Ensures the safety and control of the vehicle by allowing it to

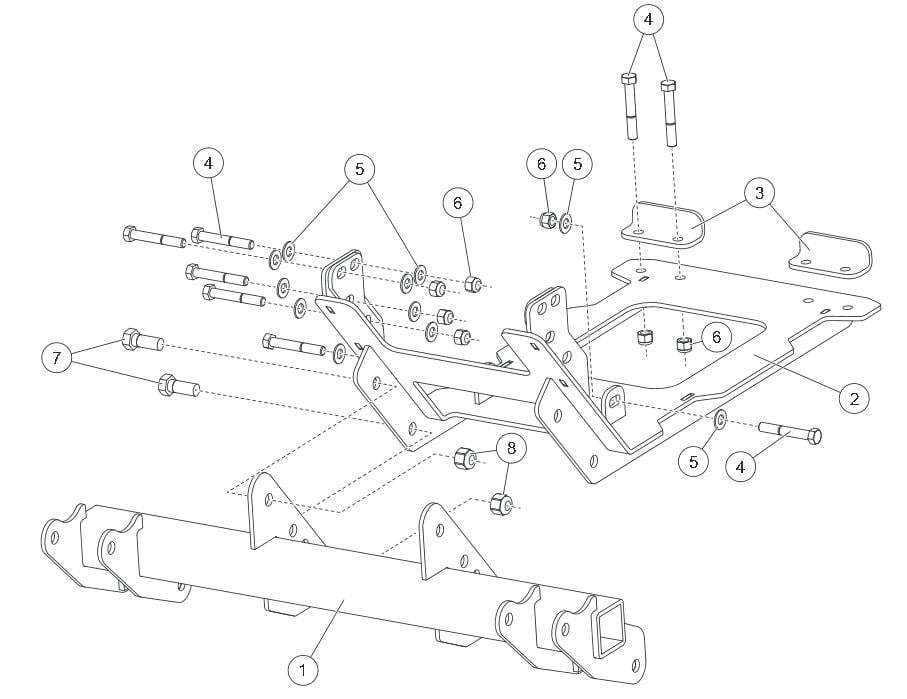

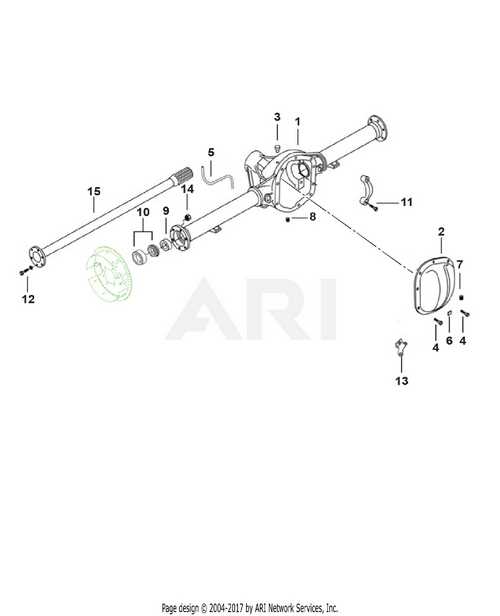

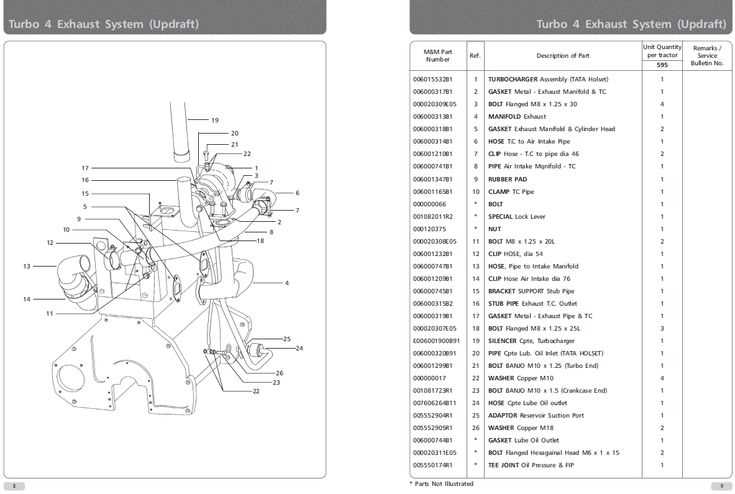

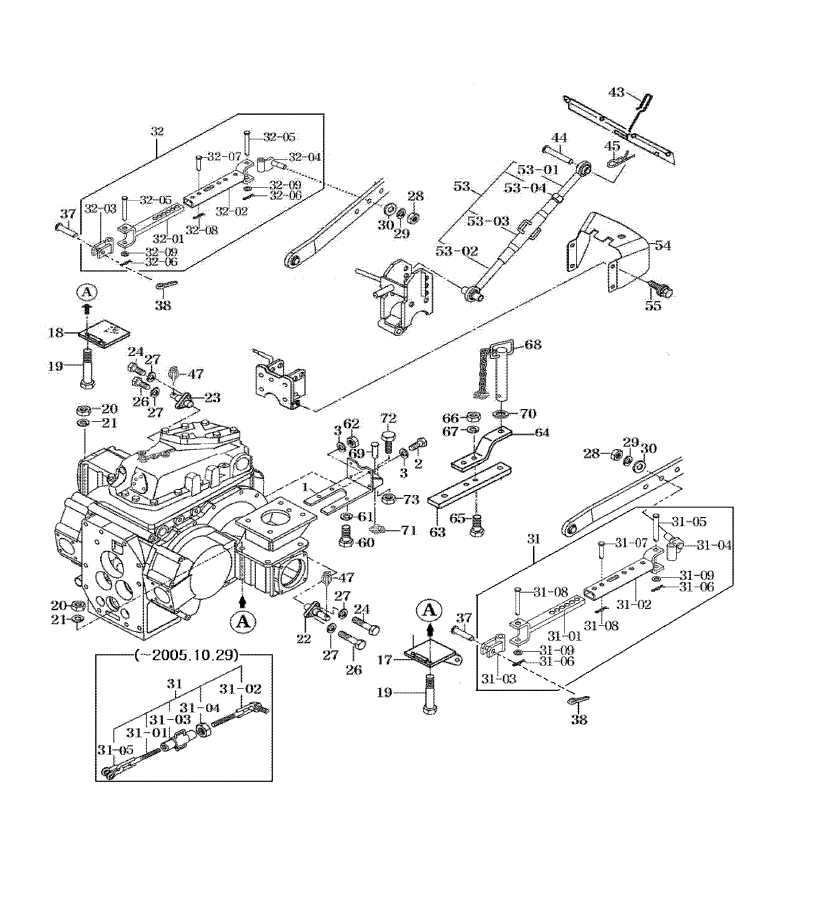

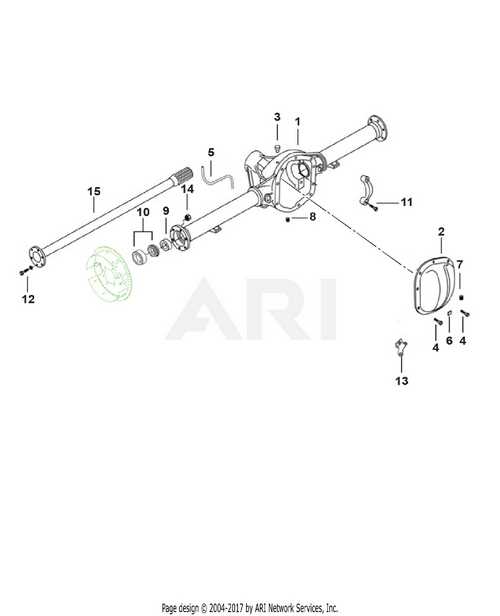

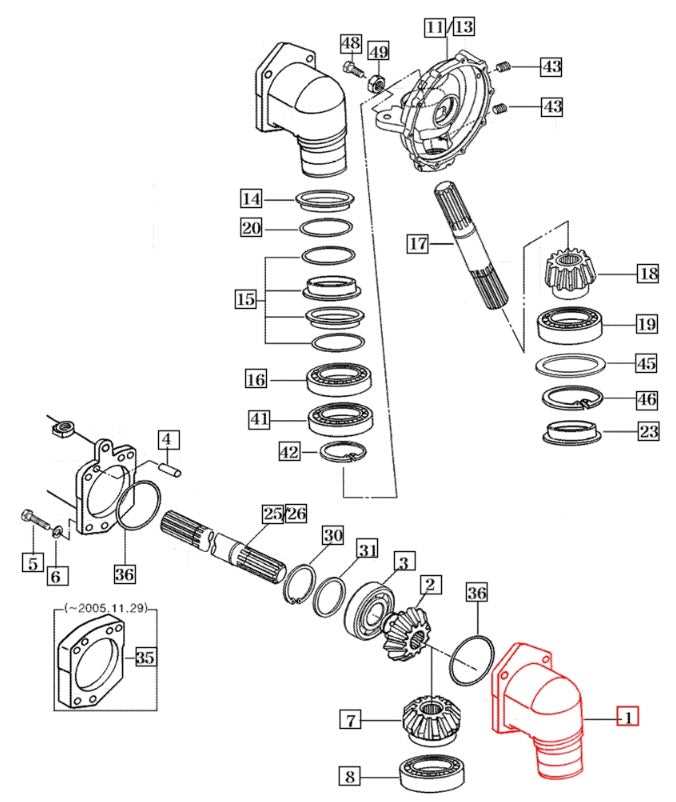

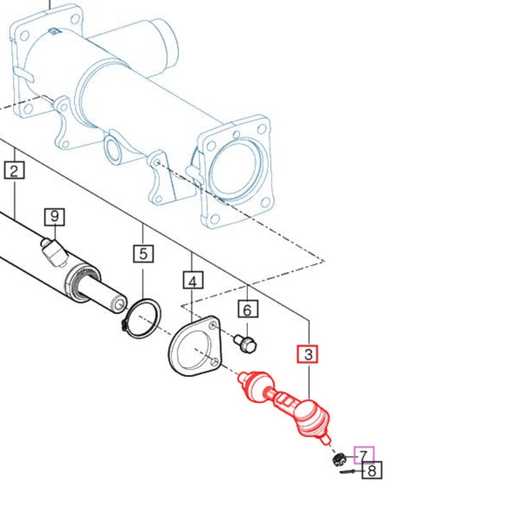

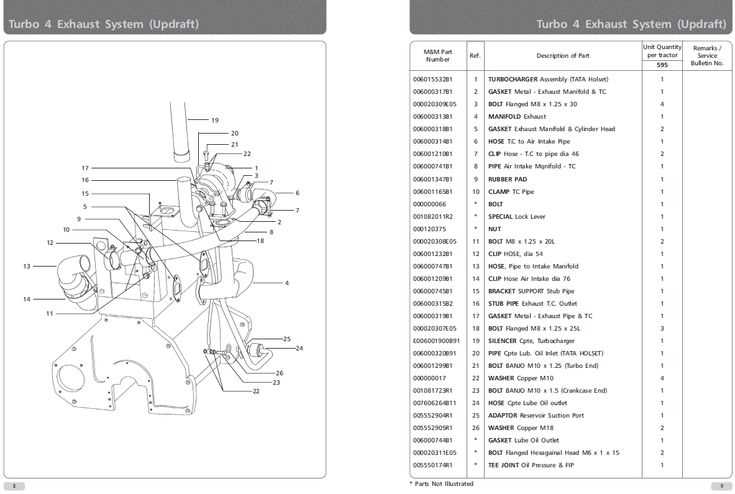

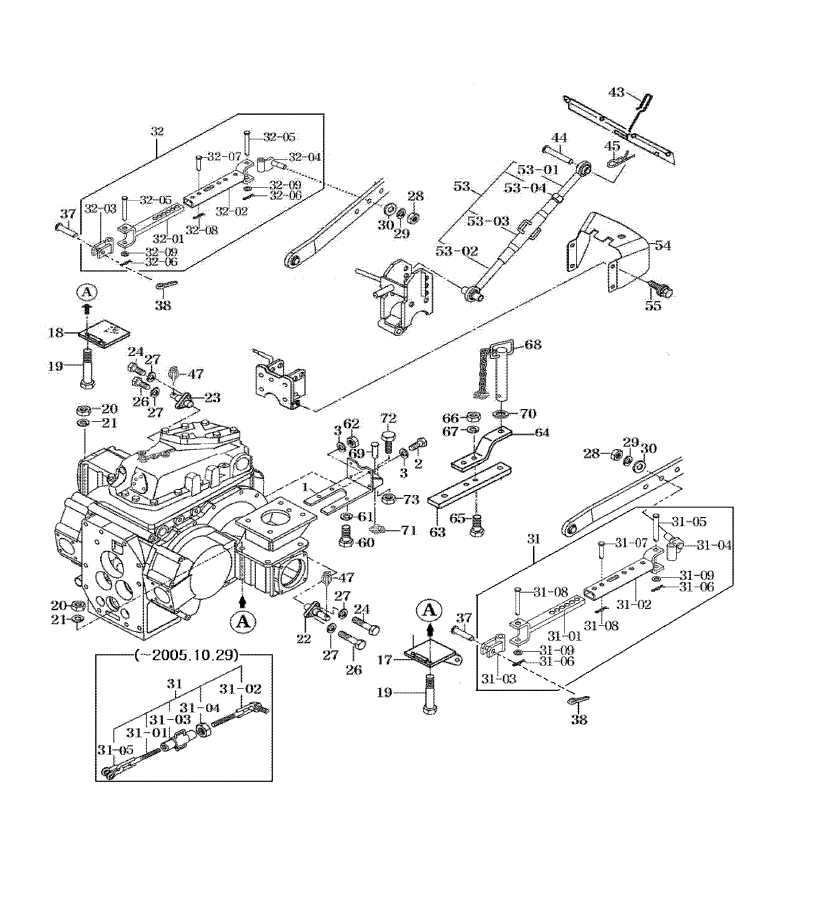

How to Read Parts Diagrams

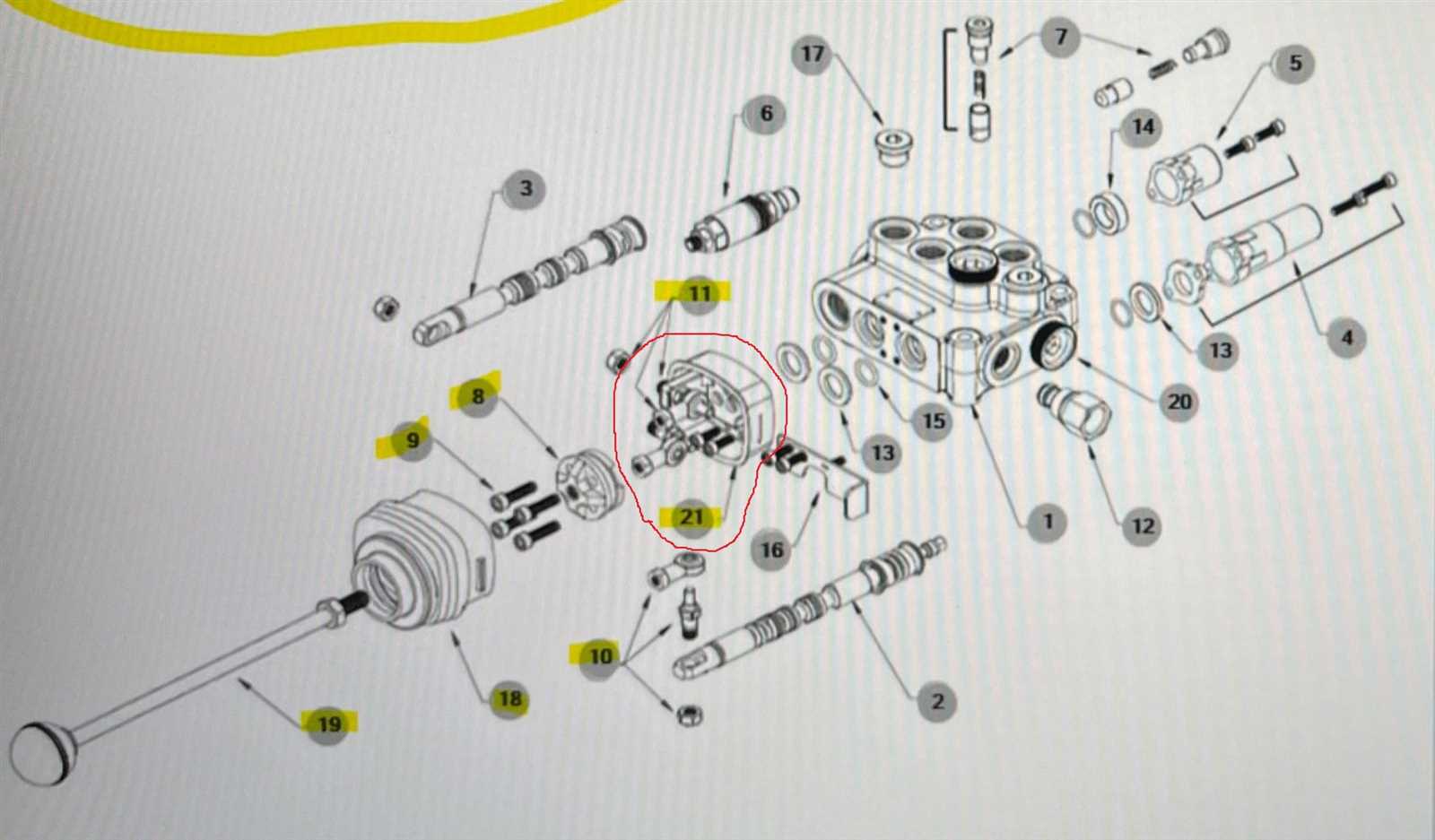

Understanding component illustrations is essential when performing repairs or maintenance on any machinery. These visual representations provide crucial information about how different elements are arranged and connected, helping users quickly identify specific components and their relationships.

To effectively interpret these drawings, it’s important to focus on key aspects like labeling, positioning, and the order of elements. Below are a few tips to guide you:

- Labels: Each item is typically assigned a number or a code, which corresponds to a reference in a list or chart.

- Positioning: The placement of components on the illustration shows how they fit into the overall assembly, allowing you to understand where each piece belongs.

- Connections: Pay attention to the lines, arrows, or symbols that indicate how different parts are interconnected.

By following these guidelines,

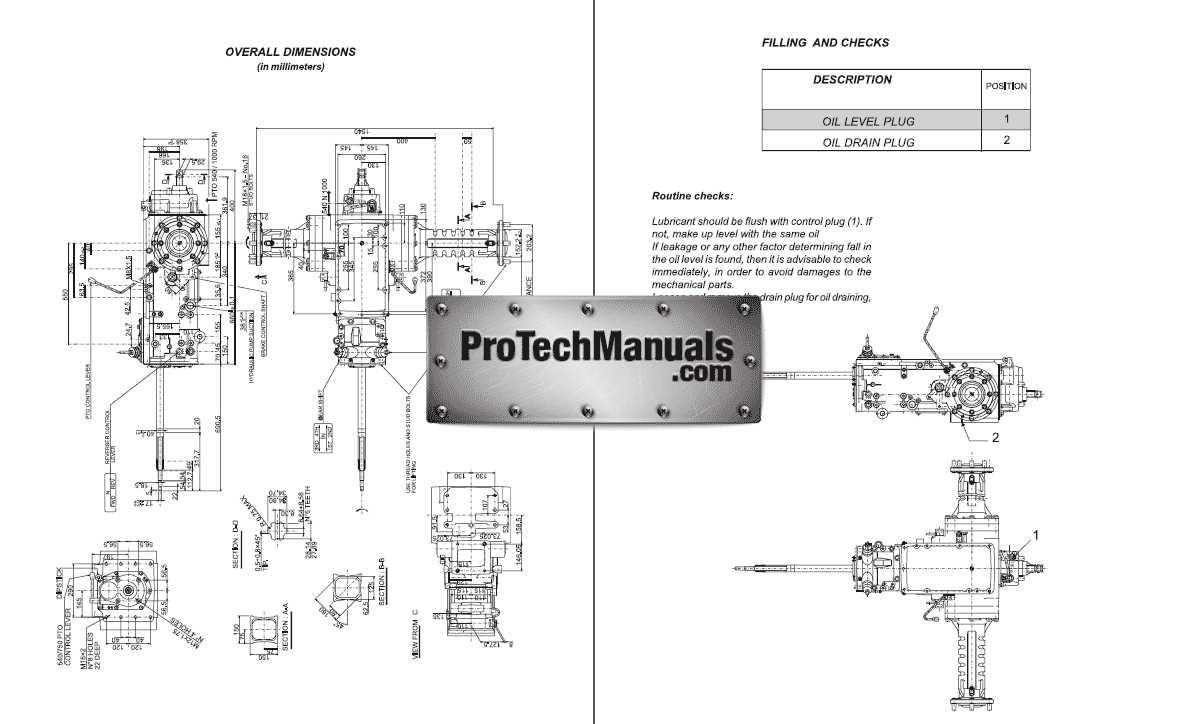

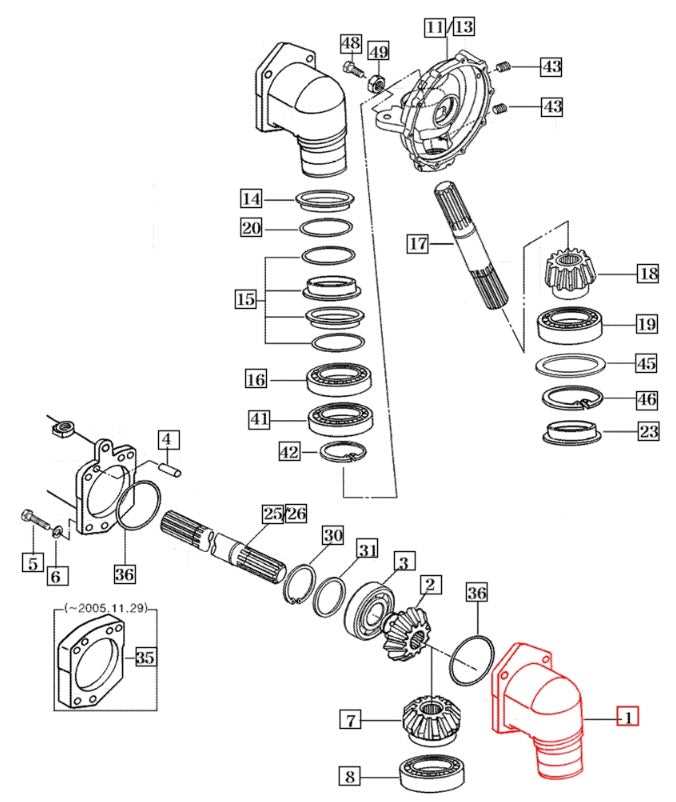

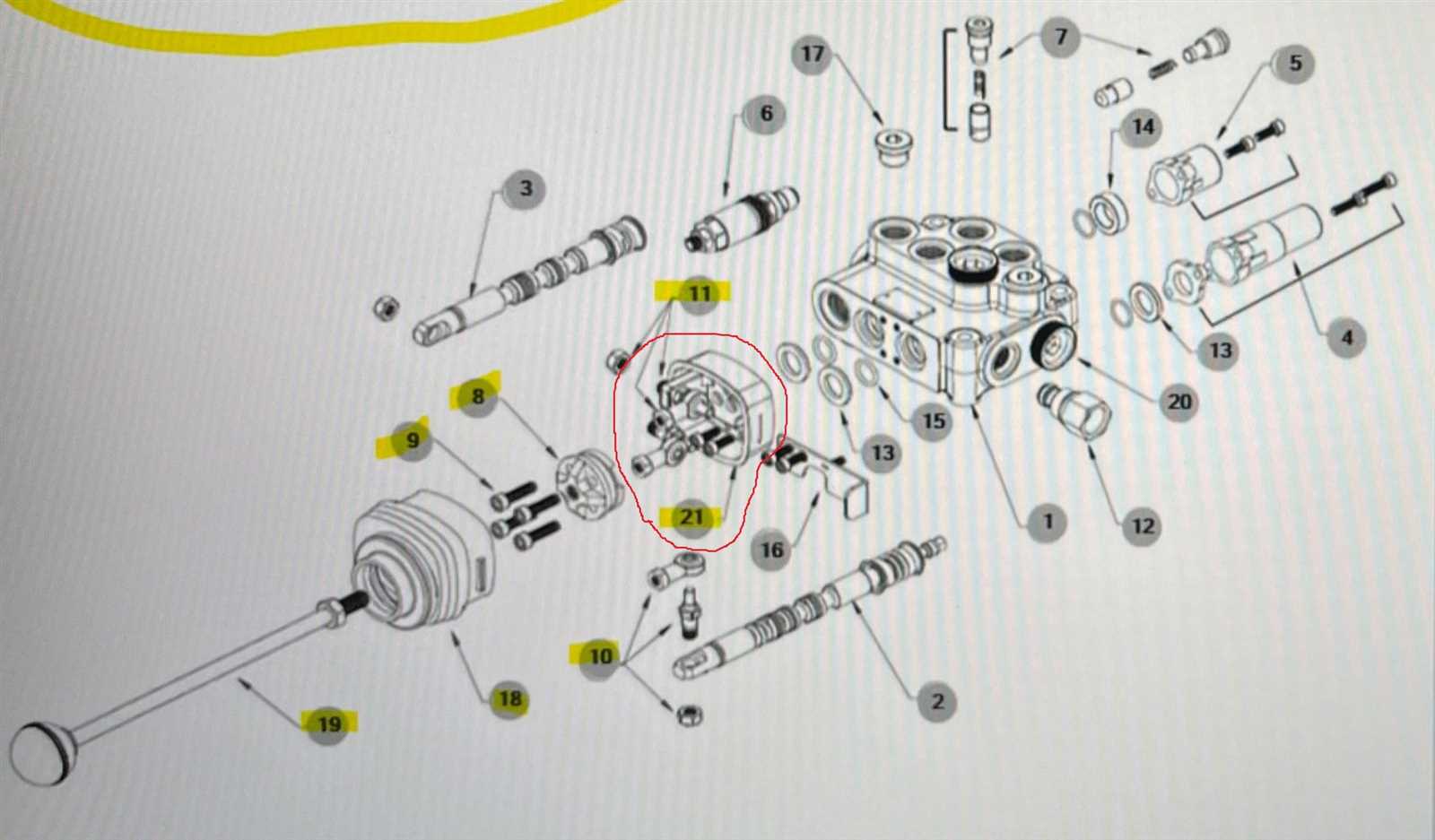

Utilizing Diagrams for Maintenance

Visual aids play an essential role in ensuring the smooth upkeep of various equipment. When maintaining complex systems, having a clear, structured image of components can significantly streamline the repair process. Understanding the relationships between individual elements allows for quicker identification of potential issues, leading to more efficient servicing.

To make the most of these visual resources during maintenance, follow these key steps:

- Familiarize yourself with the layout and structure before starting any work.

- Use the visual guide to trace the sequence of tasks, ensuring accuracy.

- Refer to the details provided to correctly match replacement elements and tools.

- Document any deviations or modifications to keep future servicing more organized.

By incorporating these strategies, you can reduce downtime and enhance the overall effectiveness of your maintenance efforts.

Differences Between Models Explained

Understanding the distinctions between various models is crucial for ensuring compatibility and optimal performance. Each version is tailored to meet specific needs, offering unique features and configurations that set them apart. Knowing these variations allows users to make informed decisions when selecting the right option for their requirements.

Engine capacities often differ across versions, with some emphasizing power for heavy-duty applications, while others focus on fuel efficiency. These variations directly impact the overall functionality and suitability for different tasks.

Another key difference lies in the technology integration, where newer models tend to incorporate advanced systems for enhanced control and precision. Older versions, while reliable, may lack some of these modern enhancements, making them better suited for simpler tasks.

Additionally, there can be structural differences in terms of size and build, affecting maneuverability and operational scope

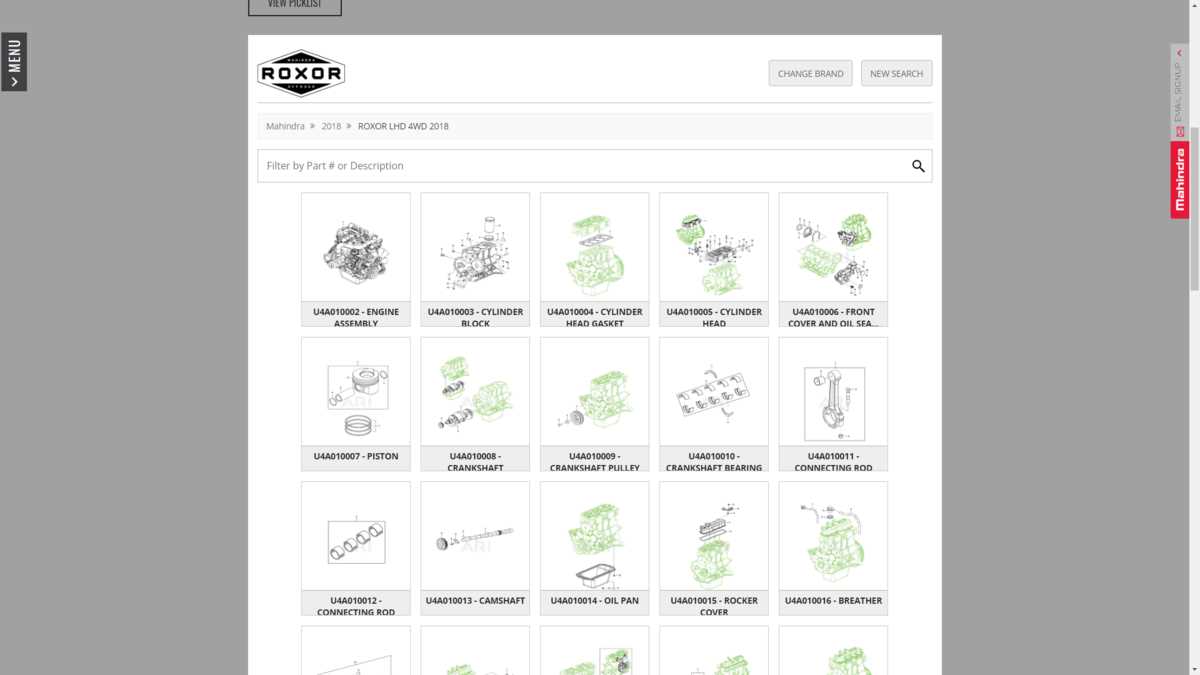

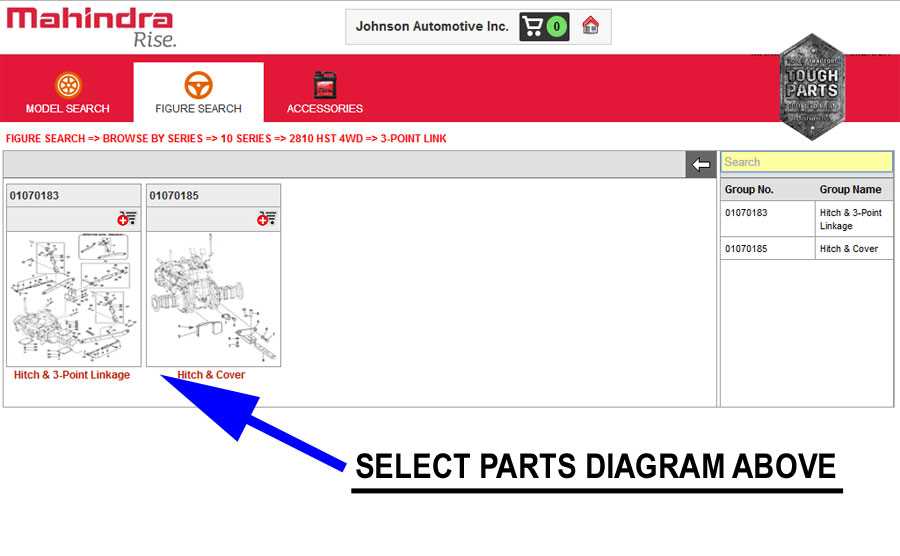

Finding Replacement Parts Efficiently

When maintaining or repairing equipment, sourcing the right components quickly is essential to ensure minimal downtime and efficient performance. Understanding how to identify the required items based on the specifications and matching them with available resources can greatly reduce the time spent on replacements.

To streamline the process, follow these steps:

- Identify the issue and isolate the affected area of the machinery.

- Consult reliable resources to cross-reference model numbers and component specifications.

- Search for suppliers that offer fast shipping and warranties for added reliability.

- Check user reviews and ratings to verify the quality of the replacement.

Efficient sourcing often comes down to having access to accurate information and trusted vendors, ensuring both reliability and long-term functionality of the equipment.

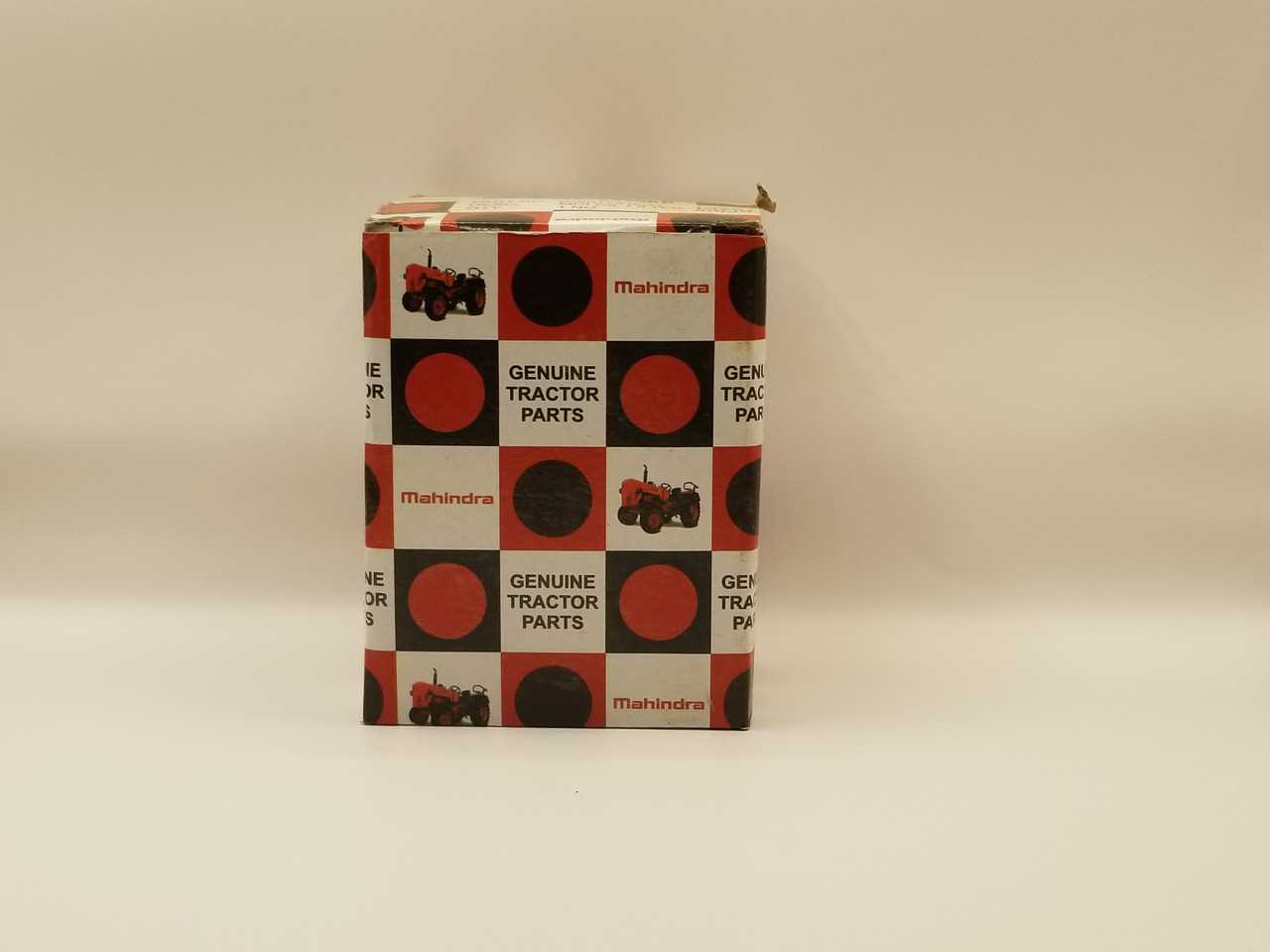

Benefits of Using OEM Components

Choosing original equipment manufacturer components offers numerous advantages in terms of reliability, performance, and longevity. These parts are designed specifically for the equipment, ensuring a perfect fit and seamless integration. By opting for original replacements, users can maintain the original standards and avoid potential complications that may arise from using alternatives.

Enhanced Durability and Performance

Original components are tested to meet stringent quality standards, offering durability that ensures longer service life. They are tailored to work in harmony with other parts, maximizing performance and reducing the risk of breakdowns.

Warranty and Peace of Mind

Another key benefit is the warranty protection that often accompanies these components. Using authorized parts typically ensures that warranties remain intact, providing confidence and security in the equipment’s operation.

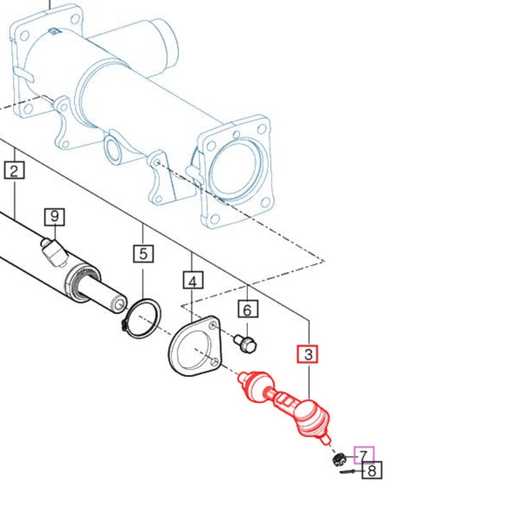

Integrating Diagrams into Repair Processes

Incorporating visual representations into maintenance workflows enhances the efficiency and accuracy of repair tasks. These illustrations serve as essential references, guiding technicians through complex procedures and ensuring that each step is executed correctly. By leveraging such tools, repair processes become more streamlined, reducing the likelihood of errors and improving overall outcomes.

Furthermore, clear visuals provide a shared understanding among team members, facilitating communication and collaboration. When everyone involved has access to the same references, it minimizes misunderstandings and promotes consistency in approaches. This integration not only accelerates the learning curve for new technicians but also enhances the performance of experienced personnel, enabling them to tackle repairs with greater confidence.

In summary, the use of illustrative materials in maintenance operations significantly contributes to operational effectiveness. By making these resources readily available, organizations can optimize their repair processes, ensuring that tasks are completed efficiently and accurately.

Common Mistakes to Avoid

When working with vehicle components and their configurations, certain errors can significantly impact performance and safety. Understanding these pitfalls is crucial for ensuring a smooth and efficient repair or maintenance process. By being aware of common missteps, one can navigate the complexities of assembly and ensure optimal functionality.

Neglecting Proper Research

One frequent oversight is failing to conduct thorough research before beginning a task. Inadequate knowledge about specific elements can lead to incorrect installations or replacements. Always ensure that you understand the specifications and compatibility of the components involved.

Ignoring Manufacturer Guidelines

Another common mistake is overlooking the manufacturer’s recommendations. Not following these instructions can result in improper fittings or damage to the system. Always refer to official documentation to ensure that you are adhering to the prescribed standards for installation and maintenance.

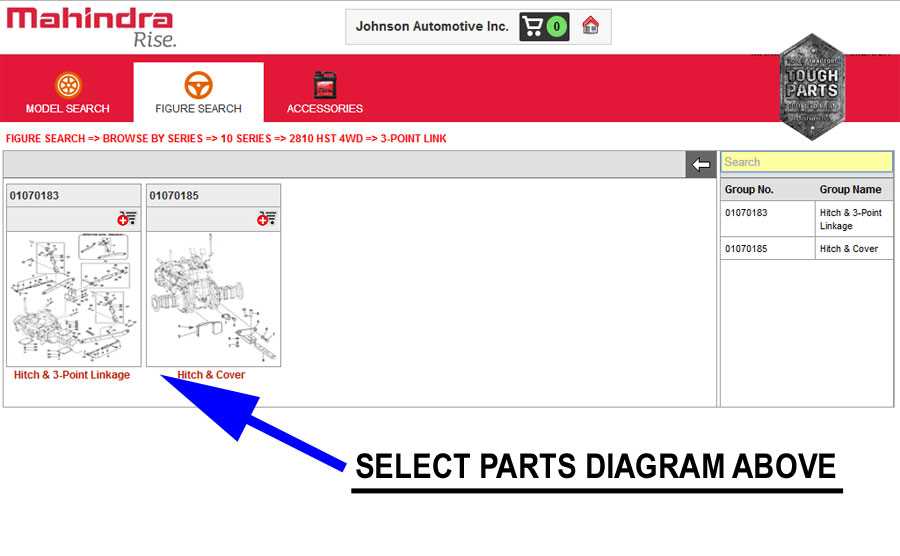

Resources for Mahindra Parts Information

Accessing comprehensive resources for vehicle components is crucial for owners and mechanics alike. Understanding where to find reliable information can significantly enhance maintenance and repair processes, ensuring that every task is executed efficiently.

Online Platforms

Numerous websites offer extensive databases, including illustrations and specifications of various automotive components. These platforms often feature user-friendly search functions, allowing users to easily locate specific items by model or category. Some sites may also include customer reviews and installation guides, which provide valuable insights into the performance and compatibility of the components.

Manufacturer Publications

Official documentation from the manufacturer serves as an excellent reference for detailed information on components. These publications often include service manuals, technical bulletins, and catalogs that outline installation procedures and maintenance tips. Utilizing these resources ensures that users are following the manufacturer’s recommendations, contributing to the longevity and reliability of the vehicle.

|