In the realm of agricultural equipment, having a clear visual representation of various components is essential for effective maintenance and repair. These layouts serve as valuable references, providing insight into the arrangement and functionality of different elements within the machinery. With an accurate illustration at hand, operators and technicians can identify specific areas that require attention, ensuring the longevity and efficiency of their equipment.

The importance of comprehending the intricate details of these illustrations cannot be overstated. Such visuals facilitate troubleshooting and enable users to quickly pinpoint any discrepancies or malfunctions. By familiarizing oneself with the layout, individuals can approach repairs with confidence, ultimately reducing downtime and enhancing productivity in the field.

Moreover, a well-structured representation not only aids in identifying components but also helps in understanding their interactions within the entire system. This holistic view is crucial for optimizing performance and implementing effective strategies for regular upkeep. In an industry where precision is key, having access to detailed layouts empowers users to make informed decisions regarding their equipment.

Massey Ferguson 1230 Overview

This section provides a comprehensive look at a specific agricultural machinery model, highlighting its design and functionality. The equipment is renowned for its reliability and efficiency, making it a valuable asset for farmers and landowners. Understanding its key features and components can greatly enhance the user’s experience and performance.

Key Features

The machinery is equipped with a variety of innovative elements that facilitate smooth operation and maintenance. These features contribute to improved productivity and durability, ensuring that the equipment meets the diverse needs of its users.

Technical Specifications

Examining the technical specifications of this model offers insights into its capabilities. Below is a summary of essential characteristics that define its performance:

| Specification | Details |

|---|---|

| Engine Power | Various horsepower options |

| Transmission Type | Multiple speed options |

| Hydraulic Capacity | Optimal for various implements |

| Weight | Compact yet robust structure |

| Usage Applications | Suitable for diverse agricultural tasks |

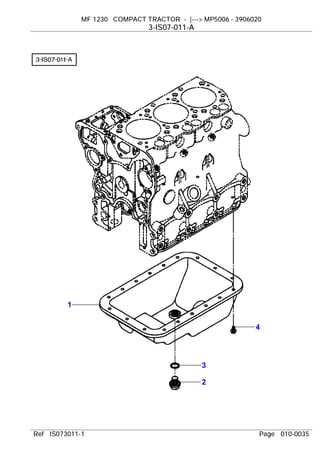

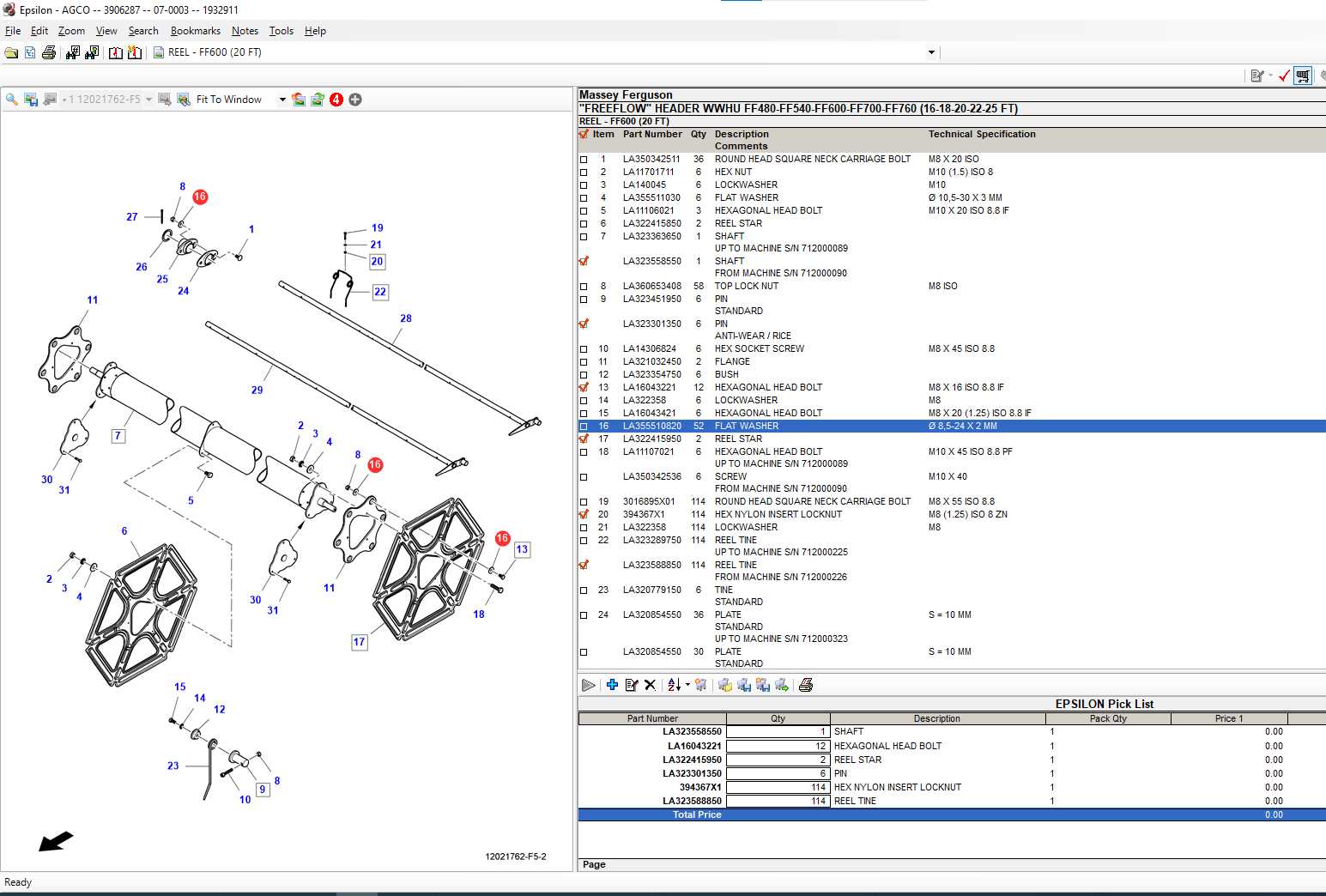

Importance of Parts Diagrams

Understanding the assembly of machinery is crucial for maintenance and repairs. Visual representations of components enhance clarity, enabling users to identify and locate each element within complex systems. This not only facilitates efficient troubleshooting but also streamlines the process of sourcing replacements when necessary.

Utilizing such visual guides ensures accuracy in reassembly and reduces the likelihood of errors that could lead to operational inefficiencies. Moreover, they serve as valuable resources for training and educating personnel about the intricate workings of the equipment. By providing a clear overview, these tools empower users to engage with machinery more confidently and effectively.

In addition, these representations can significantly contribute to cost savings over time. When users can quickly identify required components, they can avoid prolonged downtime and unnecessary expenses associated with incorrect part orders. Ultimately, effective use of these visual tools enhances both the functionality and longevity of the machinery, ensuring optimal performance in various applications.

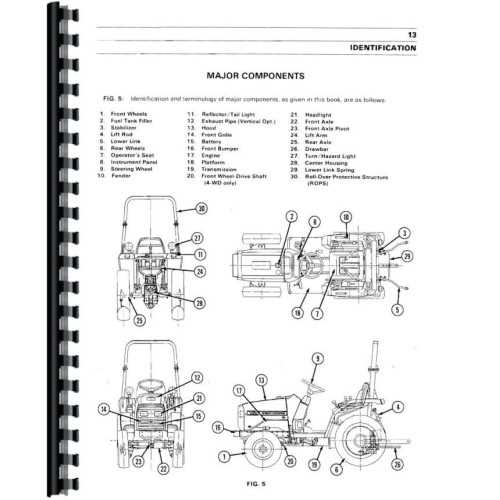

Understanding Components of the Tractor

Farm machinery plays a crucial role in modern agriculture, ensuring efficiency and productivity. Grasping the various elements that make up these machines is essential for operators and technicians alike. This section delves into the key components that contribute to the functionality and performance of tractors.

- Engine: The powerhouse of the machine, responsible for generating the necessary energy to perform various tasks.

- Transmission: This system transfers power from the engine to the wheels, enabling movement and maneuverability.

- Hydraulic System: Vital for operating attachments and implements, it uses fluid pressure to facilitate movement and force.

- Chassis: The structural framework that supports all other components, ensuring stability and durability during operation.

- Wheels and Tires: Designed for traction and stability, they play a critical role in the vehicle’s ability to navigate different terrains.

- Electrical System: Powers various electrical components, including lights, ignition systems, and sensors that enhance overall functionality.

Each of these elements works in harmony to ensure the machine operates effectively, allowing for diverse agricultural tasks to be accomplished efficiently.

How to Use the Parts Diagram

Understanding how to navigate an assembly blueprint is essential for efficient maintenance and repair of machinery. These visual representations provide a clear overview of components, making it easier to identify and locate necessary elements for any project. Familiarity with these guides can significantly enhance the repair process.

To effectively utilize the assembly blueprint, follow these steps:

- Examine the overall layout to gain a sense of the machinery structure.

- Identify the sections relevant to your task by cross-referencing with the machine manual.

- Note the unique identifiers or numbers associated with each component for easier reference.

When looking for specific items, consider these tips:

- Ensure you have the correct version of the blueprint that matches your equipment model.

- Use the legend or key provided to understand symbols and markings.

- Pay attention to any exploded views, as they illustrate how components fit together.

By mastering these techniques, you can streamline your repair efforts and ensure that all necessary components are accounted for during maintenance tasks.

Common Issues and Troubleshooting

When working with agricultural machinery, operators may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their solutions is essential for maintaining equipment functionality and ensuring a smooth operation.

Engine Performance Problems

One frequent issue is related to engine performance, which can manifest as reduced power output or irregular operation. This may stem from several factors, including fuel quality, air intake restrictions, or ignition system malfunctions. Regular maintenance, such as checking fuel filters and ensuring proper airflow, can help mitigate these problems.

Hydraulic System Malfunctions

Another area to monitor is the hydraulic system, which can experience leaks or pressure inconsistencies. These issues can hinder the machine’s ability to perform tasks effectively. Inspecting hydraulic lines for wear and ensuring fluid levels are optimal are crucial steps in troubleshooting this system.

Finding Replacement Parts Efficiently

Locating suitable components for machinery can be a challenging task. However, with the right approach, the process can be streamlined. Understanding where to search and what resources to utilize is crucial for acquiring necessary items quickly and effectively.

Begin by exploring reputable online retailers and specialized marketplaces that focus on agricultural equipment. These platforms often provide a vast selection of components, making it easier to find what is needed. Additionally, consider reaching out to local suppliers who may have physical stock available, offering immediate solutions without the delay of shipping.

Another useful strategy is to consult with communities and forums dedicated to agricultural machinery. Engaging with experienced users can yield valuable insights into where to source quality components. Often, fellow enthusiasts can recommend trusted vendors or even sell items they no longer require.

Lastly, keep a detailed record of any specifications and model numbers relevant to the components you seek. Having this information readily available not only simplifies the search process but also ensures compatibility, reducing the chances of acquiring incorrect items.

Recommended Tools for Repairs

When undertaking maintenance tasks, having the right equipment is essential for ensuring efficiency and effectiveness. A well-prepared toolkit not only simplifies the repair process but also enhances safety and minimizes the risk of errors. Below is a list of essential tools that every technician should consider for optimal performance during repairs.

Basic Hand Tools

- Wrenches: Adjustable and fixed types are crucial for loosening and tightening bolts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will help in handling different types of screws.

- Pliers: Needle-nose and standard pliers are useful for gripping and twisting.

- Hammer: A reliable hammer assists in driving nails and other fasteners.

- Measuring Tape: Accurate measurements are vital for fitting parts correctly.

Power Tools

- Drill: A cordless drill is handy for making holes and driving screws quickly.

- Grinder: Useful for cutting, grinding, and polishing various materials.

- Impact Wrench: Ideal for loosening tight bolts effortlessly.

- Angle Grinder: Suitable for more extensive cutting tasks and shaping materials.

Equipping yourself with these tools will significantly improve your ability to perform repairs effectively and with confidence. Ensuring you have the right gear is a step toward successful maintenance projects.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your machinery requires a consistent maintenance routine. Proper care not only enhances functionality but also extends the lifespan of the equipment. Regular attention to essential components can significantly prevent unexpected failures and costly repairs.

Regular Inspections: Conduct frequent checks on all critical parts to identify wear and tear early. This proactive approach allows for timely replacements and adjustments, helping to avoid more severe damage.

Lubrication: Maintain optimal functioning by regularly lubricating moving components. This minimizes friction and reduces wear, ensuring smooth operation and enhancing overall efficiency.

Cleaning: Keep the machinery clean from dirt and debris. Accumulation of particles can lead to overheating and mechanical failure. A clean environment promotes better performance and reliability.

Following Guidelines: Adhere to the manufacturer’s recommendations for service intervals and replacement schedules. These guidelines are designed to maximize performance and safety.

Storage Conditions: Properly store the equipment when not in use. Protecting it from harsh weather conditions and environmental factors can prevent premature deterioration.

Differences Between Models

When evaluating agricultural machinery, it’s crucial to recognize the distinctions among various models. Each iteration often incorporates enhancements, catering to specific user needs and improving overall efficiency. Understanding these variations can aid in making informed decisions regarding equipment selection and utilization.

Key differences may include:

- Engine Specifications: Variations in horsepower and fuel efficiency can significantly impact performance.

- Dimensions: Changes in size and weight may affect maneuverability and suitability for different tasks.

- Technological Advancements: Newer models often feature upgraded controls and monitoring systems for better operation.

- Attachments and Accessories: The compatibility with different implements can vary, influencing versatility.

- Durability and Build Quality: Improvements in materials and construction techniques enhance longevity and reliability.

By examining these factors, users can identify which model best aligns with their agricultural practices and operational requirements.

Consulting with Professionals

Engaging with experts in the field can significantly enhance the understanding and management of machinery and equipment. These professionals possess a wealth of knowledge and experience, allowing them to offer valuable insights into optimal usage and maintenance practices. By consulting with specialists, users can ensure they are making informed decisions that promote efficiency and longevity in their operations.

Understanding Complex Systems

Complex machinery often involves intricate components that require detailed knowledge for effective operation. Professionals can help decode these systems, providing clarity on how each part interacts with others. Their guidance can facilitate better troubleshooting, enabling users to identify and rectify issues promptly.

Enhancing Operational Efficiency

Expert advice can lead to improved operational procedures, helping users maximize performance and minimize downtime. By leveraging the expertise of seasoned professionals, individuals can implement strategies that enhance productivity while ensuring the safety and reliability of their equipment.

Resources for Further Information

For those seeking additional insights and support regarding machinery and its components, various resources are available. These materials can aid in enhancing understanding, troubleshooting issues, and ensuring optimal performance. Utilizing these references can be invaluable for both experienced users and newcomers.

Online Platforms

Numerous websites offer extensive data, manuals, and community forums. Engaging with these platforms allows users to share experiences and seek advice from fellow enthusiasts.

| Website | Description |

|---|---|

| www.tractorforum.com | A community-driven platform featuring discussions, manuals, and guides for various machinery. |

| www.tractordata.com | A comprehensive database that provides specifications and historical information about numerous models. |

| www.yourmechanic.com | An online service that connects users with mechanics and offers DIY maintenance tips. |

Books and Manuals

Printed resources remain an excellent option for in-depth knowledge. Various handbooks and service manuals contain crucial information on maintenance and troubleshooting.

Owner Experiences and Reviews

Many individuals who own this agricultural machinery share their insights and observations based on real-world usage. These accounts often highlight both the strengths and weaknesses encountered during operation, providing valuable information for potential buyers and current owners alike. User reviews encompass aspects such as reliability, performance, and ease of maintenance, which are crucial for ensuring efficient farm operations.

Performance Insights

Users frequently commend the robust nature of the machinery, noting its ability to handle various tasks effectively. Many appreciate its power and agility in different terrains, allowing them to complete their work efficiently. However, some reviews indicate that regular maintenance is essential to keep the machinery running smoothly and to prevent unexpected downtime.

Maintenance and Support

Owner feedback often emphasizes the importance of routine upkeep and the availability of support services. Many find that obtaining replacement components is straightforward, which contributes positively to their overall experience. Furthermore, the community surrounding this equipment often shares tips and tricks for effective maintenance, fostering a sense of camaraderie among users.