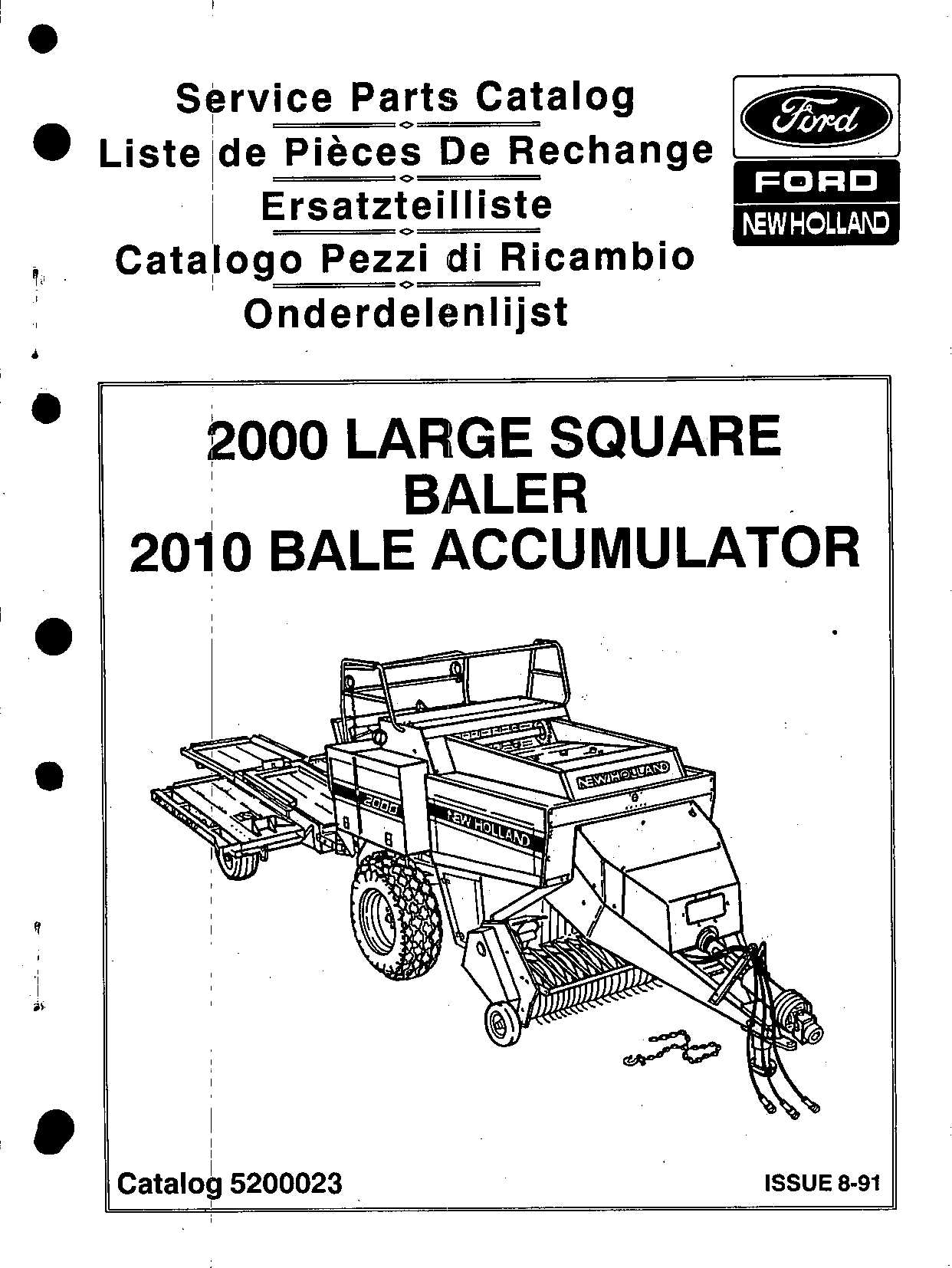

The intricacies of modern agricultural equipment play a crucial role in enhancing productivity on farms. Knowledge of the essential elements that constitute these machines empowers operators and technicians alike, ensuring efficient performance and longevity. This section aims to shed light on the various components integral to a specific type of hay-making machinery.

By exploring the layout and function of these elements, users can gain valuable insights into maintenance and repair processes. Such understanding is vital for optimizing operations and preventing costly downtime, ultimately leading to better yield management. The following content will provide a comprehensive overview, complete with visual representations for easier comprehension.

Whether you are a seasoned professional or a novice in the field, familiarizing yourself with these components will significantly enhance your operational expertise. Emphasizing clarity and accessibility, this guide will serve as a useful reference for anyone involved in agricultural practices.

Massey Ferguson 224 Baler Overview

This section provides a comprehensive overview of a well-regarded agricultural machine designed for efficient crop management. Its robust engineering and user-friendly features make it an essential tool for farmers seeking productivity and reliability in the field.

Equipped with advanced technology, this implement ensures optimal performance while minimizing downtime. Its design facilitates ease of operation, enabling users to achieve high levels of efficiency in their harvesting processes.

| Feature | Description |

|---|---|

| Build Quality | Durable construction to withstand tough agricultural conditions. |

| Efficiency | High throughput rate allows for rapid processing of materials. |

| User-Friendly | Intuitive controls simplify operation for all skill levels. |

| Maintenance | Designed for easy access to components for quick servicing. |

With a focus on productivity, this machine offers excellent performance that meets the demands of modern farming practices. Its versatility ensures it can handle a variety of crops, making it a valuable addition to any agricultural operation.

Key Components of the Baler

The efficient operation of any agricultural implement relies on its essential elements, which work in harmony to achieve optimal performance. Understanding these components is crucial for maintenance and troubleshooting, ensuring that the machinery functions smoothly during critical tasks.

Feed Mechanism: This system is responsible for guiding the material into the chamber, allowing for a consistent flow that enhances productivity. Proper adjustment is necessary to avoid jams and ensure uniform feeding.

Compression Chamber: Here, the collected material is compacted into bales. The design and size of this chamber significantly affect the density and quality of the output.

Knots and Twine System: This element secures the finished product by binding it tightly. A reliable knotting system is essential for maintaining bale integrity during handling and transport.

Pickup Header: The initial point of contact with the crop, this component collects the material from the field. Its efficiency directly influences the overall harvest yield.

Power Transmission: This mechanism transfers energy from the tractor to the implement, ensuring that all parts operate effectively. Regular inspection can prevent performance issues and prolong equipment lifespan.

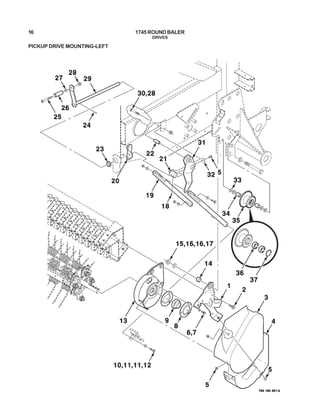

Understanding the Parts Diagram

Grasping the layout of machinery components is essential for effective maintenance and operation. This visual representation serves as a vital resource, allowing users to identify and locate individual elements, ensuring smooth functionality and timely repairs. By familiarizing oneself with the arrangement, operators can better understand how each piece interacts within the overall system.

The Importance of Component Recognition

Recognizing each element is crucial for troubleshooting and maintenance tasks. When operators can pinpoint specific components, they are better equipped to diagnose issues, perform repairs, and replace faulty sections. This not only enhances the lifespan of the machinery but also boosts operational efficiency.

Navigating the Visual Representation

To effectively navigate the visual layout, pay attention to the labeling and grouping of parts. Often, related elements are clustered together, which can provide insight into their function and interaction. Understanding the relationships between different sections can significantly improve your ability to handle mechanical challenges.

Importance of Regular Maintenance

Routine upkeep of agricultural machinery is crucial for ensuring optimal performance and longevity. Neglecting this aspect can lead to inefficiencies and costly repairs, ultimately affecting productivity.

Benefits of Consistent Upkeep

- Enhances operational efficiency

- Prevents unexpected breakdowns

- Extends the lifespan of equipment

- Ensures safety for operators

Key Maintenance Practices

- Regularly inspect and clean components

- Lubricate moving parts as needed

- Check fluid levels and replace when necessary

- Monitor wear and tear, replacing parts timely

Common Issues with the Baler

Various challenges can arise during the operation of a hay collection machine, impacting efficiency and performance. Understanding these problems is crucial for maintaining optimal functionality and prolonging the equipment’s lifespan.

Frequent Problems

- Jamming: Occurs when material gets stuck in the mechanism.

- Uneven Bales: Often results from inconsistent feeding of material.

- Wear and Tear: Components can degrade over time, leading to breakdowns.

Maintenance Tips

- Regularly inspect and clean moving parts.

- Ensure proper lubrication of all components.

- Monitor tension and adjustments as per manufacturer guidelines.

How to Identify Replacement Parts

Understanding how to pinpoint components for machinery is essential for maintaining optimal performance. It involves recognizing specific features, measurements, and functionalities of each element to ensure compatibility and efficiency.

Begin by consulting the manufacturer’s manual, which often includes detailed descriptions and specifications. Take note of any part numbers, as these can significantly simplify your search. Additionally, examining the existing components closely can reveal essential characteristics, such as size, shape, and connection types.

Online resources and community forums can also be invaluable. Engaging with other users who have faced similar challenges can provide insights and recommendations for sourcing the necessary elements. When in doubt, reaching out to suppliers for expert advice can further guide your selection process.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for efficiency and effectiveness. A well-equipped toolbox ensures that all repairs can be conducted smoothly, minimizing downtime and enhancing the longevity of the machinery.

Essential Hand Tools

Basic hand tools like wrenches, screwdrivers, and pliers are fundamental for any repair job. A ratchet set can be particularly useful for reaching tight spaces, while a socket set allows for quick and easy fastening.

Power Tools and Accessories

In addition to hand tools, power tools such as drills and impact wrenches can expedite the repair process. Ensure that you have a variety of batteries and drill bits on hand to accommodate different tasks effectively.

Finding Genuine Massey Ferguson Parts

Locating authentic components for your agricultural machinery is essential for optimal performance and longevity. Genuine items ensure compatibility and reliability, preventing potential issues down the line.

Benefits of Authentic Components

- Enhanced durability and performance

- Manufacturer warranty and support

- Consistent quality and specifications

Where to Find Genuine Components

- Authorized dealerships and retailers

- Official manufacturer websites

- Reputable online marketplaces specializing in agricultural equipment

Step-by-Step Repair Process

When it comes to maintaining agricultural machinery, a systematic approach is essential for effective restoration. This guide outlines a clear process for troubleshooting and repairing equipment to ensure optimal performance and longevity.

1. Initial Assessment: Begin by conducting a thorough inspection of the machinery. Look for visible signs of wear, damage, or misalignment. Take note of any unusual noises or operational issues during use.

2. Gather Necessary Tools: Before starting the repair, assemble all required tools and replacement components. Having everything at hand will streamline the process and minimize downtime.

3. Disassembly: Carefully disassemble the affected parts, ensuring to document the order and orientation of each component. This will simplify reassembly and help avoid mistakes.

4. Cleaning and Inspection: Clean all disassembled components thoroughly. Inspect each piece for signs of damage, wear, or malfunction. Replace any parts that do not meet quality standards.

5. Reassembly: Once all components are cleaned and inspected, begin reassembling the machinery in the reverse order of disassembly. Ensure that all parts are aligned correctly and securely fastened.

6. Testing: After reassembly, conduct a test run to verify that the machinery operates as expected. Monitor for any irregularities and make adjustments as necessary.

7. Maintenance Routine: Finally, establish a regular maintenance schedule to prevent future issues. This should include routine checks, cleaning, and lubrication of critical components.

Tips for Baler Optimization

Maximizing efficiency and performance in agricultural machinery requires a strategic approach to maintenance and operation. By focusing on key practices, users can enhance output and prolong equipment lifespan, ensuring a more productive farming season.

Regular Maintenance Checks

Consistent inspections are vital for identifying wear and tear. Lubricating moving parts and replacing worn components promptly can prevent costly breakdowns and maintain optimal functionality.

Adjusting Settings for Optimal Performance

Tweaking operational settings based on crop type and moisture levels can lead to improved results. Tailoring feed rates and tension can help achieve the best compression and minimize waste.

Cost Factors for Replacement Parts

Understanding the financial aspects associated with acquiring new components is essential for efficient machinery maintenance. Several elements can influence the overall expense, ranging from the quality of materials to the supplier’s pricing strategy.

Quality of Components: Higher-quality items often come with a steeper price tag, but they may offer greater durability and performance, ultimately reducing long-term costs.

Market Demand: Availability and demand for specific components can fluctuate, affecting their market value. Scarcity may drive prices up, while a surplus can lead to discounts.

Supplier Reputation: Established vendors may charge more due to their reliability and customer service, which can be worthwhile if it ensures prompt delivery and support.

Compatibility: Components that fit a broader range of machinery might be priced differently than specialized items, impacting purchasing decisions.

In summary, being aware of these factors can aid in making informed decisions when sourcing new components.

Resources for Further Information

For those seeking deeper insights into agricultural machinery and its components, various sources offer valuable knowledge and guidance. Accessing the right information can enhance understanding and improve maintenance practices, ensuring optimal performance in the field.

Online Forums and Communities

Participating in dedicated online platforms allows users to connect with fellow enthusiasts and experts. These communities often share experiences, troubleshooting tips, and insights into the latest developments in the industry.

Manufacturer’s Websites and Manuals

Visiting official websites provides access to detailed guides and specifications. Technical manuals and documentation often include crucial details that can assist in identifying specific components and their functionalities.