Delving into the inner workings of a compact marine propulsion unit reveals a complex network of interconnected components, each playing a crucial role in the engine’s performance and reliability. This examination goes beyond surface-level descriptions, offering a detailed exploration of the internal architecture and functional integration that defines its operational prowess.

Highlighting the intricacies of its mechanical framework, this comprehensive breakdown unveils the intricate assembly of gears, valves, and chambers that synchronize seamlessly to generate propulsion. Understanding these interdependencies provides a deeper appreciation of how precision engineering translates into efficient marine navigation, essential for both leisure and professional boating.

Through meticulous observation and diagrammatic representation, this article aims to illuminate the operational synergy that powers this essential equipment. By demystifying the inner workings, it empowers enthusiasts and technicians alike to grasp the engineering marvels that propel maritime adventures forward.

This section aims to explore the fundamental elements of a specific marine propulsion system. By breaking down its various components, readers can gain insights into how each part contributes to overall functionality and performance. Understanding these individual elements is crucial for maintenance, troubleshooting, and effective operation.

Key Components of the Engine

- Powerhead: This section houses the engine’s combustion process, crucial for generating the necessary power.

- Gearcase: Contains the gearing mechanism that transmits power to the propeller.

- Fuel System: Manages the intake and delivery of fuel, ensuring efficient combustion.

- Cooling System: Maintains optimal operating temperatures by regulating engine heat.

- Electrical System: Provides the necessary power for ignition and other electronic functions.

Understanding the Functionality

- The powerhead generates energy through the combustion of fuel and air.

- This energy is transmitted through the gearcase to turn the propeller.

- The fuel system ensures a steady supply of fuel to the powerhead.

- The cooling system prevents overheating, which could lead to engine failure.

- The electrical system powers ignition and other essential functions for smooth operation.

Key Parts of Mariner 9.9

Understanding the essential components of a small outboard engine is crucial for effective maintenance and optimal performance. Each element plays a significant role in the overall functionality and reliability of the machinery, ensuring a smooth operation on the water.

Powerhead: This is the core unit housing the engine, including the cylinders and combustion chamber. It is responsible for generating the power necessary for propulsion.

Gear Case: This section houses the transmission components that transfer power from the engine to the propeller. It includes gears and shafts that allow for the adjustment of speed and torque.

Propeller: A vital element that converts the engine’s rotational energy into thrust, enabling the vessel to move through the water. The design and size of the propeller directly influence performance and efficiency.

Fuel System: This system comprises the fuel tank, lines, and carburetor, which work together to deliver the appropriate fuel mixture to the engine for combustion. Proper functioning of this system is essential for reliable starts and efficient operation.

Cooling System: Maintaining optimal temperature is critical for engine longevity. This system circulates water to dissipate heat, preventing overheating during operation.

Electrical System: This includes components like the ignition system, battery, and wiring that provide the necessary electrical power for starting the engine and powering auxiliary devices.

Each of these crucial components contributes to the overall efficiency and performance of the outboard engine, emphasizing the importance of regular inspections and maintenance to ensure reliable operation.

Functionality of Each Component

This section explores the essential roles played by various elements within the system, emphasizing their individual contributions to overall performance. Understanding these functionalities helps users appreciate the intricate design and operational efficiency of the machinery.

Core Elements and Their Roles

Each component has a specific function that contributes to the effective operation of the entire assembly. These roles range from generating power to regulating movement and ensuring safety during use.

| Component | Function |

|---|---|

| Power Unit | Generates the necessary energy for operation. |

| Control Mechanism | Regulates speed and direction. |

| Cooling System | Maintains optimal temperature to prevent overheating. |

| Fuel Delivery | Ensures a consistent flow of fuel for efficiency. |

| Safety Features | Protects against malfunctions and potential hazards. |

Interaction Among Components

The interplay between different parts enhances the functionality and reliability of the system. Each element must work harmoniously with others to ensure seamless operation and longevity of the equipment.

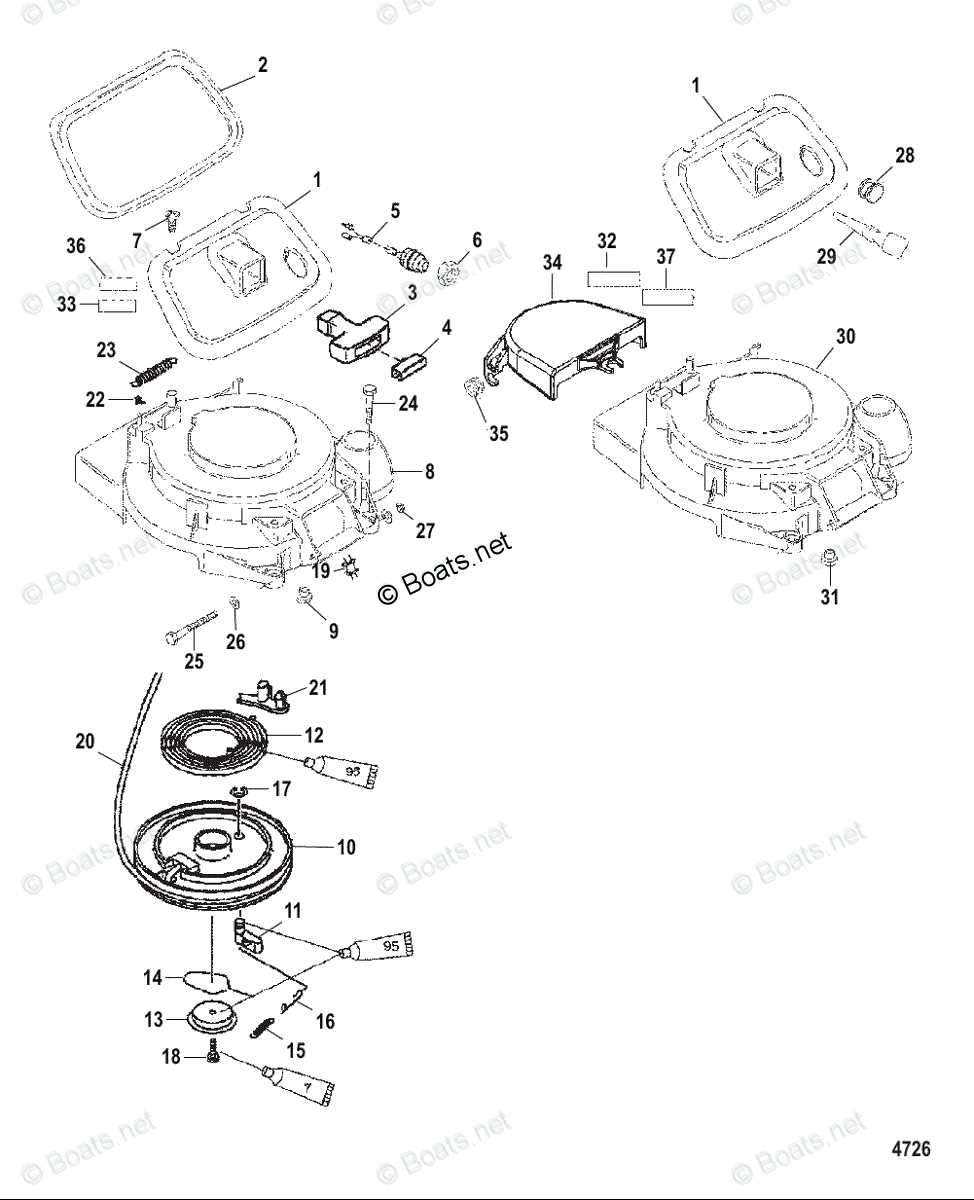

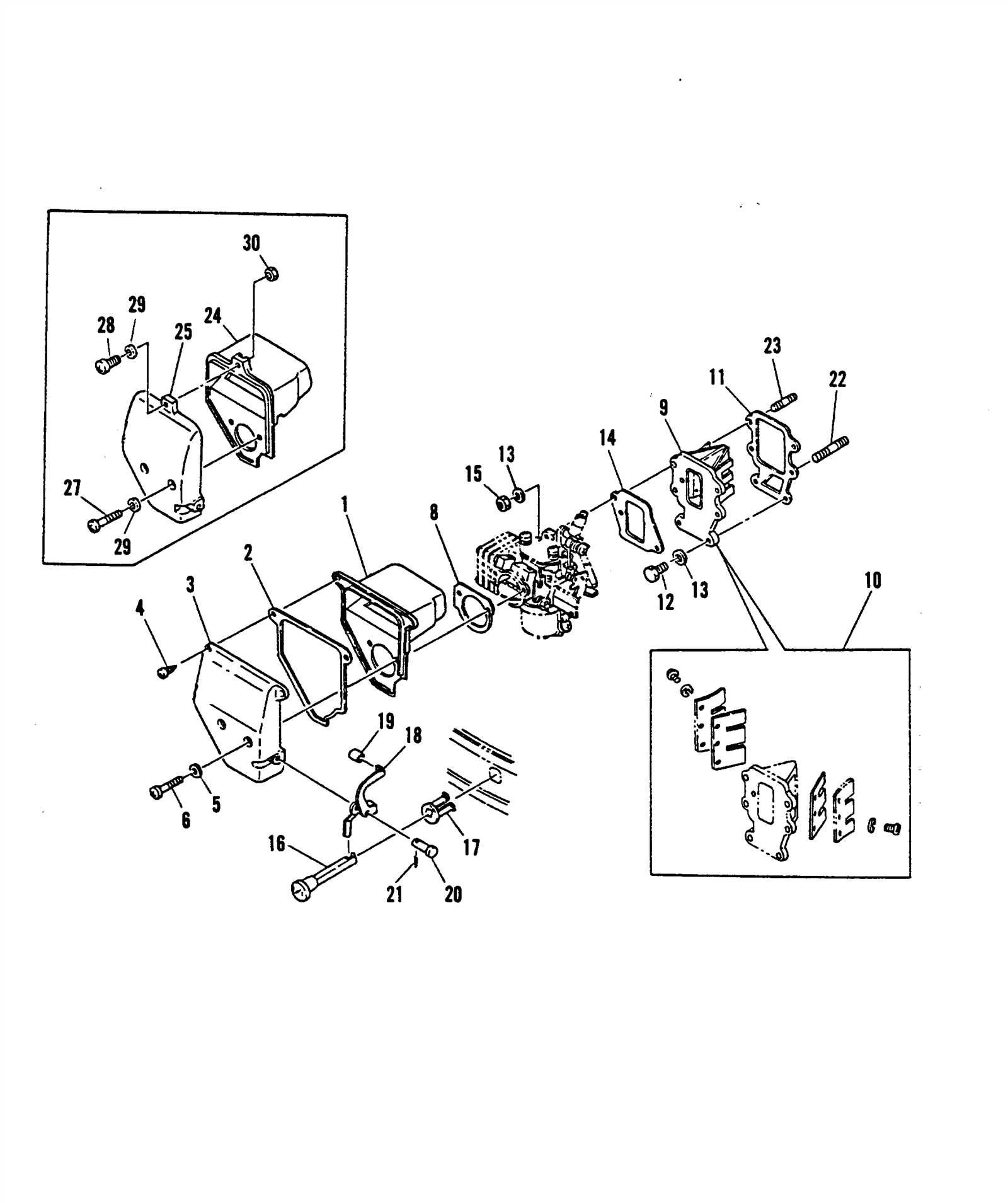

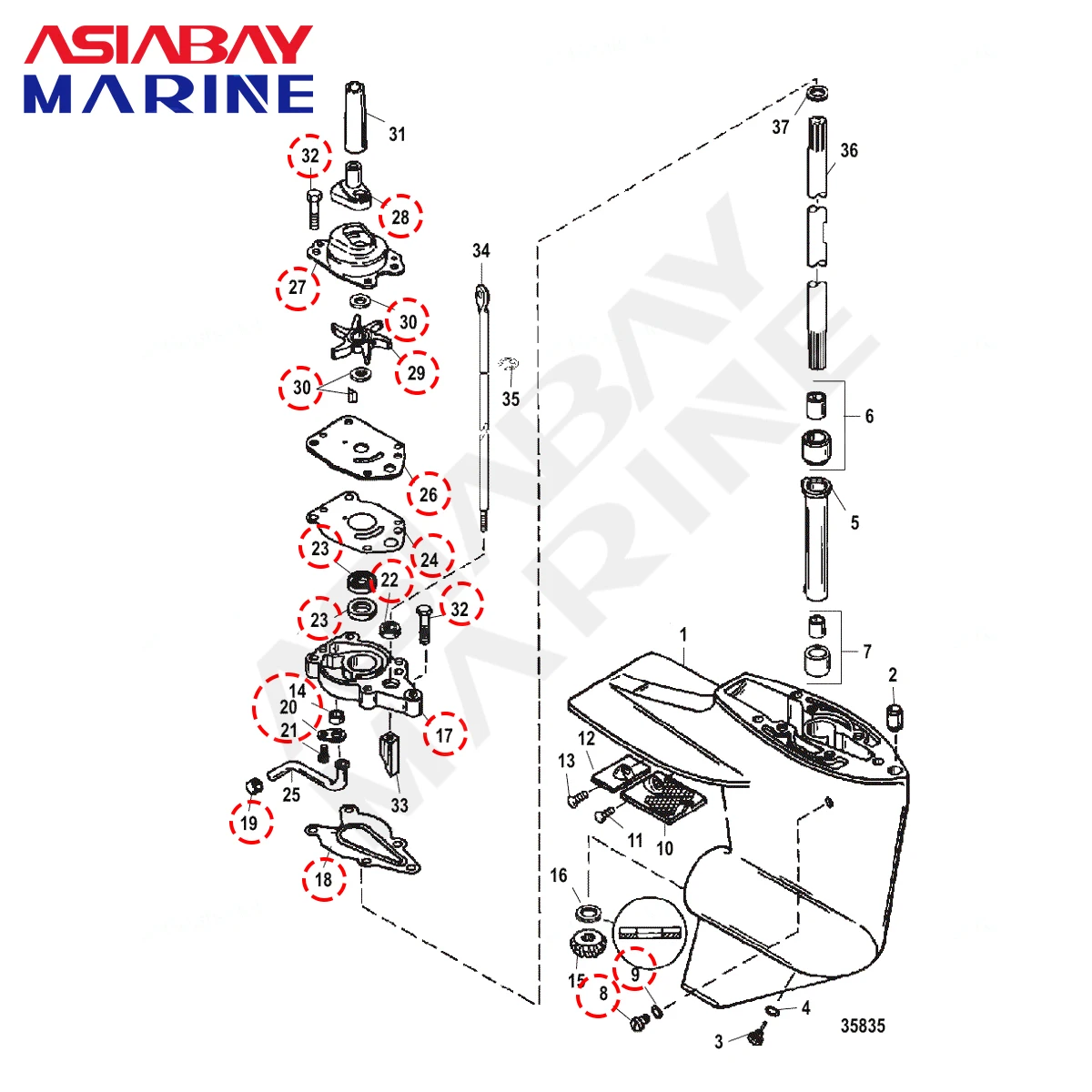

Visual Representation of Components

This section aims to provide a comprehensive overview of the various elements involved in a specific mechanical assembly. A clear and detailed illustration of each component facilitates better understanding and maintenance of the overall system.

By examining the layout and relationships between the different elements, users can gain insight into the functionality and assembly process. The following aspects are essential:

- Identification of individual components

- Understanding the arrangement and connectivity

- Recognizing the roles each piece plays in the assembly

Utilizing visual aids enhances the ability to diagnose issues and perform repairs effectively. Here are some critical benefits of having a visual reference:

- Improved accuracy in identifying parts that may require replacement

- Enhanced troubleshooting capabilities

- Streamlined assembly and disassembly processes

In conclusion, a well-structured visual representation serves as a valuable resource for both novice and experienced users, promoting efficient handling of the mechanical unit.

How to Read the Diagram

Understanding technical illustrations is crucial for effective maintenance and repair of mechanical equipment. These visuals serve as a guide, offering a clear representation of components and their interconnections, allowing users to identify and troubleshoot issues efficiently.

Begin by familiarizing yourself with the symbols and notations used within the visual representation. Each element typically corresponds to a specific part or function. Pay close attention to the legends or keys that explain these symbols, as they provide essential context for interpretation.

Next, trace the flow of operation through the illustration. This often involves following arrows or lines that indicate movement or interaction between different elements. Understanding this flow can help in diagnosing problems and ensuring that all parts are functioning harmoniously.

Finally, take note of any annotations or numbers associated with the elements. These references often link to additional documentation or parts lists, which can provide further insight into the specifications and maintenance requirements of each component.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your marine engine requires regular care and attention. By implementing a systematic maintenance routine, you can significantly enhance performance and reliability while minimizing potential issues.

Regular Inspections: Conduct frequent checks on all essential components, including the fuel system, cooling system, and electrical connections. Early detection of wear or damage can prevent costly repairs and extend the engine’s life.

Cleanliness is Key: Keep the engine and surrounding areas clean to prevent debris buildup, which can lead to overheating and operational inefficiencies. Regularly remove dirt and grime, especially from the cooling vents.

Fluid Management: Change the oil and filters as per the manufacturer’s recommendations. Using high-quality fluids helps maintain optimal performance and protects internal components from wear.

Proper Storage: When not in use, ensure the engine is stored in a dry and secure location. This prevents rust and corrosion, particularly during off-seasons. Use protective covers to shield against dust and moisture.

Follow Guidelines: Adhere to the manufacturer’s maintenance schedule for inspections and replacements. Staying proactive with servicing can greatly enhance reliability and reduce the risk of unexpected breakdowns.

Common Issues and Solutions

When it comes to outboard motors, several frequent challenges can arise, affecting performance and reliability. Understanding these issues and their remedies can enhance the overall experience and ensure smoother operation.

| Issue | Description | Solution |

|---|---|---|

| Overheating | Engines may experience excessive heat due to inadequate cooling or blockages. | Check the cooling system for clogs and ensure proper water intake. |

| Starting Problems | Difficulty in starting may stem from fuel issues or electrical faults. | Inspect the fuel supply and battery connections; replace faulty components as needed. |

| Fuel Leaks | Leaks can occur in the fuel system, leading to potential hazards. | Examine hoses and connections for wear and replace any damaged parts immediately. |

| Unresponsive Controls | Throttle or steering mechanisms may become sluggish or unresponsive. | Lubricate moving parts and check for obstructions or corrosion in the control system. |

Parts Replacement Procedures

Maintaining the functionality of your equipment requires careful attention to its components. This section outlines the essential steps for effectively swapping out various elements to ensure optimal performance. Understanding the proper methodology can prevent complications and extend the life of your machinery.

Step-by-Step Process

Follow these guidelines for efficient replacement of critical components:

| Step | Description |

|---|---|

| 1 | Identify the specific component that needs replacement and gather the necessary tools. |

| 2 | Disconnect the equipment from any power sources to ensure safety during the procedure. |

| 3 | Carefully remove the old part, taking note of its orientation and connection points for proper installation of the new unit. |

| 4 | Install the new component, ensuring it is securely fastened and aligned correctly. |

| 5 | Reconnect any power sources and perform a functionality test to confirm successful installation. |

Safety Considerations

Always prioritize safety when handling equipment. Wear appropriate protective gear and follow manufacturer guidelines to avoid potential hazards during the replacement process.

Tools Required for Repairs

When undertaking maintenance or fixing machinery, having the right instruments at your disposal is crucial for a smooth and efficient process. Proper tools not only enhance the quality of work but also ensure safety and ease of use.

Here’s a list of essential tools commonly needed for repairs:

- Wrenches: Various sizes are necessary for loosening and tightening bolts and nuts.

- Screwdrivers: A selection of flathead and Phillips screwdrivers will accommodate different types of screws.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Socket Set: This collection allows for quick adjustments and efficient handling of fasteners.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Multi-tool: Handy for various small tasks, combining several functions into one tool.

- Measuring Tools: Rulers or calipers help in taking precise measurements during repairs.

By equipping yourself with these instruments, you can facilitate a more effective repair process, minimizing potential setbacks and achieving satisfactory results.

Where to Find Replacement Parts

When it comes to maintaining your outboard motor, sourcing the right components is crucial for ensuring optimal performance. There are several avenues to explore for acquiring the necessary items, each offering unique advantages.

Authorized Dealers

One of the most reliable sources for obtaining replacements is through authorized dealers. These establishments provide genuine components that meet the manufacturer’s standards, ensuring compatibility and quality. Additionally, their staff can offer expert advice on installation and maintenance.

Online Retailers

In the digital age, numerous online platforms specialize in marine equipment. These websites often have extensive inventories, allowing you to compare prices and read customer reviews. However, it’s important to verify the credibility of the site and confirm the authenticity of the items.

| Source | Advantages |

|---|---|

| Authorized Dealers | Genuine parts, expert advice, warranty options |

| Online Retailers | Convenience, price comparison, wider selection |

| Local Marine Shops | Personal service, immediate availability, community support |

| Second-Hand Marketplaces | Cost savings, rare finds, environmentally friendly options |

Comparing Mariner 9.9 Models

When exploring different engine models, it’s essential to understand the variations in specifications, features, and performance. Each variant offers distinct advantages tailored to various boating needs. This section delves into key comparisons, helping enthusiasts make informed decisions based on their requirements.

Key Features Overview

Different models present unique features that cater to diverse boating applications. Factors such as horsepower, fuel efficiency, and weight are crucial when assessing which engine suits your vessel best. Below is a comparative table highlighting some of the fundamental characteristics:

| Model Variant | Horsepower | Fuel Type | Weight (lbs) |

|---|---|---|---|

| Model A | 9.9 HP | Gasoline | 85 |

| Model B | 9.9 HP | Gasoline | 90 |

| Model C | 9.9 HP | Gasoline | 88 |

Performance Considerations

Evaluating the performance metrics of various engine types is vital for selecting the right option. Factors like acceleration, top speed, and reliability play a significant role in ensuring a seamless boating experience. By analyzing these aspects, boaters can choose a model that best fits their usage scenarios.

Owner Experiences and Feedback

This section aims to highlight the diverse experiences and insights of users regarding a specific outboard engine. Collecting feedback from various boat enthusiasts can provide valuable perspectives on performance, reliability, and overall satisfaction.

General Impressions

Many individuals who have used this engine express a high level of satisfaction. Common themes among user reviews include:

- Ease of use and maintenance

- Reliability during extended outings

- Fuel efficiency compared to similar models

Common Challenges

While most users appreciate the engine’s strengths, some have reported occasional challenges. The following issues have been noted:

- Difficulty in sourcing specific components

- Need for occasional technical support

- Varying performance in extreme weather conditions

In summary, the collective feedback from users offers a comprehensive overview of the engine’s strengths and areas for improvement, aiding potential buyers in making informed decisions.

Resources for Further Learning

Expanding your knowledge about engine maintenance and repair can significantly enhance your skills and confidence. Numerous resources are available that provide valuable insights into various aspects of small motor systems, including operational techniques, troubleshooting, and maintenance practices. Below are some recommended materials to aid your learning journey.

Online Courses and Tutorials

Enrolling in online courses or following tutorials can provide structured guidance and practical knowledge. Many platforms offer specialized classes that cover essential topics in engine operation and repair.

Books and Manuals

Books written by experts in the field can serve as excellent reference materials. Comprehensive manuals often contain detailed instructions, diagrams, and troubleshooting tips that are beneficial for hands-on learners.

| Resource Type | Name | Link |

|---|---|---|

| Online Course | Small Engine Repair | View Course |

| Book | Engine Repair Basics | Buy Now |

| Tutorial | Understanding Engine Components | Access Tutorial |