In the realm of farming equipment, understanding the intricate structure of machinery is essential for optimal performance and maintenance. This section delves into the significance of comprehending the various elements that constitute a specific model of tractor. Each component plays a vital role in ensuring efficiency and longevity, making it imperative for operators and technicians alike to familiarize themselves with the configuration and functionality of these parts.

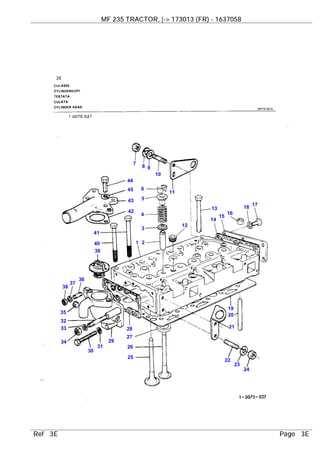

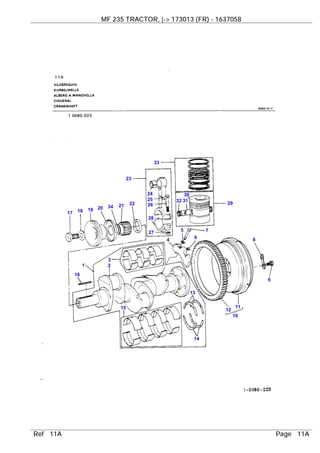

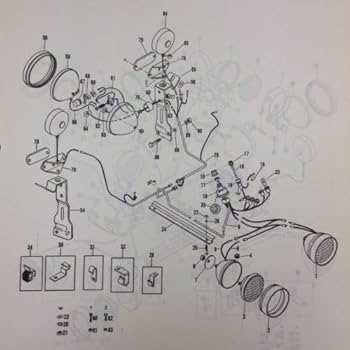

Utilizing visual aids can greatly enhance one’s ability to grasp the relationships and functions of different sections within the machinery. Detailed illustrations serve as valuable resources, allowing individuals to pinpoint specific features, identify potential issues, and streamline repair processes. By gaining insight into the layout and design of these components, users can enhance their troubleshooting skills and ensure the reliable operation of their equipment.

Whether one is a seasoned professional or a novice in the field, accessing comprehensive resources on machinery components fosters a deeper appreciation for agricultural technology. As we explore these essential visuals, we empower ourselves to maintain and operate our equipment more effectively, ultimately contributing to improved productivity in the agricultural sector.

Massey Ferguson 235 Overview

This section provides a comprehensive look at a well-regarded agricultural machine known for its reliability and efficiency. Designed for various farming tasks, it has earned a reputation among operators for its robust performance and user-friendly features.

Engine Performance: The model is equipped with a powerful engine that delivers impressive torque, ensuring optimal operation under different conditions. This makes it suitable for both light and heavy-duty tasks.

Versatility: Its adaptability allows it to be utilized for numerous applications, from tilling to hauling. This multifunctionality enhances its value on any farm.

Maintenance: Regular upkeep is straightforward, thanks to the accessible design of its components. This aspect is crucial for minimizing downtime and maximizing productivity.

Overall, this machine stands out as an ultimate choice for those seeking a dependable and effective solution for their agricultural needs.

Importance of Parts Diagrams

Understanding the intricate layout of machinery components is essential for effective maintenance and repair. Visual representations serve as invaluable tools that facilitate the identification and organization of various elements within a system. These illustrations help technicians grasp the overall structure, ensuring they can execute tasks with precision and confidence.

Clarity and Efficiency are two significant advantages of utilizing visual schematics. When mechanics have access to clear images, they can quickly locate specific sections, reducing the time spent troubleshooting. This efficiency not only accelerates the repair process but also minimizes downtime, which is critical in agricultural and industrial settings.

Enhanced Communication is another key benefit. Illustrations provide a universal language that transcends verbal explanations, making it easier for teams to collaborate. This visual approach ensures that everyone involved understands the components and their functions, leading to fewer misunderstandings and improved teamwork.

Additionally, these representations can be vital for training purposes. New technicians can familiarize themselves with the machinery by studying the visuals, which aids in knowledge retention and boosts their confidence when working on complex systems. Overall, well-crafted illustrations are essential for successful operations and effective management of equipment.

Common Issues with Massey Ferguson 235

Farm equipment often encounters a variety of challenges that can impact performance and efficiency. Understanding these common problems is essential for timely maintenance and optimal operation. This section highlights prevalent concerns that users may face.

Engine Overheating: One frequent issue is overheating, which can result from coolant leaks or a malfunctioning thermostat. Regular checks can help prevent severe damage.

Transmission Difficulties: Users may experience shifting problems, often linked to low fluid levels or worn components. Ensuring proper maintenance can mitigate these issues.

Electrical Failures: Electrical systems can be prone to faults, leading to starting problems or malfunctioning lights. Routine inspections of wiring and connections are crucial.

Poor Hydraulics: Hydraulic systems may exhibit reduced efficiency due to leaks or air in the lines. Addressing these issues promptly ensures reliable performance.

Fuel System Blockages: Blockages in the fuel system can cause performance drops. Regular filter changes and fuel quality checks can enhance engine efficiency.

Key Components and Their Functions

This section explores the essential elements of agricultural machinery, highlighting their roles and importance in ensuring optimal performance. Understanding these components can significantly enhance maintenance and operational efficiency.

- Engine: The powerhouse that drives all functions, converting fuel into mechanical energy.

- Transmission: Responsible for transferring power from the engine to the wheels, facilitating speed and torque adjustments.

- Hydraulic System: Enables the operation of attachments and implements by utilizing pressurized fluid.

- Chassis: The structural framework providing support and stability to the machine.

- Cooling System: Maintains optimal operating temperatures to prevent overheating and ensure longevity.

- Electrical System: Powers lights, starter, and other electrical components, ensuring functionality.

Each of these critical parts works in harmony to deliver the ultimate performance, making proper understanding and maintenance vital for operators.

Finding Replacement Parts Online

In today’s digital age, sourcing essential components for machinery has become more accessible than ever. The internet provides a vast array of resources to help users locate high-quality substitutes efficiently. From specialized retailers to online marketplaces, the options are plentiful, making it easier to maintain and restore equipment.

Utilizing Specialized Retailers

Many websites focus exclusively on agricultural machinery components, offering detailed catalogs and user-friendly interfaces. These platforms often include filters that allow users to narrow down their search by model and type, ensuring a precise match for the required item.

Exploring Online Marketplaces

General online marketplaces present another avenue for finding necessary components. Here, users can browse a wide selection from various sellers, compare prices, and read reviews. Utilizing search functions and category filters can help streamline the process, making it easier to find the ultimate solution for your machinery needs.

Understanding Hydraulic System Diagrams

The hydraulic system is a vital component in many machinery applications, relying on fluid mechanics to transmit power and facilitate movement. Comprehending these intricate schematics can greatly enhance one’s ability to maintain and troubleshoot equipment effectively. Each element within the system plays a specific role, contributing to the overall functionality and efficiency.

Key components such as pumps, cylinders, and valves are represented in these illustrations, often using standardized symbols. Recognizing these symbols is crucial for interpreting the flow of hydraulic fluid and understanding how pressure is generated and regulated throughout the system. By analyzing the connections and interactions depicted in these visuals, operators can diagnose issues and perform necessary repairs.

Moreover, hydraulic schematics provide insight into the sequence of operations. They illustrate how different components work together, enabling a clearer understanding of the entire system’s dynamics. This knowledge is not only beneficial for troubleshooting but also essential for optimizing performance and ensuring longevity.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your agricultural machinery. By following a structured maintenance routine, operators can enhance the functionality of their equipment, prevent unexpected breakdowns, and ultimately save on repair costs.

1. Routine Inspections: Schedule frequent checks of key components such as filters, belts, and hoses. Look for signs of wear and tear to address issues before they escalate. This proactive approach will keep machinery running smoothly.

2. Lubrication: Ensure all moving parts are adequately lubricated. This reduces friction, minimizes wear, and helps prevent overheating. Use the recommended lubricants and adhere to the specified intervals for application.

3. Fluid Levels: Regularly monitor and maintain fluid levels, including engine oil, coolant, and hydraulic fluids. Keeping these at optimal levels is crucial for effective operation and can prevent serious damage.

4. Cleaning: Keep the exterior and working parts of the machinery clean. Accumulated dirt and debris can hinder performance and lead to mechanical failures. A clean machine also allows for better inspections.

5. Seasonal Preparation: Before changing seasons, prepare your equipment for the specific demands of the upcoming tasks. This may involve changing attachments or making adjustments to settings for optimal performance in varying conditions.

6. Professional Servicing: Don’t hesitate to seek professional help for complex repairs or overhauls. Certified technicians can provide insights and ensure that your equipment meets industry standards, enhancing overall reliability.

By implementing these maintenance practices, operators can achieve peak performance and extend the operational life of their machinery, ensuring it remains a reliable partner in their agricultural endeavors.

Using Diagrams for Repairs

Visual representations are invaluable tools when it comes to conducting repairs on machinery. They provide clear guidance on the assembly and disassembly processes, helping to identify components and their relationships. By utilizing these illustrations, technicians can enhance their understanding of complex systems, ensuring that maintenance tasks are performed accurately and efficiently.

Benefits of Visual Guides

Employing visual aids streamlines the repair process in several ways. Firstly, they minimize the likelihood of errors by offering a step-by-step approach that outlines specific procedures. Secondly, these resources help in locating parts quickly, reducing downtime and improving overall productivity. Moreover, they serve as excellent reference materials, allowing users to revisit intricate details as needed.

Practical Tips for Effective Use

To maximize the effectiveness of visual guides, it is essential to approach them with a systematic mindset. Start by familiarizing yourself with the layout of the illustrations, noting key components and their functions. Always refer to the guide throughout the repair process, rather than relying solely on memory. Taking the time to follow the visual instructions closely will ensure a successful outcome and prolong the lifespan of the machinery.

Comparison with Other Tractor Models

Understanding the distinctions between various agricultural machinery can greatly enhance decision-making for farmers and operators. Each model offers unique features that cater to specific needs, making it essential to analyze their capabilities, performance, and suitability for different tasks.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 50 HP | 55 HP | 60 HP |

| Weight | 3,000 kg | 3,200 kg | 3,500 kg |

| Hydraulic Capacity | 40 L/min | 45 L/min | 50 L/min |

| Price | $15,000 | $18,000 | $20,000 |

Ultimately, comparing these specifications aids in selecting the right equipment that meets specific agricultural demands, ensuring efficiency and productivity on the field.

Resources for Technical Support

When facing challenges with machinery, having access to reliable support resources is essential. These tools can provide guidance, troubleshooting steps, and valuable insights to ensure optimal performance. Utilizing the right materials can save time and enhance efficiency in addressing technical issues.

Online Forums and Communities: Engaging with online platforms dedicated to equipment enthusiasts can be incredibly beneficial. These forums often host discussions where users share experiences, solutions, and recommendations. Participating in these communities allows for direct interaction with knowledgeable individuals who can offer practical advice.

Manufacturer’s Manuals: Official documentation is an invaluable asset for understanding specific machinery functions. Manuals typically include detailed instructions, maintenance schedules, and troubleshooting tips. Having a copy of these documents on hand can greatly assist in resolving operational challenges.

Technical Support Hotlines: Many manufacturers provide dedicated support lines for immediate assistance. Speaking directly with a technician can lead to swift resolutions for urgent issues. Keep the contact information readily available to ensure quick access when needed.

Video Tutorials: Visual aids can significantly enhance comprehension. Numerous platforms host video tutorials that demonstrate repairs and maintenance procedures step by step. These resources are especially useful for those who prefer learning through visual representation.

Local Dealerships: Establishing a relationship with nearby dealers can provide access to expert advice and support. Dealers often have trained staff who can assist with inquiries and may offer additional services such as repairs and maintenance.