In the world of power equipment, a comprehensive grasp of individual elements is crucial for effective maintenance and operation. Knowing how various sections fit together enhances both functionality and longevity of the tools. This section aims to unravel the intricacies of a specific cutting device, showcasing its essential components and their interrelations.

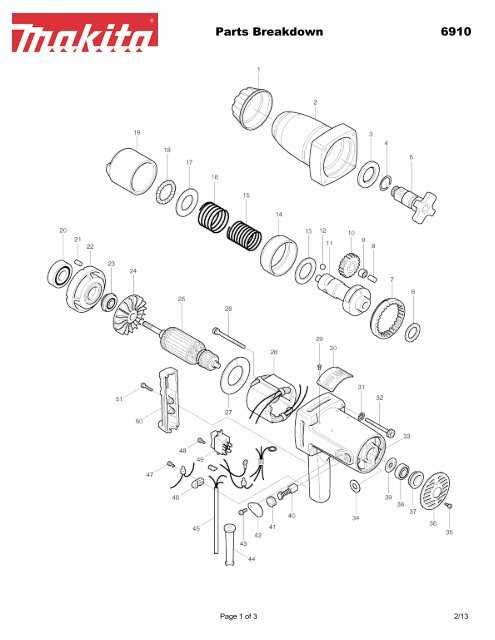

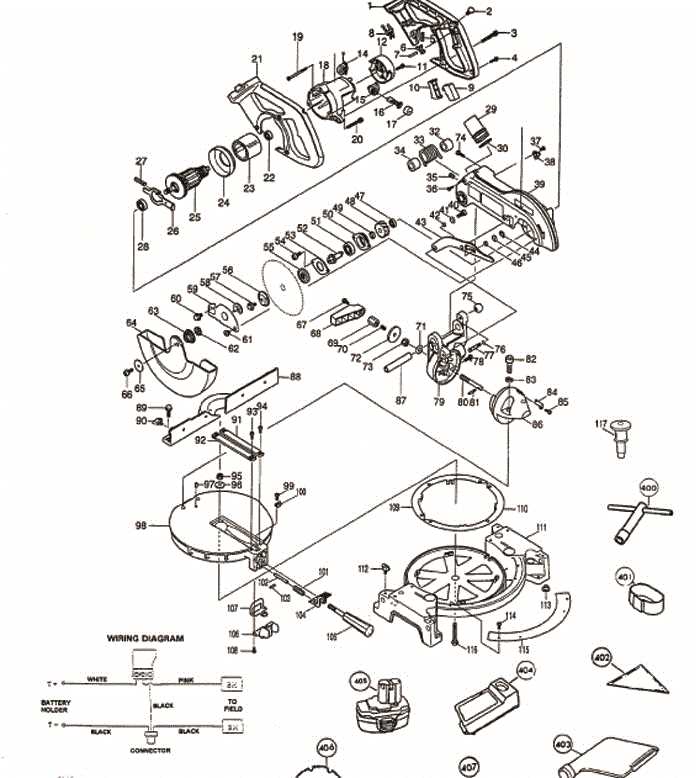

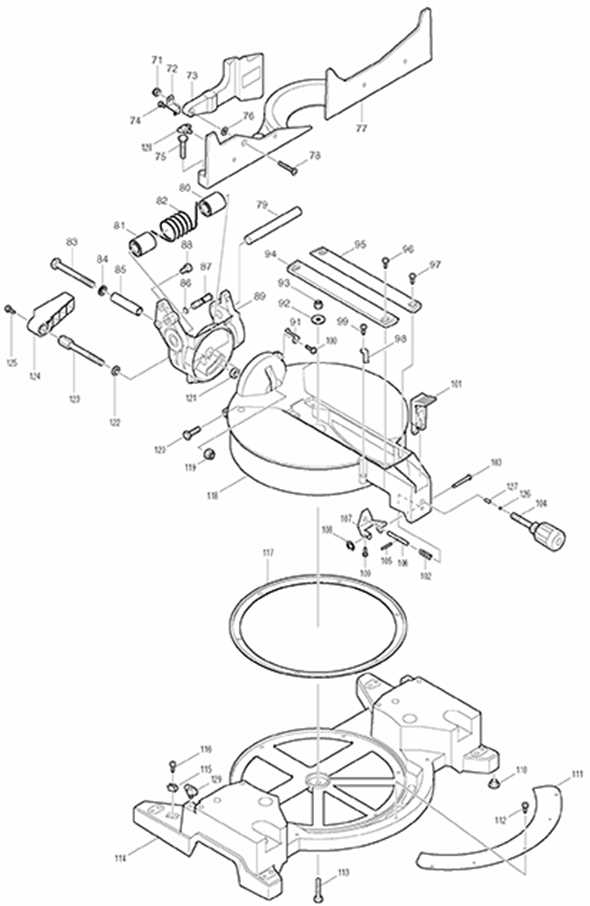

Visual representations serve as invaluable resources for both seasoned users and newcomers alike. They provide clarity, allowing one to navigate through the assembly and recognize each part’s role within the larger mechanism. A detailed exploration into these elements can ultimately empower users to execute repairs and upgrades with confidence.

By delving into this subject, one can appreciate the engineering behind each component, revealing not just their individual importance but also how they contribute to the tool’s overall performance. Understanding these dynamics can transform the approach to tool maintenance, making it more intuitive and less daunting.

Understanding Makita LS1011 Components

Grasping the various elements of power tools is essential for effective operation and maintenance. Each component plays a crucial role in the overall functionality, enhancing performance and ensuring safety. By familiarizing oneself with these elements, users can better appreciate how to optimize usage and troubleshoot issues as they arise.

| Component | Description |

|---|---|

| Motor | The heart of the machine, providing the necessary power for operation. |

| Base | Stabilizes the tool, ensuring accuracy during cutting tasks. |

| Blade | Essential for cutting through various materials with precision. |

| Guard | Enhances safety by covering the blade during operation. |

| Adjustable Angles | Allows for customized cuts at various angles, increasing versatility. |

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements serve as invaluable resources for technicians and DIY enthusiasts alike. They provide a clear overview of each individual part, aiding in identification and assembly processes.

Benefits of Visual Guides

- Enhanced Clarity: Visual aids break down complex systems into manageable sections, making it easier to comprehend how each piece fits into the whole.

- Improved Efficiency: Quick reference tools save time during repairs by allowing users to locate specific elements swiftly.

- Accurate Reassembly: Understanding the layout of components minimizes the risk of errors during reassembly, ensuring optimal functionality.

Applications in Maintenance

- Preventive Care: Regular reference to these guides can help identify worn or damaged components before they lead to major failures.

- Replacement Planning: Knowing the exact specifications of each part aids in sourcing accurate replacements.

- Training Resources: New technicians can benefit from these visual tools as they familiarize themselves with different models and their respective components.

Common Issues with LS1011

In the realm of power tools, certain models may encounter frequent challenges that can affect performance and user satisfaction. Understanding these common complications can aid in troubleshooting and maintenance, ensuring longevity and efficiency in operation. Below are some prevalent problems that users might face with this particular cutting tool.

Motor Overheating

One of the most frequent issues involves the overheating of the motor during prolonged use. This can stem from several factors, including improper ventilation, excessive load, or accumulated debris within the housing. Regular cleaning and ensuring adequate airflow can help mitigate this problem.

Another common concern is blade misalignment, which can lead to inaccurate cuts and increased wear on the tool. This misalignment may occur due to improper setup or impact during use. Regular checks and adjustments can help maintain precision and enhance the tool’s cutting capabilities.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as a guide to identify individual elements, their arrangement, and how they interact within a larger assembly.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols:

- Identify common icons that represent specific components.

- Learn the meaning of lines and arrows indicating relationships and movements.

- Observe the Layout:

- Pay attention to the organization of parts, as this often reflects their assembly order.

- Look for clusters that indicate sections or modules of the machinery.

- Refer to the Legend:

- Check for any accompanying keys that define symbols and numbers.

- Use the legend to clarify any confusion regarding specific components.

- Cross-Reference with Manuals:

- Use technical manuals to understand the context of each element.

- Look for assembly instructions that complement the visual information.

By following these guidelines, you will enhance your ability to interpret visual aids effectively, making your repair and maintenance tasks much more manageable.

Essential Tools for Repairs

When it comes to tackling repair tasks, having the right equipment at your disposal is crucial. The effectiveness and efficiency of any project can be greatly enhanced by using quality tools designed for specific purposes. A well-organized toolkit not only simplifies the process but also ensures that each task is executed with precision.

Basic Tools for Every Project

To start, a selection of fundamental instruments is necessary. These typically includes a reliable screwdriver set, which is essential for loosening or tightening various fasteners. Additionally, a good wrench collection will help you handle nuts and bolts of different sizes. Don’t forget a sturdy hammer, as it’s vital for both assembly and disassembly tasks.

Specialized Equipment for Advanced Repairs

For more complex projects, consider incorporating specialized devices. A quality multimeter is invaluable for electrical diagnostics, allowing you to troubleshoot circuits with ease. If woodworking is involved, a precise saw will ensure clean cuts, while a level guarantees that your installations are perfectly aligned. Investing in these advanced tools can significantly elevate the quality of your repairs.

Replacing the Blade on LS1011

Changing the cutting tool on your equipment is essential for maintaining optimal performance and achieving precise cuts. Over time, blades can become dull or damaged, making replacement necessary. This process not only enhances the tool’s efficiency but also ensures safety during operation.

Before you begin, ensure that the machine is unplugged and all safety precautions are in place. Gather the necessary tools, including a suitable wrench and safety gloves. Start by locating the blade release mechanism, which typically involves loosening screws or levers that secure the blade in place.

Once you have access to the blade, gently remove it while being cautious of sharp edges. It’s important to inspect the arbor and other components for any wear or damage. Place the new cutting tool onto the arbor, ensuring it is aligned correctly. Secure it firmly using the release mechanism.

After the new blade is installed, double-check all components to confirm that everything is tight and in place. Finally, plug the equipment back in and perform a test run to ensure smooth operation. Regularly changing the blade will greatly enhance your cutting results and prolong the life of your tool.

Identifying Wear and Tear

Recognizing the signs of deterioration in equipment is essential for maintaining optimal performance and safety. Regular inspection can prevent further damage and extend the lifespan of the tools. Here are key indicators to help identify wear and tear:

- Visual Inspection: Look for scratches, cracks, or discoloration on surfaces.

- Functional Tests: Check if the tool operates smoothly and efficiently.

- Unusual Noises: Listen for grinding or rattling sounds during operation.

- Heat Generation: Monitor for excessive heat that could indicate friction or malfunction.

In addition to these signs, certain components may require closer examination:

- Blades: Inspect for dullness or chips that affect cutting performance.

- Bearings: Check for looseness or roughness, which can lead to failure.

- Electrical Parts: Look for frayed wires or burnt connectors that pose safety risks.

- Handles: Ensure grips are intact and secure for safe operation.

By routinely monitoring these factors, users can ensure that their equipment remains reliable and effective in its function.

Where to Find Replacement Parts

Finding suitable components for your equipment is crucial for maintaining its performance and longevity. Various resources can help you locate the necessary items, ensuring that your machinery continues to operate effectively.

Here are some reliable options to consider:

- Official Manufacturer Website: Start by visiting the manufacturer’s official site. They often provide a comprehensive catalog of components specific to your model.

- Authorized Dealers: Reach out to authorized dealers in your area. They can offer genuine replacements and expert advice.

- Online Retailers: Numerous online platforms specialize in machinery supplies. Look for websites with user reviews and return policies to ensure you’re making a wise choice.

- Local Hardware Stores: Check local stores that sell equipment. They may carry essential items or be able to order them for you.

Using these resources will help you find the right components to keep your tools in top shape.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular upkeep and attention. Proper maintenance practices not only enhance performance but also extend the lifespan of your tools, preventing premature wear and costly repairs. Here are some essential tips to keep your machinery in optimal condition.

Regular Cleaning

Keeping your tools clean is crucial for their performance. Dust, debris, and residues can accumulate, leading to malfunctions. Follow these cleaning practices:

- Wipe down surfaces after each use to remove dust and grime.

- Use compressed air to blow out any particles from hard-to-reach areas.

- Inspect and clean the cutting components regularly to ensure sharpness and efficiency.

Routine Inspections

Performing regular checks on your equipment can help identify potential issues before they escalate. Consider the following:

- Examine electrical connections and wiring for any signs of wear or damage.

- Check moving parts for lubrication needs; apply oil or grease as necessary.

- Look for any unusual noises or vibrations during operation, which may indicate a problem.

By implementing these maintenance tips, you can significantly enhance the performance and longevity of your equipment, ensuring it remains a reliable asset in your toolkit.

Upgrading Your Makita LS1011

Enhancing the performance of your cutting tool can lead to improved efficiency and precision. By exploring various upgrades, users can unlock the full potential of their equipment, making it more versatile and reliable for various tasks.

Consider motor upgrades for increased power, which can significantly impact the cutting speed and quality. Additionally, investing in higher-quality blades can provide cleaner cuts and longer-lasting performance, reducing the frequency of replacements.

Another aspect to consider is ergonomic improvements. Adding features like better grips or adjustable stands can enhance comfort during extended use. Upgrading the dust collection system can also help maintain a cleaner workspace and improve visibility while working.

Finally, exploring accessory options such as clamps or laser guides can enhance accuracy and safety. Each of these upgrades contributes to a more efficient and enjoyable cutting experience.

Comparing LS1011 with Other Models

This section explores the differences and similarities between a specific saw model and its counterparts in the market. By examining various features, capabilities, and user experiences, we aim to provide a comprehensive overview that can assist potential buyers in making an informed decision.

Key Features Comparison

- Cutting Capacity: One model may offer a larger cutting capacity, making it more suitable for larger projects.

- Weight and Portability: Some units are lighter, enhancing portability and ease of use on job sites.

- Power Source: Variants may operate on different power sources, affecting versatility in various environments.

- Blade Type: The type of blade supported can influence cutting precision and material compatibility.

User Experience and Feedback

- Ease of Use: Certain models may be praised for user-friendly features, while others may have a steeper learning curve.

- Durability: Feedback often highlights the longevity and reliability of specific units under heavy use.

- Maintenance: Some devices require less frequent maintenance, appealing to users looking for convenience.

- Price Point: Budget considerations can significantly impact buyer choices, with some options offering more value for money.