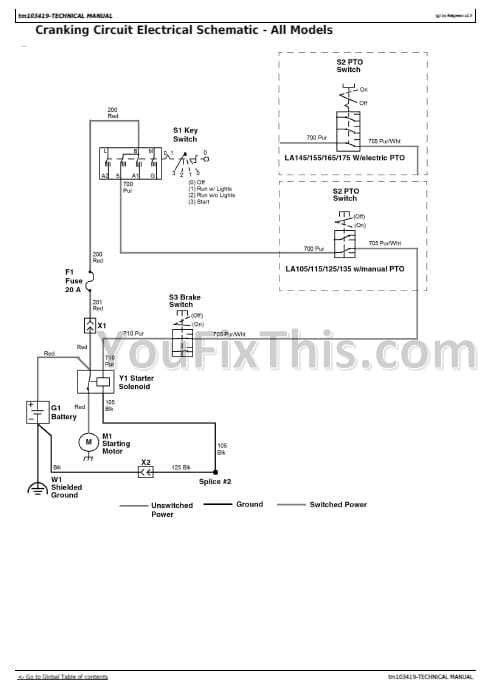

The intricate layout of machinery components plays a crucial role in ensuring optimal performance and maintenance. A well-organized schematic provides insights into how various elements interact, aiding both troubleshooting and repair processes.

By examining the arrangement of each segment, users can gain a deeper understanding of functionality and identify potential areas for enhancement. This visualization is invaluable for both seasoned technicians and newcomers alike, facilitating efficient repairs and upgrades.

Utilizing this structured representation allows for precise identification of individual elements, streamlining the process of replacement or adjustment. Mastery of this information not only enhances operational efficiency but also fosters confidence in handling complex tasks.

Importance of Understanding Parts Diagrams

Grasping the layout and components of machinery is crucial for effective maintenance and repair. Familiarity with these visual representations enhances one’s ability to identify necessary elements, facilitating informed decisions during troubleshooting.

Enhanced Problem-Solving Skills

Recognizing each component’s role allows for quicker diagnostics. When users can pinpoint issues based on visual aids, they can address problems efficiently, saving time and resources.

Improved Maintenance Practices

Understanding these illustrations fosters better upkeep strategies. Users who can interpret these visuals are more likely to perform regular checks and replacements, prolonging equipment life.

| Component | Function |

|---|---|

| Element A | Description of function A |

| Element B | Description of function B |

| Element C | Description of function C |

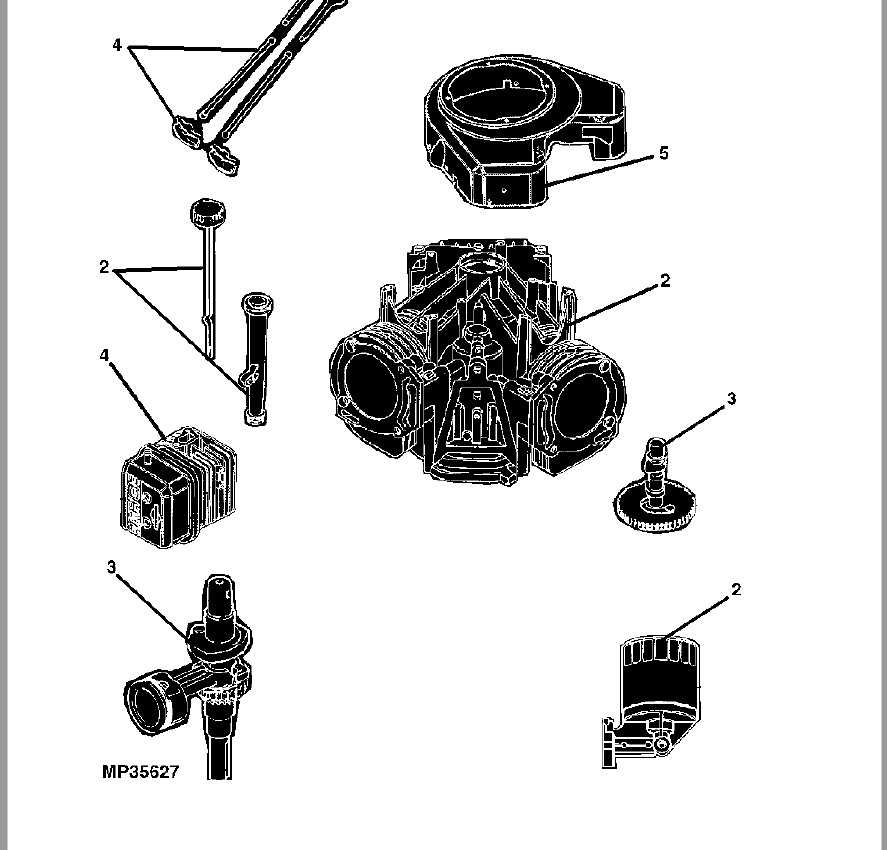

Key Elements in the Diagram

This section outlines the essential components depicted in the visual representation, highlighting their significance in the overall functionality. Understanding these elements is crucial for efficient operation and maintenance.

Main Components

- Structure: The foundational framework supporting all other elements.

- Mechanisms: Moving parts responsible for various operations.

- Connections: Links that facilitate interaction between components.

Functional Highlights

- Efficiency: Optimizes performance through streamlined design.

- Durability: Ensures longevity through robust materials.

- Accessibility: Allows for easy maintenance and repair processes.

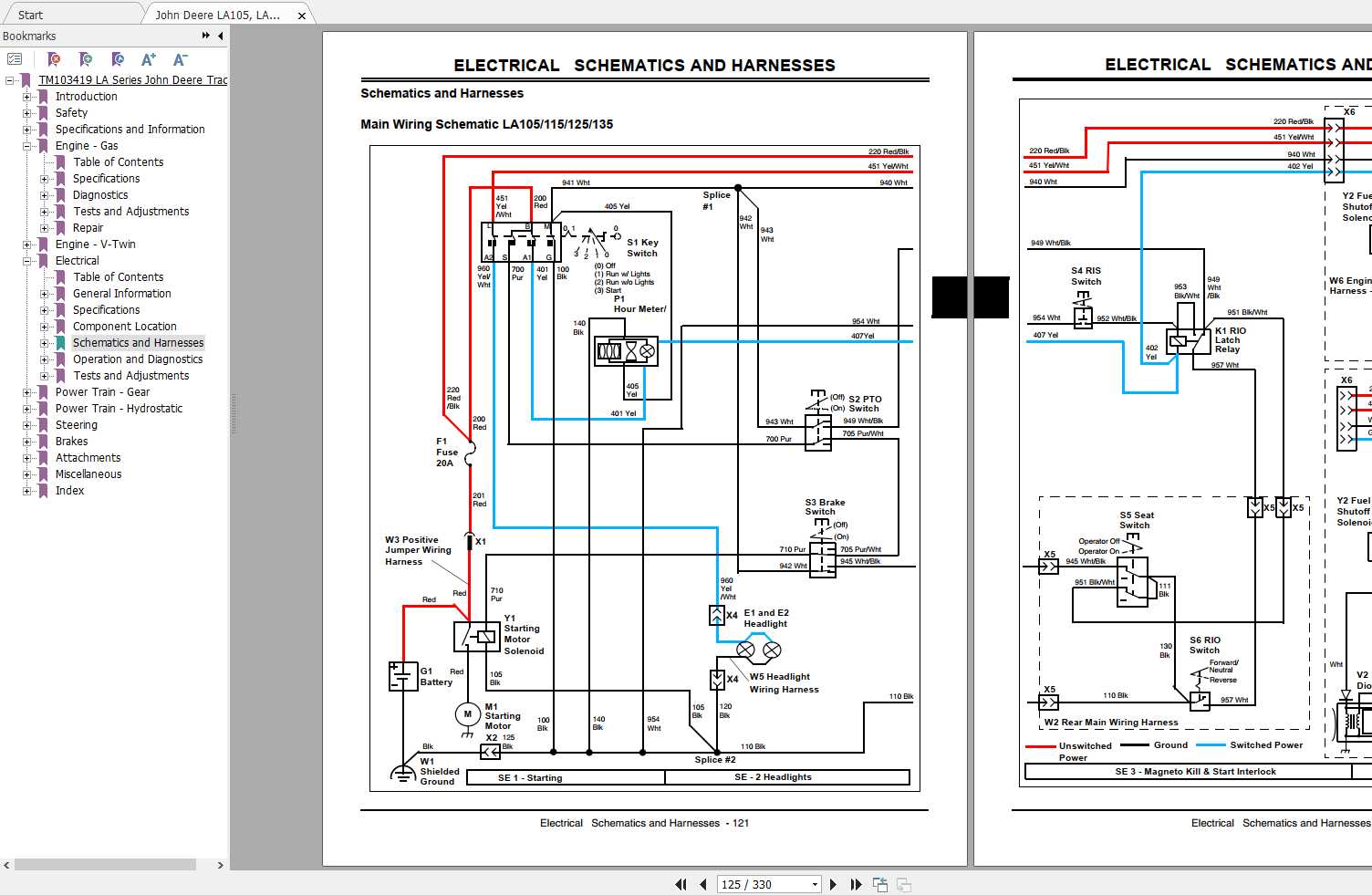

How to Interpret the Diagram

Understanding the layout of components is crucial for effective maintenance and troubleshooting. This section provides insights on how to read and utilize the visual representation effectively, ensuring clarity in identifying various elements and their functions.

Familiarize Yourself with Symbols

Each icon and marking in the visual representation serves a distinct purpose. By becoming acquainted with these symbols, users can navigate the layout with confidence, facilitating a smoother interaction with the equipment.

Follow the Flow of Components

Observing the connections and arrangements of different elements allows for a comprehensive grasp of how each part interacts with others. This understanding can aid in diagnosing issues and implementing solutions more efficiently.

Common Issues and Solutions

This section addresses frequent challenges encountered with this equipment and offers effective resolutions. Understanding these common problems can enhance the overall performance and longevity of the machinery.

Frequent Malfunctions

Users may experience a variety of malfunctions, often linked to wear and tear or improper usage. Recognizing these issues promptly can prevent further complications.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Inconsistent Performance | Clogged filters, worn components | Regular maintenance, replace damaged parts |

| Unusual Noises | Loose fittings, lack of lubrication | Tighten connections, apply appropriate lubricants |

| Overheating | Blocked vents, insufficient cooling | Clear obstructions, ensure proper airflow |

Preventive Measures

Implementing regular checks and maintenance routines can significantly reduce the occurrence of these issues. Staying proactive is essential for optimal functionality.

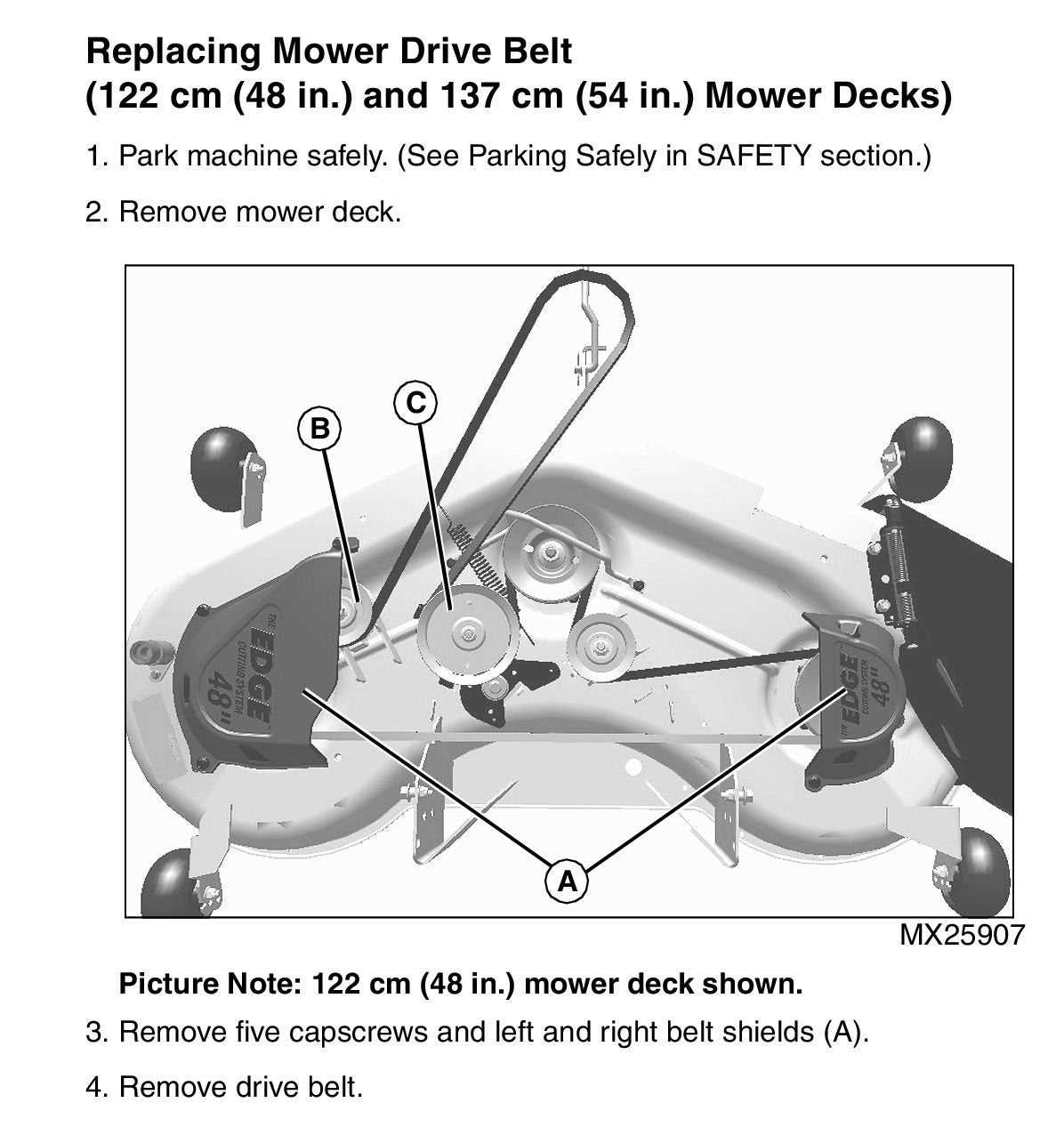

Parts Replacement Process

The procedure for exchanging components involves a systematic approach to ensure optimal functionality. Understanding the sequence of actions required can significantly enhance the efficiency of maintenance tasks.

Initially, it is essential to gather all necessary tools and components before commencing the replacement. This preparation helps to minimize downtime and ensures that the task can be completed smoothly.

Next, follow the outlined steps to safely remove the existing elements. Be cautious to avoid damaging surrounding areas during this process. Once the old components are detached, inspect the new items for any defects or inconsistencies.

After verification, install the new components by carefully positioning them according to the established guidelines. Ensure that each part is secured properly to maintain structural integrity.

Finally, conduct a thorough examination of the entire assembly to confirm that everything functions correctly. Running tests can help identify any potential issues before returning the equipment to operational status.

Where to Find Genuine Parts

Locating authentic components for your machinery is essential for ensuring optimal performance and longevity. Reliable sources can help you acquire the necessary items without compromising quality.

Authorized Dealers

One of the most dependable ways to obtain original components is through authorized distributors. These vendors maintain a stock of genuine items, ensuring you receive the correct specifications.

Online Marketplaces

Numerous online platforms specialize in providing authentic equipment. Always verify the seller’s reputation and read customer reviews to guarantee the legitimacy of the products.

Maintenance Tips for Longevity

To ensure the lasting performance of your equipment, regular upkeep is essential. Implementing a few simple strategies can significantly extend its lifespan and enhance efficiency.

- Regular Cleaning: Remove dirt and debris to prevent buildup that can affect performance.

- Routine Inspections: Frequently check components for signs of wear or damage.

- Proper Lubrication: Use the recommended lubricants to minimize friction and wear.

- Timely Replacements: Replace worn parts promptly to avoid further damage to the system.

- Follow Manufacturer Guidelines: Adhere to maintenance schedules and procedures outlined in the manual.

By following these guidelines, you can maintain optimal functionality and avoid costly repairs.

Using the Diagram for Repairs

Utilizing a visual representation of components can significantly enhance the repair process. This tool allows users to identify various elements, facilitating efficient troubleshooting and maintenance. By following the outlined details, one can streamline repairs and ensure a thorough understanding of assembly and disassembly.

Steps to Follow

- Start by locating the relevant section in the visual guide.

- Identify the specific components that require attention.

- Refer to any accompanying notes for assembly instructions.

- Document any findings or necessary replacements.

Benefits of Using Visual Aids

- Enhances clarity during complex repairs.

- Reduces the risk of errors in reassembly.

- Saves time by providing a clear reference.

Comparative Analysis with Similar Models

This section explores the distinctions and similarities among various machinery types that share comparable functionalities and specifications. By examining their features, users can make informed choices tailored to specific needs.

- Performance Metrics:

- Power output comparisons

- Efficiency ratings

- Durability assessments

- Design Features:

- Dimensions and weight variations

- Construction materials used

- Ergonomic considerations

- Maintenance Requirements:

- Service intervals

- Common issues and troubleshooting

- Replacement part availability

Ultimately, understanding these aspects aids users in selecting the most suitable equipment for their tasks, ensuring optimal performance and reliability.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and component identification for specific machinery. Here, users can find answers to various concerns and tips to enhance understanding.

- What is the best way to locate components?

Utilizing reference materials and visual aids can significantly simplify the identification process.

- How often should I check the components?

Regular inspections are recommended to ensure optimal performance, typically every few months or as per usage guidelines.

- Where can I find replacement parts?

Authorized dealers and reputable online retailers are reliable sources for acquiring genuine replacements.

- What should I do if I encounter a malfunction?

It is advisable to consult the troubleshooting section of your reference material or seek professional assistance.

Resources for Further Information

For those seeking to enhance their understanding and acquire detailed insights, various resources are available to aid in your exploration. These platforms offer comprehensive guides, technical manuals, and community forums that can provide valuable information.

Online Forums: Engaging in discussions with fellow enthusiasts can lead to practical advice and shared experiences that deepen your knowledge.

Official Manuals: Accessing manufacturer documentation is essential for accurate specifications and maintenance guidelines.

Educational Videos: Visual learning through tutorials can be particularly helpful, showcasing real-life applications and repairs.

Community Groups: Joining local or online clubs dedicated to similar equipment can foster a supportive environment for learning and sharing.