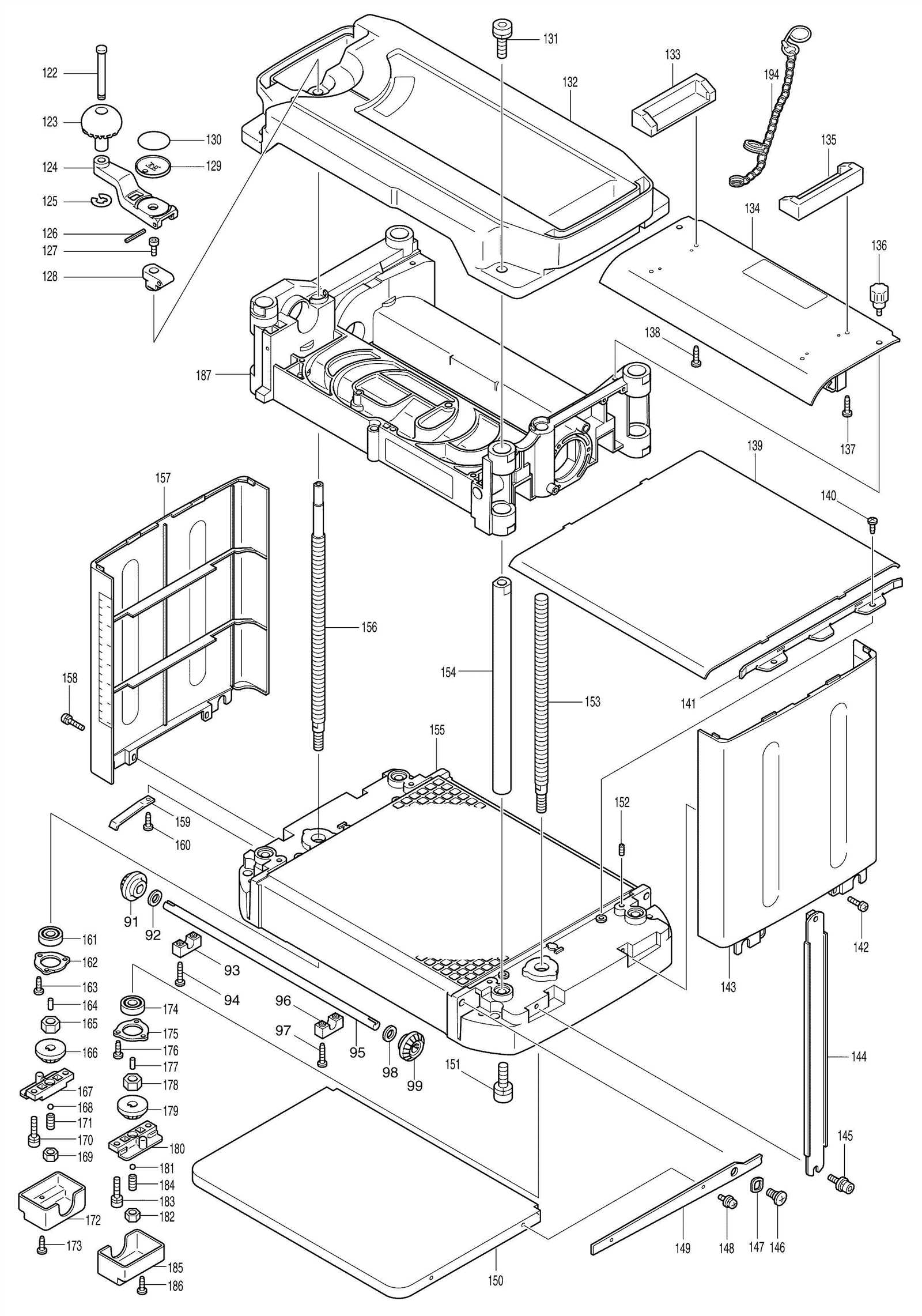

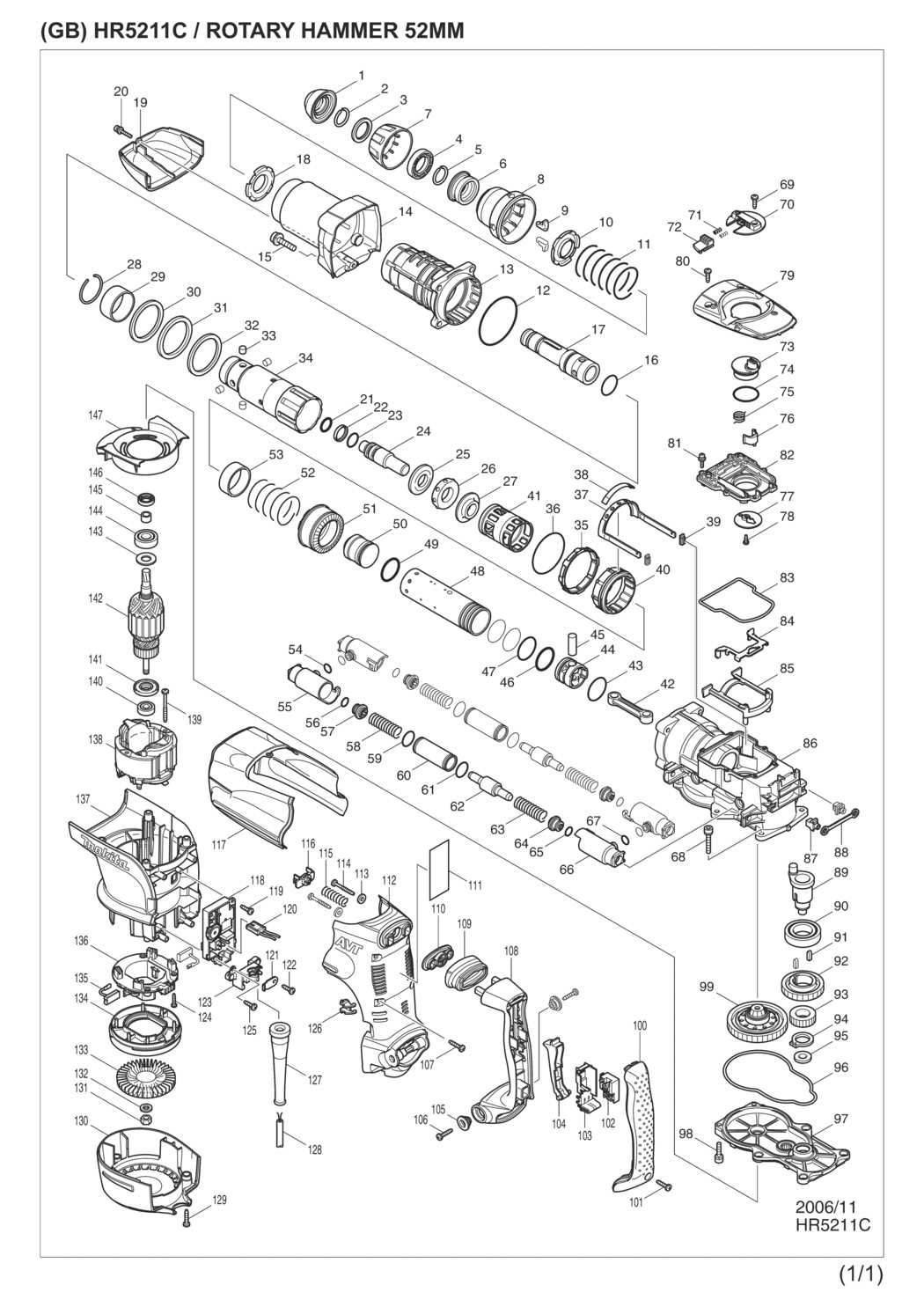

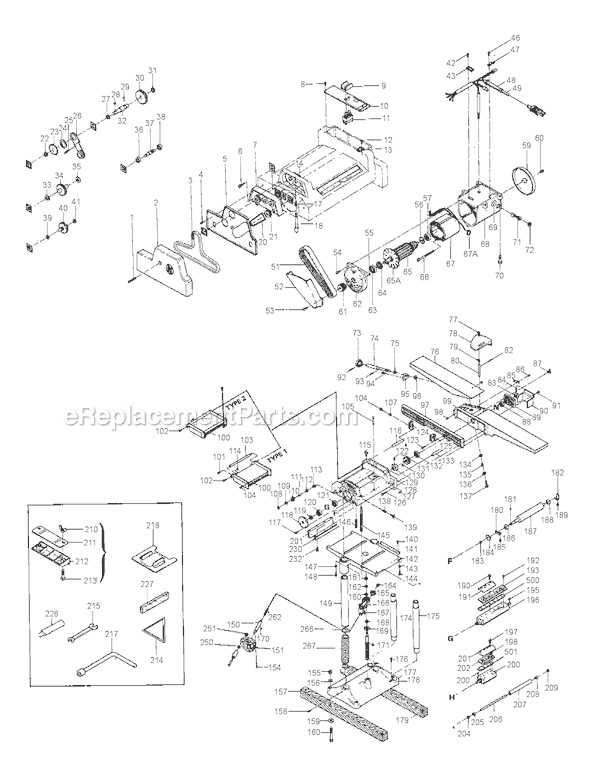

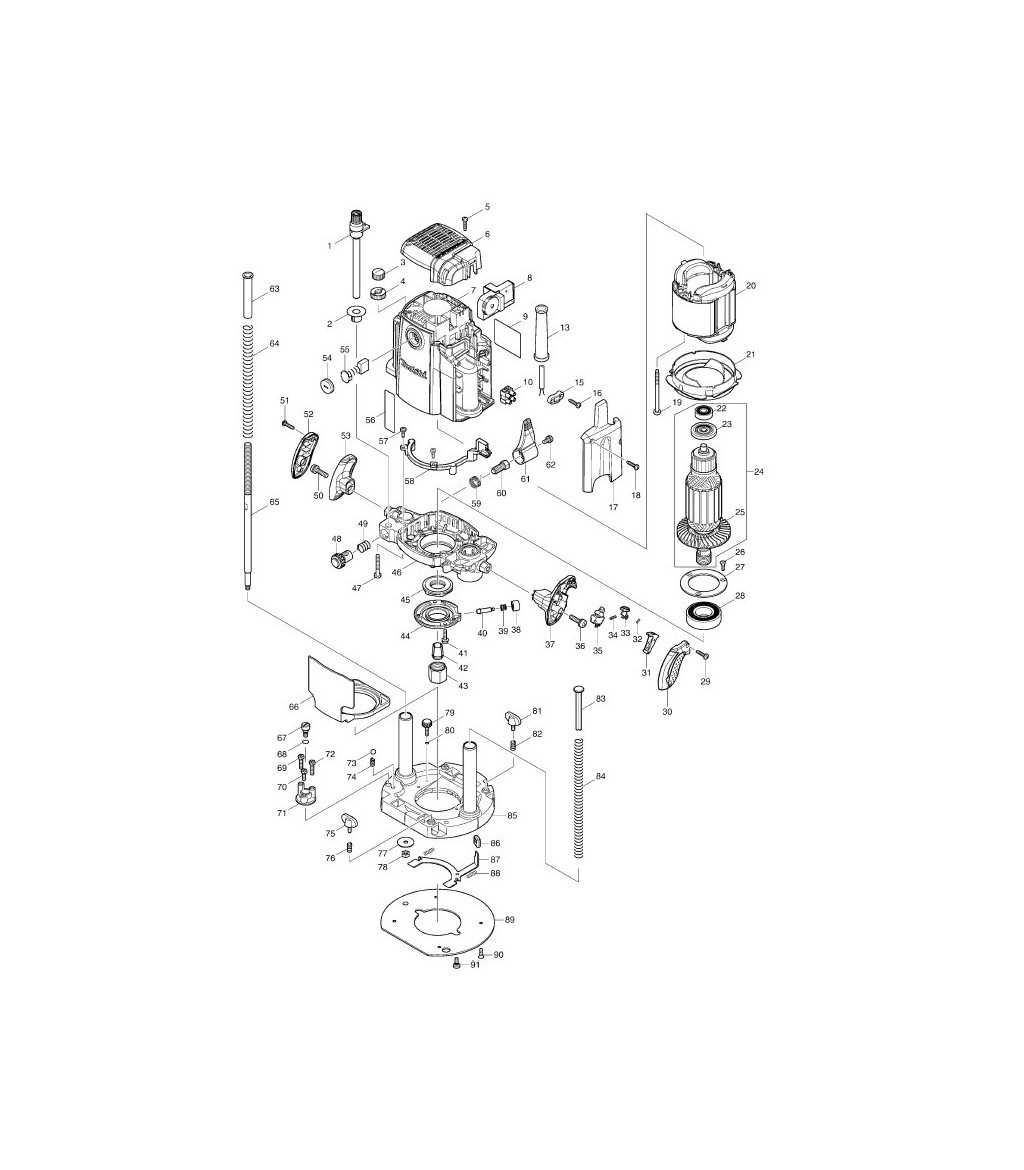

Understanding the structure and arrangement of various elements within a tool is crucial for both maintenance and repairs. Whether you’re an experienced technician or just beginning your journey in tool upkeep, having a clear visualization of internal configurations ensures that you can address issues effectively and prolong the lifespan of your equipment.

In this section, we will explore the intricate layouts that comprise modern power devices, focusing on the arrangement of key components. By examining the internal setup, you’ll gain insights into how these tools are designed to operate efficiently, and how each element contributes to the overall functionality.

Through detailed illustrations and explanations, you’ll be able to identify critical parts, understand their roles, and learn how to replace or maintain them with confidence. This guide will serve as a valuable resource for anyone looking to keep their equipment in optimal condition.

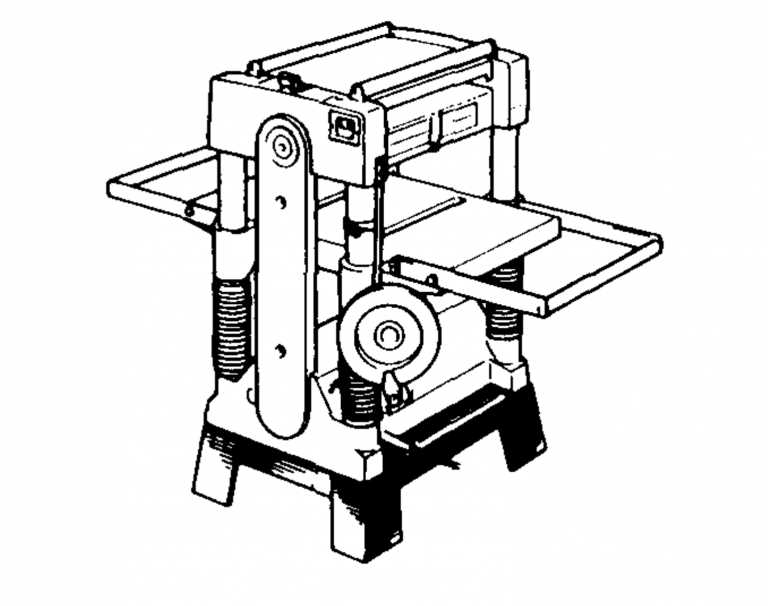

Makita Planer Parts Overview

Understanding the key components of a high-performance wood-shaving tool is crucial for maintaining its functionality and efficiency. Each element plays a specific role, ensuring precise cuts and smooth operation during woodwork projects. By familiarizing yourself with these integral pieces, you can better troubleshoot, replace, or upgrade them when needed.

- Cutterhead: The core of the device responsible for shaving wood with precision. It holds the blades and rotates at high speeds.

- Blades: Sharp edges attached to the cutterhead, designed to slice through wood smoothly. Regular maintenance and replacement are essential for optimal results.

- Drive Belt: This belt connects the motor to the cutterhead, transferring the necessary power for operation.

- Depth Adjustment Knob: A mechanism allowing fine-tuning of how deep the blades cut into the material, crucial for precision.

- Dust Collection Port: An outlet for extracting wood shavings and dust, keeping the workspace clean and improving visibility.

Main Components of Makita Planer

The core elements of this woodworking tool are designed to ensure precise and efficient operation. Each piece works together to achieve smooth surface finishes, making the tool indispensable for carpentry tasks. Below, we will explore the key functional parts that contribute to its performance and durability.

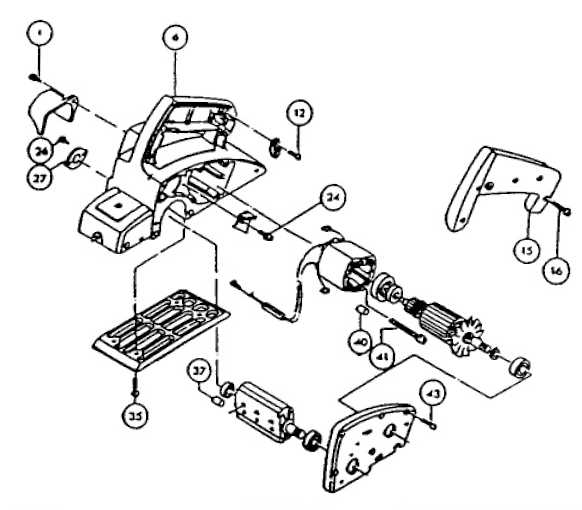

Motor and Drive System

The motor is responsible for powering the tool, delivering the necessary force to rotate the blades. The drive system transfers this power efficiently, ensuring the smooth movement of the blades across the material. Together, they form the central mechanism that allows the tool to function effectively.

Blade and Adjustment Mechanism

The cutting blade is the essential component for material removal. It can be adjusted to different heights and angles, depending on the desired depth of the cut. The adjustment mechanism allows users to fine-tune the settings, offering precision and control over the final outcome.

| Component | Function |

|---|---|

| Motor | Provides power to drive the blades |

| Blades | Cut and smooth the surface of the material |

| Adjustment Mechanism | Controls the depth and angle of the cut |

| Drive System | Transfers power from the motor to the blades |

Functions of Key Planer Parts

In woodworking equipment, various elements work together to ensure precise and efficient material shaping. Each component plays a specific role in maintaining accuracy and durability, contributing to the overall performance of the tool.

| Component | Function | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cutterhead | The primary element responsible for cutting the material, rotating at high speed to remove thin layers. | |||||||||||||||||||||||||

| Adjustment Knob | Allows the user to fine-tune the depth of material removal, ensuring consistent results. | |||||||||||||||||||||||||

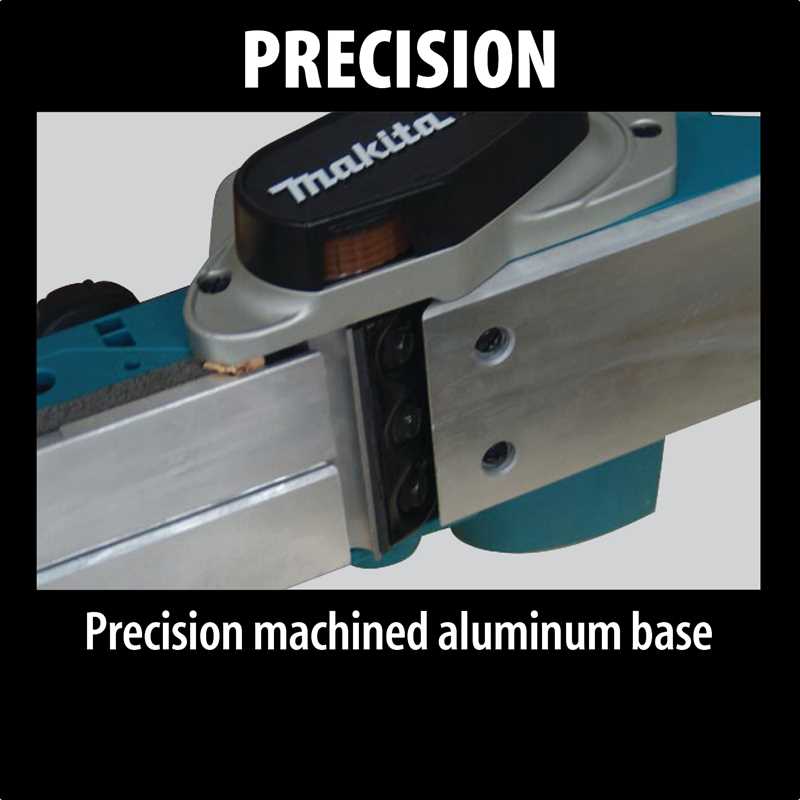

| Base Plate |

| Step | Action |

|---|---|

| 1 | Ensure the device is unplugged for safety. |

| 2 | Locate the depth adjustment knob or lever. |

| 3 | Turn the knob or move the lever to raise or lower the cutting depth. |

| 4 | Make small adjustments, typically around 1/16 inch at a time. |

| 5 | Plug in the tool and perform a test cut on scrap material. |

| 6 | Inspect the thickness of the cut and repeat the adjustment if necessary. |

Regularly checking and fine-tuning the depth setting ensures the accuracy and quality of your finished pieces. By implementing these adjustments, you can maintain high standards in your woodworking endeavors.

Troubleshooting Issues with Planer Parts

When working with various woodworking tools, it is common to encounter specific challenges related to their components. Addressing these issues promptly can help maintain optimal performance and extend the tool’s lifespan. Understanding potential problems and their solutions is essential for anyone looking to ensure smooth operation and avoid unnecessary downtime.

Common Problems and Solutions

Below is a table outlining frequent challenges encountered with tool components, along with suggested solutions for each issue:

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Inconsistent results | Worn or damaged blades | Inspect and replace blades if necessary |

| Unusual noises | Loose or misaligned components | Tighten screws and ensure proper alignment |

| Overheating | Excessive friction or lack of lubrication | Lubricate moving parts and check for debris |

Additional Tips for Maintenance

Regular maintenance is crucial to prevent issues from arising. Keep the tool clean and inspect components periodically to ensure everything is functioning correctly. Following the manufacturer’s guidelines for care can also significantly reduce the risk of encountering problems.