When discussing heavy lifting equipment, it’s crucial to grasp the overall assembly that allows these machines to function effectively. Each section plays a pivotal role in ensuring stability, power, and precision during operation. By breaking down the individual elements, one can better understand how they work together to lift and move substantial loads.

The key to efficient operation lies in the seamless interaction of mechanical and hydraulic systems. These systems are engineered to provide both strength and flexibility, enabling the machine to adapt to various tasks in challenging environments. Proper maintenance and inspection of these interconnected systems are essential to prevent malfunctions and prolong the machine’s lifespan.

In this article, we’ll delve into the specific structures that make up this powerful equipment, offering insights into how each element supports the machine’s overall functionality and safety.

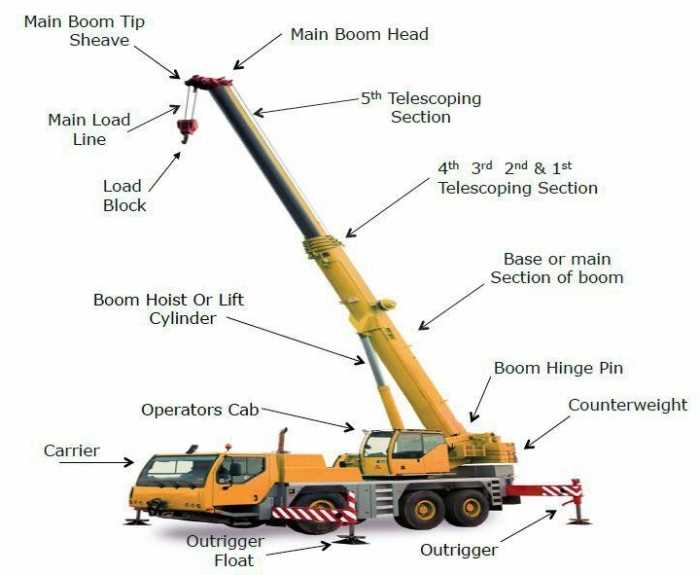

Overview of Essential Mobile Crane Components

Heavy lifting equipment is a complex system of various interconnected elements, each playing a significant role in ensuring safe and efficient operation. Understanding these core elements provides valuable insight into how such machines function during various lifting tasks. By analyzing the roles and characteristics of these key elements, one can gain a better appreciation of their importance in the overall performance of the equipment.

Structural Frame: The foundation that supports all other elements, providing the necessary stability and strength. It is designed to withstand heavy loads and external forces, ensuring safe and reliable operation during different lifting scenarios.

Telescopic Boom: This extendable section is responsible for adjusting the reach and height. Its ability to elongate makes it crucial for tasks requiring flexibility in distance and height. The design ensures precision and strength, even

Structure and Frame Design

The foundational framework is essential for ensuring stability and balance during the operation of the machinery. The layout and design of the supporting components are meticulously crafted to handle heavy loads and provide the necessary rigidity. Understanding how these elements interact contributes to the overall durability and efficiency of the system.

Key Framework Elements

Several major structural components form the backbone of the equipment. These elements are designed to distribute weight evenly and ensure that the machine can withstand operational stresses. Reinforced materials are commonly used in areas where high pressure and force are applied.

Importance of Reinforcement

Reinforcement is critical in maintaining the integrity of the system. Strong support beams and stabilizers work in unison to prevent bending or warping under extreme conditions. The strategic placement of these reinforcements

Hydraulic System Functionality

The hydraulic system plays a crucial role in managing the movement and control of various components, allowing for smooth and precise operation. It relies on fluid dynamics to transmit force, enabling the effective handling of heavy loads with minimal effort. By converting mechanical energy into hydraulic power, this system ensures efficient control over different operational processes.

| Component | Function | |||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pump | Generates the hydraulic pressure necessary for the operation of other components. | |||||||||||||||||||||||||||||||||

| Cylinder | Converts hydraulic pressure into linear mechanical movement, allowing for the lifting or lowering of objects. | |||||||||||||||||||||||||||||||||

| Valve |

| Counterweight Type | Weight (lbs) | Purpose |

|---|---|---|

| Standard Block | 1,000 | Basic stability |

| Adjustable Weights | Up to 2,000 | Fine-tuning balance |

| Extended Counterweight | 1,500 | Increased reach capabilities |

Outrigger Functions for Stability

Stabilizing devices play a crucial role in enhancing the safety and efficiency of heavy lifting operations. Their primary purpose is to provide a broader base of support, ensuring that the equipment remains balanced during various tasks. By extending beyond the main structure, these supports significantly reduce the risk of tipping over, especially when handling substantial loads at significant heights.

Understanding the functionality of these stabilizers is essential for optimal operation. They are designed to distribute the weight evenly across the ground, minimizing pressure points that could lead to instability. Moreover, the effective use of these devices contributes to maintaining proper alignment, which is vital for precise maneuvering and load handling.

| Function | Description |

|---|---|

| Weight Distribution | Evenly spreads the load across a larger area to prevent ground sinking. |

| Preventing Tipping | Enhances the overall balance by increasing the contact area with the ground. |

| Leveling | Adjusts the height and angle to maintain a stable working surface. |

| Improving Safety | Reduces the likelihood of accidents caused by instability during operations. |

Electrical Wiring and Control Systems

This section focuses on the intricate systems responsible for power distribution and operational management in heavy machinery. Understanding the wiring and control mechanisms is essential for ensuring safety, efficiency, and functionality in various applications. Properly designed electrical circuits facilitate seamless operation and contribute to the overall performance of the equipment.

In these systems, various components work together to control movement and power flow. The connections must be meticulously organized to prevent malfunctions and ensure reliable operation under demanding conditions.

| Component | Function |

|---|---|

| Power Supply Unit | Provides electrical energy to all systems. |

| Control Panel | Interface for operators to manage functions and monitor systems. |

| Sensors | Detect various parameters and provide feedback for adjustments. |

| Actuators | Convert electrical signals into physical motion. |

| Wiring Harness | Ensures proper connections between electrical components. |

Effective management of these electrical systems enhances operational safety and performance. Regular maintenance and inspections are crucial for identifying potential issues, ensuring that each element functions as intended.

Slewing Mechanism for Rotation

The slewing mechanism serves as a critical component in enabling the rotational movement of heavy equipment. Its design allows for smooth and precise turning, essential for various operational tasks. This functionality is achieved through a combination of mechanical elements working in harmony to provide stability and control during motion.

Components of the Slewing Mechanism

This assembly typically includes a rotating base, a gearbox, and bearings, which facilitate the desired rotation. The rotating base forms the foundation, while the gearbox ensures that torque is effectively transferred. Additionally, high-quality bearings reduce friction, allowing for seamless rotation.

Importance of the Slewing Mechanism

Understanding the significance of this mechanism is crucial for optimizing equipment performance. Efficient rotation enhances operational productivity, making it easier to position loads accurately. Furthermore, the reliability of the mechanism directly impacts the overall safety and functionality of the equipment.

Safety Devices and Emergency Systems

Ensuring the highest levels of protection during operations requires the integration of various safety mechanisms and contingency protocols. These features are essential for minimizing risks and safeguarding personnel and equipment. A robust framework of protective elements not only enhances operational efficiency but also fosters a culture of safety within the workplace.

Critical Safety Mechanisms

Preventive measures play a vital role in mitigating hazards. Systems such as load limiters, anti-collision technologies, and secure locking mechanisms work together to ensure that operations are conducted within safe parameters. Regular maintenance and testing of these systems are imperative to maintain their functionality and reliability.

Emergency Response Protocols

In the event of an unforeseen incident, having well-defined emergency procedures is crucial. These protocols should include immediate actions to be taken, communication plans, and evacuation routes. Training personnel in these procedures ensures swift and effective responses, reducing the likelihood of injury and damage.