When delving into the intricate world of machinery, one often encounters the necessity to grasp the configuration and arrangement of various elements within a system. A thorough exploration of these layouts not only enhances comprehension but also aids in effective troubleshooting and maintenance.

Having a clear visualization of how different components interact is essential for anyone looking to optimize performance or resolve issues. This section provides insights into the systematic organization of parts, highlighting their relationships and functionalities.

By examining these layouts, users can gain valuable knowledge about the mechanics at play, leading to improved operational efficiency and informed decision-making in repair and assembly processes. Engaging with these illustrations can significantly boost one’s understanding of the underlying technology.

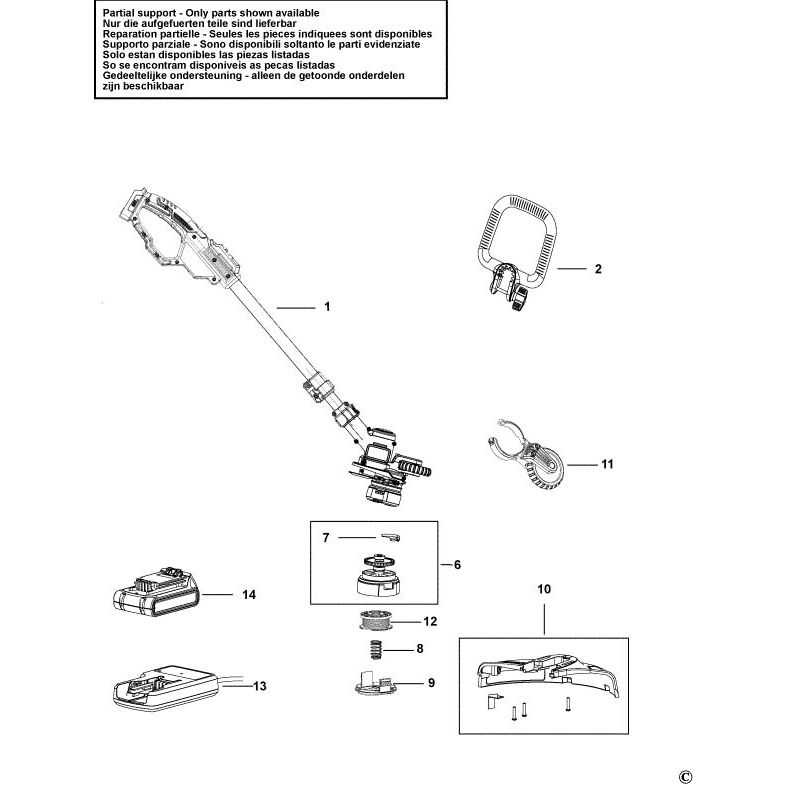

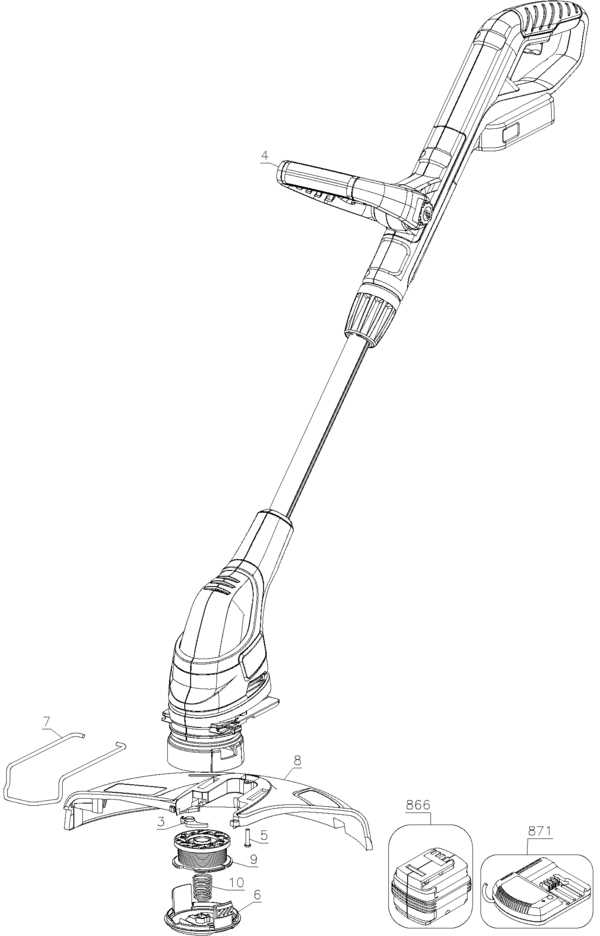

Overview of LST201 Components

This section provides a comprehensive examination of the various elements that make up the system, highlighting their functions and interconnections. Understanding these components is crucial for effective maintenance and operation.

Key Elements and Their Functions

The primary components play vital roles in the overall functionality. Each element is designed to work harmoniously, ensuring that the system operates efficiently. Identifying these key parts can help users troubleshoot issues and enhance performance.

Importance of Proper Maintenance

Regular upkeep of these components is essential for longevity and reliability. Neglecting maintenance can lead to diminished performance and potential failures. Familiarizing oneself with the components aids in recognizing when service is required.

Importance of Parts Diagrams

Visual representations of components play a crucial role in various fields, enhancing understanding and facilitating effective communication. These illustrations serve as a roadmap, guiding users through complex structures and ensuring clarity in assembly, maintenance, and repair processes. By providing a clear overview of individual elements and their relationships, they significantly contribute to efficiency and accuracy in technical tasks.

Enhancing Clarity and Understanding

Utilizing visual aids helps demystify intricate systems. Users can easily identify specific elements, comprehend their functions, and recognize how they fit together within a larger assembly. This clarity is essential not only for technicians and engineers but also for anyone involved in the operational aspects of machinery or devices.

Facilitating Maintenance and Troubleshooting

Effective visual guides are invaluable during maintenance and troubleshooting. They allow users to quickly locate potential issues and determine the necessary steps for resolution. By streamlining the repair process, these representations minimize downtime and enhance overall productivity.

Identifying Key Parts in LST201

Understanding the critical components of a machine is essential for effective operation and maintenance. Each element plays a significant role in the overall functionality, ensuring that the system performs optimally. Familiarity with these components not only aids in troubleshooting but also enhances the efficiency of repairs and replacements.

When examining the various sections, it is important to recognize the main functionalities and how they interconnect. Each segment contributes uniquely, influencing the overall performance and reliability. By familiarizing oneself with these elements, operators can better manage the system and anticipate potential issues before they arise.

Utilizing a comprehensive overview allows users to visualize the arrangement and significance of each section. This knowledge is invaluable for anyone involved in the upkeep and operation of the equipment, enabling a proactive approach to maintenance and an improved understanding of its workings.

Understanding LST201 Assembly Process

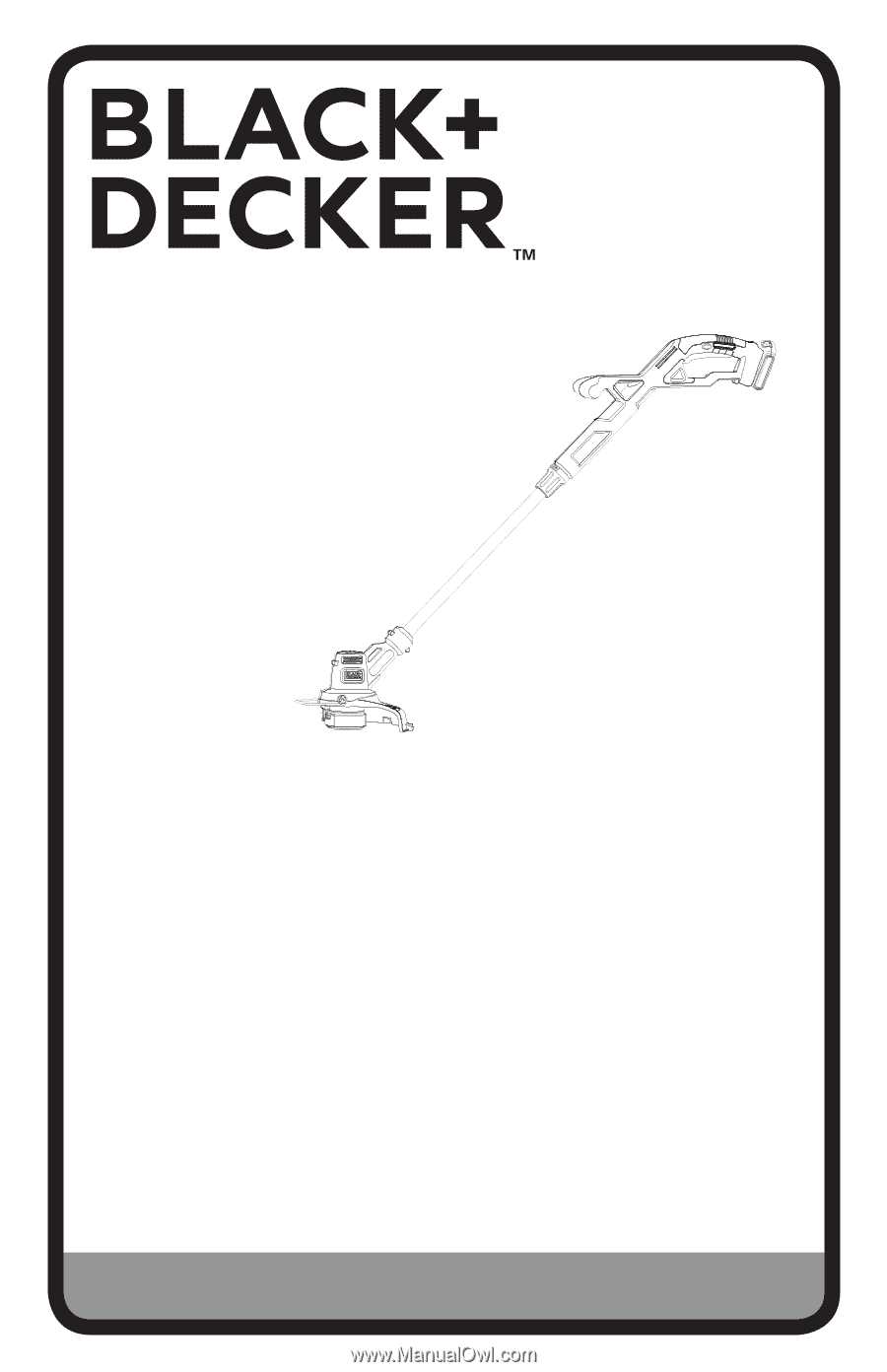

The assembly process for complex machinery involves meticulous attention to detail and a thorough comprehension of each component’s role within the larger system. This intricate procedure ensures that every element functions harmoniously, contributing to the overall efficiency and reliability of the final product.

To effectively navigate this assembly, one must familiarize themselves with the various components involved. Each piece plays a pivotal role, and understanding how they interact is crucial for a successful build. Proper organization and systematic approach can significantly enhance the assembly experience.

Moreover, it is essential to consider the tools and methods employed during the construction phase. Utilizing the right equipment and adhering to recommended techniques can streamline the process, reducing the likelihood of errors and ensuring that all components fit together seamlessly.

Finally, thorough inspection and testing are vital steps that should not be overlooked. Assessing the assembled machinery allows for the identification of any potential issues, ensuring optimal performance and longevity. This comprehensive understanding of the assembly process fosters a deeper appreciation for the craftsmanship involved in creating complex mechanical systems.

Common Issues with LST201 Components

When dealing with various elements in machinery, users often encounter a range of challenges that can affect performance and reliability. Understanding these common issues can help in effective troubleshooting and maintenance, ensuring smoother operation and extended lifespan of the equipment.

Frequent Problems

- Wear and Tear: Components can deteriorate over time due to friction and constant use, leading to decreased efficiency.

- Misalignment: Incorrect positioning of parts can result in operational failures and unusual noises during operation.

- Fluid Leaks: Seals and gaskets may fail, causing leaks that compromise functionality and can damage surrounding parts.

Troubleshooting Tips

- Regular Inspections: Conduct routine checks to identify wear before it becomes a significant issue.

- Proper Alignment: Ensure all components are correctly aligned during installation to prevent operational disruptions.

- Seal Maintenance: Replace seals and gaskets as part of routine maintenance to avoid leaks and preserve efficiency.

Maintenance Tips for LST201 Parts

Regular upkeep is crucial for ensuring the longevity and efficiency of your equipment. Proper care can prevent unnecessary wear and tear, ultimately saving time and costs associated with repairs or replacements. Here are some essential practices to maintain optimal functionality.

Routine Inspections

- Check for any visible signs of damage or wear.

- Ensure that all components are securely attached and functioning correctly.

- Look for signs of corrosion or dirt buildup that could affect performance.

Cleaning and Lubrication

Keeping your machinery clean is vital for its performance. Regular cleaning can help remove debris that may impede functionality.

- Use appropriate cleaning solutions to avoid damaging sensitive parts.

- Apply lubricants where necessary to ensure smooth operation.

- Follow manufacturer guidelines for the types of products to use.

Implementing these simple maintenance strategies can lead to improved performance and extend the lifespan of your machinery.

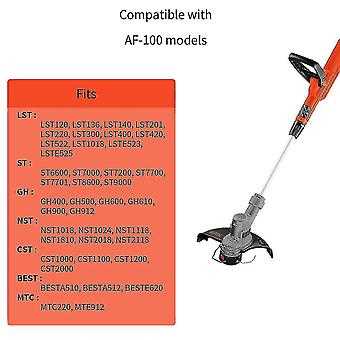

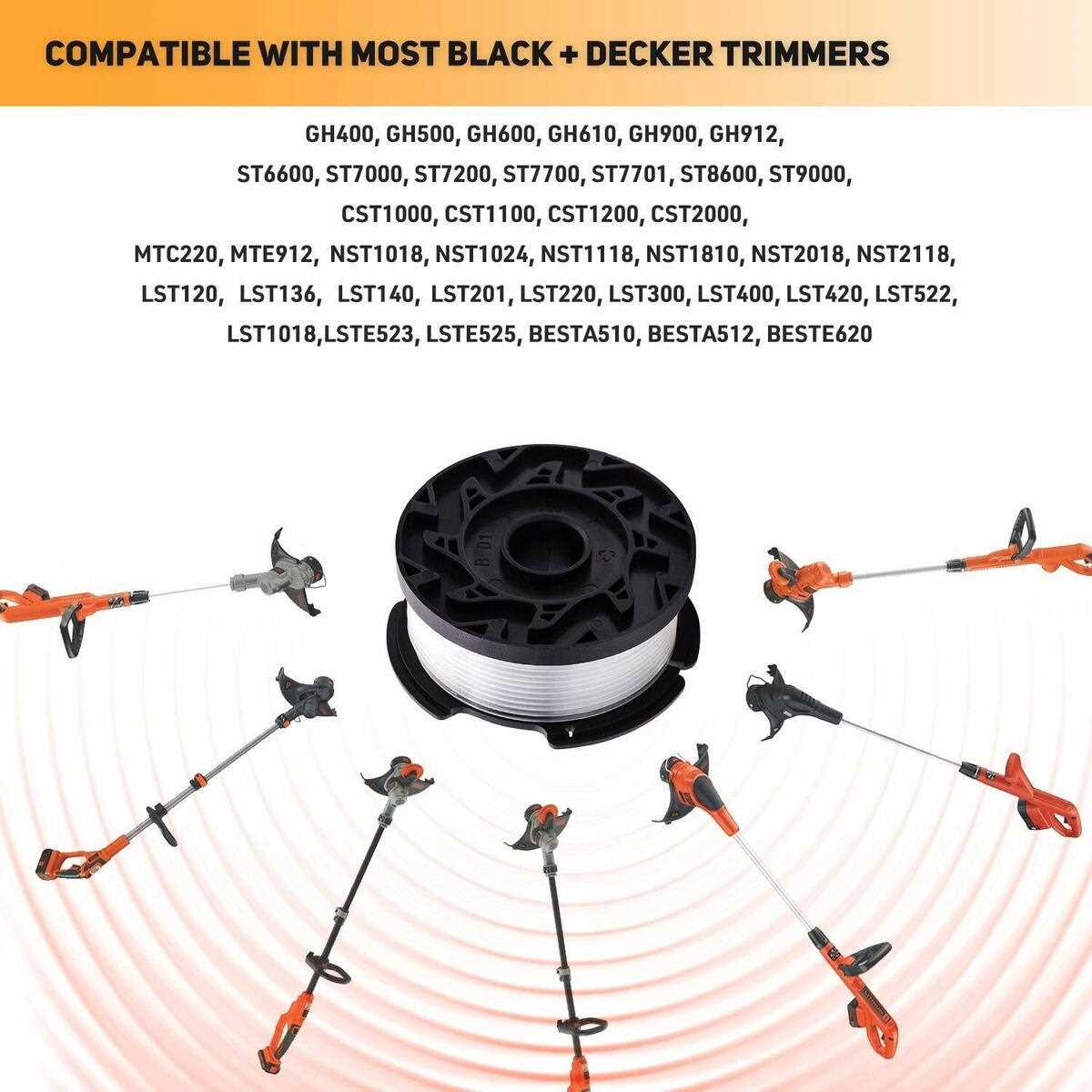

Replacement Options for LST201 Parts

When seeking alternatives for components in machinery, it is essential to consider various solutions that ensure optimal functionality and longevity. Different choices may vary in quality, compatibility, and price, impacting the overall performance of the equipment.

OEM Alternatives: Original equipment manufacturers typically provide high-quality replacements that are designed to meet the specifications of the original components. These options often guarantee reliability but may come at a higher cost.

Aftermarket Solutions: There are numerous aftermarket options available that can provide a cost-effective solution without compromising quality. These alternatives may offer similar performance but vary in durability and lifespan.

Refurbished Components: For those looking to save money, refurbished items can be an excellent choice. These parts have been restored to working condition and can serve as a viable option, especially when budget constraints are a concern.

Custom-Made Options: In some cases, custom solutions may be necessary. Working with manufacturers who can create tailored components ensures that specific needs are met, albeit at potentially higher prices and longer lead times.

Ultimately, selecting the right alternatives involves evaluating factors such as cost, performance, and availability to ensure the best outcomes for your machinery.

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to grasp the intricacies of mechanical systems. These visual representations provide a detailed view of components, their arrangements, and functions, making it easier to identify and address issues. By familiarizing oneself with these images, users can enhance their troubleshooting skills and maintenance capabilities.

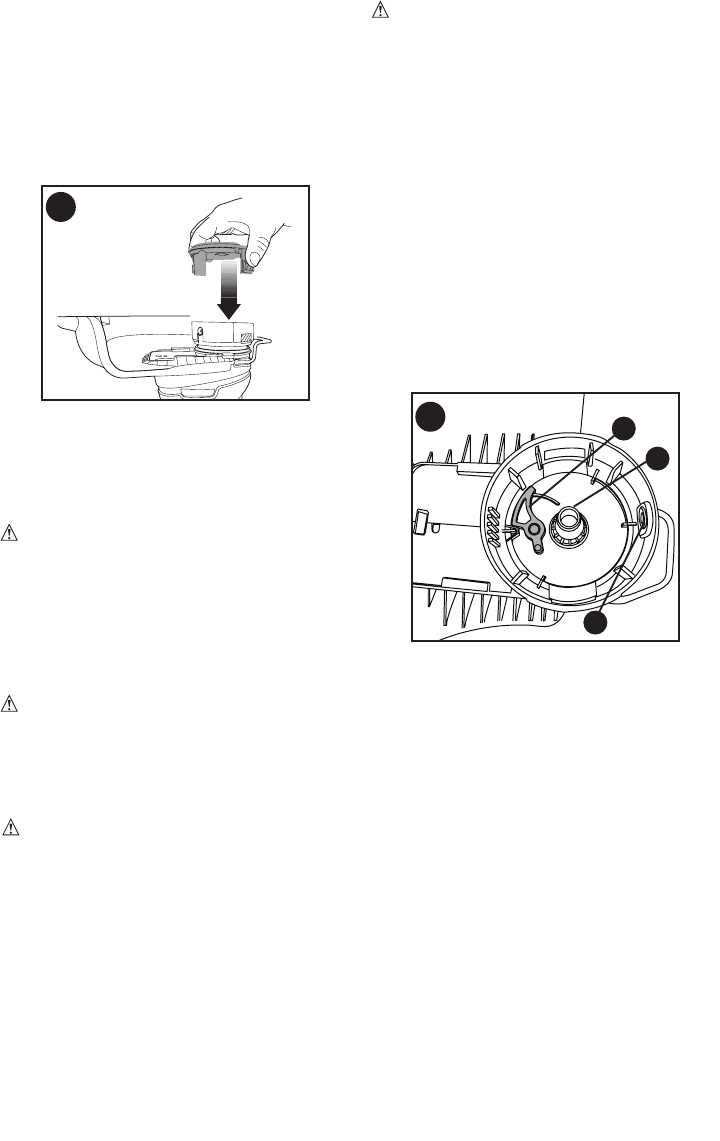

Identifying Components

Start by familiarizing yourself with the various elements depicted in the visual aid. Each item is typically labeled with unique identifiers, often accompanied by a numerical or alphabetical code. Pay attention to these designations, as they correspond to specific items in accompanying documentation or catalogs. Recognizing these labels is crucial for effective communication and ordering replacements.

Understanding Relationships

Next, focus on the relationships between different elements. Lines and arrows often illustrate connections, indicating how components interact within the overall assembly. Observing these connections helps in understanding the flow of operation, whether it’s fluid, electrical, or mechanical. This knowledge is invaluable for diagnosing problems and determining the necessary steps for repairs.

By mastering these skills, you will be better equipped to interpret technical visuals, leading to more efficient maintenance and repairs.

Differences Between LST201 Models

Understanding the variations among different iterations of a particular model is crucial for users seeking optimal performance and compatibility. Each version may showcase unique features, modifications, and improvements that cater to specific needs and preferences. This section aims to highlight the distinct aspects that set these models apart.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Power Output | 1500 W | 1800 W | 2000 W |

| Weight | 25 kg | 30 kg | 28 kg |

| Dimensions | 60 x 40 x 50 cm | 65 x 45 x 55 cm | 63 x 43 x 52 cm |

| Control Interface | Analog | Digital | Hybrid |

| Efficiency Rating | 85% | 90% | 88% |

Sources for LST201 Parts

When it comes to acquiring components for your machinery, having reliable resources is essential. Numerous suppliers offer a variety of items tailored to specific models, ensuring that users can find what they need without hassle. Whether you are looking for original or aftermarket options, exploring different avenues can lead to successful sourcing.

Online Retailers: Many websites specialize in the distribution of machine components. These platforms often feature user-friendly interfaces, enabling customers to search for specific items quickly. They also provide detailed descriptions and specifications, making it easier to compare products and choose the right fit for your needs.

Local Dealers: Visiting nearby dealerships can yield positive results. These establishments typically maintain a stock of essential items and can offer personalized assistance. Engaging with knowledgeable staff can help you identify suitable alternatives and enhance your understanding of various options available.

Manufacturer’s Websites: Checking the official sites of manufacturers is another effective strategy. They frequently list authorized distributors and provide updated information regarding new releases. This ensures that customers access genuine components, thereby maintaining the integrity of their machinery.

Forums and Community Groups: Engaging with online communities can be incredibly beneficial. These platforms allow users to share their experiences, recommendations, and tips on where to find specific items. Members often post reviews, which can assist you in making informed decisions about your purchases.

Future Upgrades for LST201

As technology continues to evolve, enhancing existing systems becomes crucial for maintaining optimal performance and efficiency. The potential for improvement in current models presents numerous opportunities for users to benefit from cutting-edge features and advanced capabilities. Exploring various enhancements can lead to a more versatile and effective device, tailored to meet the diverse needs of users.

Performance Enhancements

Upgrading components can significantly boost overall functionality. For instance, increasing processing speed or enhancing memory capacity can lead to a smoother experience and quicker response times. Additionally, integrating more efficient energy management systems can prolong usage time and reduce operational costs.

Customizability Options

Offering a range of customizable features allows users to tailor their devices to their specific requirements. This can include modular attachments that expand capabilities or software upgrades that provide new functionalities. Such options ensure that users can adapt their devices as their needs evolve over time.

| Upgrade Type | Potential Benefits |

|---|---|

| Processing Speed Increase | Faster operations and improved multitasking capabilities. |

| Memory Expansion | Enhanced storage capacity for applications and data. |

| Energy Efficiency Improvements | Longer usage time and lower energy costs. |

| Modular Attachments | Increased versatility and adaptability for various tasks. |

| Software Upgrades | Access to new features and improved user interface. |