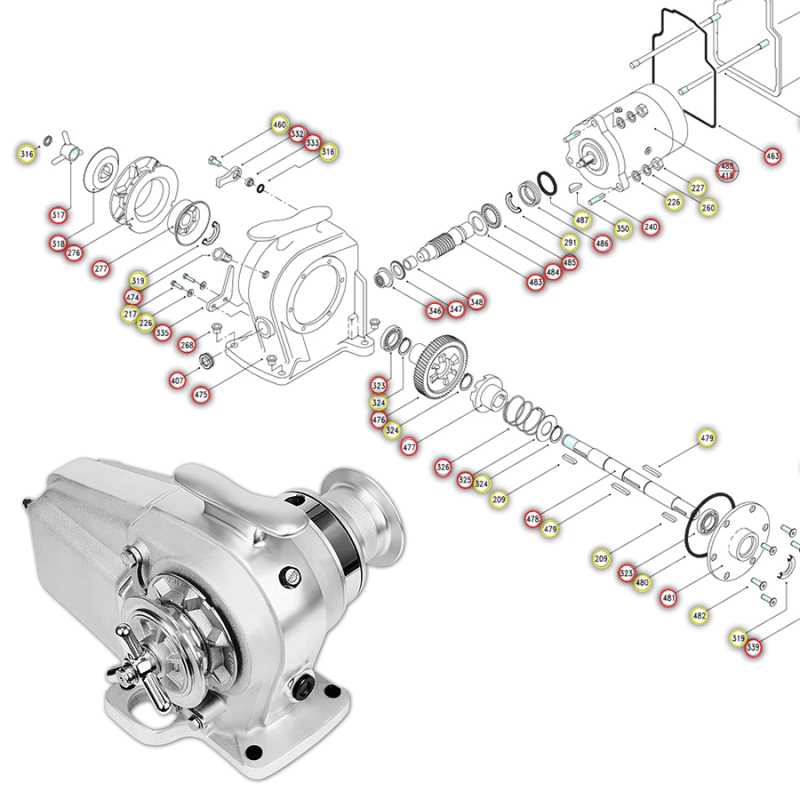

The effective functioning of marine systems relies heavily on a variety of intricate elements that work in harmony. These components are crucial for ensuring safety and reliability during maritime operations. A comprehensive grasp of these items can significantly enhance one’s ability to maintain and operate such mechanisms efficiently.

In this section, we delve into the various constituents that make up essential marine devices. Recognizing how each element interacts and contributes to the overall functionality can aid in troubleshooting and repairs. Familiarity with these key features is invaluable for both professionals and enthusiasts alike.

By exploring the design and arrangement of these crucial elements, one can gain insights into their operation and the importance of regular maintenance. Understanding these intricacies not only promotes longevity but also optimizes performance in challenging conditions.

Regular upkeep is essential for ensuring the longevity and optimal performance of mechanical systems. Proper maintenance not only enhances efficiency but also prevents unexpected failures, saving time and resources in the long run.

Implementing systematic maintenance practices offers several benefits:

- Increased Reliability: Consistent checks help identify potential issues before they escalate, ensuring dependable operation.

- Cost Savings: Early detection of problems can lead to less expensive repairs compared to addressing major breakdowns.

- Enhanced Performance: Routine servicing ensures that components function at their best, leading to improved efficiency.

- Safety Assurance: Well-maintained systems reduce the risk of accidents, protecting both users and equipment.

Incorporating a thorough maintenance routine not only contributes to the overall health of the equipment but also supports its reliable use over time.

Common Issues with Windlass Parts

Mechanical devices designed for anchoring can encounter various challenges that may affect their performance and reliability. Understanding these common problems is crucial for ensuring smooth operation and longevity.

One frequent issue is wear and tear on components due to continuous use. This can lead to reduced efficiency and may require replacement of certain elements to restore functionality. Regular maintenance checks are essential to identify signs of deterioration early.

Another concern involves corrosion, particularly in marine environments where saltwater exposure is prevalent. This can compromise the integrity of components, resulting in failures. Implementing protective measures, such as using corrosion-resistant materials, can mitigate these risks.

Additionally, misalignment during installation can cause operational difficulties. Ensuring proper alignment during setup is vital to prevent unnecessary strain on the mechanism, which can lead to malfunction. Proper installation procedures should always be followed.

Replacement Parts Overview

Understanding the components necessary for the efficient operation of your anchoring system is crucial. This section outlines essential elements that may require attention or substitution over time, ensuring optimal performance and reliability.

| Component | Description | Function |

|---|---|---|

| Motor Assembly | Drives the anchor mechanism. | Provides power for lowering and raising the anchor. |

| Gearbox | Transmits power from the motor. | Reduces speed and increases torque. |

| Control Switch | Interface for operator commands. | Enables user to control the device remotely. |

| Chain Gypsy | Holds and guides the chain. | Facilitates smooth operation of the anchor line. |

| Brake Assembly | Ensures stability during operation. | Prevents uncontrolled descent of the anchor. |

Identifying Wear and Tear

Recognizing signs of degradation in mechanical components is crucial for maintaining optimal functionality. Regular inspections can help in detecting issues early, preventing more extensive damage and costly repairs.

- Visual Inspection: Look for cracks, corrosion, or unusual discoloration.

- Surface Condition: Check for roughness or abnormal wear patterns on surfaces.

- Operational Sounds: Listen for any unusual noises during operation that might indicate malfunction.

By systematically evaluating these aspects, one can effectively determine the state of the equipment and address potential problems before they escalate.

Benefits of Using Original Parts

Utilizing authentic components in your equipment ensures enhanced performance and reliability. These specialized elements are crafted to meet specific standards, leading to improved efficiency and longevity of the overall system.

Enhanced Reliability

Genuine components are rigorously tested to ensure they function correctly within their designated systems. This reliability minimizes the risk of failures and unexpected downtimes, offering peace of mind to users.

Improved Performance

When you choose original items, you can expect superior performance compared to alternatives. These elements are designed to work harmoniously with other components, maximizing the operational capacity and functionality of your machinery.

Diagram Interpretation Tips

Understanding technical illustrations can significantly enhance your ability to work with mechanical systems. These visual representations provide insights into the arrangement and function of various components, allowing for effective troubleshooting and maintenance.

When analyzing these visuals, consider the following strategies:

| Tip | Description |

|---|---|

| Familiarize Yourself with Symbols | Many illustrations use standardized symbols. Knowing what these mean can save time and reduce confusion. |

| Study the Layout | Observe how components are arranged. Recognizing relationships between parts can aid in understanding their functions. |

| Use a Reference | Keep manuals or guides handy for clarification on specific elements or assembly instructions. |

| Take Notes | Document any observations or questions as you go. This will help reinforce your understanding and address uncertainties later. |

By applying these approaches, you’ll improve your ability to decode these visual tools, making your maintenance and repair tasks more efficient.

Safety Precautions While Repairing

Engaging in maintenance and repair tasks requires careful consideration to ensure the well-being of individuals involved. Adhering to safety protocols not only protects personal health but also prevents potential damage to equipment.

First and foremost, always wear appropriate protective gear, including gloves, goggles, and helmets. This attire serves as a barrier against injuries caused by sharp objects or hazardous materials.

Additionally, ensure the workspace is well-lit and organized to minimize the risk of accidents. Keep tools within reach and in good condition to facilitate efficient and safe handling.

Lastly, be aware of the equipment’s operational guidelines and manufacturer recommendations. Familiarity with these instructions can prevent errors that may lead to dangerous situations.

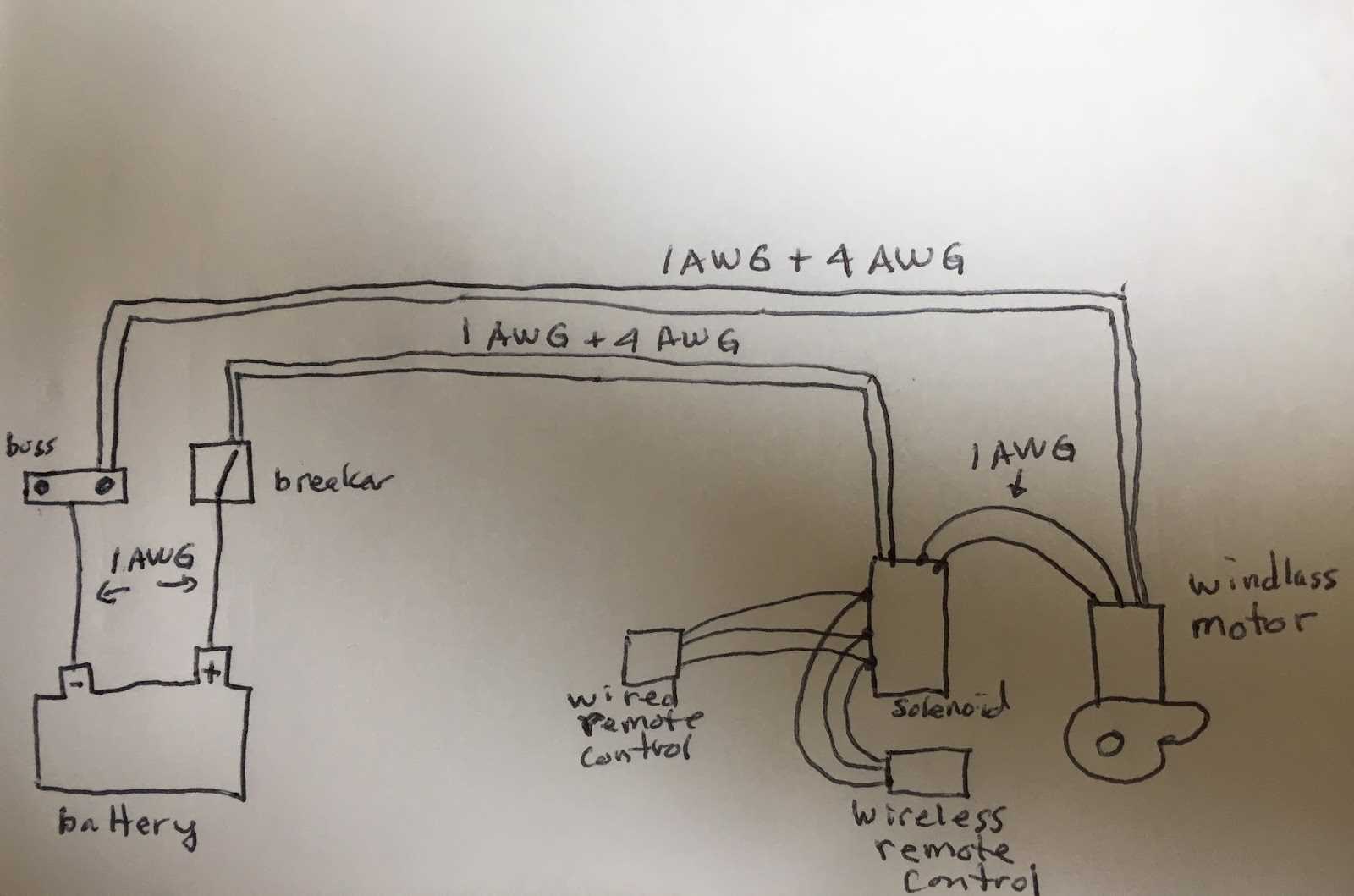

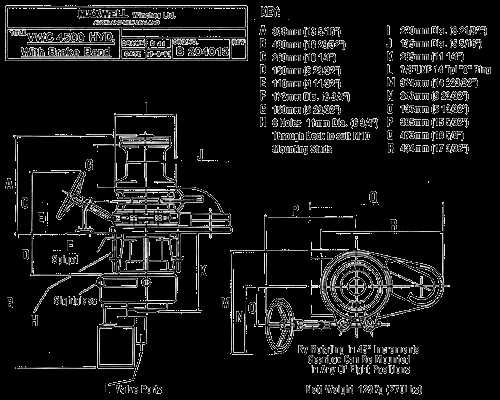

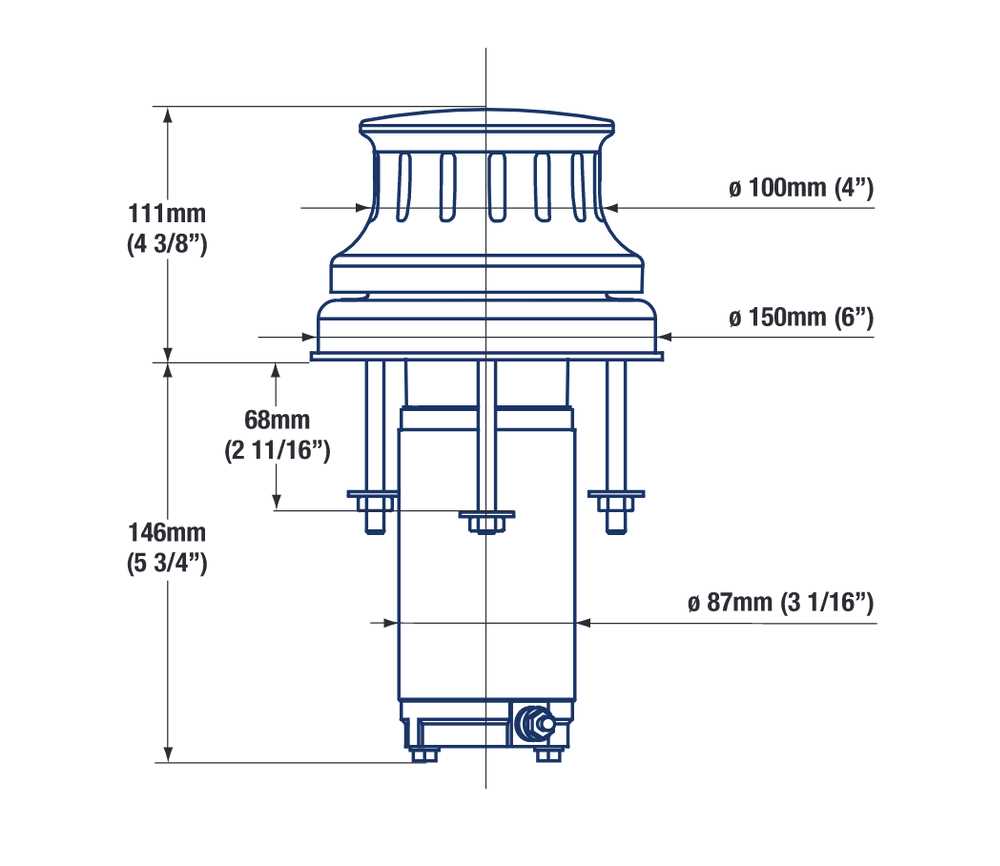

Windlass Assembly Instructions

Assembling your anchoring mechanism requires careful attention to detail and an understanding of each component’s role. Proper installation ensures optimal performance and longevity of the equipment.

Follow these steps for successful assembly:

- Gather all necessary components and tools.

- Begin by securing the base unit to the designated location.

- Attach the motor assembly, ensuring it is aligned correctly.

- Connect the power supply according to the specifications provided.

- Install the gearing mechanism, verifying that it operates smoothly.

- Finally, test the complete system to ensure functionality.

Remember to consult the specific guidelines for your model to address any unique features or requirements during the assembly process.

Tools Required for Installation

Successfully completing the installation process involves utilizing a variety of essential instruments. These tools not only facilitate the assembly but also ensure that everything is secured properly for optimal functionality.

Basic Tools

The foundational tools typically needed include a screwdriver, wrench, and socket set. These items are crucial for tightening bolts and securing components in place.

Specialized Equipment

In addition to standard tools, having pliers, torque wrenches, and measuring tapes can greatly enhance the efficiency of the installation. These specialized tools assist in precise adjustments and measurements, contributing to a successful setup.

Upgrading Your Windlass System

Enhancing your anchoring mechanism can significantly improve the efficiency and reliability of your marine operations. This section discusses various methods to elevate the performance and functionality of your system, ensuring a smoother experience on the water.

One of the first steps in this enhancement process is assessing your current setup. Consider the following factors:

| Factor | Considerations |

|---|---|

| Capacity | Ensure your mechanism can handle the weight and size of your anchor. |

| Control System | Evaluate whether a remote control or upgraded switch panel could improve usability. |

| Maintenance | Check for wear and tear, and replace any components that show signs of damage. |

| Power Supply | Ensure that your power system is adequate to support the enhanced features. |

Investing in higher-quality components or additional features can also greatly increase performance. Consider options such as automatic retrieval systems or enhanced anchoring capabilities to streamline your operations. By taking these steps, you can ensure a more efficient and reliable anchoring solution for your vessel.