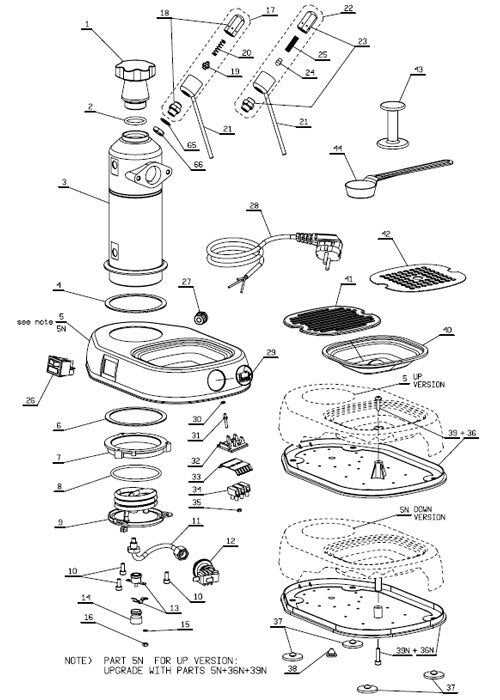

Understanding the components that make up a classic coffee machine is essential for maintaining its performance and longevity. By becoming familiar with the structure and mechanics, you can gain insights into how each element works in harmony to create the perfect brew. This knowledge is especially useful for those who take pride in maintaining their equipment in peak condition.

Each element plays a crucial role in the overall process, from heating water to creating the necessary pressure for extraction. A deeper understanding of these connections allows for better troubleshooting and upkeep. Whether you’re interested in enhancing your machine’s performance or simply want to ensure it lasts for years to come, knowing how its parts interact can offer valuable insight.

In this section, we will take a closer look at the assembly and identify key areas where attention to detail can make all the difference in both function and maintenance. This approach will provide a clearer picture of how the internal components contribute

Understanding Key Components of the Machine

To fully grasp how this classic coffee machine operates, it is essential to break down its primary elements. Each part plays a crucial role in ensuring that the brewing process is seamless and efficient. By recognizing the function of each element, users can maintain and operate the machine with greater confidence.

Core Functional Elements

- Boiler: Responsible for heating the water to the right temperature, ensuring optimal coffee extraction.

- Pressure Gauge: Monitors the internal pressure, allowing users to keep track of the machine’s performance.

- Steam Wand: Used for frothing milk, this component is vital for preparing drinks like cappuccinos and lattes.

Additional Mechanisms

- Lever Mechanism: Central to the machine’s operation, the lever controls the flow of water through the coffee grounds, ensuring consistent pressure and extraction.

- Filter Basket:

Exploring the Boiler’s Inner Workings

The intricate design of the heating chamber plays a crucial role in the overall functionality of the machine. Understanding the inner components of this core element provides valuable insights into how heat is distributed and maintained. By examining the structure, one can appreciate the craftsmanship behind the thermal system, which ensures consistent performance.

At the heart of the heating unit is a carefully engineered network that regulates temperature and pressure. Key components work in harmony to transfer heat efficiently, making sure that the system operates smoothly under various conditions. Regular maintenance of these elements is essential for long-term reliability and optimal performance.

By gaining a deeper knowledge of the heating system’s internal mechanisms, users can troubleshoot potential issues more effectively and extend the lifespan of their device. A well-maintained chamber ensures a steady flow of energy, resulting in a more consistent operation overall.

Details of the Steam Wand Mechanism

The steam wand plays a crucial role in the overall operation of the machine, allowing for the creation of perfectly textured milk for various beverages. Its functionality hinges on a system designed to control the release of pressurized steam, offering precision and control during frothing. Understanding how this component works is essential for maintaining the equipment’s performance and ensuring consistent results.

At the core of the system is a valve that regulates the steam flow. When the knob is turned, the valve opens, releasing steam from the boiler. The steam travels through the wand, which is designed to withstand high temperatures and pressure, directing the steam efficiently. This mechanism is fine-tuned to provide users with the ability to achieve the desired froth quality, from microfoam for lattes to more aerated textures for cappuccinos.

Another key aspect of the design is the nozzle at the end of the wand. This small yet critical piece influences how the steam interacts with the milk, allowing for precise control over the frothing process. Different nozzle configurations can affect the way steam is distributed, making it important to understand its role in achieving specific outcomes. Regular cleaning and

How the Portafilter Assembly Functions

The portafilter assembly plays a crucial role in preparing a quality cup of espresso. This component ensures that the coffee grounds are evenly distributed and held in place during the brewing process. It is designed to create an optimal environment for water to pass through the grounds, extracting the rich flavors and aromas needed for a perfect shot.

Main Components

The assembly consists of a handle, a metal filter basket, and a locking mechanism that secures it in place. Each part serves a unique purpose, working together to maintain consistency in every extraction. The filter basket holds the coffee, while the handle offers control during operation, ensuring ease of use.

Functionality

When engaged, the portafilter locks into position, forming a tight seal. This allows pressurized water to flow through the coffee grounds at the right rate. The assembly’s design minimizes leakage and ensures even distribution of water, creating the perfect brew.

Examining the Pressure Gauge Role

Understanding the function of the pressure gauge is key to optimizing the operation of any brewing system. This component offers real-time insights into the internal dynamics of the machine, allowing for more precise control over the process.

Monitoring Consistent Performance

The gauge serves as a vital indicator of pressure stability. By tracking fluctuations, users can ensure that the machine maintains the necessary levels for a smooth operation, preventing unwanted pressure spikes or drops.

- Ensures pressure remains within optimal range

- Helps identify issues before they escalate

- Supports consistent results with each use

Improving User Control

Analyzing the Water Reservoir Structure

The water storage unit is a vital component in espresso machines, significantly impacting performance and efficiency. Understanding its design and functionality can enhance user experience and machine longevity. This section delves into the intricacies of this crucial element, exploring its construction and role in the brewing process.

Typically, the reservoir is crafted from durable materials to withstand heat and pressure, ensuring a reliable supply of water for optimal brewing. Its shape and capacity are carefully designed to meet the needs of various brewing styles while maintaining stability during operation. A well-structured reservoir allows for easy filling and cleaning, contributing to overall convenience.

Feature Description Material Durable, heat-resistant substances to ensure longevity. Capacity Designed to hold sufficient water for multiple servings. Shape Engineered for stability and easy integration with the machine. Access User-friendly design for effortless refilling and maintenance. By analyzing the structure of the water reservoir, users can appreciate the importance of its role in delivering a seamless brewing experience. A well-thought-out design ensures consistent performance, making it essential for any espresso enthusiast.

Role of the Grouphead in Brewing

The grouphead serves as a crucial component in the espresso extraction process. It acts as the interface between the brewing unit and the coffee basket, playing a vital role in ensuring the proper interaction of water and coffee grounds. A well-functioning grouphead enhances the overall flavor profile and consistency of the brewed beverage.

Key functions of the grouphead include:

- Water Distribution: Ensures even saturation of coffee grounds, allowing for optimal extraction.

- Temperature Control: Maintains the ideal brewing temperature, critical for achieving the best flavor.

- Pressure Regulation: Creates the necessary pressure to extract oils and aromas from the coffee, contributing to a rich crema.

Moreover, the design and material of the grouphead can influence the brewing experience:

- Material: Stainless steel and brass are popular choices for their durability and heat retention properties.

- Size and Shape: Different designs can affect the flow rate and extraction time, impacting the final taste.

- Maintenance: Regular cleaning and upkeep ensure the grouphead remains in optimal condition, preventing buildup that can alter flavors.

In conclusion, the grouphead is integral to brewing high-quality espresso. Its ability to regulate water, temperature, and pressure significantly impacts the flavor and quality of the final product.

The Importance of the Heating Element

The heating component plays a crucial role in the overall functionality of any espresso machine. It is responsible for generating the necessary temperature to brew coffee, ensuring that the extraction process is optimal for a rich and flavorful beverage. Without this essential element, the machine would be unable to perform its primary function effectively.

Temperature control is vital for achieving the perfect brew. A well-designed heating mechanism allows for precise regulation, which directly impacts the quality of the espresso. If the temperature is too low, the coffee may be under-extracted, leading to a weak and sour taste. Conversely, excessive heat can cause over-extraction, resulting in a bitter flavor profile. Thus, the efficiency of the heating element significantly influences the brewing outcome.

Moreover, the longevity and reliability of the machine are often linked to the performance of this component. A robust heating system not only improves the brewing experience but also minimizes the risk of malfunctions. Regular maintenance and timely replacement of this critical part can ensure the machine operates smoothly for years, providing consistent quality in every cup.

Functions of the Lever System

The lever mechanism in espresso machines plays a crucial role in the brewing process, influencing the extraction of flavors and aromas from the coffee grounds. This system combines mechanical advantage with user control, allowing for precise manipulation of pressure and flow during brewing. Understanding its functions can enhance the overall coffee-making experience and the quality of the final beverage.

Pressure Application

One of the primary functions of the lever system is to apply consistent pressure to the coffee bed. By pulling the lever, users can create the necessary force to extract flavors effectively. This manual control enables adjustments based on the type of coffee being brewed, resulting in a more personalized cup. The ability to modify pressure dynamics can lead to variations in taste, aroma, and body of the espresso.

Flow Regulation

Another vital aspect of the lever mechanism is its role in regulating the flow of water through the coffee grounds. As the lever is engaged, it not only generates pressure but also influences the rate at which water passes through the coffee bed. This regulation ensures an even extraction, preventing under-extraction or over-extraction, which can adversely affect the flavor profile. Mastering flow control through the lever system empowers users to refine their brewing technique and achieve the desired taste in every cup.

Understanding the Role of Safety Valves

Safety valves are critical components in any pressure-based system, serving to prevent hazardous situations by regulating pressure levels. Their primary function is to ensure that the system operates within safe parameters, avoiding potential damage and ensuring user safety.

These mechanisms work by automatically releasing excess pressure when it reaches a predetermined limit. This action prevents the risk of catastrophic failure, making it essential for maintaining the integrity of the equipment. Here are some key aspects of safety valves:

- Pressure Regulation: Safety valves help maintain optimal pressure levels within the system, preventing overpressure conditions.

- Automatic Operation: They operate automatically, activating without the need for manual intervention, which enhances safety.

- Protection Against Failures: In case of a malfunction in the system, safety valves provide a fail-safe mechanism to release excess pressure.

- Compliance with Standards: Many systems are required to have safety valves to meet industry safety regulations and standards.

Understanding the importance of these components is vital for anyone operating or maintaining pressure systems. Regular inspection and maintenance of safety valves ensure their reliability and effectiveness in protecting both the equipment and the user.

Maintaining the Seals and Gaskets

Proper upkeep of seals and gaskets is essential for ensuring optimal performance and longevity of your equipment. These components play a crucial role in preventing leaks and maintaining pressure, which are vital for the overall functionality of the system. Regular inspection and timely replacement can help avoid potential issues that may arise from wear and tear.

To maintain these critical elements, start by regularly checking for signs of deterioration, such as cracks, fraying, or hardening. Clean the surfaces where the seals and gaskets sit to remove any debris or buildup that could compromise their effectiveness. It is also advisable to use the recommended lubricants to enhance their lifespan and ensure a snug fit.

When replacing any worn or damaged seals and gaskets, choose high-quality materials designed for the specific application. This will ensure compatibility and help maintain the integrity of the assembly. By prioritizing the care of these components, you can significantly improve the reliability and efficiency of your equipment.