Provides the

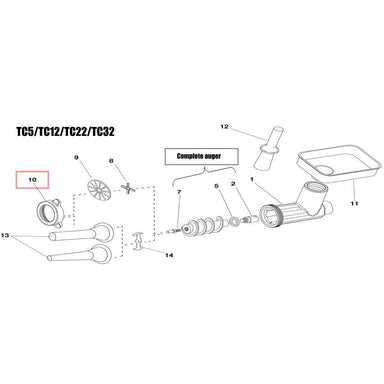

How the Feeding Tube Works

The feeding tube serves a vital role in the process of introducing ingredients into a specific appliance designed for food preparation. This component is strategically designed to ensure a smooth and efficient flow of material, allowing for optimal functionality during operation.

Functionality and Design

This essential element is typically elongated and designed to guide food items directly into the processing chamber. Its unique shape and construction help prevent blockages while facilitating a continuous feed, ensuring that the device operates seamlessly. Additionally, the design often incorporates features that enhance user convenience, such as a secure locking mechanism to keep the contents in place.

Importance in Food Processing

The effectiveness of the feeding tube significantly impacts the overall efficiency of the appliance. A well-designed tube not only minimizes waste but also maximizes the quality of the final output. By providing a consistent feed rate, it allows for a more uniform processing experience, which is crucial for achieving the desired results in culinary applications.

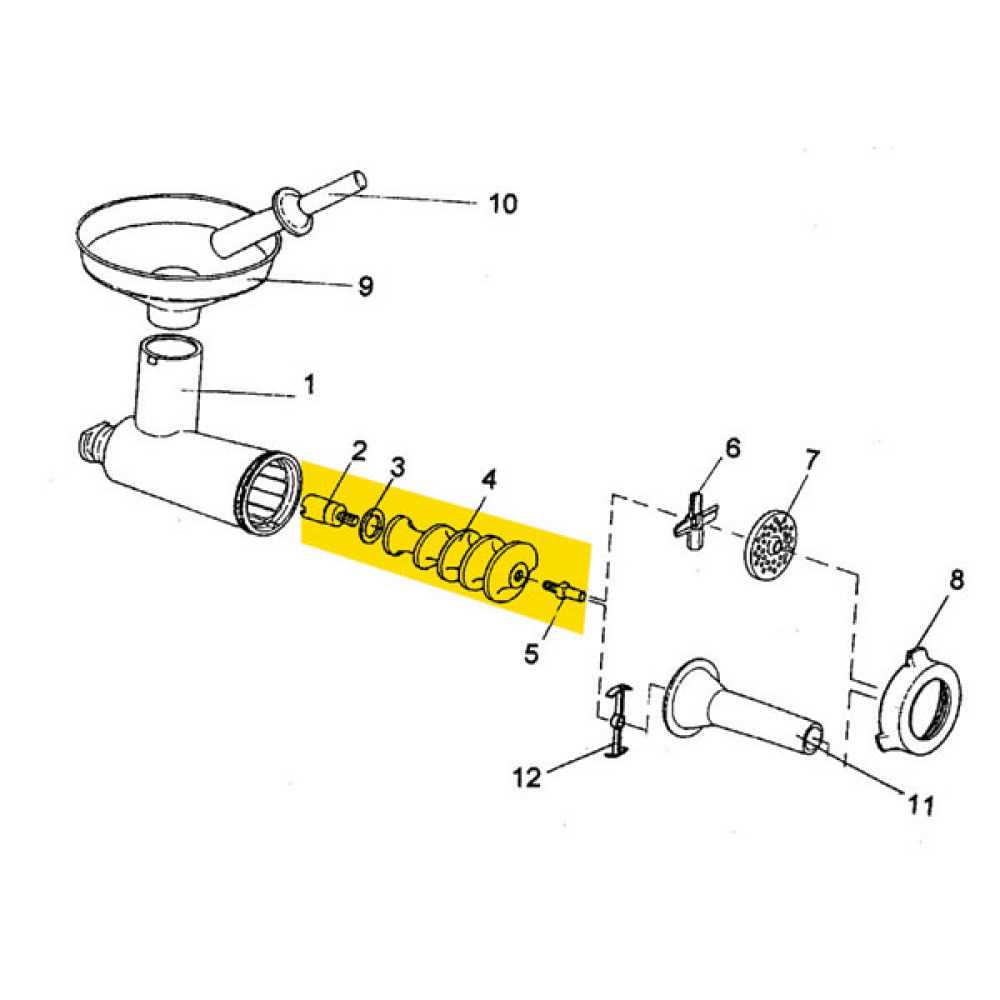

Explaining the Role of the Auger

The auger serves as a vital component in the processing system, ensuring the efficient movement of materials through the machine. Its design facilitates the effective transportation and compression of various substances, making it an essential element in achieving optimal functionality.

Functionality and Design

Crafted with a spiral configuration, the auger is engineered to push contents toward a designated output. This unique shape not only aids in movement but also helps in breaking down the material, allowing for a smoother flow and more uniform consistency. The efficiency of the entire mechanism relies heavily on the performance of this integral part.

Impact on Processing Efficiency

The effectiveness of the auger significantly influences the overall productivity of the device. A well-designed auger minimizes blockages and enhances the rate at which materials are processed. Its role in maintaining consistent pressure and flow ensures that the end product meets the desired quality standards, making it indispensable for achieving high efficiency.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended lifespan of your kitchen appliance. By following a few simple guidelines, you can maintain optimal performance and prevent unnecessary wear and tear.

Begin with routine cleaning after each use to remove any residual substances. Additionally, inspect components periodically for signs of damage or wear. Addressing minor issues promptly can prevent more significant problems later.

Lubricating moving elements is crucial to maintain smooth operation. Always use food-safe lubricants, and be sure to apply them sparingly. Moreover, storing the device in a dry environment protects against moisture damage.

| Task |

Frequency |

Details |

| Cleaning |

After each use |

Wipe down surfaces and disassemble for thorough cleaning. |

| Inspection |

Monthly |

Check for wear or damage on all components. |

| Lubrication |

Every three months |

Apply food-safe lubricant to moving parts as needed. |

| Storage |

After use |

Keep in a dry place to avoid moisture-related issues. |

Cleaning Techniques for Grinder Parts

Maintaining optimal hygiene and performance in food preparation appliances is essential. Effective cleaning methods not only ensure longevity but also promote safety during use. Various techniques can be employed to keep components in pristine condition, addressing both residues and potential contaminants.

Here are some recommended cleaning approaches for the various elements:

| Component |

Cleaning Method |

Recommended Frequency |

| Blades |

Soak in warm, soapy water and scrub gently. |

After each use |

| Hoppers |

Wipe down with a damp cloth and disinfect. |

Daily |

| Feed tubes |

Use a bottle brush to remove debris and rinse thoroughly. |

After each use |

| Casings |

Clean with a non-abrasive cleaner and soft cloth. |

Weekly |

Incorporating these methods into your routine will not only enhance performance but also ensure a safe environment for food processing activities. Regular attention to cleanliness is a key aspect of effective equipment management.

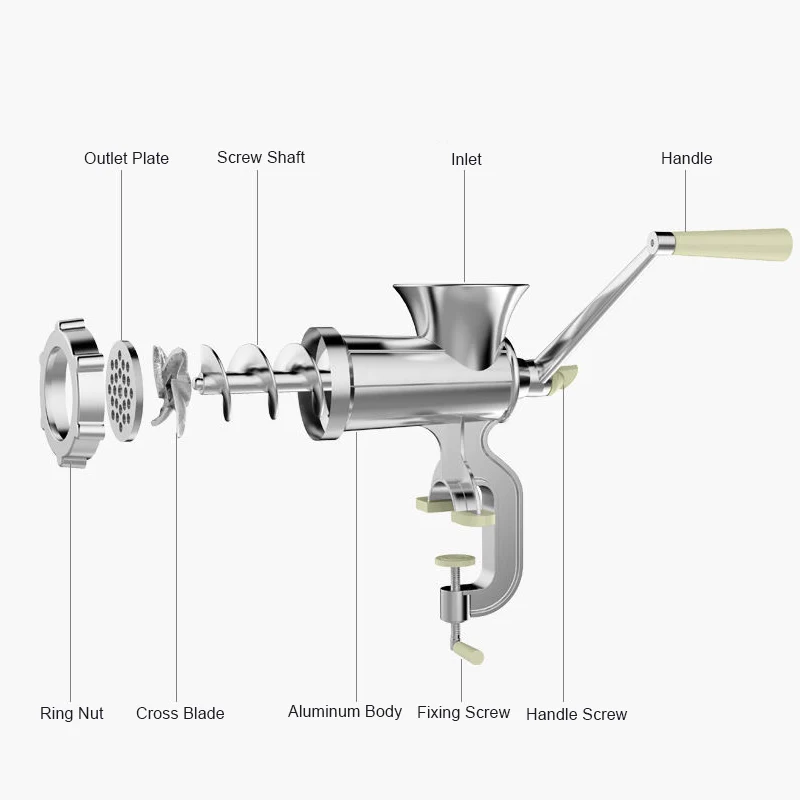

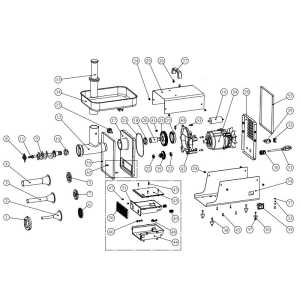

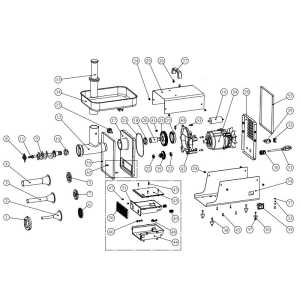

Common Replacement Parts and Their Use

In any machinery that processes food, specific components may require substitution over time to maintain optimal performance. Understanding the various elements that can be replaced helps ensure the appliance operates efficiently and effectively. This section outlines the most frequently needed components and their roles in the overall function.

Essential Components

Several critical components can become worn or damaged, necessitating their replacement. Each plays a vital role in the operation, contributing to the smooth processing of ingredients and ensuring the quality of the final product.

Replacement Component Overview

| Component |

Description |

Function |

| Feed Tube |

A funnel-like structure that directs ingredients into the processing chamber. |

Facilitates even loading of materials for consistent results. |

| Cutting Blade |

A sharp implement designed to chop or slice the ingredients. |

Ensures uniformity in texture and size of processed items. |

| Auger |

A spiral mechanism that moves ingredients through the machine. |

Promotes efficient and continuous processing of the materials. |

| Plate |

A flat surface with holes of varying sizes for texture control. |

Determines the fineness or coarseness of the output. |

| Housing |

The outer shell that encases all internal mechanisms. |

Provides stability and protection for internal components. |

Troubleshooting Common Grinder Issues

Addressing frequent complications with food processing appliances can enhance performance and extend longevity. Understanding potential malfunctions and their symptoms is crucial for maintaining efficiency and ensuring consistent results.

Clogging is a common problem that may arise due to excess residue or inappropriate ingredients. Regular cleaning and avoiding overloading the appliance can significantly reduce this issue. When facing a blockage, disassemble the unit carefully and remove any trapped materials.

Another frequent concern is overheating, which can occur if the device is used for extended periods without breaks. Allowing the equipment to cool down periodically will help prevent this. If overheating persists, consider checking the motor for signs of wear or malfunction.

Noisy operation can indicate underlying issues with the internal components. Unusual sounds may signal that parts are misaligned or require lubrication. Inspecting these components and ensuring proper assembly can mitigate such noises.

Lastly, if the output is inconsistent or lacks desired texture, adjustments in speed or technique may be necessary. Experimenting with different settings and methods can improve the quality of the final product, leading to better results overall.

|