Understanding the essential elements of machinery is crucial for ensuring smooth operation and longevity. This section provides an in-depth look at various crucial elements that make up the functioning of a reliable piece of equipment. By familiarizing yourself with the core components, maintenance becomes more straightforward, helping you avoid unnecessary issues and extend the life of your machine.

Each element of your equipment serves a specific purpose, and knowing their placement and function can streamline repairs and replacements. Whether you are performing routine check-ups or addressing unexpected issues, a thorough understanding of these mechanical aspects will aid in efficient upkeep.

In the following sections, we will break down the structure of key operational elements, offering insights into how these parts contribute to overall performance. This approach allows for targeted solutions, minimizing downtime and enhancing the machine’s efficiency.

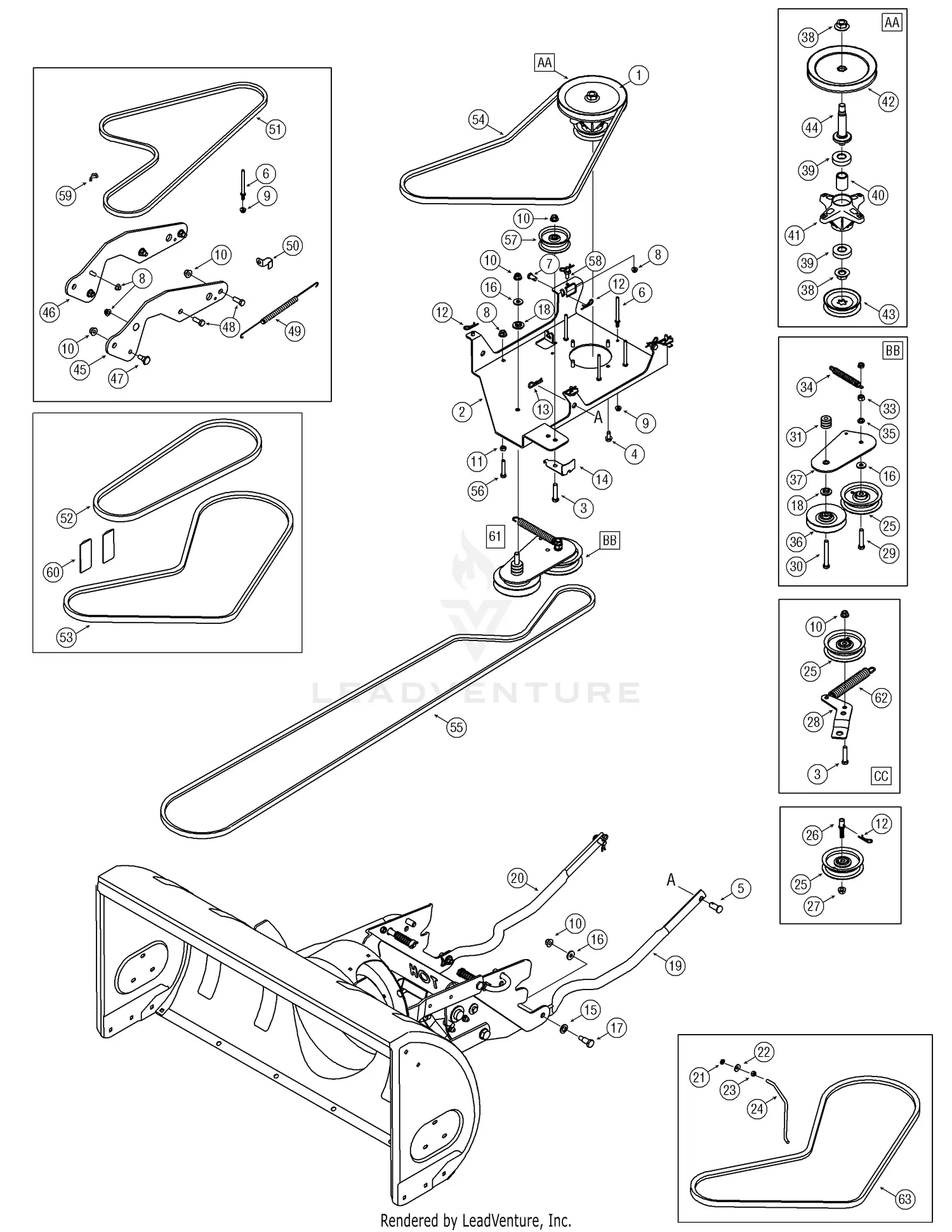

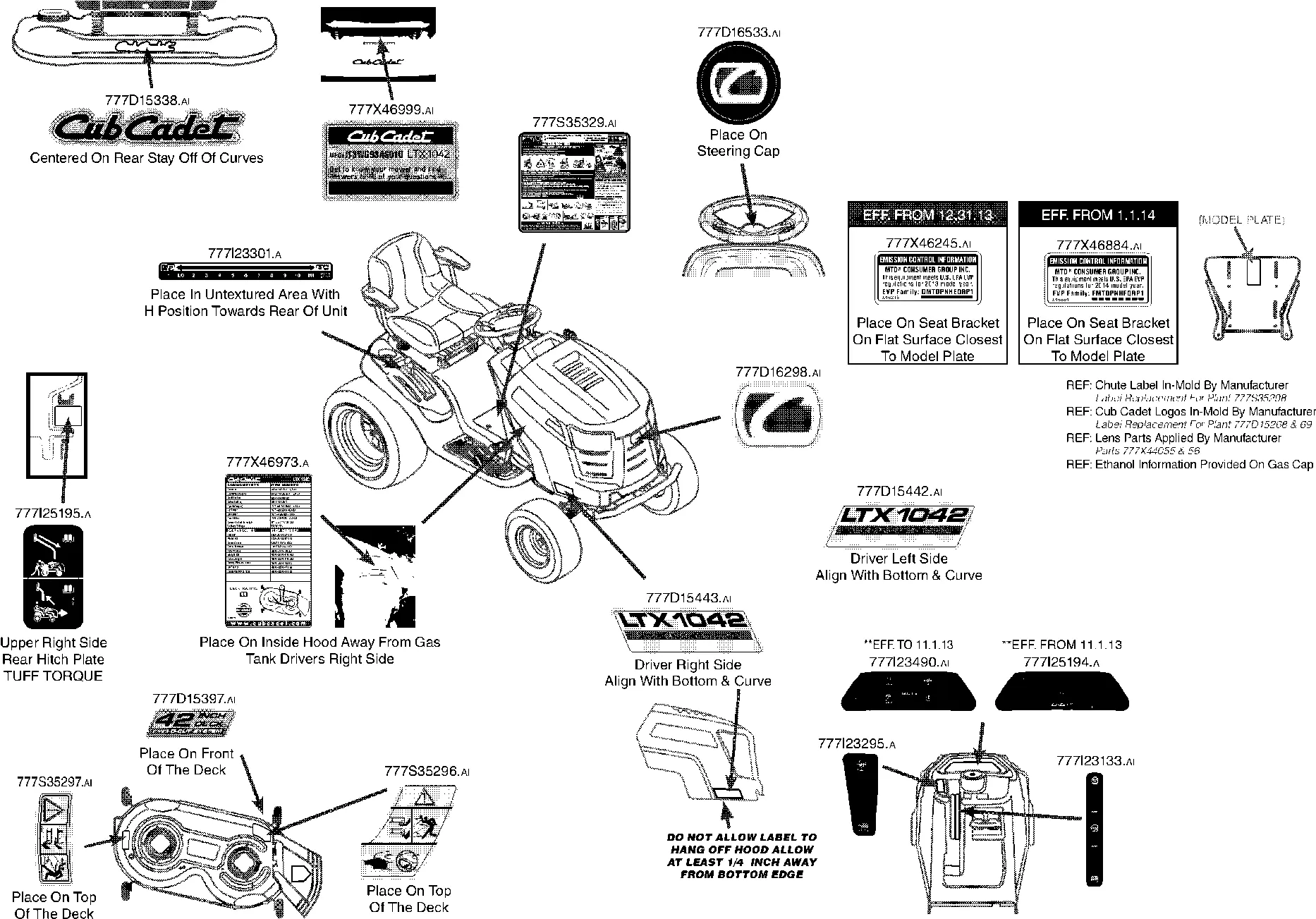

Ltx1042: Detailed Parts Breakdown

This section provides an in-depth look at the individual elements that contribute to the overall functionality of the machine. Each component is essential for the system’s smooth operation, ensuring that it performs its tasks efficiently and reliably. Understanding the various elements will help in maintaining and repairing the equipment with precision.

Key Mechanical Components

The machine is built from numerous mechanical units, each serving a specific purpose. From the power delivery system to the steering mechanisms, these elements work together to create a cohesive and functional structure. The synchronization of these components is crucial for optimal performance.

Functional Systems Overview

Beyond the mechanical units, the equipment includes various supporting systems such as the drive assembly and control mechanisms. These interconnected systems ensure that the machine operates with stability and accuracy. Proper care of these areas is vital for longevity and consistent functionality.

Main Components Overview

The structure of the machine consists of several key elements that work together to ensure smooth operation and efficiency. These essential elements are responsible for driving movement, providing control, and enabling functionality. Understanding how each part contributes to the overall mechanism is crucial for maintenance and optimal performance.

Engine and Transmission

Power generation and transmission are the heart of the system. The engine converts fuel into energy, which is then transferred through the transmission, ensuring motion and adaptability to different conditions. Both components require regular checks to ensure proper function and longevity.

Control and Steering System

Another vital aspect is the control system, which allows for precise steering and handling. This system includes a set of levers and gears that work harmoniously, allowing the operator to maneuver the machine with accuracy. Maintaining this system ensures ease of use and reliability.

Engine Structure and Key Elements

The core design of an engine involves a system of interconnected components that work together to convert fuel into mechanical energy. Understanding its structure and primary elements is essential for ensuring optimal performance and maintenance. Each component plays a vital role in this process, contributing to the overall functionality of the machine.

| Element | Function |

|---|---|

| Pistons | Transform combustion pressure into mechanical force, driving the crankshaft. |

| Crankshaft | Converts the reciprocating motion of pistons into rotational energy. |

| Valves | Regulate the intake of air and fuel and the release of exhaust gases. |

| Cylinder | Forms the space where fuel combustion takes place, housing the pistons. |

| Camshaft | Controls the timing of valve operation in coordination with piston movement. |

Transmission and Drive System Layout

The transmission and drive system are crucial components that ensure the smooth operation of the vehicle by transferring power from the engine to the wheels. These systems work in coordination to regulate speed, torque, and direction of movement, providing efficient control over the vehicle’s mobility.

| Component | Function |

|---|---|

| Transmission | Manages the power flow from the engine, adjusting speed and torque for optimal performance. |

| Drive Belt | Transfers rotational force from the engine to the axle or wheels, ensuring smooth motion. |

| Axle | Supports the wheels and transmits power from the drive belt to create movement. |

| Pulley System | Assists in redirecting and maintaining the correct tension in the belt for efficient operation. |

| Clutch | Engages and disengages the drive system to control power transmission during operation. |

Blades and Cutting Mechanism Details

The cutting system plays a crucial role in maintaining the efficiency and performance of your lawn equipment. Understanding how the blades and the cutting mechanism work together ensures optimal results, making mowing easier and more effective. A well-maintained setup guarantees smooth operation and extends the lifespan of your machine.

Blade Types and Functions

The blades come in different shapes and materials, each designed for specific tasks. Some blades are crafted for precision cutting, while others focus on mulching or bagging grass. Regularly inspecting and sharpening the blades is essential for maintaining their sharpness and reducing the strain on the cutting system.

Cutting Mechanism Operation

The cutting mechanism is powered by a rotating system that ensures the blades move at the required speed. Proper alignment and tension of the components are critical to prevent any disruptions in performance. Regular maintenance of this mechanism helps to achieve a clean cut and minimizes damage to the lawn.

Steering Assembly and Functionality

The steering system is a crucial component of any vehicle, ensuring precise control and direction. It plays a vital role in enabling the operator to navigate smoothly and maintain stability while driving. Understanding its structure and how it operates is essential for effective maintenance and repair.

Components of the Steering System

The steering assembly consists of several key elements that work together to facilitate movement. Each part has a specific function that contributes to the overall efficiency of the system. The primary components include:

- Steering Wheel: The interface for the operator to control the direction.

- Column: The shaft connecting the steering wheel to the gear mechanism.

- Gearbox: Converts the rotational motion from the steering wheel into lateral movement.

- Linkages: Connect various parts, allowing for the transfer of motion.

- Wheel Assembly: The final point where steering input is translated into directional change.

Functionality Overview

When the steering wheel is turned, the force is transmitted through the column to the gearbox, which alters the angle of the wheels. This transformation allows the vehicle to turn left or right as desired. The efficiency of this system is paramount for safe operation, as any malfunction can lead to compromised control. Regular inspection of each component is recommended to ensure optimal performance.

Electrical System and Wiring Guide

This section provides a comprehensive overview of the electrical components and wiring configurations essential for the efficient operation of machinery. Understanding the layout and functionality of these elements is crucial for maintenance and troubleshooting.

Key Components of the Electrical System

- Batteries: Store electrical energy and supply power to the system.

- Fuses: Protect the circuit from overcurrent and potential damage.

- Switches: Control the flow of electricity and enable or disable devices.

- Connectors: Facilitate secure connections between different wiring sections.

Wiring Configuration

Wiring arrangements play a vital role in ensuring reliable operation. Proper installation and maintenance of wiring are essential to prevent electrical failures.

- Check for corrosion or wear at connection points.

- Ensure wires are properly insulated to prevent short circuits.

- Follow the correct color coding for wires to maintain consistency.

Adhering to these guidelines will enhance the performance and longevity of the electrical system.

Chassis and Frame Components

The structural foundation of any vehicle plays a crucial role in its overall performance and stability. This section delves into the essential elements that form the backbone of machinery, highlighting their importance in ensuring durability and reliability during operation.

Key Structural Elements

Various components work in unison to provide strength and support. These include the main frame, cross members, and support brackets, each designed to withstand stress and distribute loads effectively. The integration of these parts contributes to the overall integrity of the machinery.

Functionality and Importance

The functionality of the chassis and frame is paramount, as they influence handling, maneuverability, and safety. A well-designed structure ensures that the vehicle can endure challenging conditions while maintaining optimal performance, making it a vital consideration for any operator.

Fuel System Parts and Configuration

The fuel delivery mechanism is crucial for optimal engine performance. It comprises various components that work together to ensure the proper flow and mixture of fuel, enabling efficient combustion. Understanding these elements is essential for troubleshooting and maintenance.

Key Components of the Fuel Delivery Mechanism

- Fuel Tank: Stores the fuel until it is needed by the engine.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel to protect engine components.

- Fuel Injector: Atomizes the fuel, allowing for precise delivery into the combustion chamber.

- Fuel Lines: Facilitate the movement of fuel between components.

Configuration and Setup

Proper configuration of the fuel delivery system is vital for maintaining efficiency and performance. This includes ensuring the correct alignment of the fuel lines and securing connections to prevent leaks. Regular inspection of the filter and injectors can enhance fuel flow and improve overall engine function.

Maintenance Tips for Critical Parts

Ensuring the longevity and optimal performance of essential components requires regular upkeep and attention. This section highlights some effective strategies to maintain these crucial elements, enhancing their durability and efficiency. Adopting proactive measures can prevent costly repairs and extend the lifespan of the equipment.

Regular Inspections

Frequent evaluations of key components can help identify wear and tear early. Look for signs of deterioration, such as unusual noises, leaks, or reduced functionality. Establish a routine schedule for these checks to ensure no issues are overlooked.

Proper Lubrication

Maintaining appropriate lubrication levels is vital for the smooth operation of moving parts. Use the recommended lubricants to reduce friction and wear. Always follow the manufacturer’s guidelines to select the right type and amount of lubricant.

| Maintenance Activity | Frequency | Recommended Action |

|---|---|---|

| Visual Inspection | Weekly | Check for visible damage and leaks |

| Lubrication | Monthly | Apply appropriate lubricant |

| Functional Testing | Quarterly | Test all critical functions |

Troubleshooting Common Issues with Parts

When working with mechanical components, various challenges can arise, affecting performance and functionality. Understanding the typical problems associated with these elements is essential for effective resolution and maintenance. This section outlines common issues and practical steps to address them, ensuring optimal operation and longevity.

Identifying Common Problems

- Inconsistent performance: Components may not function as expected due to wear and tear or misalignment.

- Unusual noises: Grinding, rattling, or clicking sounds can indicate internal damage or loose fittings.

- Overheating: Excessive heat generation can result from friction, inadequate lubrication, or obstruction.

Steps to Resolve Issues

- Inspect for visible damage or signs of wear.

- Check for proper alignment and secure fittings.

- Ensure adequate lubrication is applied where necessary.

- Test the functionality after making adjustments to confirm improvements.

By following these guidelines, users can effectively troubleshoot and resolve issues, enhancing the reliability of their equipment.