In the realm of woodworking and construction, precision is key. A specific type of cutting apparatus is essential for achieving clean and accurate angles in various projects. To optimize the functionality and longevity of such a device, it’s crucial to familiarize oneself with its individual elements. Each component plays a significant role in the overall performance, making a comprehensive understanding invaluable for users of all skill levels.

Exploring the various sections of this instrument allows enthusiasts and professionals alike to troubleshoot issues effectively and perform maintenance tasks with confidence. By gaining insight into how each piece interacts with others, one can ensure the tool operates at peak efficiency, ultimately leading to better craftsmanship. This knowledge also aids in the timely identification of any necessary replacements, enhancing the overall reliability of the equipment.

Whether you are an experienced craftsman or a novice, having access to a detailed overview of the internal structure can greatly enhance your ability to work with this device. Such awareness not only empowers users to tackle challenges head-on but also fosters a deeper appreciation for the engineering behind this indispensable tool.

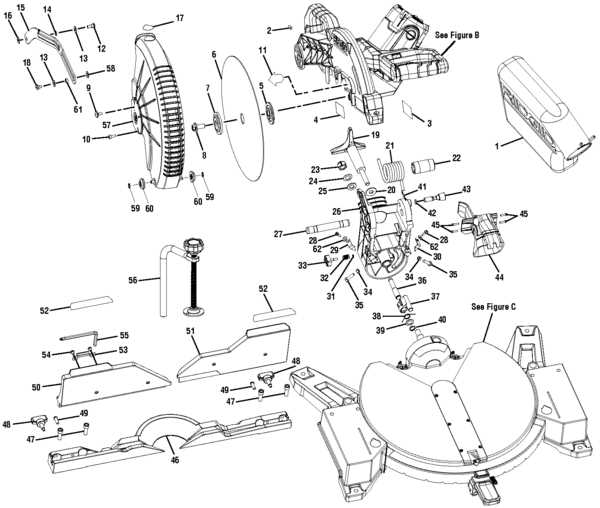

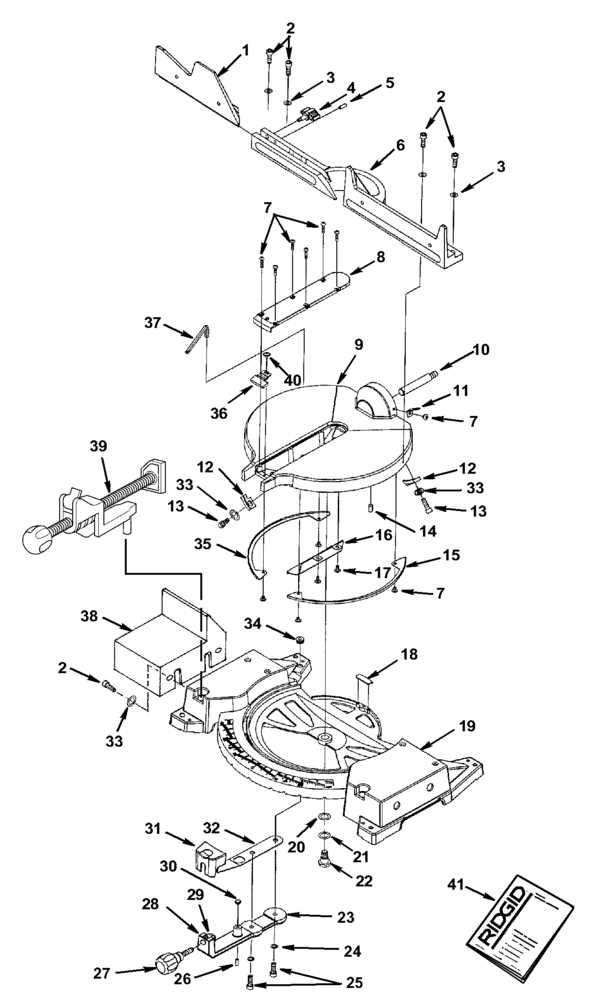

Understanding the Mastercraft Mitre Saw

This section aims to provide a comprehensive overview of a specific type of cutting tool commonly utilized in woodworking and construction. By delving into its various components and functionalities, users can better appreciate how to operate and maintain this essential equipment for precise and efficient cutting tasks.

Key Features and Benefits

The tool is designed for versatility, enabling users to make angled cuts with ease. Its robust construction ensures durability, while features such as adjustable angles and multiple blade options enhance its functionality. This adaptability makes it a valuable asset for both professional craftsmen and DIY enthusiasts.

Safety Considerations

Prioritizing safety is crucial when operating this equipment. Users should always wear appropriate protective gear and familiarize themselves with the tool’s safety features, such as blade guards and emergency shut-off switches. Proper maintenance and adherence to operating guidelines significantly reduce the risk of accidents and injuries.

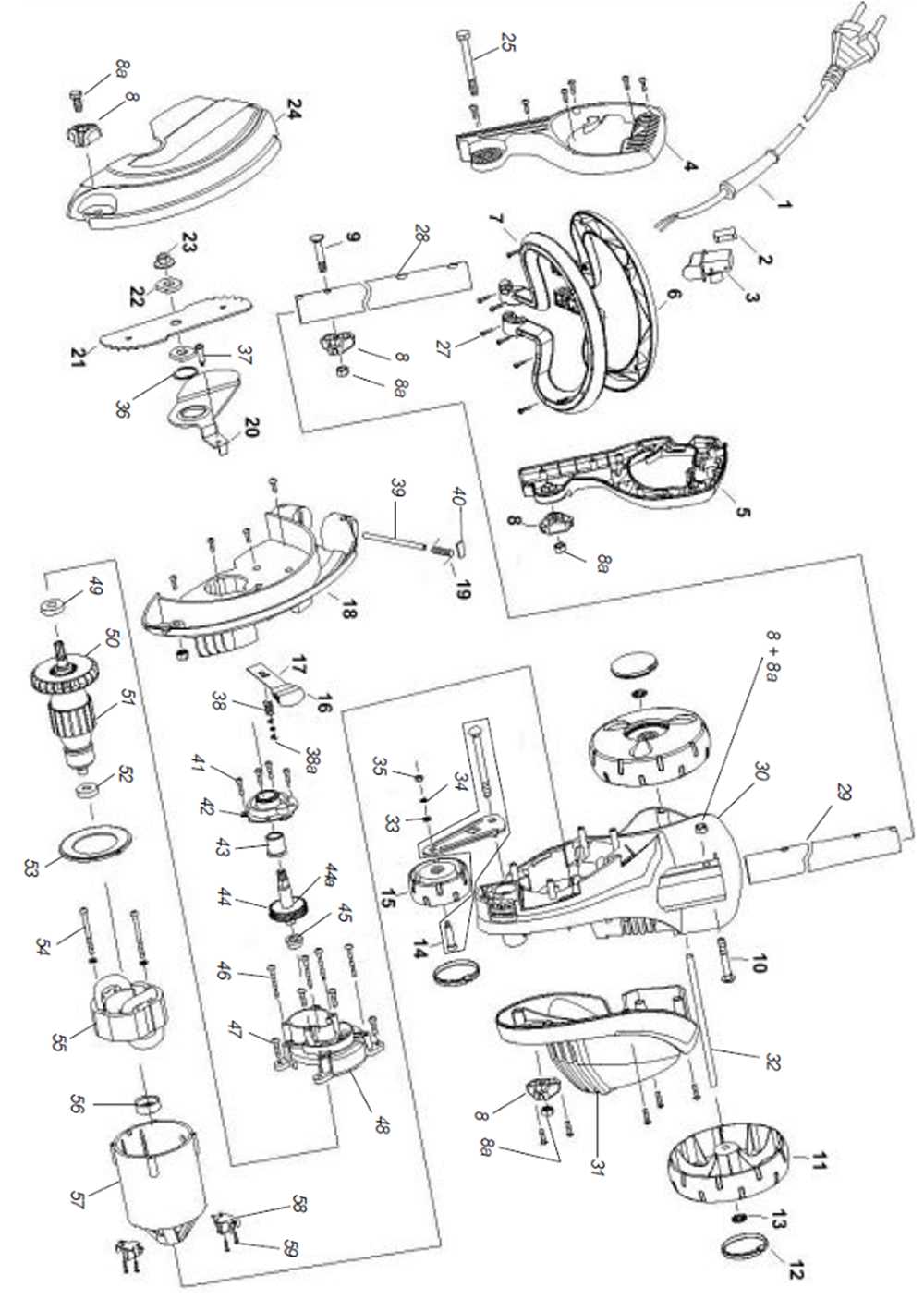

Key Components of the Tool

This section delves into the essential elements that constitute the equipment, focusing on their functions and significance in achieving precise results during operation. Understanding these components enhances the user’s ability to effectively utilize the tool for various tasks.

Essential Elements

- Base Plate: The sturdy foundation that supports the entire apparatus, ensuring stability during usage.

- Blade: The sharp instrument responsible for making accurate cuts through different materials.

- Fence: A guide that assists in maintaining straight cuts by providing a reference point for alignment.

- Handle: The part that enables the operator to maneuver the tool comfortably and securely.

- Motor: The power source that drives the blade, allowing for efficient cutting.

Additional Features

- Dust Bag: Collects debris generated during cutting, promoting a cleaner workspace.

- Angle Adjustment Mechanism: Allows for the adjustment of cutting angles for versatile applications.

- Safety Guard: A protective cover that enhances safety by preventing accidental contact with the blade.

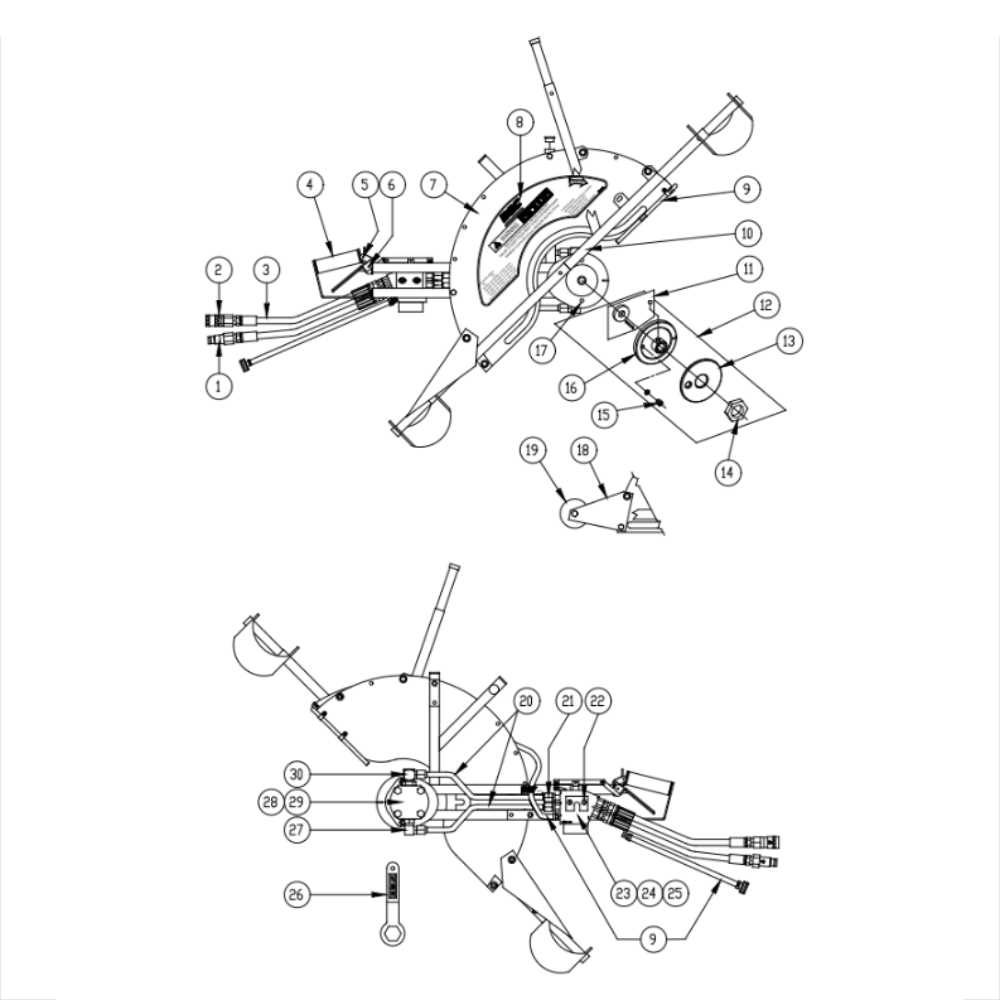

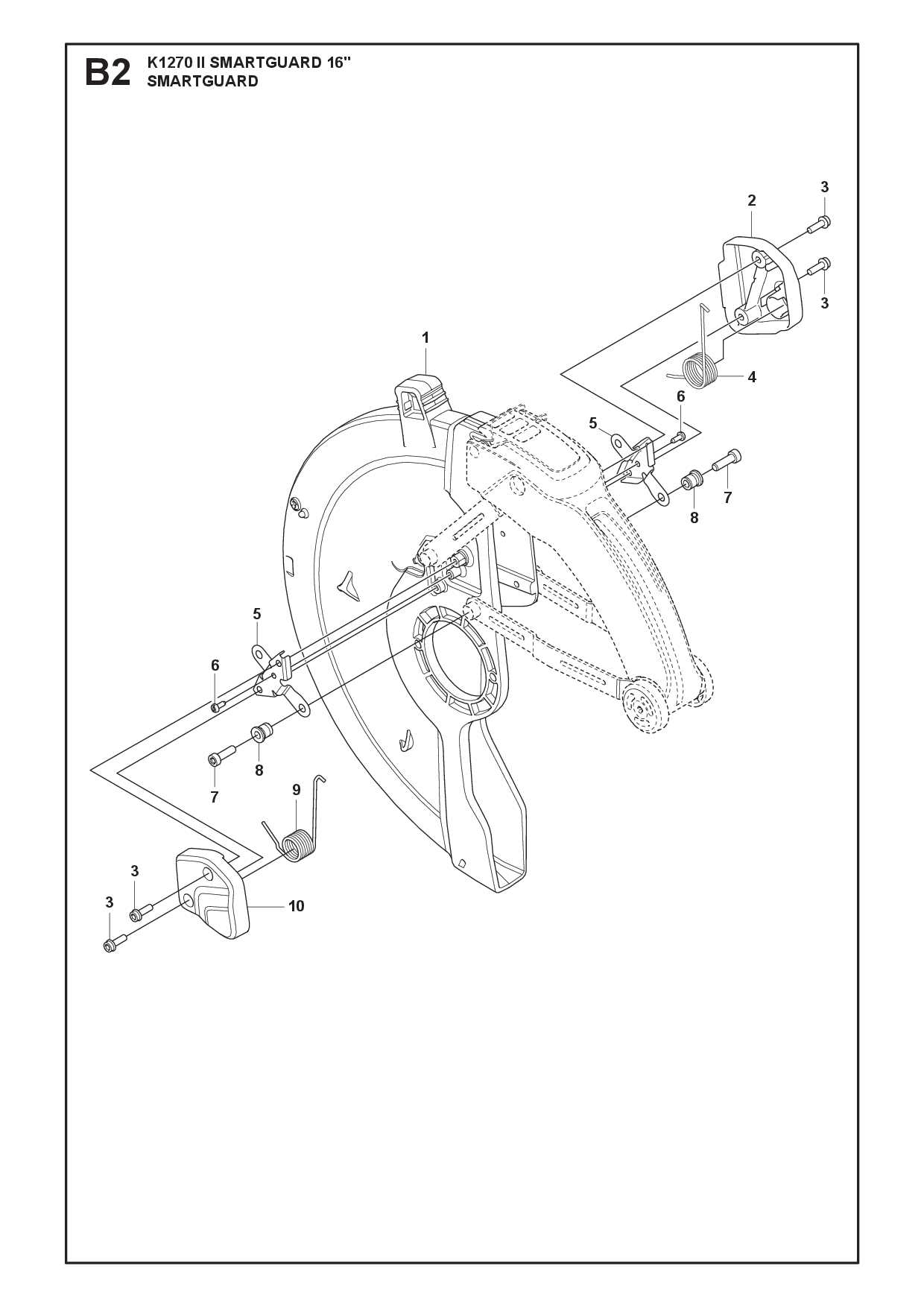

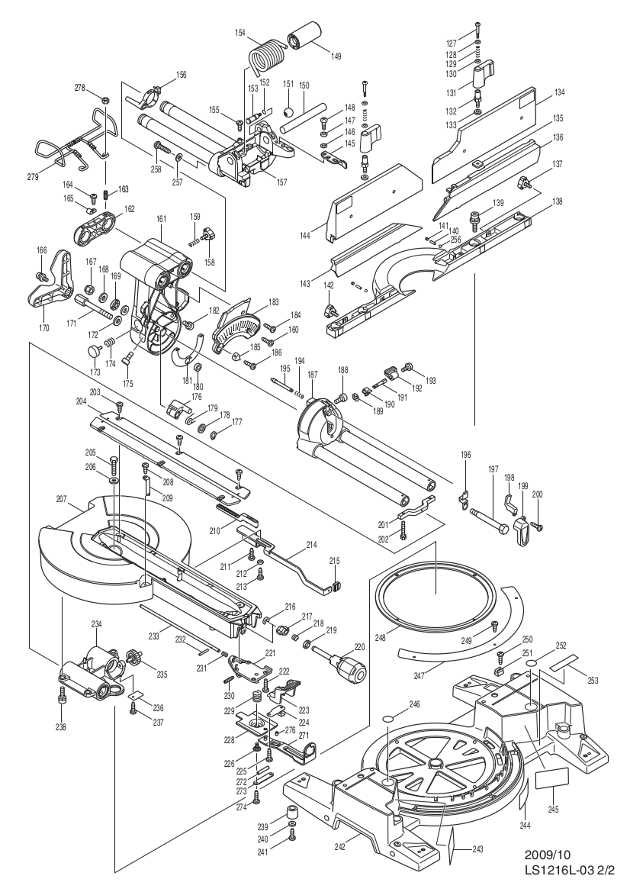

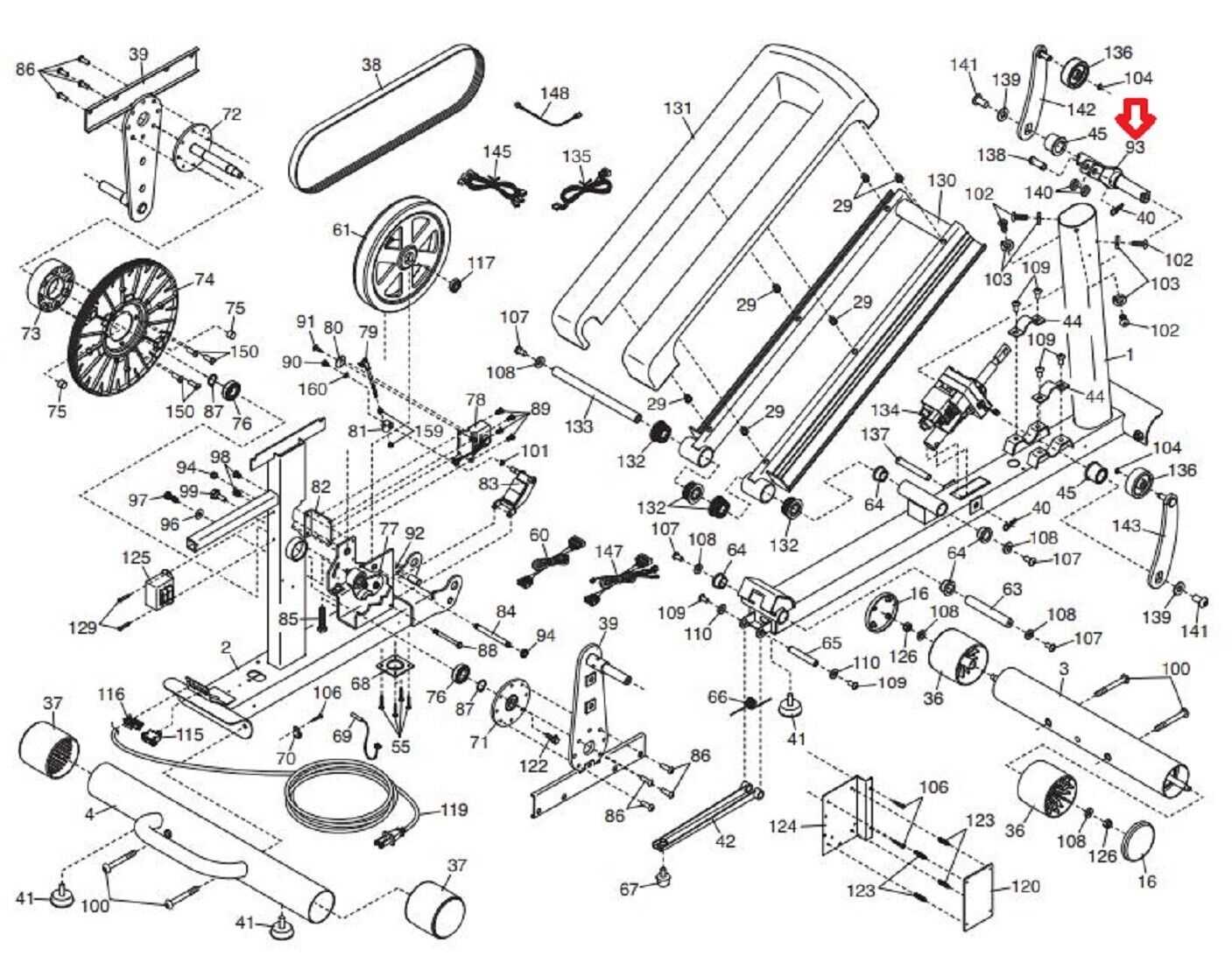

Importance of Accurate Diagrams

Detailed illustrations play a crucial role in understanding complex machinery and tools. They provide clear representations that guide users in assembling, repairing, or operating equipment effectively. The precision of these visuals ensures that every component is accurately identified, reducing the likelihood of errors during maintenance or usage.

Clarity is essential when interpreting technical information. Well-crafted illustrations help convey intricate details that might be overlooked in written descriptions. This visual aid enables users to grasp the layout and functionality of each element within the system.

Moreover, accurate representations facilitate efficient troubleshooting. When issues arise, users can refer to these visuals to pinpoint the problem areas quickly. This not only saves time but also minimizes the risk of further damage to the equipment, as users can address issues with confidence.

In conclusion, the significance of precise illustrations cannot be overstated. They are indispensable tools that enhance comprehension, promote safety, and improve overall efficiency when working with intricate systems.

Identifying Essential Spare Parts

Understanding the key components of your cutting tool is crucial for maintaining optimal performance. Recognizing the various elements that contribute to its functionality ensures that you can quickly address any issues that arise during use. This section aims to highlight the most important components that may need replacement over time, enhancing the tool’s longevity and efficiency.

Common Components to Monitor

Several key elements should be regularly checked for wear and tear. These include the cutting mechanism, adjustment features, and support structures. Paying attention to these components allows users to identify when they may need to be replaced to avoid unexpected breakdowns during projects.

Importance of Quality Replacements

Choosing high-quality replacements is essential for sustaining the reliability of your equipment. Opting for original or reputable alternatives ensures compatibility and performance. Investing in durable components can save time and resources in the long run, preventing frequent replacements and enhancing overall user experience.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the long-term functionality and efficiency of your equipment. By following a few straightforward guidelines, you can enhance performance, minimize wear, and extend the lifespan of your tools. Consistent care not only keeps your tools in optimal condition but also promotes safety during use.

Routine Cleaning

Keeping your tools clean is crucial. Dust, debris, and residue can accumulate over time, leading to potential malfunctions. Regularly wipe down surfaces and remove any buildup around moving parts to maintain smooth operation.

Periodic Inspection

Conduct regular checks to identify any signs of wear or damage. Early detection of issues can prevent more significant problems down the line. Pay special attention to blades, motors, and electrical components during your inspections.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Clean the tool | After each use | Remove debris and ensure smooth operation |

| Inspect components | Monthly | Identify wear and prevent malfunction |

| Lubricate moving parts | Every 6 months | Reduce friction and enhance performance |

| Replace worn blades | As needed | Ensure precise cuts and efficiency |

Common Issues and Solutions

Working with cutting tools can sometimes lead to various challenges that affect performance and efficiency. Identifying common problems and their corresponding solutions can help users maintain their equipment and ensure smooth operation. This section will explore prevalent issues encountered during usage and provide practical solutions to address them.

1. Inaccurate Cuts

One of the most frequent complaints among users is the inability to achieve precise cuts. This can result from misalignment or dull blades. To resolve this issue, regularly check the alignment of the cutting mechanism and ensure it is calibrated correctly. Additionally, replace dull blades with new, sharp ones to enhance cutting accuracy.

2. Excessive Vibration

Another common problem is excessive vibration during operation, which can affect user comfort and cutting stability. This issue may arise from loose components or improper setup. To minimize vibrations, inspect all connections and tighten any loose screws or bolts. Furthermore, ensure the tool is placed on a stable surface to reduce movement while in use.

How to Read Parts Diagrams

Understanding illustrations that depict component arrangements is essential for effective assembly, maintenance, and repair of equipment. These visual representations provide detailed insights into the organization and interaction of various elements within a device, enabling users to locate, identify, and replace parts efficiently.

To effectively interpret these visuals, one should familiarize themselves with the various symbols and annotations used. Each symbol corresponds to a specific component, while accompanying labels often indicate the part numbers or descriptions. The following table outlines some common symbols you may encounter and their meanings:

| Symbol | Description |

|---|---|

| Tool required for assembly or disassembly | |

| Fastener needed for securing components | |

| Indicates the mounting location of a part | |

| ⚠️ | Safety precaution or important note |

Additionally, paying attention to the scale of the illustration can help in visualizing the actual size of the components. Some visuals may include a scale bar to assist with this. By taking the time to study these representations, users can enhance their comprehension of the assembly and ensure proper functioning of the device.

Ordering Replacement Components

When it comes to maintaining and repairing your tools, obtaining the correct replacement components is essential for optimal performance and longevity. Understanding how to efficiently source these elements can save both time and money, ensuring your equipment remains in excellent working condition.

Identifying the Needed Parts: Begin by assessing the specific components that require replacement. Make a detailed list of the items, including any model or serial numbers that can assist in identifying the correct replacements.

Where to Order: There are several reliable avenues to procure components. Consider official distributors, authorized retailers, or reputable online marketplaces that specialize in tool supplies. Always ensure that the source is trustworthy to avoid counterfeit or substandard items.

Checking Compatibility: Before placing an order, verify that the selected components are compatible with your equipment. This may involve cross-referencing part numbers or consulting the manufacturer’s specifications to ensure a proper fit.

Reviewing Return Policies: It’s prudent to familiarize yourself with the return policies of the supplier. In case the ordered items are incorrect or do not function as expected, knowing the return options available will help mitigate any inconvenience.

Placing the Order: Once you have identified the necessary components and a reliable supplier, proceed with your order. Pay attention to shipping options and estimated delivery times to ensure timely receipt of your items.

By following these steps, you can efficiently navigate the process of obtaining replacement components, ensuring your tools remain functional and ready for use.

Safety Features Explained

Understanding the safety mechanisms in power tools is essential for ensuring user protection during operation. These features are designed to minimize the risk of accidents and enhance the overall safety of the equipment. With proper awareness and adherence to safety guidelines, users can significantly reduce potential hazards associated with tool use.

One of the primary safety components is the blade guard, which automatically covers the cutting element when not in use. This barrier helps prevent accidental contact, reducing the chance of injury. Another important feature is the electric brake, which quickly halts the movement of the blade when the trigger is released. This functionality enhances control and minimizes the time the blade remains in motion after the cut is completed.

Moreover, anti-kickback mechanisms are implemented to prevent the tool from jerking backward unexpectedly during use, which could lead to serious injuries. Additionally, many models include ergonomic handles that promote a comfortable grip, allowing users to maintain better control and reduce fatigue during prolonged use.

Lastly, the presence of indicator lights serves as a visual cue for operational readiness, ensuring that the tool is functioning correctly before engaging in cutting tasks. By prioritizing these safety features, manufacturers aim to provide a safer experience, empowering users to focus on their projects with confidence.

Tools Needed for Assembly

Assembling a cutting device requires a selection of essential implements to ensure a smooth and efficient process. Having the right tools on hand can significantly reduce the time and effort needed to complete the assembly, allowing for a more enjoyable and productive experience.

Here is a list of tools you will need:

- Screwdriver Set: A variety of screwdrivers, including flathead and Phillips, will help in fastening and securing components together.

- Wrenches: Both adjustable and fixed wrenches are necessary for tightening bolts and nuts during the assembly process.

- Allen Keys: These are often required for assembling parts that utilize hexagonal screws.

- Pliers: A good pair of pliers can assist in gripping and manipulating various small components.

- Measuring Tape: Accurate measurements are crucial for ensuring all parts align correctly.

- Safety Gear: Protective eyewear and gloves should always be worn to safeguard against potential hazards during assembly.

Gathering these essential tools beforehand will streamline the assembly process, making it easier to focus on the task at hand.

Comparing Different Model Versions

When examining various iterations of a tool, it is essential to assess their unique characteristics and functionalities. Each version often incorporates distinct features, performance enhancements, and design modifications that can significantly influence user experience and efficiency.

Functionality is a crucial aspect to consider. Some versions may offer advanced capabilities, such as improved cutting precision or enhanced motor power, while others focus on user-friendly interfaces or safety mechanisms. Additionally, materials used in construction can vary, affecting durability and maintenance requirements.

Another critical element is portability. Certain models may be designed for easier transport, featuring lighter weights or compact designs, which can be advantageous for users who need to move their equipment frequently. Conversely, larger models may provide additional stability and performance but at the cost of mobility.

Lastly, price points among the different variations can indicate market positioning and target audience. Budget-friendly options may lack some advanced features but are suitable for casual users, while premium models cater to professionals seeking high performance and reliability.

Upgrades and Accessories Available

Enhancing your cutting tool’s performance can significantly boost its efficiency and versatility. Various upgrades and supplementary items are available to optimize functionality and tailor the device to specific tasks. These enhancements range from precision guides to advanced blades, ensuring you can tackle any project with confidence.

Consider investing in high-quality blades designed for specific materials, as they can drastically improve cut accuracy and finish. Additionally, laser guides can provide clear cutting lines, ensuring precision in every operation. For those seeking better dust management, a reliable vacuum attachment is an excellent accessory that maintains a clean workspace.

Furthermore, clamps and work supports can enhance stability, allowing for safer and more controlled cuts. Adopting these upgrades and accessories not only elevates the performance of your equipment but also enriches your overall woodworking experience.

Expert Recommendations for Users

When utilizing advanced cutting tools, it’s essential to consider a variety of factors to enhance performance and ensure safety. Expert advice can significantly improve the user experience, making it not only more efficient but also safer. Understanding key components and their maintenance can lead to better outcomes in your projects.

Regular Maintenance Tips

Maintaining your equipment is crucial for optimal performance. Regular checks and upkeep will prolong its lifespan and functionality. Here are some essential maintenance tips:

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean the blade | After each use | Prevents resin buildup and improves cutting efficiency |

| Inspect moving parts | Weekly | Identifies wear and tear before it becomes an issue |

| Lubricate hinges and pivots | Monthly | Ensures smooth operation and reduces strain on components |

| Check power cords | Before each use | Reduces risk of electrical hazards |

Safety Guidelines

Prioritizing safety while working with cutting tools is paramount. Adhering to these guidelines will help prevent accidents and injuries:

- Always wear appropriate personal protective equipment.

- Ensure that the work area is well-lit and free of obstructions.

- Keep hands clear of cutting paths and use push sticks where necessary.

- Be aware of the tool’s limitations and capabilities.