The mechanics of marine propulsion systems are both intricate and fascinating. These propulsion units consist of various essential elements, each playing a key role in ensuring smooth and reliable performance on the water. For boat enthusiasts and mechanics alike, comprehending how these pieces interact is vital to maintaining efficiency and preventing potential issues.

Within the structure of these systems, several individual elements come together to form a cohesive mechanism. Each component serves a distinct function, contributing to the overall performance of the drive unit. Identifying and familiarizing oneself with the essential elements is critical for both routine maintenance and troubleshooting.

Ensuring proper function and understanding how the different components fit into the larger system helps in keeping the vessel operational. Knowing what to look for when examining the internal workings can lead to more efficient repairs and a deeper appreciation of the engineering behind these powerful systems.

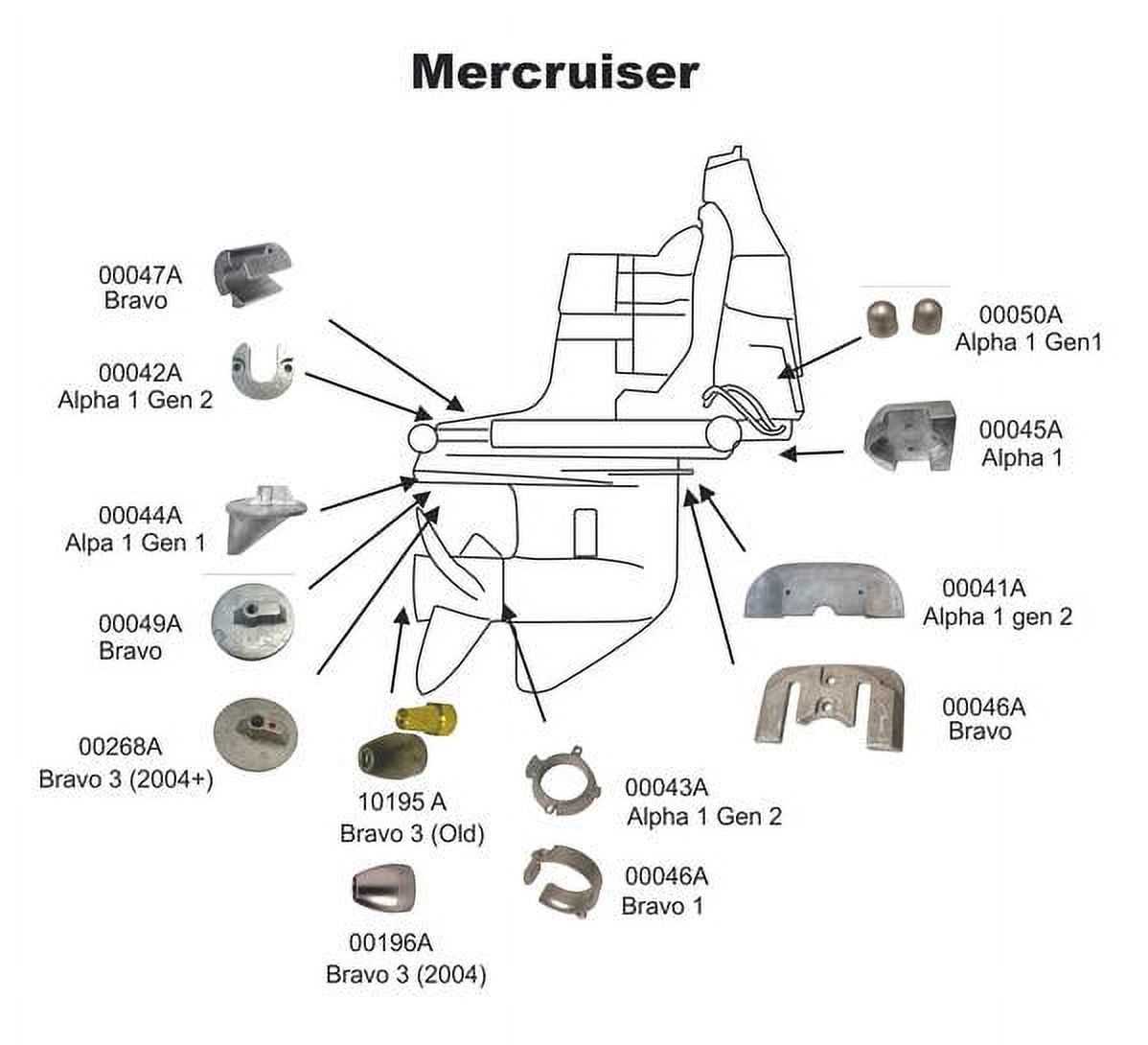

Mercruiser Alpha 1 Gen 1 Parts Overview

The boating engine system under discussion features a variety of key elements that ensure its smooth and reliable operation. These components work in unison to deliver power, control, and performance to the marine vessel. Each element plays a vital role in maintaining the overall efficiency and durability of the propulsion system, ensuring a seamless boating experience.

Here’s a breakdown of the

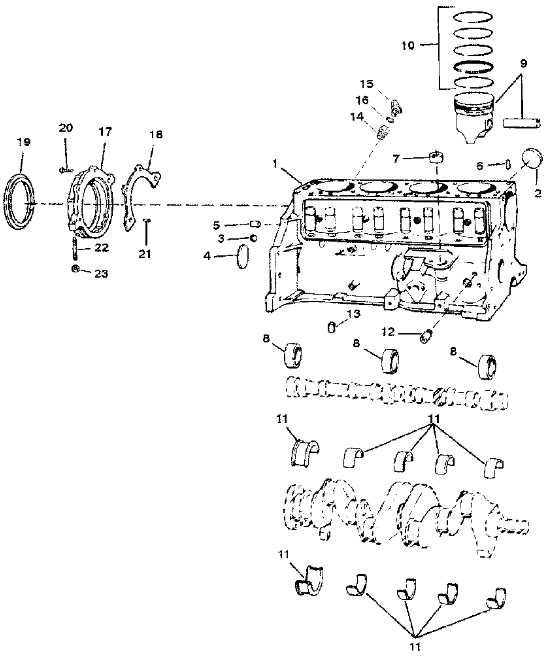

Engine Components Breakdown

The heart of any marine propulsion system is its engine, and understanding its individual elements is essential for proper maintenance and efficient performance. Each part works in tandem to ensure smooth operation, with specific roles and functions that contribute to the overall efficiency and power delivery of the vessel. By breaking down these components, one can gain a deeper appreciation for how each piece contributes to the entire system’s functionality.

Key Engine Elements: The main engine comprises various sections, including the cylinder block, pistons, crankshaft, and valve assembly. Each of these components plays a crucial role in generating power, controlling the intake and exhaust gases, and converting the energy produced into movement.

Performance and Maintenance: Regular checks and replacements of these parts are critical for ensuring optimal performance. Components like the fuel system, ignition system, and cooling elements must work in harmony to provide reliability and prevent potential failures.

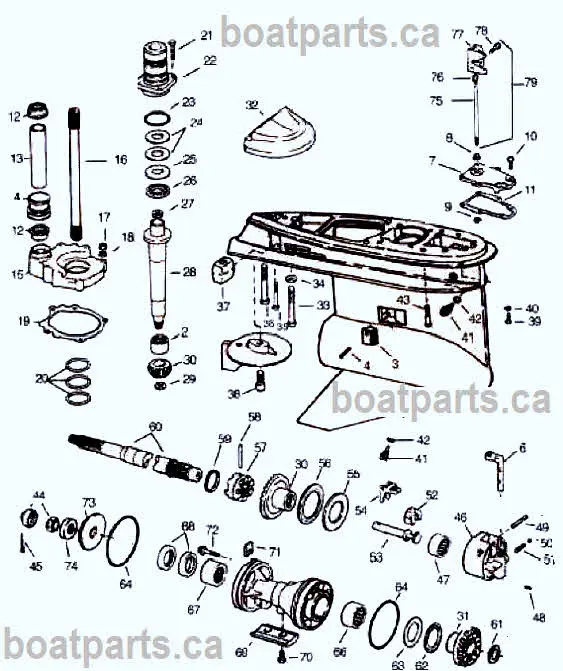

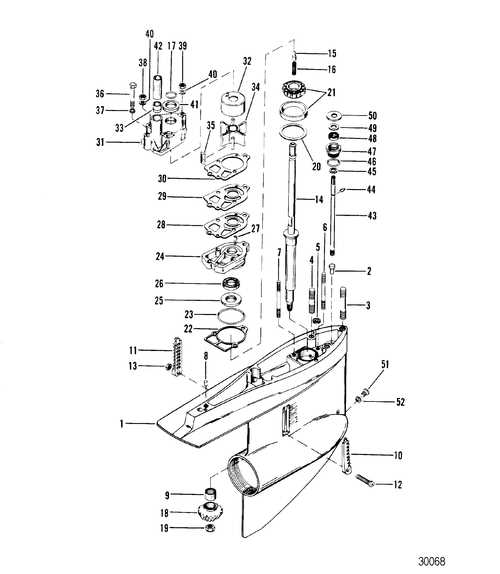

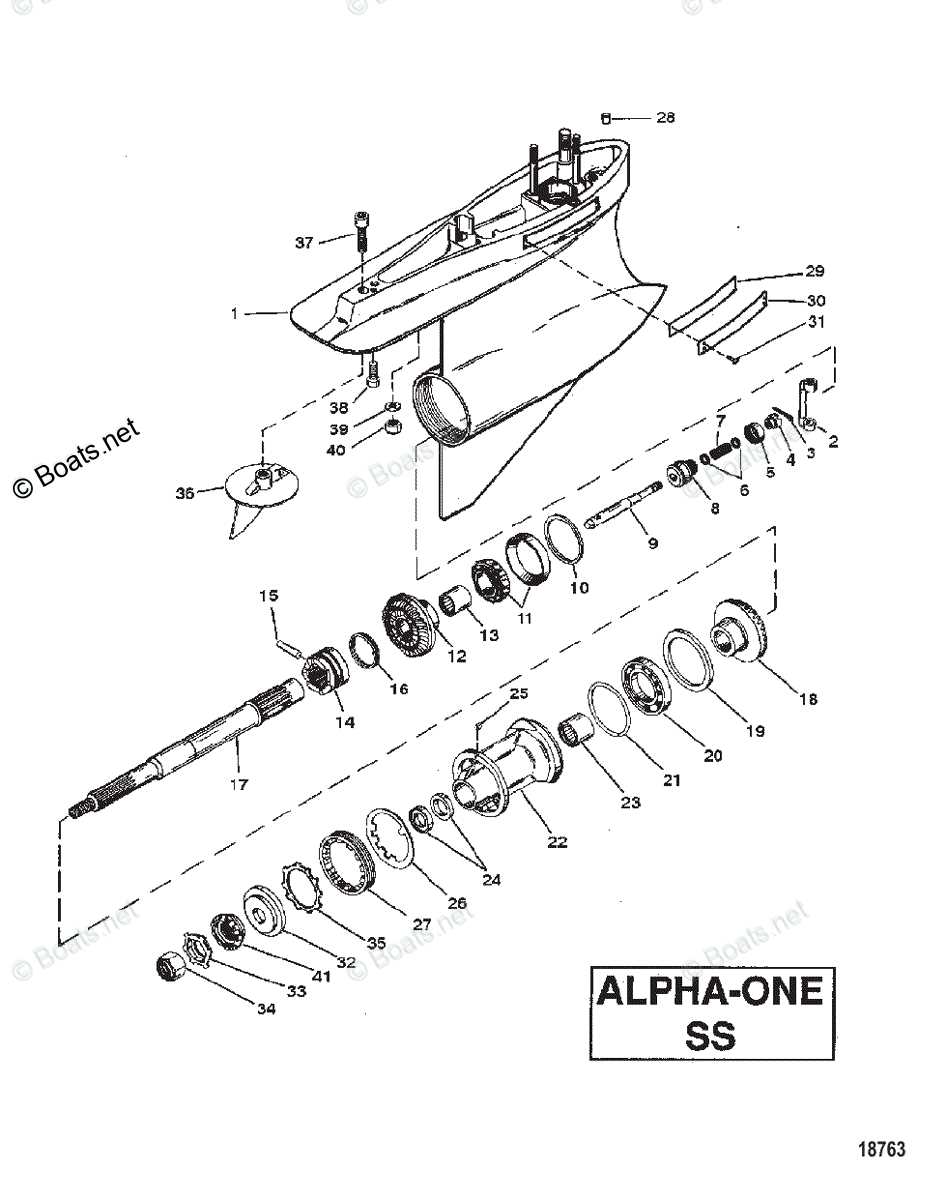

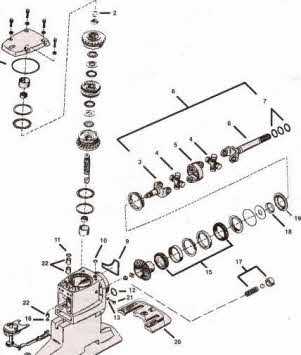

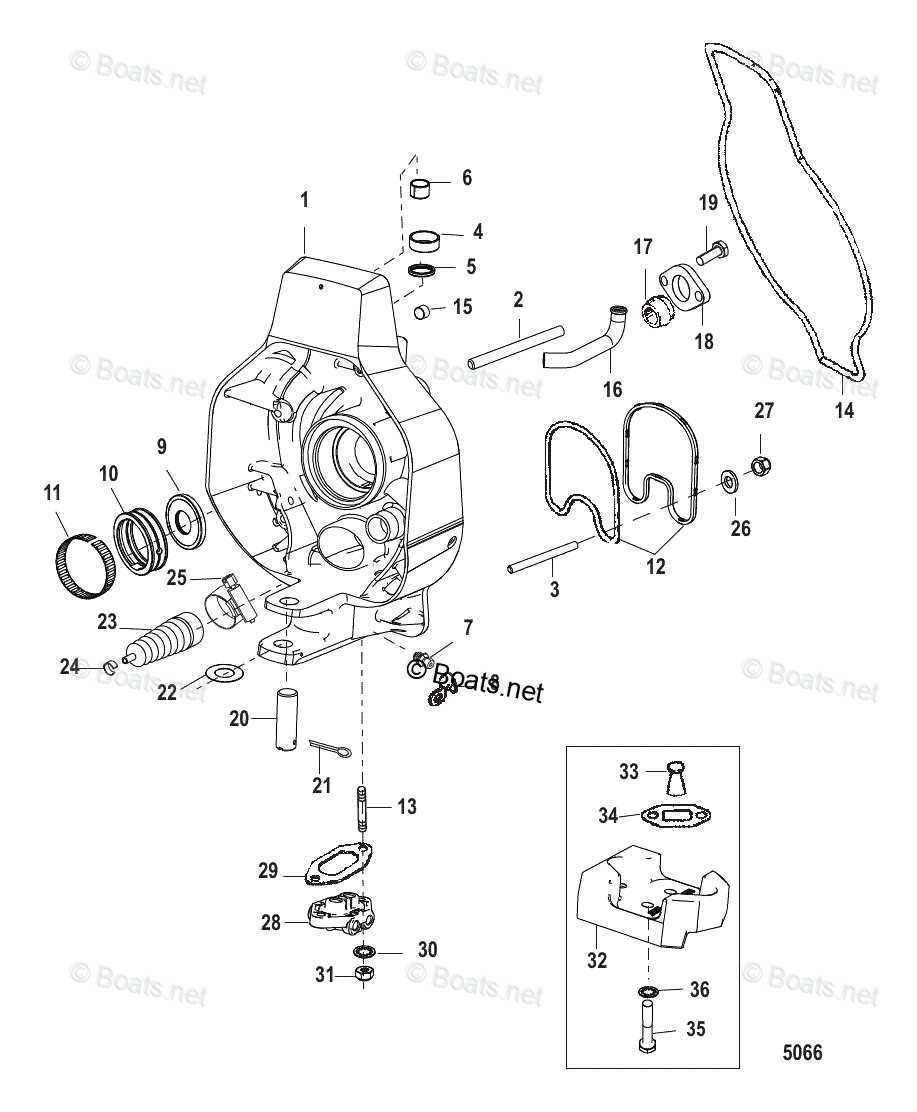

Gear Housing Assembly Diagram

The gear housing assembly is a crucial component in the propulsion system, housing various mechanisms that enable the smooth operation of the boat’s drive. Understanding the configuration and relationship between the parts can help with proper maintenance, troubleshooting, and repairs.

The assembly typically includes the following key components:

- Housing Cover: Protects the internal gears and other components from external elements.

- Drive Shaft: Transfers power from the engine to the propeller.

- Gears: Work in unison to transmit torque and control the rotation of the propeller.

- Bearings: Provide support and allow smooth rotation of the gears and shafts.

- Seals: Prevent water from entering the housing and causing damage to the internal components.

- O-Rings: Ensure tight sealing around the housing joints.

Proper alignment of these components is essential for efficient operation and to prevent premature wear or damage. Each part plays a critical role in ensuring the drive unit operates smoothly, especially during high-speed or heavy-load situations.

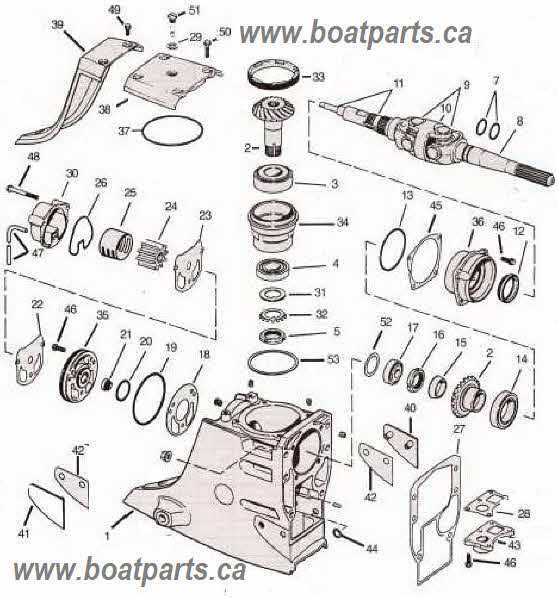

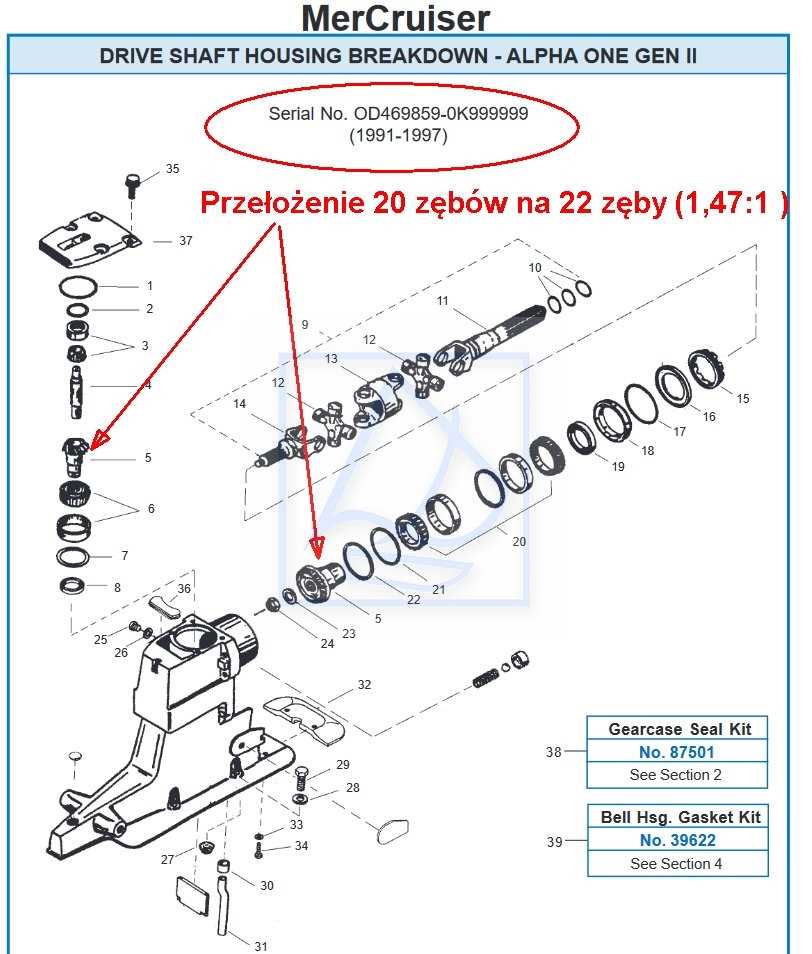

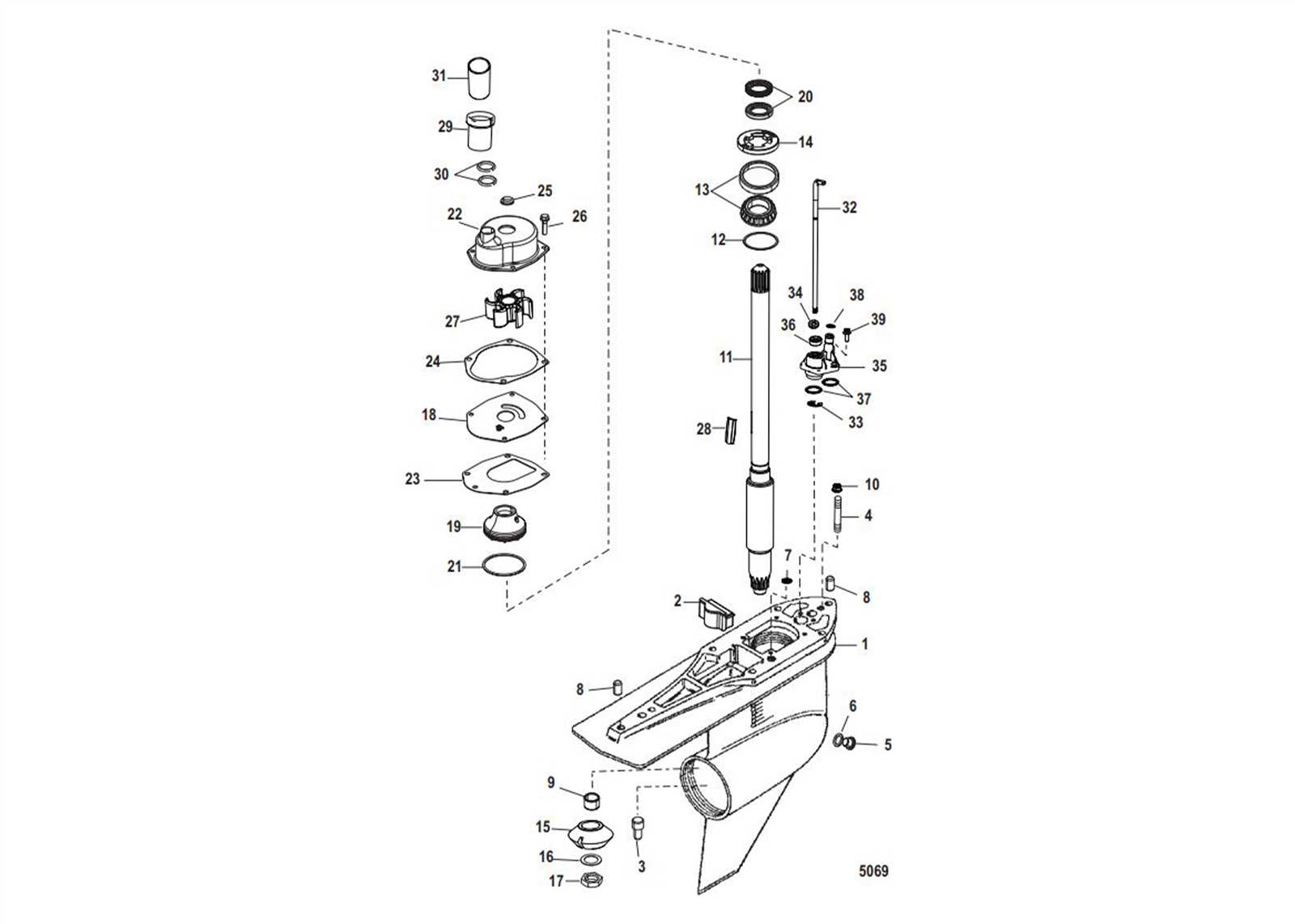

Propeller System and Related Parts

The propulsion mechanism of a boat is essential for smooth and efficient movement through the water. This system consists of various components that work together to transfer power from the engine to the propeller, generating thrust. Proper functioning and maintenance of these elements ensure optimal performance and durability, minimizing wear and enhancing overall boating experience.

Key Components of the Propulsion System

- Propeller: The central component responsible for moving the boat through the water. It converts engine power into thrust.

- Drive Shaft: A crucial part that transmits power from the engine to the propeller, ensuring consistent rotation.

- Gimbal Bearing: Helps to stabilize the drive shaft, ensuring smooth rotation and preventing unnecessary stress on the system.

- Throttle Control: Regulates engine speed and controls the amount of power sent to the propeller.

Maintenance and Adjustments

Regular inspection and adjustment of these components are vital for maintaining efficient operation. Common maintenance tasks include checking for signs of wear, ensuring proper lubrication, and adjusting alignment to prevent misalignment or vibration. Any issues with the propeller or related elements can lead to reduced performance, increased fuel consumption, or even damage to the engine.

Water Pump Assembly Insights

The water pump is a crucial component in ensuring the proper cooling of the engine and preventing overheating. It circulates water through the system, allowing heat to be dissipated efficiently. Understanding the assembly of this unit is essential for maintenance and performance optimization.

- Impeller: The impeller is the heart of the water pump, responsible for drawing in and pushing out water. It is important to inspect it regularly for signs of wear or damage.

- Housing: The housing provides structural support to the water pump components, protecting them from external elements and maintaining proper alignment.

- Seal: A durable seal ensures that no water leaks from the assembly, preventing potential damage to the system.

- Drive Shaft: This part connects the pump to the engine, transferring mechanical power to drive the impeller.

Regular maintenance of these components can help extend the lifespan of the system and ensure efficient engine cooling under various conditions.

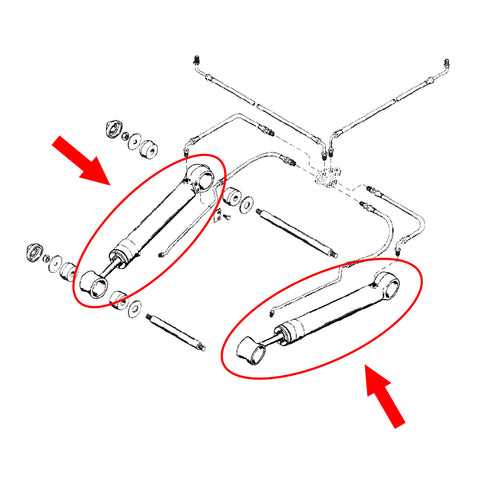

Steering and Control Components

Steering and control elements are essential for the precise handling and safe operation of watercraft. These components ensure that the vessel responds accurately to the operator’s inputs, allowing smooth navigation through various water conditions. Properly functioning steering and control systems provide not only stability but also ease of maneuvering, contributing to the overall performance and safety of the boat.

The steering mechanism typically involves a system of linkages, cables, and hydraulic units that translate the operator’s movements into turning the boat. Control systems, on the other hand, include throttles, shifters, and brake components that manage the speed and direction of the vessel. Together, these systems create a seamless interface between the captain and the boat’s movements, ensuring optimal handling in different situations.

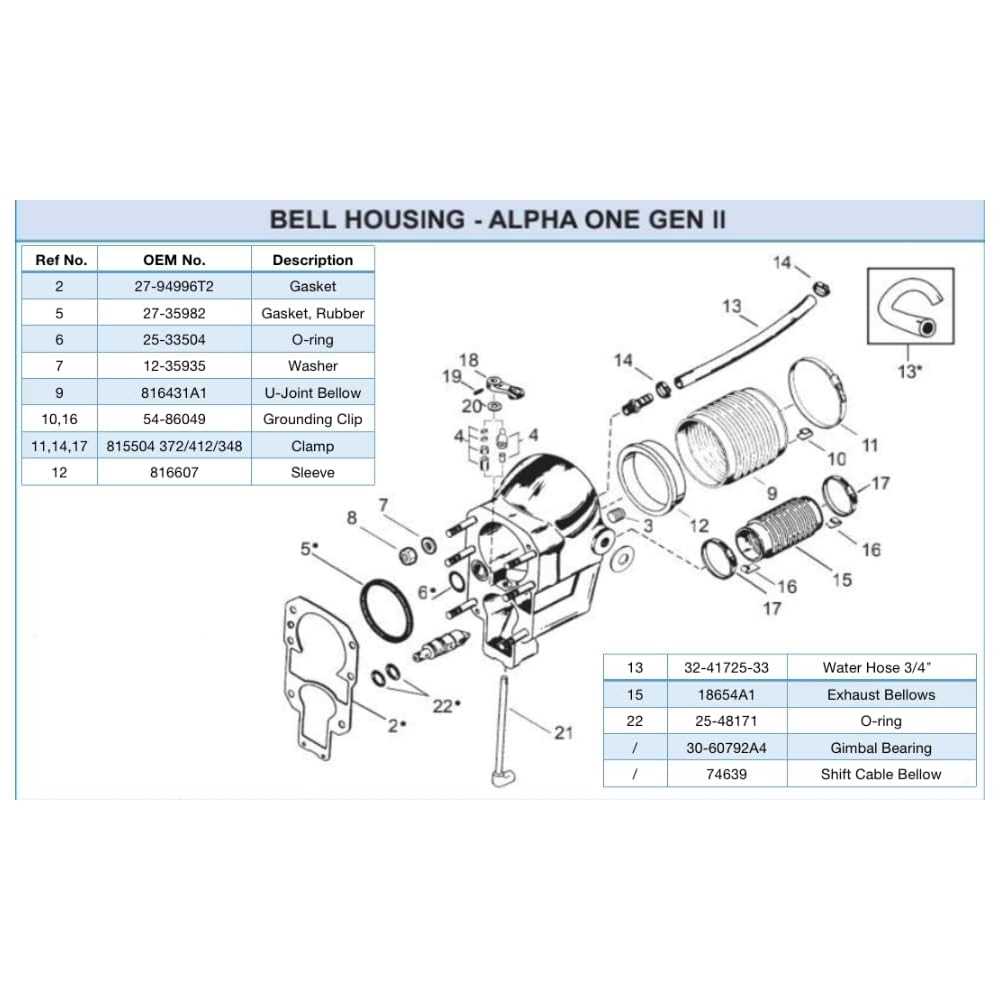

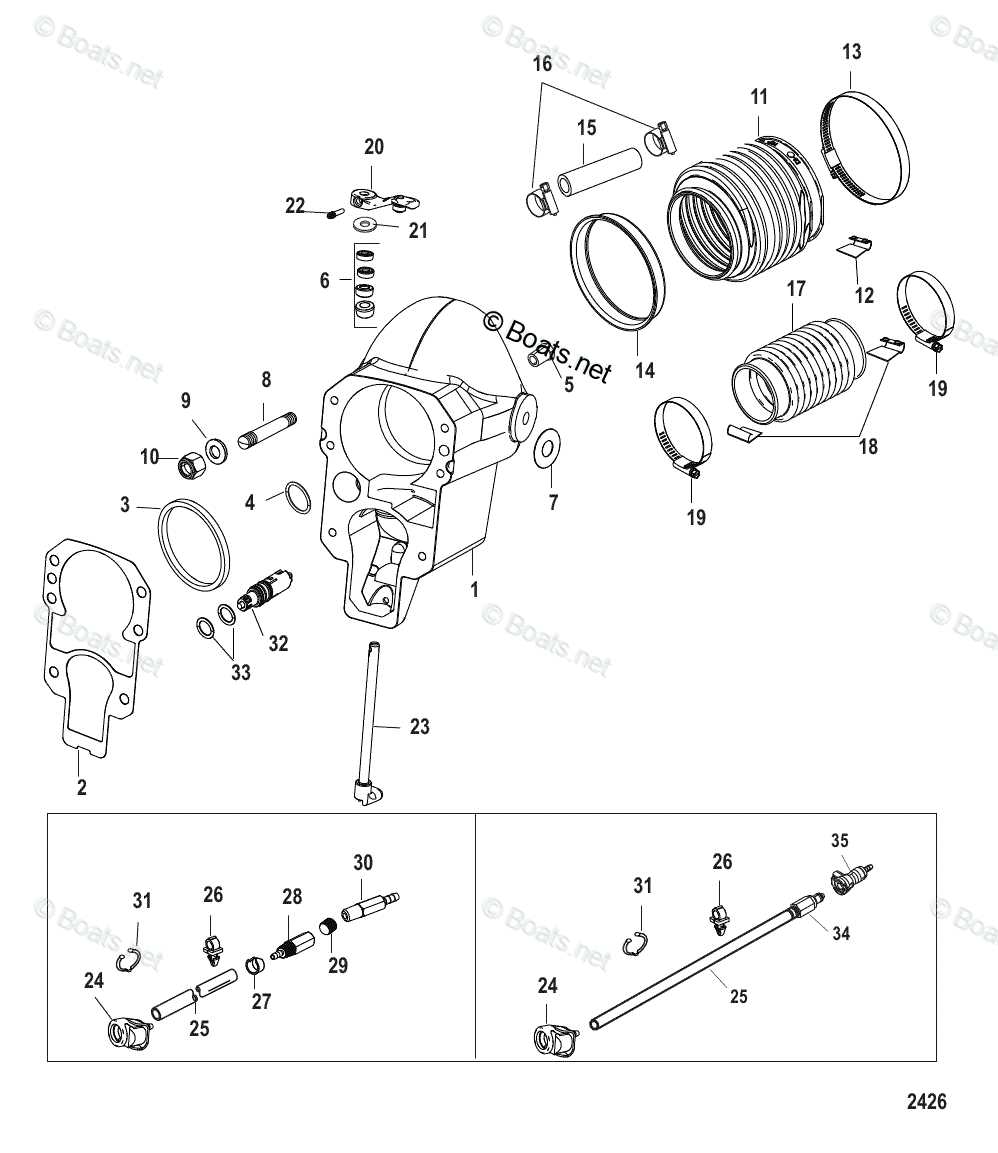

Transom Assembly Parts Explained

The transom assembly is a crucial component in the propulsion system, ensuring the smooth transfer of power from the engine to the drive unit. Understanding the key elements of this assembly is essential for maintaining optimal performance and ensuring the durability of your boat’s stern structure.

Mounting Brackets serve as the foundation, securing the drive unit to the boat’s hull. These brackets provide stability and alignment, preventing excessive movement that could lead to damage over time.

Trim Cylinders are responsible for adjusting the angle of the drive unit, allowing for smoother transitions when navigating through different water conditions. Proper maintenance of these cylinders ensures efficient movement and reduces wear on the assembly.

Gimbal Bearing is an essential element that supports the drive shaft, allowing it to rotate freely without any resistance. It is a critical part in maintaining the alignment and function of the drive system.

Water and Exhaust Hoses play a vital role in directing both water intake and exhaust flow, ensuring that the engine operates at the proper temperature while keeping the vessel free from excess water accumulation.

Trim and Tilt Mechanism Overview

The trim and tilt system plays a crucial role in optimizing the angle of the propulsion unit, enhancing both performance and fuel efficiency. This mechanism allows the boat’s drive unit to be adjusted vertically, providing better control in different water conditions and improving overall navigation. A well-maintained trim and tilt system ensures smoother operation and protects the vessel from potential damage due to rough seas or shallow water.

Key Functions of the Trim and Tilt System

- Trim Adjustment: Controls the angle of the propulsion unit relative to the hull, influencing speed, handling, and fuel consumption.

- Tilt Function: Allows the engine to be raised or lowered, providing clearance in shallow waters and minimizing underwater drag.

- Improved Navigation: Helps maintain optimal engine performance by adjusting to varying water conditions, reducing strain on the motor.

Components Involved in the System

- Hydraulic Pump: Powers the tilting action, allowing for smooth and quick adjustments.

- Trim Cylinders: Responsible for the vertical movement of the drive unit.

- Control Switch: Allows the operator to adjust the trim and tilt settings easily from the helm.

Exhaust System Components

The exhaust system in a marine engine is essential for controlling and directing the flow of gases produced during combustion. Each component of this system plays a crucial role in ensuring that emissions are safely expelled while also minimizing noise and enhancing performance. Proper functioning of the exhaust system helps maintain engine efficiency and prolongs its lifespan.

Key elements include the manifolds, risers, and the exhaust bellows, all of which work together to channel the exhaust gases away from the engine. The manifolds direct the gases from the engine into the risers, where water cooling can take place before they are expelled through the transom or outdrive. The bellows serve as flexible connections, reducing vibrations and allowing for movement without compromising the integrity of the system.

Maintaining these components is crucial, as any failure or degradation can lead to reduced engine performance, increased emissions, or even damage to the engine itself. Regular inspection and timely replacement of worn parts ensure smooth and reliable operation of the exhaust system.

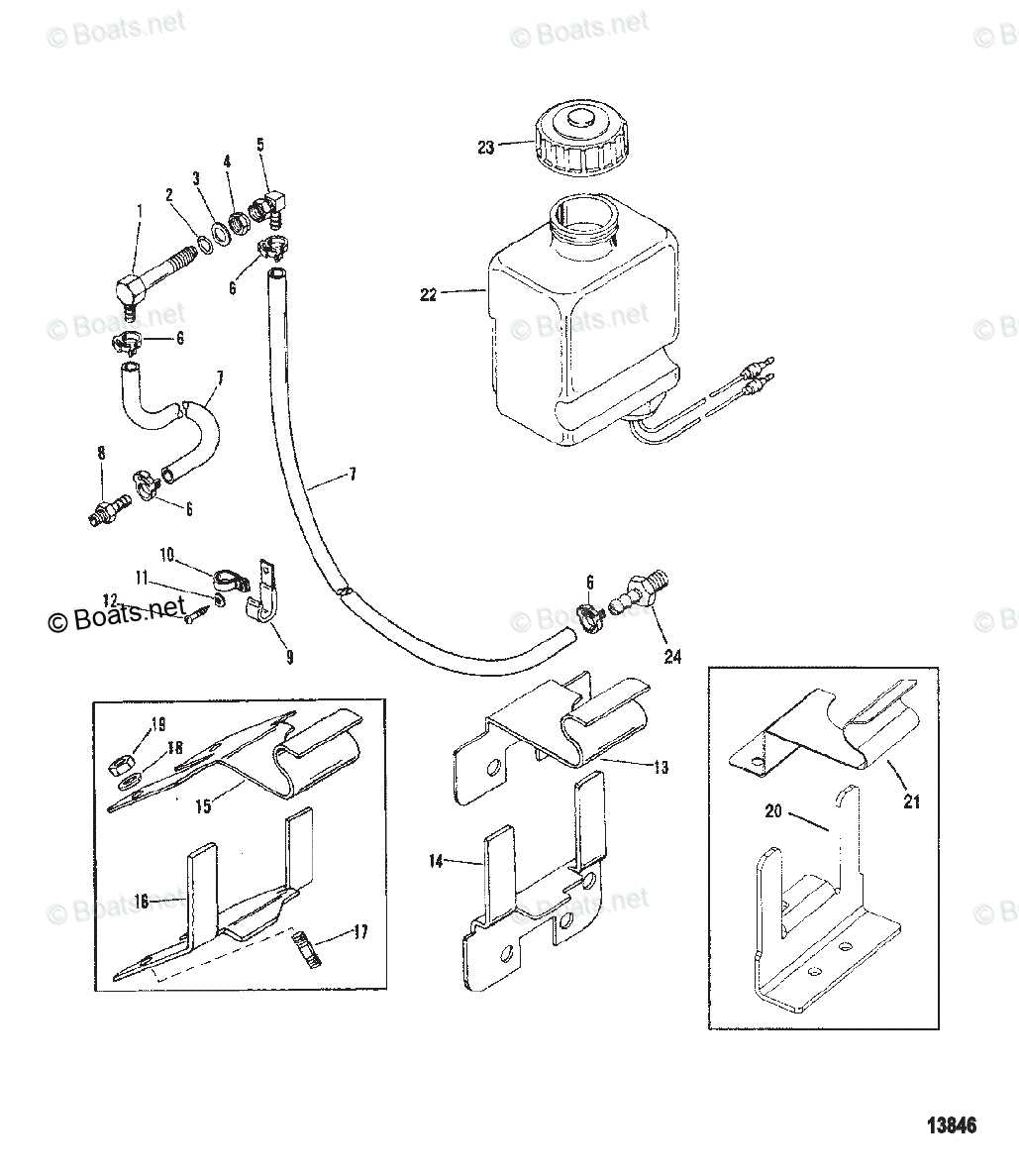

Lubrication and Cooling System Diagram

The lubrication and cooling system of a marine engine is essential for maintaining optimal performance and preventing overheating. These systems ensure that all moving parts are properly lubricated and that the engine operates at a safe temperature, avoiding damage due to excessive heat.

Lubrication System Overview

Lubrication plays a crucial role in reducing friction between the engine components. It circulates oil to the engine’s vital parts, such as the crankshaft and bearings, ensuring smooth operation. This process also helps in cooling the engine, reducing wear and tear over time.

Cooling System Design

The cooling system manages the heat generated by the engine. Water is drawn from the surrounding environment, typically through an intake, and circulated around the engine. This system helps to regulate the engine’s temperature, preventing overheating and ensuring the engine runs efficiently.

Electrical Components and Wiring Layout

The electrical system of a boat’s propulsion unit plays a critical role in its performance and safety. Properly understanding the layout and connections of electrical elements ensures reliable functionality. From the ignition system to the battery and alternator, every component must be precisely connected to work efficiently. This section covers the essential electrical elements and their wiring setup to guarantee smooth operation and prevent potential issues.

| Component | Description | Function |

|---|---|---|

| Ignition Switch | Controls the activation of the engine’s electrical system. | Starts and stops the engine. |

| Battery | Stores electrical energy for the unit. | Provides power to the electrical system and starts the engine. |

| Alternator | Generates electricity while the engine runs. | Charges the battery and powers the electrical system during operation. |

| Fuse Box | Houses the fuses that protect various circuits. | Prevents overloading of the electrical system by disconnecting faulty circuits. |

| Wiring Harness | A network of wires connecting electrical components. | Transmits power and signals between components. |

A clear and correct wiring scheme is essential for troubleshooting and maintenance. Knowing how each component is wired allows for quick identification of potential electrical issues, ensuring the system operates safely and efficiently.