Understanding the essential elements of a mechanical system can help in maintaining its proper operation and prolonging its lifespan. Each component within the system plays a vital role in ensuring smooth functionality, from the smallest to the largest part. Identifying these individual elements and their interrelations provides a comprehensive view of how the entire mechanism operates.

In this section, we will explore the core components, focusing on their specific functions and how they contribute to the overall efficiency of the machine. Gaining insight into these elements will allow for more effective maintenance and troubleshooting.

Maintenance and proper functionality rely heavily on a clear understanding of each component’s role. This information will empower you to make informed decisions regarding any adjustments or replacements necessary for optimal performance.

Overview of LT155 Components

The system is composed of several essential elements that ensure its proper functionality and performance. Each of these elements plays a critical role in maintaining overall efficiency and reliability, allowing smooth operation across various settings.

- The power unit is responsible for providing energy to all other elements, ensuring consistent and stable operation.

- Control mechanisms allow precise adjustments and fine-tuning, enabling better user control and system adaptability.

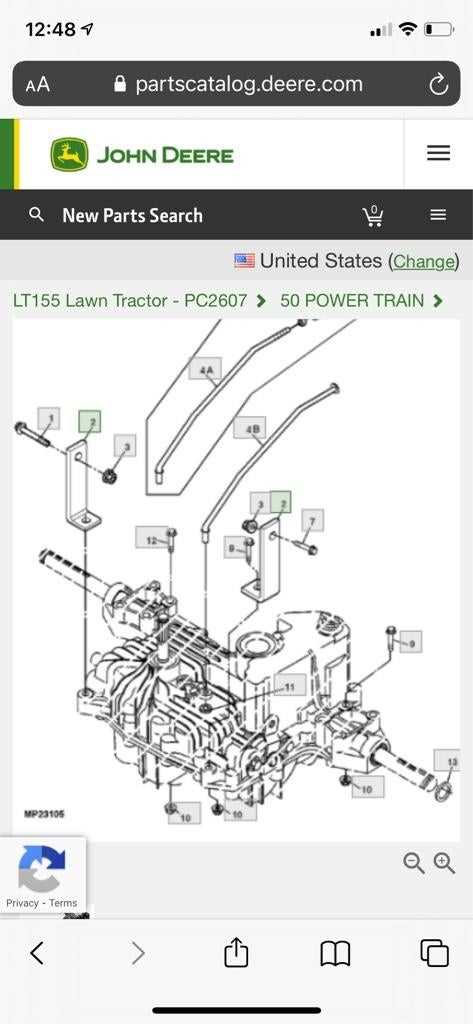

- The drive assembly ensures motion and movement, which is vital for operational efficiency and speed regulation.

- Safety features protect both the user and the system from potential hazards or failures, enhancing overall reliability.

Main Sections of the LT155 System

The structure of this system can be divided into several key components that work together to ensure smooth operation. These elements are designed to interact efficiently, providing stability and functionality across different areas of use. Understanding each section’s purpose is crucial for maintaining optimal performance and identifying potential areas for improvement.

One of the essential areas includes the core operational units responsible for driving the primary functions. These units are supported by additional mechanisms that ensure continuous and precise execution of tasks. Furthermore, the system is equipped with controls that allow for easy adjustments and fine-tuning, ensuring that it meets specific user requirements.

Another vital section focuses on safety and durability. This area is designed to prevent malfunctions and extend the system’s life span, protecting it from potential damage during use. Robust materials and secure connections make this part integral to the overall system’s reliability.

Detailed Breakdown of Mechanical Parts

The intricate construction of mechanical systems can be better understood by examining each individual component’s role and how they interact. This analysis highlights the critical elements responsible for the efficient functioning of the entire structure, offering a comprehensive view of their purpose and placement.

- Framework Components: The core structural elements provide stability and ensure all other segments are securely attached. These parts are often crafted from robust materials to withstand external forces and support the system’s overall integrity.

- Movement Mechanisms: These elements are responsible for converting energy into motion, ensuring smooth transitions and precise control. They typically include gears, levers, and shafts that coordinate the entire operation.

- Control Units: These systems regulate the various functions and ensure that the equipment operates within the desired parameters. They often include sensors and mechanical triggers to maintain performance consistency.

- Fastening and Support Elements: Screws, bolts, and brackets serve to connect and stabilize different segments, ensuring that

Electrical Components and Their Functions

Understanding the various electrical elements in machinery is crucial for ensuring optimal performance and longevity. Each component has a specific role, working together to power and control different functions within the system. Below, we will explore the key elements that form the electrical foundation of such systems.

- Wiring: Connects all the electrical elements, ensuring efficient power transmission throughout the machine.

- Battery: Provides the initial energy required to start and power various systems, acting as the primary power source.

- Fuse: Protects the system from electrical overloads by breaking the circuit if excessive current is detected.

- Switches: Allow users to control specific functions by opening or closing electrical circuits.

- Alternator: Recharges the battery and provides power to the electrical systems while the machine is operating.

These core components work in harmony to ensure the electrical integrity of the system, preventing malfunctions and ensuring continuous operation.

Key Features of the LT155 Structure

The framework of this model is designed to ensure durability and efficient functionality. Its components are carefully arranged to support optimal performance and long-lasting use, with each element serving a specific role in the overall system. This structure is built to handle a variety of tasks while maintaining stability and reliability.

One of the key elements of this design is its strategic configuration, which allows for easy access to critical areas. The layout promotes both balance and strength, ensuring that all mechanisms operate smoothly. Furthermore, the integration of high-quality materials enhances its resistance to wear and tear.

Another important aspect of this structure is its modularity, which provides flexibility for maintenance and potential upgrades. This thoughtful approach allows users to efficiently address any technical needs without compromising the overall stability of the machine.

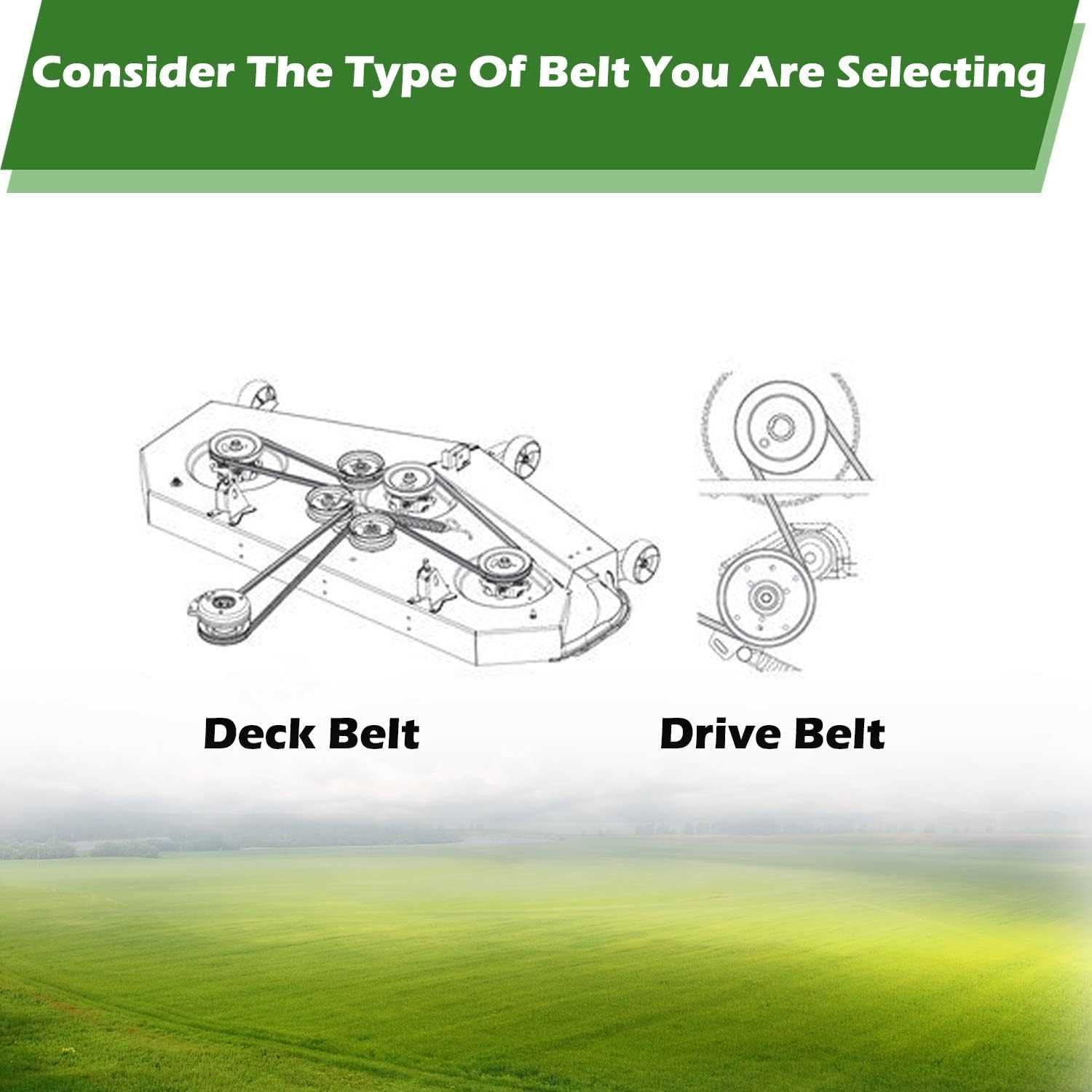

Commonly Replaced Parts in LT155

Maintenance is essential for ensuring the longevity and efficiency of any machine. Certain components are frequently substituted to maintain optimal performance. Understanding which elements often require replacement can help users manage their equipment effectively.

Key Components That Often Need Replacement

- Blades

- Battery

- Fuel filter

- Spark plug

- Air filter

Signs Indicating Replacement

- Decreased performance during operation

- Unusual noises while in use

- Difficulty starting the machine

- Visible wear or damage on components

Regular checks and timely replacements can significantly enhance the functionality and lifespan of your equipment, ensuring it runs smoothly for years to come.

Steps to Identify Worn Out Components

Identifying components that have experienced significant wear is crucial for maintaining optimal performance and extending the lifespan of your machinery. Regular inspections can help detect signs of degradation early, preventing further damage and costly repairs.

Start by performing a thorough visual examination of each element. Look for cracks, chipping, or any signs of physical damage that could indicate wear. Pay close attention to areas subjected to friction or stress, as these are often the first to show signs of deterioration.

Next, assess the functionality of each component. Listen for unusual noises during operation, which may suggest internal wear or misalignment. If any parts do not operate smoothly or exhibit irregular movements, they may need further inspection or replacement.

Finally, consult the manufacturer’s guidelines for recommended maintenance intervals and signs of wear specific to your equipment. This information can provide valuable insight into which components may require closer monitoring or replacement.

Understanding the Functionality of LT155 Subsystems

This section delves into the intricate workings of various components within the specified model, highlighting their roles and interactions. Each subsystem contributes to the overall performance and efficiency, ensuring seamless operation in diverse conditions.

Key Components and Their Roles

- Power Supply System: Responsible for providing energy to all operational parts, ensuring stability and reliability.

- Control Mechanism: Facilitates the management and coordination of different functions, enhancing user experience.

- Drive Assembly: Transmits power to the movement elements, playing a crucial role in performance and efficiency.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and ensuring longevity.

Interconnected Operations

The various components operate in tandem, creating a cohesive unit that enhances functionality. Understanding these connections is vital for troubleshooting and optimizing performance:

- The power supply feeds energy into the control mechanism, which directs other subsystems.

- The drive assembly responds to signals from the control unit, executing movement based on user input.

- The cooling system monitors temperatures, adjusting operations to prevent overheating.

How to Access and Remove Parts Safely

When working on machinery, it is essential to approach the disassembly process with caution to prevent damage and ensure personal safety. Proper techniques and tools can facilitate a smooth experience, making it easier to access various components without compromising their integrity.

Here are some steps to follow for safe removal:

- Prepare the workspace:

- Clear the area of any clutter to avoid accidents.

- Ensure good lighting to see all components clearly.

- Gather the necessary tools:

- Use appropriate tools for disassembly, such as screwdrivers and wrenches.

- Keep a magnetic tray handy to hold small fasteners.

- Disconnect power sources:

- Always turn off and unplug the equipment before starting work.

- If applicable, remove any batteries to eliminate electrical hazards.

- Follow a systematic approach:

- Refer to documentation for guidance on component locations.

- Remove components in a logical sequence to avoid confusion.

- Handle with care:

- Be gentle when detaching items to avoid bending or breaking.

- Store removed components in labeled containers to keep track of them.

By adhering to these guidelines, you can ensure a safer and more efficient process when accessing and removing elements from your equipment.

Maintenance Tips for Prolonging Component Lifespan

Ensuring the longevity of machinery elements requires regular care and attention. By implementing effective maintenance practices, users can enhance performance, reduce the likelihood of malfunctions, and ultimately extend the lifespan of crucial components. This section outlines essential tips to promote durability and efficiency.

Regular Inspection

Frequent checks are vital for identifying potential issues before they escalate. Look for signs of wear, corrosion, or any irregularities that may indicate a need for repairs or replacements. Addressing problems early can prevent more significant damages and ensure smooth operation.

Proper Lubrication

Applying the right lubricants is critical for reducing friction and minimizing wear. Ensure that all moving parts are adequately lubricated according to manufacturer specifications. Using the appropriate type of lubricant can significantly enhance the performance and durability of components.

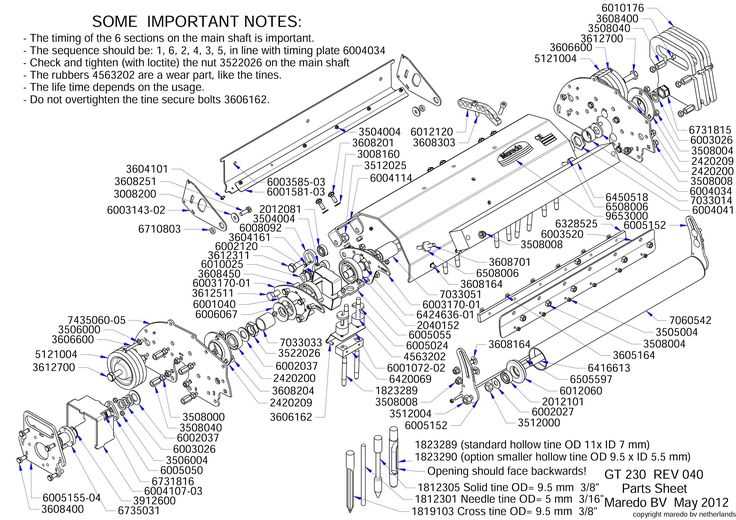

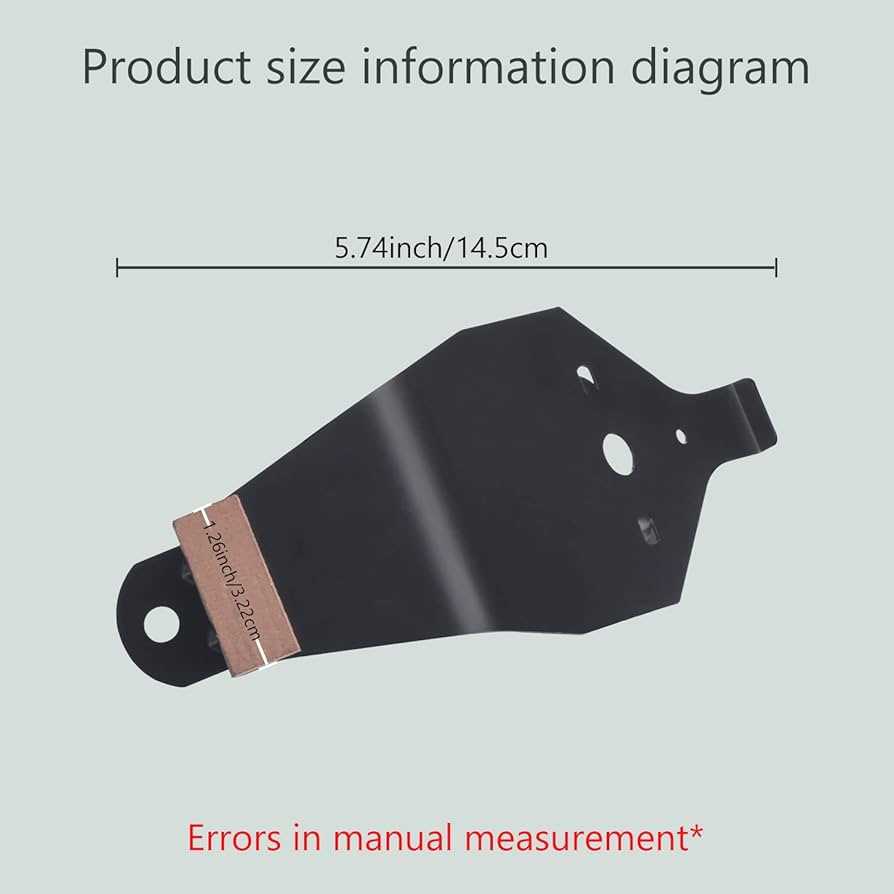

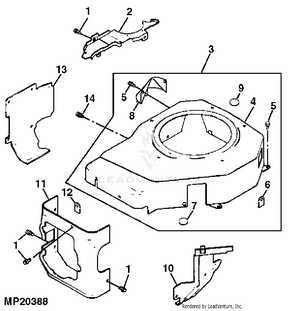

Tip Frequency Benefits Inspect for Wear Monthly Early problem detection Clean Components Every three months Prevents buildup and damage Lubricate Moving Parts Every six months Reduces friction and wear Diagrams for Quick Identification of Parts

Visual representations play a crucial role in efficiently recognizing components within a complex assembly. These illustrations simplify the process of understanding various elements, aiding users in locating and differentiating each segment swiftly. Utilizing these graphical tools enhances clarity and ensures that necessary replacements or repairs can be executed with minimal confusion.

Benefits of Using Visual Guides

Employing visual guides provides several advantages:

- Improved comprehension of component relationships.

- Faster identification of specific elements.

- Streamlined maintenance and repair procedures.

Types of Visual References

Different styles of visual references can be utilized to assist in recognizing components:

Reference Type Description Schematic Drawings Stylized representations that depict the arrangement of components and their connections. Exploded Views Illustrations showing parts separated but positioned to indicate how they fit together. 3D Models Digital renderings that provide a comprehensive view of components from multiple angles. Tools Required for LT155 Part Replacement

When it comes to replacing components in your equipment, having the right instruments is crucial for a smooth process. The correct tools not only facilitate efficient disassembly and reassembly but also ensure that each part is handled safely and securely.

Essential items include socket wrenches for loosening and tightening fasteners, screwdrivers in various sizes for accessing different screws, and pliers for gripping and maneuvering small parts. Additionally, a torque wrench can help ensure that bolts are tightened to the manufacturer’s specifications, preventing potential damage.

Don’t forget to equip yourself with cleaning supplies to maintain a tidy workspace and avoid contaminating new components. A magnetic tray is also beneficial for keeping small fasteners organized during the replacement process.

Guidelines for Ordering the Correct Components

Ensuring the acquisition of the appropriate elements for your machinery is crucial for optimal performance and longevity. Understanding how to navigate the ordering process can significantly reduce the risk of errors and enhance your overall experience.

Identifying Your Requirements

Before placing an order, it is essential to accurately determine the specific elements you need. Consider the following steps:

- Review your current inventory to identify missing or worn-out items.

- Consult the manufacturer’s documentation for detailed specifications.

- Note any model or serial numbers that may assist in locating the correct components.

Choosing a Reliable Supplier

Selecting a trustworthy supplier is vital to ensure you receive quality items. Keep these points in mind:

- Research potential suppliers and read customer reviews.

- Verify their return policy and warranty options.

- Inquire about their sourcing practices to ensure authenticity.