This section aims to provide a comprehensive overview of the layout of essential machinery elements, focusing on their organization and interrelations. Understanding the configuration of various components is crucial for effective maintenance and troubleshooting, enabling users to maximize the efficiency of their equipment.

By exploring the arrangement of these critical elements, operators can gain valuable insights into how each part functions within the overall system. This knowledge is not only beneficial for routine upkeep but also enhances the ability to identify potential issues before they escalate, ensuring smoother operations in the long run.

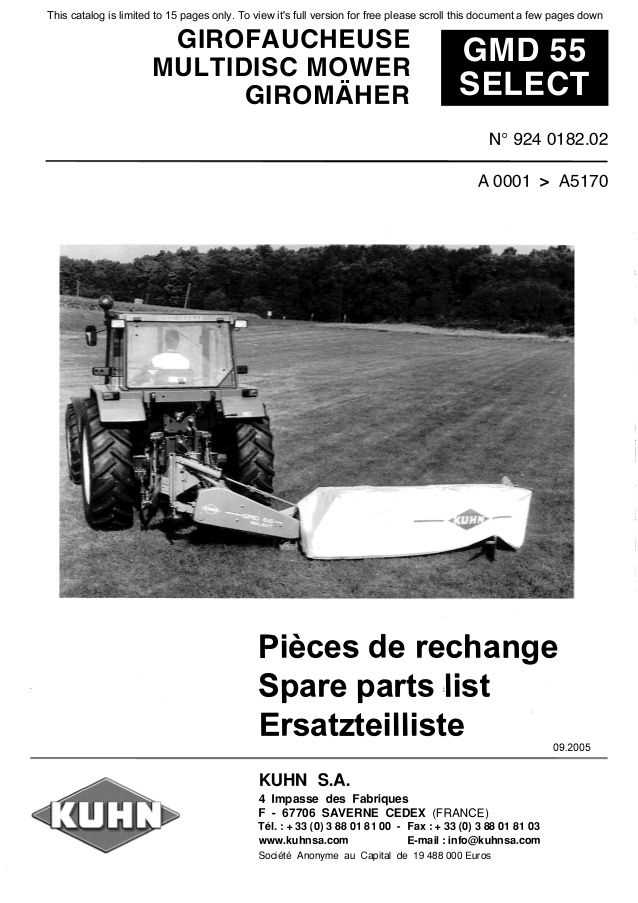

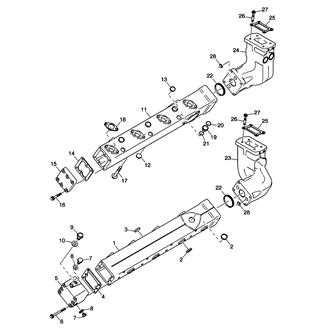

Overview of Component Layout

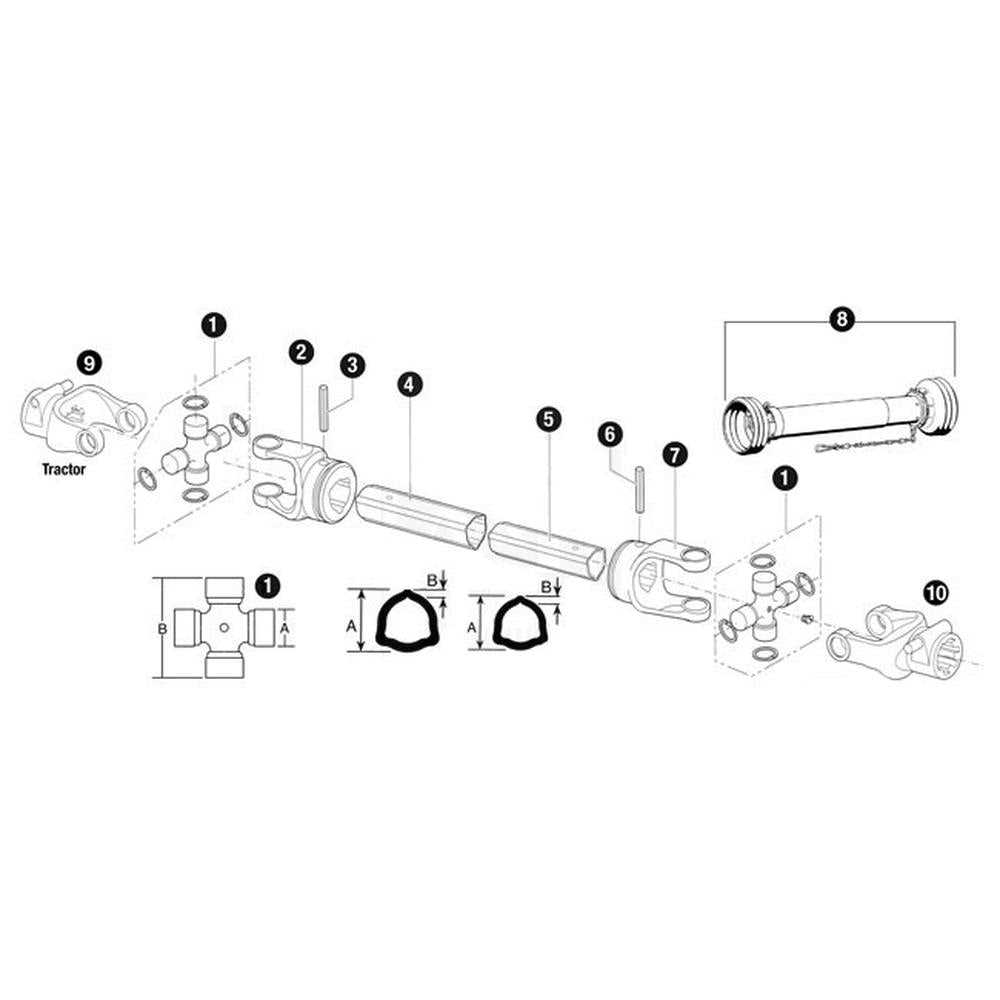

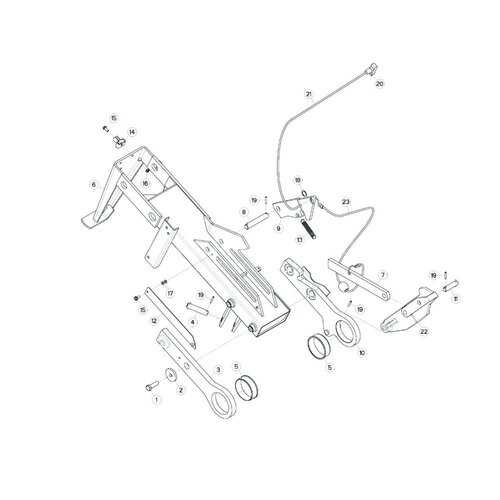

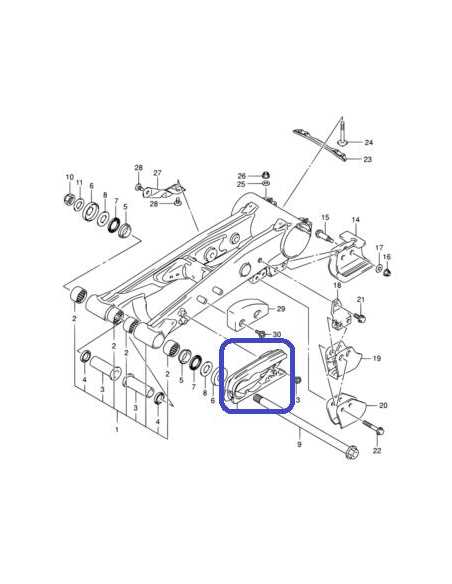

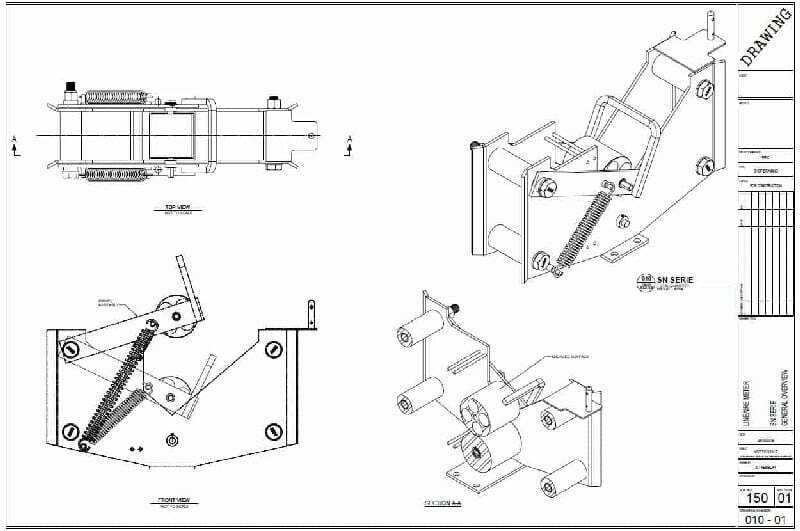

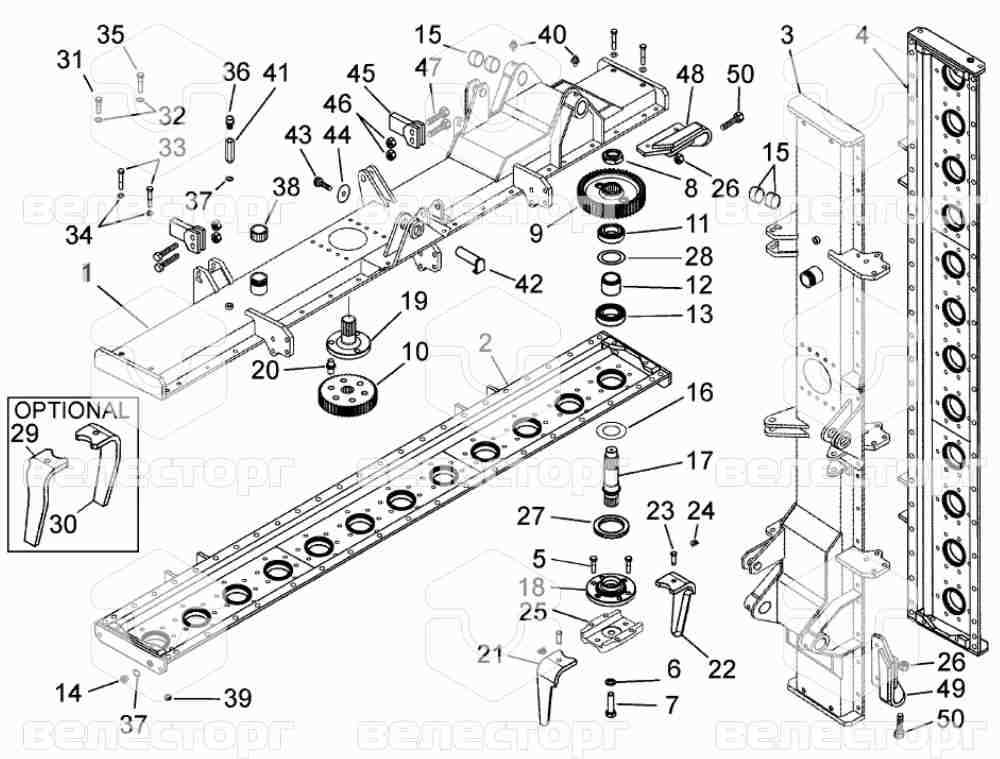

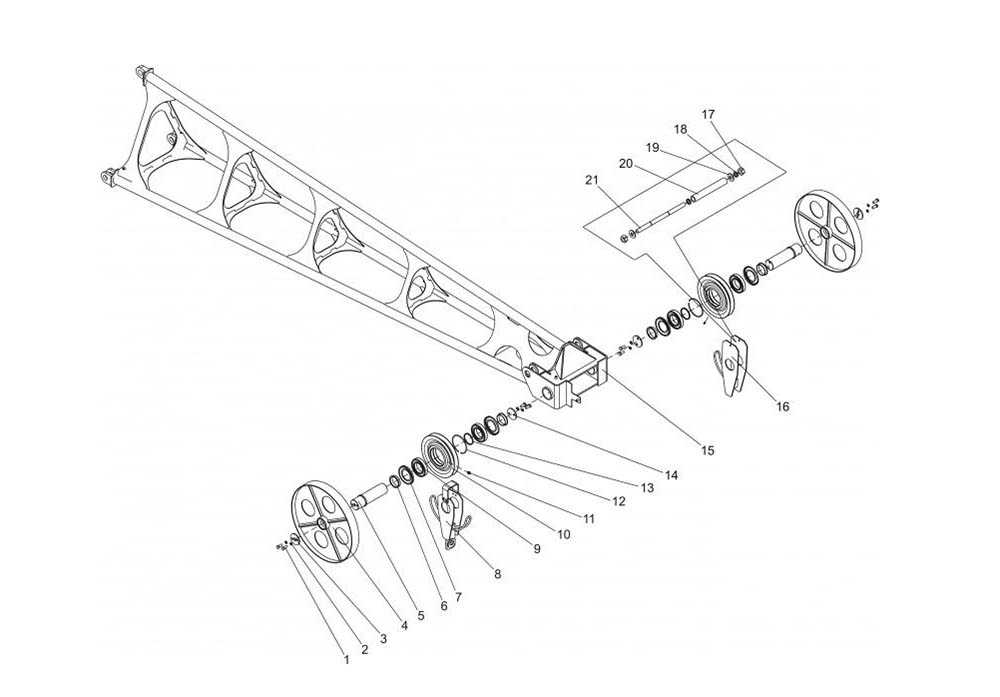

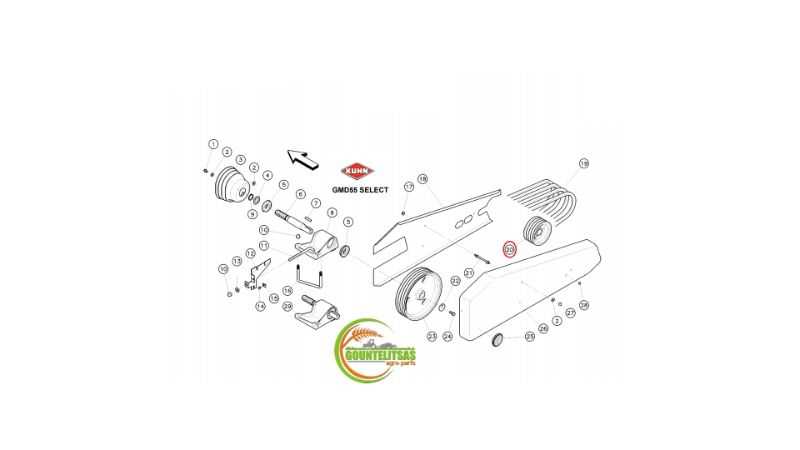

This section provides a comprehensive overview of the assembly layout for a specific agricultural implement. Understanding the arrangement of various elements is essential for effective maintenance and operation. The diagram aids in identifying crucial components and their interrelationships, facilitating troubleshooting and repairs.

Key Features

Several significant aspects contribute to the overall functionality of the implement:

- Durability: Built with high-quality materials for longevity.

- Efficiency: Designed to enhance performance during operation.

- Accessibility: Components are arranged for easy access during maintenance.

Understanding the Layout

Familiarity with the layout enables users to:

- Quickly locate specific components.

- Identify parts that may require replacement or repair.

- Improve overall efficiency during agricultural tasks.

Understanding Kuhn GMD 600 Components

This section provides insights into the various elements that make up a specific agricultural machine. By examining these components, users can gain a clearer understanding of their functions and how they contribute to the overall performance of the equipment. Knowledge of these parts is essential for effective maintenance and operation.

Key Elements of the Equipment

The main features of the machine include blades, frames, and drivetrains, each playing a crucial role in ensuring optimal operation. Blades are responsible for cutting and harvesting, while the frame provides structural integrity and support. The drivetrain connects the various components, facilitating smooth movement and energy transfer.

Importance of Regular Maintenance

Maintaining these components is vital for ensuring long-lasting efficiency and effectiveness. Regular inspections and timely replacements of worn-out elements can prevent breakdowns and enhance productivity. By understanding how each part functions, operators can better anticipate maintenance needs and extend the lifespan of the equipment.

Importance of Accurate Parts Diagram

A precise illustration of components is crucial for effective maintenance and repair. Such visual representations facilitate a clearer understanding of how various elements interact within a system. This understanding helps users quickly identify necessary replacements or adjustments, leading to improved operational efficiency.

Enhanced Efficiency in Maintenance

When users have access to detailed visuals, they can streamline the maintenance process. Clear imagery reduces the likelihood of errors during repairs, ensuring that every step is executed correctly. This efficiency translates to less downtime and more productive use of equipment.

Facilitation of Training and Skill Development

Visual aids play a significant role in educating new technicians. By providing accurate representations, training sessions become more effective. Trainees can grasp complex systems more easily, leading to quicker skill acquisition and a more knowledgeable workforce.

Key Features of Kuhn GMD 600

This section highlights the essential characteristics of a specific mower model designed for efficiency and versatility in various agricultural settings. Understanding these features can help users make informed decisions about their equipment needs.

- Robust Construction: Built with durable materials to withstand harsh operating conditions.

- Efficient Cutting Mechanism: Features a design that ensures clean and precise cutting of grass and hay.

- Adjustable Working Width: Offers flexibility in width settings to suit different field sizes and conditions.

- Easy Maintenance: Engineered for straightforward maintenance tasks, allowing for minimal downtime.

- Enhanced Safety Features: Incorporates safety measures to protect the operator and equipment during operation.

Each of these attributes contributes to the overall performance and reliability of the machine, making it a valuable asset for farmers and land managers.

How to Read the Diagram

Understanding a visual representation of components is essential for effective maintenance and operation. This section provides insights into deciphering such illustrations, making it easier to identify each element and its function within the system.

When interpreting the illustration, consider the following key points:

- Symbols: Familiarize yourself with the various symbols used in the representation. Each symbol corresponds to a specific part or function.

- Connections: Pay attention to how the elements are connected. Lines and arrows indicate relationships and flow between different components.

- Labels: Look for labels that identify each component. These are usually placed near the corresponding symbol for clarity.

- Legend: Refer to the legend or key if available. This often provides explanations for symbols and color coding used in the illustration.

By keeping these aspects in mind, you will enhance your ability to navigate the visual representation effectively, ensuring a better understanding of the overall system and its individual elements.

Common Parts and Their Functions

Understanding the essential components of agricultural machinery is crucial for effective operation and maintenance. Each element plays a vital role in ensuring optimal performance and longevity of the equipment.

- Frame: This foundational structure supports all other components, providing stability and durability.

- Blade: This sharp tool is responsible for cutting through materials, facilitating efficient harvesting or processing tasks.

- Drive System: This mechanism transmits power from the engine to the working parts, ensuring smooth operation.

- Hitch: This connection point links the machine to towing vehicles, allowing for easy transportation.

- Hydraulic System: This system powers various functions through fluid pressure, enabling adjustments and movements of different parts.

Regular inspection and understanding of these components can greatly enhance the performance and lifespan of the machinery.

Maintenance Tips for Optimal Performance

Ensuring the efficient operation of your equipment requires regular attention and care. Proper upkeep not only enhances functionality but also extends the lifespan of the machine. Implementing a consistent maintenance routine is crucial for achieving peak performance.

- Regular Inspections: Conduct thorough checks on key components to identify wear and tear early.

- Cleanliness: Keep the machinery clean and free of debris to prevent damage and maintain efficiency.

- Lubrication: Apply appropriate lubricants to moving parts as recommended to reduce friction and wear.

- Alignment Checks: Ensure all parts are properly aligned to avoid unnecessary strain on the machine.

- Monitor Performance: Keep track of operational metrics to detect any deviations from normal performance.

By adhering to these essential maintenance practices, you can ensure your equipment remains in excellent working condition, promoting productivity and reliability in your tasks.

Identifying Replacement Parts Easily

Finding suitable components for machinery can often be a challenging task. However, with the right approach, you can streamline this process significantly. Understanding the various elements and their functionalities will enable you to make informed decisions when it comes to selecting alternatives or replacements.

Begin by examining the equipment manual, which typically includes detailed descriptions of each component. Familiarizing yourself with terminology used in the manual can enhance your ability to identify the necessary items quickly. Additionally, you may find reference images or charts that illustrate the arrangement and connection of different elements.

Another effective strategy is to utilize online resources, such as manufacturer websites or dedicated forums. These platforms often provide valuable insights, including user experiences and recommendations. Engaging with a community of users can further assist in recognizing which components are most compatible with your machine.

Lastly, consider creating a list of essential components and their specifications. This inventory will serve as a handy reference guide when seeking replacements, ensuring you have the necessary information at your fingertips to make the right choice swiftly.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components of agricultural machinery. Understanding the various elements and their functions can enhance the efficiency and maintenance of your equipment.

Below are some of the most frequently asked questions regarding the different elements:

| Question | Answer |

|---|---|

| What are the essential components for maintenance? | Regular inspections and timely replacements of crucial items such as blades and belts are essential for optimal performance. |

| How do I identify the right parts for my machine? | Consult the user manual or manufacturer’s website for detailed specifications and part numbers specific to your equipment. |

| Where can I purchase replacement elements? | Replacement components can be obtained from authorized dealers or trusted online retailers that specialize in agricultural equipment. |

| How often should I replace worn parts? | It is advisable to inspect elements regularly and replace them based on usage, typically before significant wear affects functionality. |

Resources for Further Information

This section aims to provide valuable sources for those seeking additional insights and knowledge related to agricultural machinery and equipment. Understanding the components and their functionalities can enhance operational efficiency and maintenance practices.

Online Forums and Communities

Participating in online forums dedicated to farming machinery allows users to connect with experts and enthusiasts. These platforms offer a wealth of shared experiences, troubleshooting tips, and recommendations on enhancing equipment performance.

Manufacturer’s Documentation

Consulting the official documentation provided by manufacturers is essential. Manuals and user guides often include detailed information on features, maintenance procedures, and troubleshooting techniques, making them indispensable resources for users.

Comparing with Other Models

This section explores the differences and similarities between various models within the same category, focusing on their features and functionalities. Understanding these variations can provide valuable insights into performance, efficiency, and user preferences.

Performance Metrics: When evaluating different machines, it is essential to consider their performance metrics. Some units may offer enhanced speed and efficiency, while others prioritize durability and robustness. Users often find that specific models excel in particular tasks, making them more suitable for certain applications.

Design Features: The design characteristics of each model can significantly impact usability. Features such as weight, size, and ease of maintenance are crucial when comparing alternatives. Some units may incorporate advanced technology for better operation, while others focus on simplicity and straightforwardness.

User Feedback: Gathering user reviews and feedback can be instrumental in assessing the overall satisfaction with different machines. Preferences for specific functionalities, ease of use, and after-sales support often emerge, providing a clearer picture of which model may best fit individual needs.

Benefits of Using Original Parts

Utilizing authentic components in machinery and equipment offers numerous advantages that significantly enhance performance and longevity. These genuine items are designed to meet precise specifications, ensuring compatibility and reliability. When opting for original elements, users can expect improved functionality and reduced risk of failure, which ultimately leads to cost savings and greater satisfaction.

One of the key benefits of authentic components is their quality assurance. Original manufacturers typically adhere to stringent quality control measures, resulting in superior craftsmanship. This dedication to excellence not only enhances the efficiency of the equipment but also minimizes maintenance needs over time.

| Advantage | Description |

|---|---|

| Reliability | Authentic components are rigorously tested for durability and performance. |

| Compatibility | Designed specifically for the equipment, ensuring a perfect fit and function. |

| Warranty Protection | Using genuine components often maintains warranty coverage for the machinery. |

| Performance | Enhances overall machinery efficiency and reduces operational issues. |

In summary, choosing original elements fosters better outcomes, enhancing both the lifespan and performance of machinery. This prudent decision supports not only the immediate functionality but also the long-term investment in equipment maintenance and reliability.