In this section, we delve into the essential structural elements that make up a widely popular vehicle. These elements ensure the smooth operation of the machine, maintaining performance and durability across different terrains and conditions. By exploring how each component interacts within the overall system, you’ll gain a clearer understanding of its functionality and importance in maintaining optimal performance.

Whether you’re conducting maintenance or looking for specific replacements, understanding the layout of various elements is crucial. Our guide will provide a detailed breakdown of each unit, emphasizing their role and significance in the machine’s operation. This approach will help you navigate through the technical intricacies with ease, ensuring that each part is correctly identified and handled.

Understanding the Components of the LTZ 400

The mechanical structure of this popular off-road vehicle is composed of a variety of interconnected elements that ensure smooth performance and durability. Recognizing the individual elements and their functions can help in both maintenance and repair, providing a deeper understanding of how the machine operates as a whole.

Key Mechanical Elements

- Engine System: The core powerhouse responsible for generating the necessary force to drive the vehicle.

- Suspension: Designed to absorb shocks, this system ensures a comfortable and controlled ride over uneven terrain.

- Transmission: Connects the engine to the wheels, allowing for efficient power distribution and speed control.

- Brake Assembly: Provides the critical ability to slow down

Key Engine Parts for LTZ 400

Understanding the essential components of a sport quad engine is critical for maintaining peak performance. Each element plays a specific role in ensuring smooth operation, power delivery, and reliability. In this section, we will outline the most vital parts that contribute to the engine’s overall efficiency and functionality.

Core Elements of the Power Unit

The engine is driven by several key components that work together in harmony. The piston, which moves within the cylinder, is responsible for generating power through combustion. Connected to it, the crankshaft converts linear motion into rotational energy. These parts rely on precise timing and synchronization, which is handled by the camshaft, ensuring the proper opening and closing of valves.

Essential

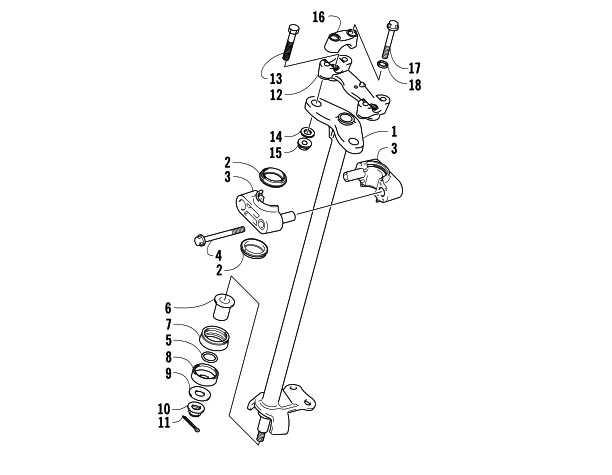

Suspension and Frame Diagram Insights

The structure and components of a vehicle’s suspension and frame play a crucial role in ensuring stability, handling, and overall performance. Understanding how these elements interact can greatly improve the knowledge of their functionality, which is vital for both maintenance and potential upgrades.

Key Components of the Suspension System

The suspension system consists of multiple elements that work together to absorb shocks, maintain wheel alignment, and provide a smooth ride. It includes control arms, springs, dampers, and various linkages, all designed to reduce the impact of uneven surfaces on the vehicle’s performance.

Frame Structure and Its Importance

The frame forms the backbone, providing structural support

LTZ 400 Electrical System Overview

The electrical system in this model is an essential component that ensures the smooth operation of all electronic functions. It encompasses a range of interconnected elements responsible for providing power, managing signals, and ensuring proper communication between various systems. Understanding the layout and functionality of these elements is crucial for troubleshooting, maintenance, and potential upgrades.

Key Components of the electrical framework include the power generation unit, wiring harness, and control modules. Each plays a distinct role in ensuring that power is efficiently distributed throughout the vehicle’s circuits, allowing all components to work harmoniously. Additionally, safety mechanisms are built into the system to prevent overloading and ensure reliability.

When considering maintenance, paying close attention to wiring connections

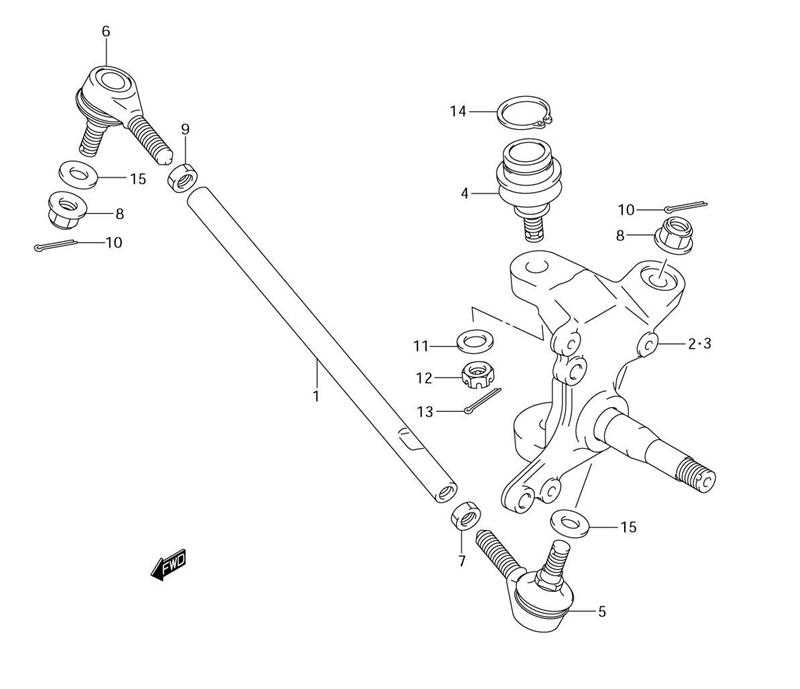

Brake System Components Breakdown

The brake system is essential for ensuring a vehicle’s safety, enabling it to slow down or stop efficiently. Understanding the various elements involved in this system can help in the maintenance and repair process, ensuring optimal performance and preventing potential issues. In this section, we will explore the primary components of the brake mechanism and how they function together to deliver reliable stopping power.

Primary Components of the Brake Mechanism

The brake system is composed of several critical parts that work in unison to control the vehicle’s speed. These include elements responsible for generating the necessary friction, distributing hydraulic pressure, and managing heat dissipation. Below is a table highlighting the main components and their respective roles in the system.

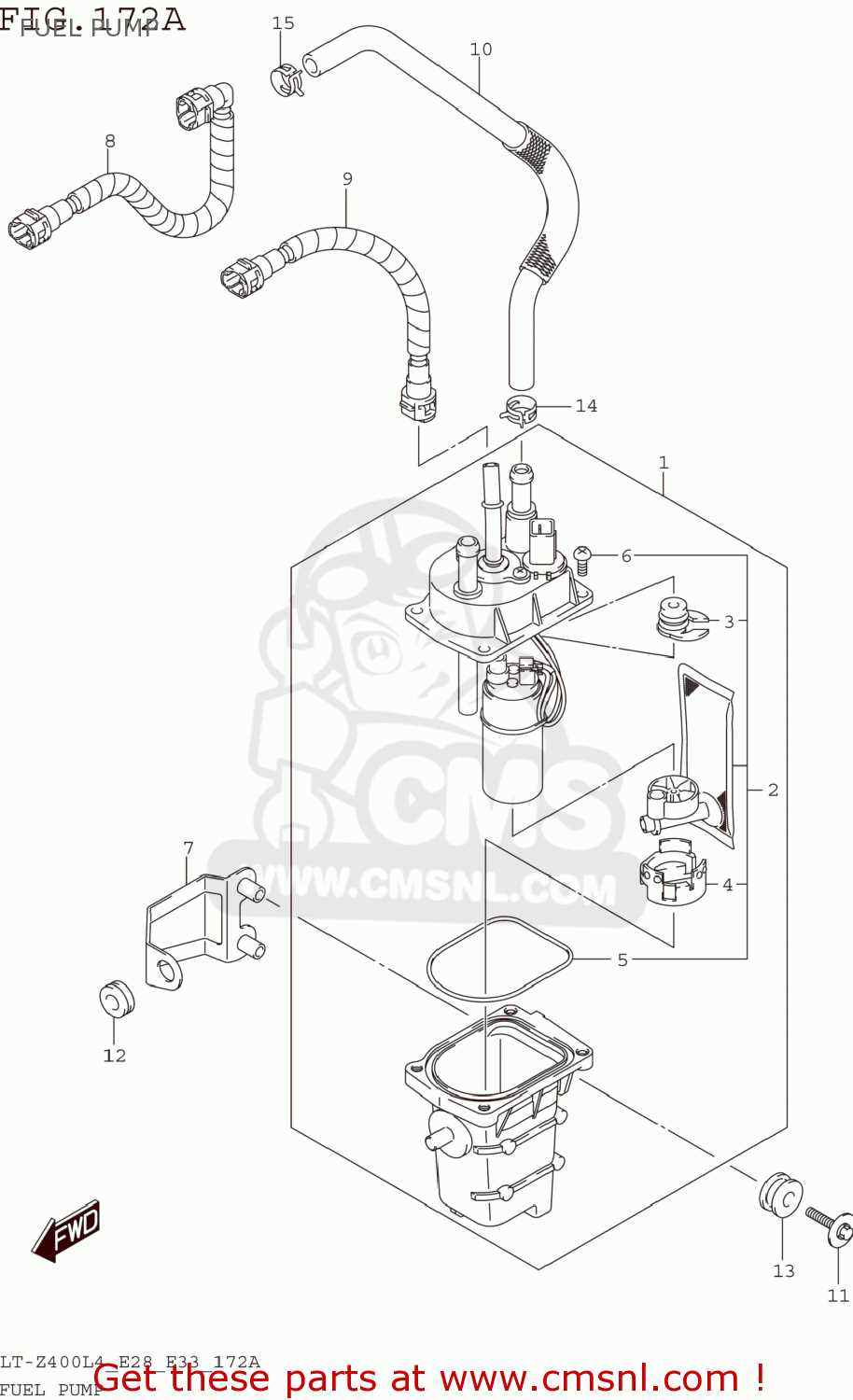

Component Fuel System and Carburetor Layout

The fuel delivery mechanism and carburetor configuration play a vital role in the overall performance of any off-road vehicle. These components work together to ensure that the engine receives the appropriate amount of fuel for efficient combustion, ultimately impacting acceleration, power output, and fuel efficiency. A thorough understanding of this system is essential for troubleshooting and maintenance.

The fuel system typically consists of a tank, fuel lines, a pump, and the carburetor itself. The tank stores the fuel, while the pump transports it to the carburetor, which mixes the fuel with air in the correct proportions. This mixture is then delivered to the engine for combustion. Proper alignment and condition of these components are crucial for optimal engine performance.

The carburetor layout often includes various adjustments to fine-tune the fuel-air mixture. These adjustments can significantly affect engine responsiveness and overall performance. Regular inspection and maintenance of the carburetor ensure that it functions correctly, preventing issues such as poor fuel economy or rough idling.

Understanding the layout of the fuel system and carburetor can aid in identifying potential issues and implementing effective solutions, enhancing the longevity and reliability of the vehicle.

Cooling System Parts and Their Functions

The cooling system plays a crucial role in maintaining optimal operating temperatures within an engine. It prevents overheating and ensures efficient performance by circulating coolant and dissipating heat. Understanding the components involved in this system is essential for effective maintenance and troubleshooting.

Component Function Radiator Dissipates heat from the coolant, allowing it to cool before returning to the engine. Water Pump Circulates coolant throughout the system, ensuring a constant flow to maintain temperature. Thermostat Regulates coolant flow based on temperature, allowing the engine to reach optimal operating temperature quickly. Coolant Reservoir Holds excess coolant and allows for expansion and contraction as temperatures fluctuate. Hoses Transport coolant between components, maintaining a closed loop within the system. Transmission and Clutch Components Explained

The transmission and clutch system is a vital part of any vehicle, playing a crucial role in the transfer of power from the engine to the wheels. Understanding the different elements within this system can enhance one’s knowledge of how a vehicle operates and improve maintenance practices. This section will explore the key components involved, their functions, and how they interact with each other.

Key Transmission Components

At the heart of the transmission system lies the gearbox, which is responsible for altering the vehicle’s speed and torque. Within the gearbox, gears of various sizes allow the vehicle to operate efficiently at different speeds. Additionally, the shift lever and linkage facilitate gear changes, enabling smooth transitions between different driving conditions. A well-functioning transmission ensures optimal performance and fuel efficiency.

Understanding the Clutch Mechanism

The clutch serves as a critical connection point between the engine and the drivetrain. Its primary function is to engage and disengage the engine from the transmission, allowing for seamless gear shifts. The main components of the clutch include the pressure plate, friction disc, and release bearing. When the clutch pedal is pressed, the pressure plate releases the friction disc, disconnecting the engine’s power and enabling a change in gears. Proper maintenance of the clutch system is essential for smooth vehicle operation.

Wheels and Tire Assembly Overview

The assembly of wheels and tires is a crucial component in any vehicle’s performance and safety. Properly functioning wheels not only provide support but also enhance the overall driving experience. Understanding the various elements involved in this assembly is essential for maintenance and optimal operation.

Key components of the wheel and tire assembly include:

- Wheels: These are the circular objects that support the tires and enable movement. They come in various sizes and materials, influencing both aesthetics and functionality.

- Tires: These are the rubber coverings that provide traction and grip on the road. Tires can vary based on tread patterns, sizes, and rubber compounds, affecting performance in different conditions.

- Rims: These are the outer edges of the wheels, holding the tire in place. Rims come in different designs and sizes, which can impact the vehicle’s handling and style.

- Valve Stems: These components allow for air inflation and deflation of the tires. A well-functioning valve stem is crucial for maintaining proper tire pressure.

- Hub Assemblies: These parts connect the wheels to the vehicle’s axles, enabling rotation and providing stability.

Regular inspection and maintenance of the wheel and tire assembly are vital for ensuring safety and enhancing the longevity of the vehicle. Proper alignment, tire pressure, and tread depth should be monitored to prevent issues and ensure optimal performance.

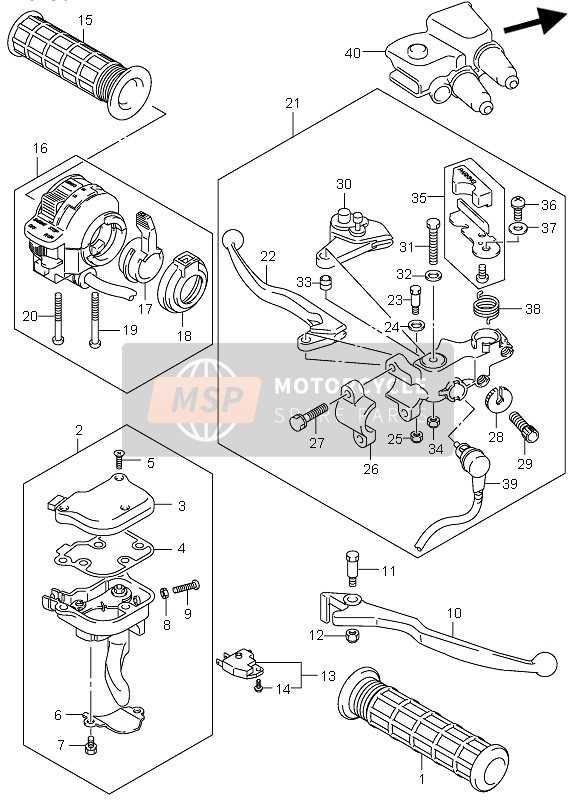

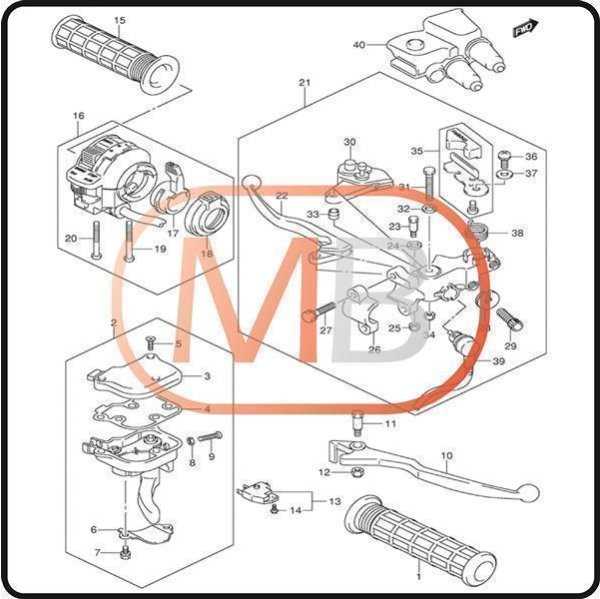

Handlebar Controls and Cable Routing

The efficiency and functionality of a vehicle greatly depend on the configuration of its control systems and the proper management of cable pathways. Understanding how to navigate these components can enhance performance and provide a smoother riding experience. In this section, we will explore the essential elements that contribute to the overall control setup.

Control Elements Overview

Handlebar controls are crucial for operating various features of the vehicle, such as throttle, brakes, and electrical functions. These elements should be positioned for easy access, ensuring that the rider can maintain full control without distraction. Ergonomic design is key, allowing for intuitive handling and responsiveness while navigating different terrains.

Effective Cable Routing

Proper cable routing is vital to prevent wear and tear, ensuring longevity and reliability. Cables must be secured and organized to minimize friction and avoid entanglement with other moving parts. Utilizing guides and clips can facilitate optimal routing, helping maintain the integrity of the control systems under various riding conditions.

Bodywork and Plastics: Full Diagram

This section provides a comprehensive overview of the exterior components and materials used in the vehicle’s construction. Understanding the arrangement and function of these elements is crucial for maintenance and repair.

The structure is composed of various panels and coverings that not only enhance the aesthetics but also contribute to the overall durability and performance. Each component plays a vital role in protecting internal mechanisms from environmental factors while ensuring a sleek appearance.

By analyzing the layout, enthusiasts and technicians can better comprehend how each part integrates with others. This knowledge is essential for effective repairs, upgrades, and modifications, ensuring the vehicle remains in optimal condition.