In the realm of agricultural machinery, a comprehensive grasp of the intricate elements that constitute each machine is essential for optimal performance and maintenance. A detailed illustration of these components serves as a vital resource for operators and technicians alike, aiding in troubleshooting and repairs.

The significance of having a visual reference cannot be overstated. Such references enhance the understanding of the layout and functionality of various parts, facilitating a more effective approach to both routine maintenance and unexpected repairs. When operators can easily identify and locate specific components, they can ensure that their equipment runs smoothly and efficiently.

Moreover, familiarity with the configuration of machinery promotes safety and reduces the likelihood of errors during handling or repairs. By studying these illustrations, users can gain valuable insights into the interplay of different elements, which ultimately contributes to the longevity and reliability of the equipment in the field.

Overview

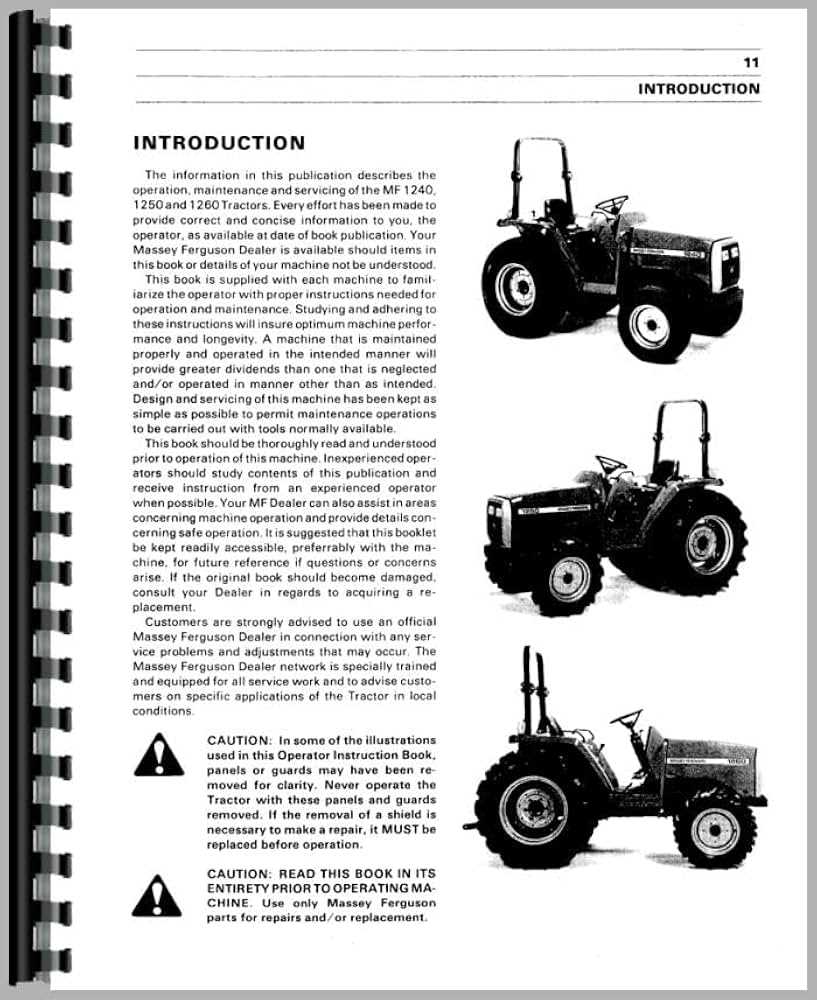

This section provides a comprehensive look at a well-known agricultural machine, highlighting its essential features and functionalities. Designed for efficiency and reliability, this model is a staple in farming operations, capable of handling various tasks with ease.

Key characteristics include:

- Powerful engine performance

- Versatile attachment options

- Robust construction for durability

- Operator-friendly controls

Farmers and operators appreciate this equipment for its:

- High productivity in the field

- Low maintenance requirements

- Exceptional maneuverability

- Fuel efficiency

Overall, this machine stands out in its class, providing solutions for a wide range of agricultural challenges, making it a valuable asset for any farming operation.

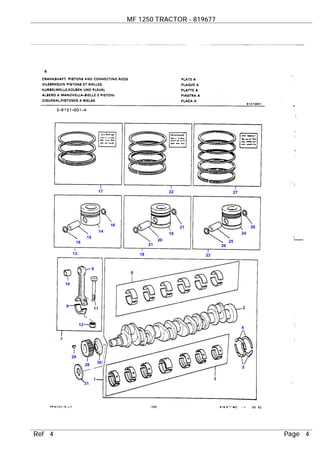

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair processes. They provide clarity and understanding, enabling users to identify, organize, and manage individual elements effectively.

Here are some key reasons why these visual aids are essential:

- Enhanced Understanding: Clear illustrations simplify the complexity of machinery, making it easier for operators to grasp how different components interact.

- Efficient Troubleshooting: When issues arise, having a visual reference allows technicians to quickly pinpoint problems, reducing downtime.

- Accurate Assembly: Step-by-step visuals guide users in putting together parts correctly, ensuring optimal performance.

- Streamlined Ordering: Understanding which elements are needed helps in procuring the right items without confusion.

- Training Tool: These resources serve as effective educational materials for new employees, helping them learn the system more rapidly.

In summary, visual guides are indispensable tools that contribute to efficient operation, maintenance, and learning in various fields, ultimately enhancing productivity and reducing errors.

Key Components of the 1250

Understanding the essential elements of this agricultural machinery is crucial for maintenance and operation. Each component plays a vital role in ensuring efficiency and performance in various farming tasks. Familiarity with these key parts can enhance both the longevity and effectiveness of the equipment.

| Component | Description |

|---|---|

| Engine | Power source that drives the machine, providing the necessary energy for operation. |

| Transmission | System that transmits power from the engine to the wheels, allowing for variable speeds. |

| Hydraulic System | Controls various attachments and implements, enhancing functionality through fluid power. |

| Chassis | Frame that supports all components, ensuring structural integrity and stability. |

| Cab | Operator’s compartment designed for comfort and visibility while controlling the machine. |

How to Read a Parts Diagram

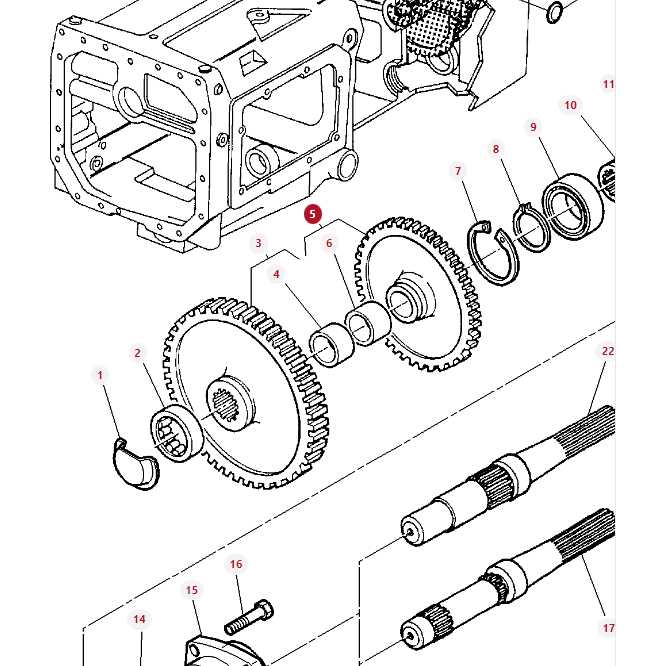

Understanding an assembly illustration is essential for effective maintenance and repair. These visual guides serve as a roadmap, helping users identify individual components and their relationships within a system. By becoming familiar with the structure and symbols used, one can streamline the troubleshooting process and ensure accurate reassembly.

Begin by examining the overall layout. Typically, the illustration will be segmented into different sections, each representing a specific assembly or subsystem. Pay attention to the labeling of each part, as these annotations provide crucial information about the item’s identification and specifications.

Next, look for a legend or key that explains any symbols or color codes present. This reference will clarify the meaning behind various markings, allowing for a better understanding of the components’ roles. Additionally, take note of any directional arrows or lines indicating movement or connections, as these can help visualize how parts interact with one another.

Finally, cross-reference the visual information with the accompanying list of components or specifications. This ensures you have a complete grasp of what is required for repairs or replacements, aiding in successful maintenance and enhancing the lifespan of your machinery.

Common Issues and Solutions

In the realm of agricultural machinery, various challenges can arise that affect performance and efficiency. Understanding these common problems and their respective solutions can significantly enhance the longevity and functionality of your equipment. Below are some frequently encountered issues along with practical solutions.

Mechanical Failures

Mechanical failures can stem from various factors, including wear and tear, inadequate maintenance, or manufacturing defects. Here are some typical mechanical issues:

- Engine overheating

- Transmission slipping

- Hydraulic system leaks

To address these issues:

- Regularly check fluid levels and maintain proper temperatures.

- Inspect belts and hoses for wear, replacing them as necessary.

- Ensure seals and fittings in the hydraulic system are tight and intact.

Electrical Problems

Electrical malfunctions can lead to operational inefficiencies and can be challenging to diagnose. Common electrical issues include:

- Battery failure

- Faulty wiring connections

- Inoperative control panels

To resolve these concerns:

- Test and replace batteries periodically to ensure reliable power.

- Examine wiring for corrosion or loose connections, repairing as needed.

- Check fuses and relays in control panels to identify any failures.

Finding Authentic Replacement Parts

Ensuring the longevity and performance of your machinery requires sourcing genuine components that meet industry standards. Authentic replacements are crucial for maintaining optimal functionality and preventing future issues. The market offers a variety of options, but identifying reliable suppliers can be a challenge.

Research is key. Start by exploring manufacturers’ official websites or authorized distributors. These platforms often provide detailed information on specifications, compatibility, and availability. Engaging with online forums and communities can also yield valuable insights and recommendations from fellow users.

Quality assurance is essential. Look for certifications and warranties that back the authenticity of the components. Avoiding counterfeit products not only safeguards your equipment but also ensures better performance and durability in the long run.

Another effective strategy is to maintain an organized inventory of the components you currently have. This allows for easier tracking and replacement of specific items as needed. Keeping a detailed record can help streamline your procurement process, reducing downtime and enhancing productivity.

In conclusion, prioritizing genuine components is vital for the reliability of your machinery. By conducting thorough research, leveraging community knowledge, and ensuring quality, you can make informed decisions that lead to successful maintenance and operation.

Maintenance Tips for Longevity

Proper care and routine upkeep are essential for maximizing the lifespan and performance of any machinery. By following a few key strategies, operators can ensure that their equipment remains in optimal condition, reducing the risk of breakdowns and enhancing productivity.

Regular Inspections

Conducting frequent assessments is crucial for identifying wear and tear early. Operators should establish a checklist that includes checking fluid levels, inspecting belts and hoses, and examining critical components for signs of damage.

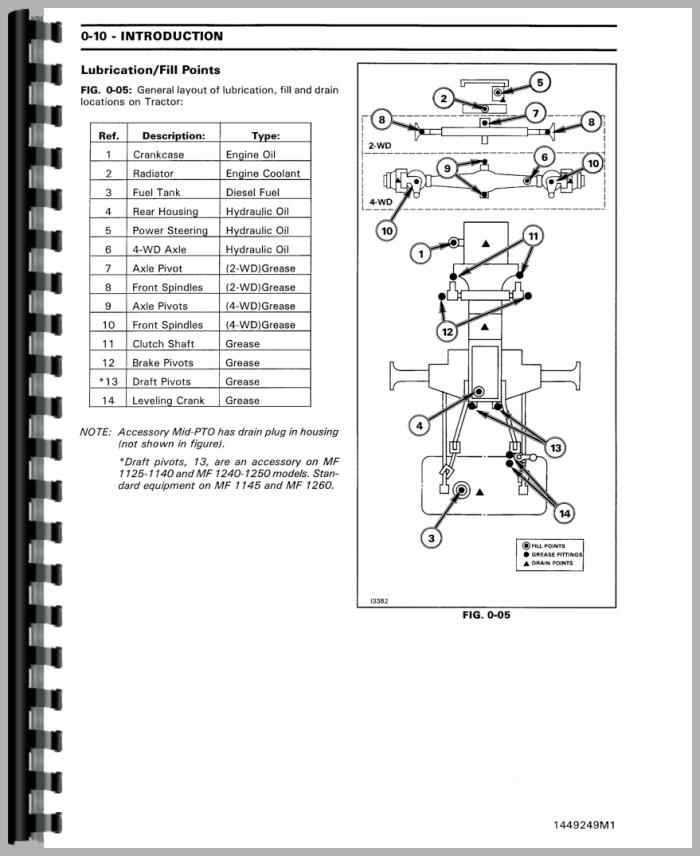

Fluid Maintenance

Keeping fluids clean and at appropriate levels is vital for efficient operation. Regularly changing engine oil, hydraulic fluid, and coolant can prevent overheating and improve overall performance. Always refer to the manufacturer’s recommendations for specific intervals.

| Fluid Type | Recommended Change Interval |

|---|---|

| Engine Oil | Every 100 hours of operation |

| Hydraulic Fluid | Every 500 hours of operation |

| Coolant | Annually |

Incorporating these practices into a regular maintenance schedule can significantly extend the life of your equipment, ensuring it operates smoothly and efficiently for years to come.

Online Resources for Parts Information

Accessing accurate information about equipment components is essential for maintenance and repair. Fortunately, numerous online platforms offer valuable resources, making it easier to find what you need. These tools not only provide detailed descriptions but also facilitate comparisons and help users make informed decisions.

Many manufacturers have official websites where you can find a wealth of information, including catalogs and technical manuals. These resources often include interactive features, allowing users to search by model or category. Additionally, online forums and communities can be great places to seek advice, share experiences, and connect with other enthusiasts.

Another beneficial option is third-party websites dedicated to parts and accessories. These platforms typically feature extensive databases that allow for quick searches based on specific criteria. Customer reviews and ratings can also provide insights into the reliability and performance of various components.

Finally, social media groups and online marketplaces often serve as hubs for discussions about equipment upkeep. By joining these communities, users can tap into a wealth of knowledge and resources that can simplify the process of finding and acquiring necessary items.

Upgrading Your Massey Ferguson

Enhancing the performance and efficiency of your agricultural machinery can significantly impact your productivity. Whether you aim to increase power, improve fuel efficiency, or add new features, there are numerous upgrades available that can transform your equipment into a more reliable workhorse. This section outlines key considerations and options for elevating your machine’s capabilities.

Performance Enhancements

Improving the overall performance involves several factors, including engine modifications, transmission upgrades, and hydraulic system enhancements. Each of these components plays a crucial role in how well your machine operates under various conditions.

| Upgrade Type | Description |

|---|---|

| Engine Tuning | Adjusting fuel injection and timing for better power and efficiency. |

| Transmission Upgrade | Installing a more efficient gearbox to improve speed and torque. |

| Hydraulic System Enhancement | Upgrading pumps and valves for improved lifting capacity and speed. |

Adding New Features

In addition to performance upgrades, consider incorporating new technology and features that can enhance usability. Modern attachments and precision farming tools can provide valuable data and improve the overall operation of your machinery.

| Feature Type | Description |

|---|---|

| GPS Guidance Systems | Implementing navigation tools for more precise fieldwork. |

| Advanced Monitoring Systems | Utilizing sensors to track performance metrics and maintenance needs. |

| Comfort Features | Adding ergonomic seats and climate control for operator comfort. |

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in various machinery, employing the principles of fluid mechanics to transmit power efficiently. These systems utilize incompressible fluids to generate force and perform work, making them essential in numerous industrial and agricultural applications. Understanding the components and functioning of these systems can significantly enhance maintenance and operational efficiency.

At the core of any hydraulic system are several key elements that work together seamlessly. The primary components include the hydraulic fluid, pump, actuator, and various control devices. Each part contributes to the overall performance, ensuring the system operates smoothly and effectively.

| Component | Function |

|---|---|

| Hydraulic Fluid | Transmits power and lubricates components |

| Pump | Converts mechanical energy into hydraulic energy |

| Actuator | Transforms hydraulic energy into mechanical motion |

| Control Valves | Regulate the flow and direction of the fluid |

Understanding how these elements interact can aid in troubleshooting and optimizing performance. By maintaining the integrity of the hydraulic system, operators can ensure longevity and reliability in their machinery.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring safety is paramount. Proper precautions help prevent accidents and injuries, creating a secure environment for both the technician and the equipment. Adhering to safety guidelines not only protects individuals but also extends the lifespan of machinery.

Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and steel-toed boots. This gear provides essential protection against potential hazards such as sharp edges, chemicals, or heavy objects.

Before starting any repair work, disconnect the power source to prevent accidental activation. Additionally, use lockout/tagout procedures to ensure that the equipment remains inoperative while maintenance is being performed.

Ensure the workspace is clean and well-lit. Cluttered areas can lead to slips and falls, while inadequate lighting may obscure potential dangers. Organize tools and materials to minimize the risk of accidents during the repair process.

Familiarize yourself with the machinery’s manual. Understanding the specifications and operational guidelines can significantly reduce the likelihood of mishaps. If unsure about any procedures, consult a knowledgeable professional for guidance.

Be cautious with heavy components. Utilize appropriate lifting techniques or equipment, such as hoists or dollies, to avoid strain or injury. Always seek assistance when handling items that are too cumbersome or awkward to manage alone.

Finally, remain alert and focused throughout the repair process. Distractions can lead to mistakes that may compromise safety. Taking regular breaks can help maintain concentration and prevent fatigue-related accidents.

Expert Recommendations for Mechanics

When it comes to maintaining and repairing heavy machinery, having the right guidance is crucial for mechanics. Understanding the intricate systems involved and knowing the best practices can significantly enhance both efficiency and safety on the job. This section provides valuable insights aimed at improving diagnostic skills and repair techniques.

1. Prioritize Safety: Always start with safety protocols. Wear appropriate protective gear and ensure the workspace is free from hazards. Regularly check equipment for potential risks before commencing work.

2. Use Quality Components: Opt for high-quality replacement elements to ensure longevity and optimal performance. Inferior parts can lead to frequent breakdowns and increased maintenance costs.

3. Familiarize Yourself with Technical Resources: Invest time in studying technical manuals and service guides. These resources provide essential information about the machinery’s specifications and troubleshooting procedures.

4. Develop a Systematic Approach: Tackle repairs methodically. Create a checklist to follow during disassembly and reassembly, ensuring no steps are overlooked, which can lead to costly mistakes.

5. Keep Up with Training: Continuous education is vital. Attend workshops and training sessions to stay updated on the latest technologies and repair methods within the industry.

6. Network with Peers: Building relationships with other professionals can provide valuable insights. Sharing experiences and solutions can lead to more effective troubleshooting and innovative techniques.

By implementing these recommendations, mechanics can improve their skills and enhance the reliability of the machinery they service, ultimately contributing to greater operational success.