is essential to recognize each part’s role. Identifying issues can become more straightforward with a clear reference to each component’s appearance and location.

How to Use the Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This illustration serves as a valuable tool, allowing users to identify various elements and their relationships within a system. Familiarizing oneself with this resource can significantly enhance the repair process.

Step 1: Begin by examining the layout. Each segment is typically labeled, offering insights into the function and position of individual pieces.

Step 2: Cross-reference the labels with the accompanying list to locate specific items. This ensures you have the correct replacement components for your needs.

Step 3: Take note of any special instructions or notes provided in the illustration. These can highlight important details, such as assembly order or alignment requirements, that may be crucial for successful repairs.

By leveraging this visual guide, you can navigate the complexities of repairs with confidence and efficiency.

Common Issues with K341 Parts

Many users encounter typical challenges when dealing with specific components in their engines. These problems can lead to decreased performance and efficiency, making it crucial to understand the common pitfalls associated with these vital parts.

Frequent Malfunctions

Some of the most prevalent malfunctions include difficulty in starting the engine, unusual noises during operation, and overheating. Addressing these issues promptly can prevent further damage and ensure optimal performance.

Maintenance Tips

Regular upkeep can significantly extend the lifespan of the engine’s components. Key practices include checking for wear and tear, ensuring proper lubrication, and replacing worn parts as necessary to maintain smooth operation.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Starting Problems | Weak battery, faulty ignition | Check battery voltage, replace spark plugs |

| Unusual Noises | Loose components, lack of lubrication | Tighten fittings, apply appropriate oil |

| Overheating | Blocked air vents, low coolant levels | Clear vents, top up coolant |

Maintenance Tips for Kohler K341

Regular upkeep is essential for ensuring the longevity and optimal performance of your engine. By following a systematic approach to maintenance, you can prevent common issues and enhance efficiency. This section outlines crucial recommendations that will help you keep your machinery in excellent condition.

Routine Checks and Care

It is vital to conduct frequent inspections of the engine components. Look for any signs of wear or damage, paying particular attention to belts, filters, and hoses. Keeping these elements clean and in good repair can significantly reduce the likelihood of unexpected breakdowns.

Fluid Maintenance

Maintaining the appropriate levels of lubricants and coolants is critical. Regularly check oil levels and replace it as needed to ensure smooth operation. Likewise, monitor the coolant to prevent overheating, which can cause severe damage over time.

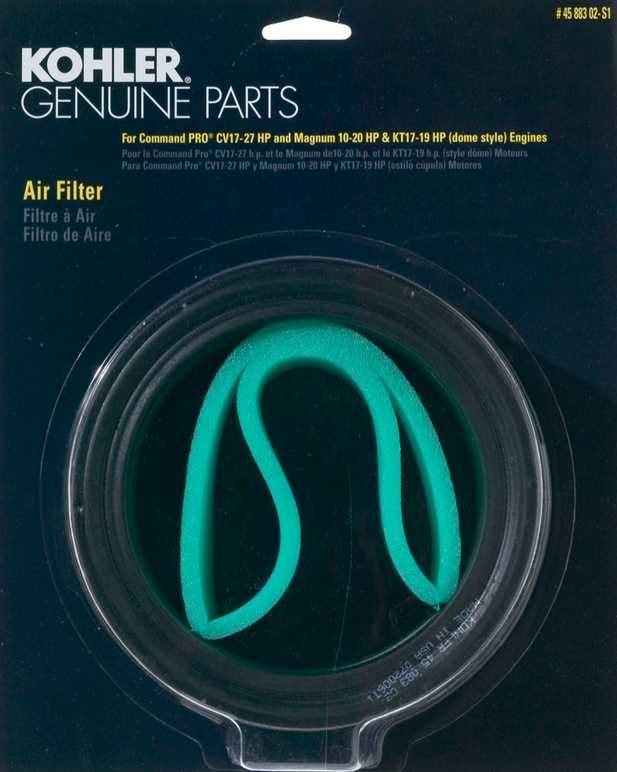

Replacement Parts for Kohler K341

When maintaining your engine, having access to the right components is essential for optimal performance. Whether you’re looking to replace worn-out elements or enhance functionality, understanding the available options is crucial.

Several key components may require attention over time. Below is a list of common replacements that can help restore efficiency and reliability:

| Component Name | Description | Recommended Brand |

|---|---|---|

| Fuel Filter | Filters contaminants from the fuel to ensure smooth operation. | Generic |

| Air Filter | Prevents dirt and debris from entering the engine, prolonging its life. | OEM |

| Spark Plug | Ignites the fuel-air mixture, essential for engine starting and performance. | Champion |

| Oil Filter | Removes impurities from the engine oil, maintaining cleanliness. | WIX |

| Gasket Set | Ensures proper sealing between engine parts to prevent leaks. | Generic |

It’s advisable to consult your manual or a trusted expert to ensure compatibility with your specific model. Investing in high-quality replacements will lead to improved performance and longevity.

Where to Find K341 Parts

Locating the necessary components for your engine can be a straightforward process if you know where to look. Various sources offer a range of options, from local retailers to online platforms, making it easier for you to find what you need.

Local Retailers

Visiting nearby hardware stores or specialized machinery shops is a great first step. These locations often carry essential items for various engines and may even have knowledgeable staff who can assist you in identifying compatible components.

Online Platforms

Exploring e-commerce websites can provide a wider selection and often better pricing. Websites dedicated to machinery supplies usually feature detailed descriptions and customer reviews, which can aid in making informed decisions. Additionally, forums and online communities related to machinery maintenance can offer valuable recommendations and links to trusted suppliers.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that can enhance the performance and longevity of your machinery. These components are specifically designed to fit perfectly and function optimally with your equipment, ensuring reliable operation and reducing the risk of malfunctions.

Quality Assurance

OEM components are manufactured to meet strict quality standards, providing assurance of durability and efficiency. Unlike aftermarket alternatives, these components undergo rigorous testing and quality control processes, ensuring they perform as expected in various conditions.

Compatibility and Reliability

Using original components guarantees compatibility with your machinery, which leads to enhanced reliability. When all parts work seamlessly together, the overall system functions more effectively, minimizing downtime and costly repairs. Investing in OEM components is a proactive approach to maintaining the efficiency of your equipment.

Upgrades for Kohler K341 Performance

Enhancing the efficiency and functionality of small engines can lead to significant improvements in their overall performance. Various modifications can be implemented to maximize power output, improve fuel efficiency, and ensure smoother operation. Below are several effective upgrades to consider for optimizing engine performance.

- Air Intake Improvements:

Upgrading the air intake system can increase airflow, leading to better combustion. Consider installing a high-performance air filter to boost engine efficiency.

- Exhaust System Enhancements:

A performance exhaust system can reduce back pressure, allowing exhaust gases to exit more freely. This modification can improve horsepower and torque.

- Carburetor Tuning:

Adjusting or replacing the carburetor can enhance fuel delivery and atomization. This change can lead to a more responsive throttle and improved acceleration.

- Upgraded Ignition System:

Investing in a high-performance ignition system can result in better spark delivery, leading to more efficient combustion and increased power.

- Performance Camshaft:

Replacing the camshaft with a performance variant can alter the timing and lift of the engine’s valves, resulting in improved airflow and overall efficiency.

Implementing these upgrades can significantly enhance the performance of your small engine, making it more powerful and efficient for various applications.

Safety Considerations When Repairing

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Adopting proper precautions and following best practices can significantly reduce risks while working on machinery. This section outlines key safety measures to keep in mind during repair activities.

Personal Protective Equipment

Wearing appropriate gear is essential for safeguarding against potential hazards. Consider the following items:

- Gloves: Protect hands from sharp objects and chemicals.

- Safety Goggles: Shield eyes from debris and harmful substances.

- Hearing Protection: Prevent damage from loud noise exposure.

- Steel-Toed Boots: Offer foot protection from heavy falling items.

Work Environment Safety

Creating a safe workspace is vital to facilitate effective repairs. Follow these guidelines:

- Clear Clutter: Keep the area tidy to avoid tripping hazards.

- Proper Lighting: Ensure adequate illumination for detailed work.

- Ventilation: Maintain airflow to prevent inhalation of harmful fumes.

- Emergency Plan: Familiarize yourself with exit routes and first aid procedures.

By adhering to these safety considerations, you can ensure a safer and more efficient repair experience.

Resources for Kohler K341 Owners

For individuals owning a particular engine model, having access to reliable information and helpful materials is crucial for proper maintenance and efficient operation. This section aims to provide valuable resources that can assist users in understanding their machinery better and ensuring optimal performance over time.

Manuals and Documentation

Owners can find a variety of manuals that cover essential aspects such as operation guidelines, troubleshooting tips, and maintenance schedules. These documents are typically available in both digital and print formats, allowing for convenient access and reference.

Online Communities and Support Groups

Engaging with fellow enthusiasts and experts in online forums can be an excellent way to gain insights and solutions to common challenges. These platforms often provide a wealth of shared experiences and advice tailored to specific needs.

| Resource Type | Access Method | Notes |

|---|---|---|

| Manuals | Manufacturer’s Website / Online Retailers | Check for PDF versions for easy download |

| Forums | Online Communities | Search for active groups related to your engine |

| Videos | YouTube / Educational Platforms | Tutorials available for visual learning |