When it comes to the maintenance and repair of your espresso maker, having a clear visual representation of its elements is essential. This guide aims to enhance your comprehension of the various components involved in the operation of your device. By familiarizing yourself with these elements, you will be better equipped to address any issues that may arise.

Recognizing each part of the machine allows you to perform effective troubleshooting and ensure optimal performance. Whether you are a seasoned barista or a casual coffee enthusiast, understanding the intricate details of your appliance can lead to improved brewing results and a more satisfying experience.

Through this exploration, you will gain insight into the functionality of each segment, enabling you to identify and resolve potential concerns with confidence. Armed with this knowledge, you can approach repairs and enhancements with a greater sense of assurance and skill.

Article Plan for Component Overview

This section aims to provide a comprehensive outline for an article focused on the essential elements and their configurations in a specific machine. Understanding these components is vital for anyone looking to enhance their knowledge or maintain the device effectively.

- Introduction to the Device

- Overview of Main Components

- Functional Description

- Visual Representation

- Assembly and Disassembly Guide

- Step-by-Step Instructions

- Safety Precautions

- Common Issues and Solutions

- Identifying Problems

- Troubleshooting Techniques

- Conclusion and Recommendations

Overview of Lelit Bianca Components

This section provides a comprehensive look at the various elements that make up a specific espresso machine, focusing on their functions and importance in the brewing process. Understanding these components is essential for anyone looking to enhance their espresso-making skills and ensure optimal performance.

Main Elements

- Brew Group: The core component responsible for extracting flavor from the coffee grounds.

- Boiler: Heats the water to the necessary temperature for brewing and steaming.

- Steam Wand: Used to froth milk, creating the perfect texture for lattes and cappuccinos.

Supportive Features

- Pressure Gauge: Displays the brewing pressure, helping to achieve the ideal extraction.

- Water Reservoir: Holds the water needed for brewing and steaming.

- Drip Tray: Collects excess water and coffee, keeping the work area tidy.

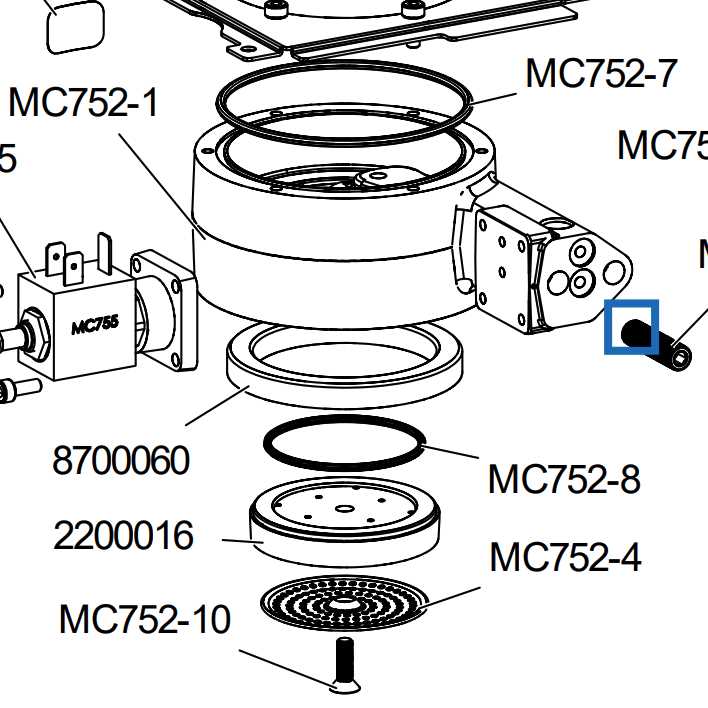

Detailed Parts List for Bianca

This section provides an extensive overview of the components essential for the operation of the equipment. Understanding each element’s function and structure can greatly enhance maintenance and repair efforts, ensuring optimal performance.

The following is a comprehensive enumeration of the various components:

- Base assembly

- Heating element

- Water reservoir

- Group head

- Steam wand

- Control panel

- Pressure gauge

- Drip tray

- Foot pads

- Portafilter

Each of these items plays a vital role in the functionality of the device, contributing to the overall user experience.

Understanding the Diagrams and Symbols

Comprehending visual representations and their associated icons is crucial for effectively navigating mechanical assemblies. These illustrations serve as essential guides, helping users identify components and understand their relationships within a system. Mastery of these symbols can significantly enhance the user’s ability to troubleshoot and maintain equipment.

| Symbol | Meaning |

|---|---|

| ⚙️ | Indicates a mechanical part |

| Represents a tool required for assembly | |

| ⚡ | Denotes electrical components |

| ️ | Indicates maintenance procedures |

| Signifies movable parts |

Common Issues with Components

Understanding the common problems that may arise with various elements of a device is essential for effective troubleshooting and maintenance. Often, these issues can significantly impact performance and functionality, leading to user frustration and decreased efficiency. By recognizing potential challenges, users can take proactive steps to ensure optimal operation.

- Leaks: One of the most frequent issues encountered is leaking, which can stem from worn seals or improper assembly.

- Overheating: Components may experience overheating due to inadequate airflow or blocked vents, resulting in potential damage.

- Electrical Failures: Malfunctions in electrical connections can lead to failures in powering the device or controlling its functions.

- Blockages: Clogs in pathways can impede the flow of liquids or gases, causing inefficient operation.

- Wear and Tear: Regular use can lead to wear on components, affecting their reliability and longevity.

Addressing these common issues requires regular inspections and maintenance, allowing users to identify problems early and take corrective actions promptly. This proactive approach can enhance the lifespan and efficiency of the device, ensuring a better overall experience.

Maintenance Tips for Lelit Parts

Ensuring the longevity of your espresso machine components is essential for optimal performance and enjoyment. Regular care not only enhances the functionality of the device but also prevents costly repairs in the future. Here are some effective strategies to maintain your equipment.

1. Regular Cleaning: It’s vital to keep all components clean to avoid buildup of coffee residues and oils. Use a damp cloth for external parts and a suitable cleaner for the internal mechanisms.

2. Inspect Seals and Gaskets: Regularly check seals and gaskets for wear and tear. Replacing them promptly can prevent leaks and ensure a proper seal, which is crucial for maintaining pressure.

3. Descaling: Mineral deposits can accumulate over time, affecting the heating elements. Schedule a descaling routine using a recommended solution to keep the system clear and efficient.

4. Proper Storage: When not in use, store your machine in a dry place. Covering it can also protect it from dust and environmental factors.

5. Use Quality Ingredients: The quality of water and coffee used can significantly affect the machine’s performance. Always opt for filtered water and high-quality beans to enhance the brewing process.

By following these maintenance tips, you can ensure your machine remains in excellent condition, providing you with delicious beverages for years to come.

Replacement Guidelines for Broken Parts

When dealing with malfunctioning components of your device, it is essential to follow proper procedures for replacement to ensure optimal performance and longevity. Understanding the various elements and their functions can aid in making informed decisions during the repair process.

Step-by-Step Process:

- Assessment: Begin by identifying the specific component that requires replacement. Conduct a thorough examination to confirm the issue and ensure that it is indeed faulty.

- Research: Gather information on compatible replacements. Look for quality options that match the specifications and requirements of your device.

- Purchase: Acquire the new component from a reliable supplier. Verify that the product is genuine and suited for your device model.

- Installation: Carefully follow the installation instructions. Take your time to ensure that each part is properly positioned and secured to avoid future complications.

- Testing: After installation, conduct tests to confirm that the replacement operates correctly and meets your expectations.

By adhering to these guidelines, you can effectively address issues with defective elements, enhancing the overall functionality and reliability of your equipment.

Tools Needed for Assembly

Assembling a machine requires a variety of essential implements to ensure the process is smooth and efficient. Having the right tools at hand not only simplifies the task but also enhances the overall experience of putting everything together. Below is a list of recommended tools that will facilitate the assembly process.

Basic Tools

The foundation of any assembly project lies in having basic tools available. This includes screwdrivers of various sizes, pliers, and wrenches. These implements are vital for handling screws, bolts, and other components effectively.

Specialized Equipment

In addition to basic tools, some specialized equipment may be required for certain tasks. This can include torque wrenches for precise tightening, as well as cutting tools for any necessary adjustments. These specialized implements can greatly improve accuracy and safety during assembly.

How to Identify Component Issues

Recognizing malfunctions within a device is essential for maintaining its optimal performance. Understanding the signs of wear or dysfunction can prevent further complications and enhance the longevity of the equipment. By systematically examining each element, users can pinpoint areas requiring attention.

Common Symptoms to Look For

Begin by observing any unusual behavior during operation. This may include irregular sounds, inconsistent performance, or failure to function as expected. Additionally, monitor for physical signs, such as leaks, discoloration, or unusual vibrations, which can indicate potential problems.

Conducting a Thorough Inspection

Performing a detailed examination involves inspecting individual parts for visible damage or wear. Utilize appropriate tools to access hard-to-reach areas. Ensure all connections are secure and check for any loose components. Document findings for reference and consult resources for specific troubleshooting steps.

Step-by-Step Assembly Instructions

Proper assembly is crucial for optimal functionality and longevity of your equipment. This guide provides clear steps to help you assemble your unit effectively, ensuring that every component is correctly placed and secured.

-

Gather Required Tools:

- Screwdriver

- Wrench

- Hex key

-

Prepare the Workspace:

Ensure that your work area is clean and organized to avoid misplacing any components. Lay out all parts in an accessible manner.

-

Start with the Base:

Begin by attaching the base to the main structure using the screws provided. Make sure to tighten them securely.

-

Install the Heating Element:

Carefully position the heating element into its designated slot. Ensure that all connections are snug and properly aligned.

-

Attach the Control Panel:

Align the control panel with the mounting points and secure it in place. Check that all buttons and knobs function correctly.

-

Complete Final Adjustments:

Go through each connection to ensure everything is tight and secure. Make any necessary adjustments to align components properly.

-

Test the Assembly:

Once fully assembled, conduct a brief test to confirm that everything operates smoothly before using it for regular tasks.

Following these detailed steps will help ensure a successful assembly process, allowing you to enjoy your equipment with confidence.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components related to the device. Understanding the intricacies of various elements can enhance the user experience and ensure optimal functionality.

What are the essential components of the device?

The fundamental elements include various mechanisms that work in unison to achieve the desired performance. Each part plays a crucial role in the overall operation.

How can I identify a malfunctioning component?

Signs of dysfunction may manifest as unusual sounds or irregular performance. Observing these indicators can help pinpoint which element may require attention.

Where can I find replacement components?

Replacement options are available through multiple channels, including online retailers and specialized shops. It is advisable to ensure compatibility with the specific model.

Can I install components myself?

While some individuals may possess the skills for self-installation, it is recommended to consult a professional for complex replacements to avoid further complications.

What maintenance should I perform on the components?

Regular maintenance, such as cleaning and inspections, can prolong the lifespan of the individual elements. Adhering to a proper maintenance routine is beneficial for sustaining optimal performance.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward process if you know where to look. Numerous sources offer high-quality alternatives, ensuring your device remains in optimal condition. By exploring various options, you can find the right replacements that meet your needs.

Authorized Dealers

One of the most reliable sources for obtaining new components is through authorized dealers. These suppliers provide genuine items, ensuring compatibility and performance. They often have knowledgeable staff who can assist you in finding the specific parts required for your device.

Online Retailers

The internet is a valuable resource for finding components. Numerous online platforms specialize in spare items, often at competitive prices. Searching for your equipment model alongside keywords such as “replacement” can yield numerous results. Be sure to check customer reviews to ensure the reliability of the seller.

Customer Reviews and Feedback on Parts

Understanding user experiences and insights regarding various components can provide valuable guidance for potential buyers. Customers often share their thoughts on quality, functionality, and overall satisfaction with the elements they have interacted with. This feedback helps create a clearer picture of what to expect when considering a purchase.

Quality Insights

Many users emphasize the importance of durability and reliability when evaluating the components. Several reviews highlight how certain pieces perform consistently over time, contributing to an enhanced overall experience. Others have noted instances where they faced challenges, underscoring the necessity of thorough research before making decisions.

User Satisfaction

Feedback also sheds light on user satisfaction levels. A significant number of individuals report positive outcomes, often praising the efficiency and ease of use of various elements. However, there are occasional critiques, which serve as reminders to consider personal needs and preferences when selecting specific items.