This section delves into the intricate arrangements and configurations of various elements found within specific models of equipment. Recognizing the significance of each component’s placement is crucial for effective assembly and maintenance. By exploring these arrangements, users can gain insights into the functionality and operational efficiency of the device.

Moreover, comprehending how each element interacts with others fosters a deeper appreciation for the overall design. This knowledge not only aids in troubleshooting but also enhances the ability to modify or upgrade systems for improved performance. Understanding the relationships between different components can lead to more informed decisions during repairs or enhancements.

Ultimately, this examination aims to provide clarity and understanding for users seeking to navigate the complexities of their equipment. By equipping oneself with this knowledge, individuals can approach their tasks with confidence, ensuring optimal usage and longevity of the machinery.

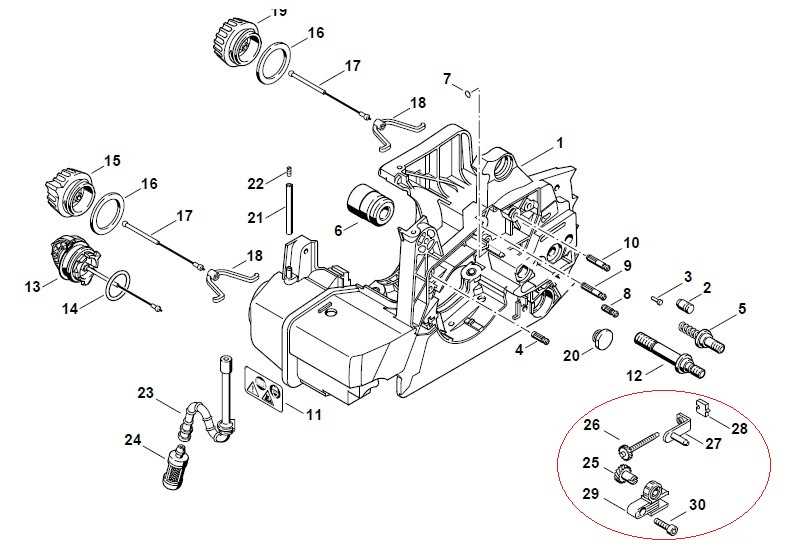

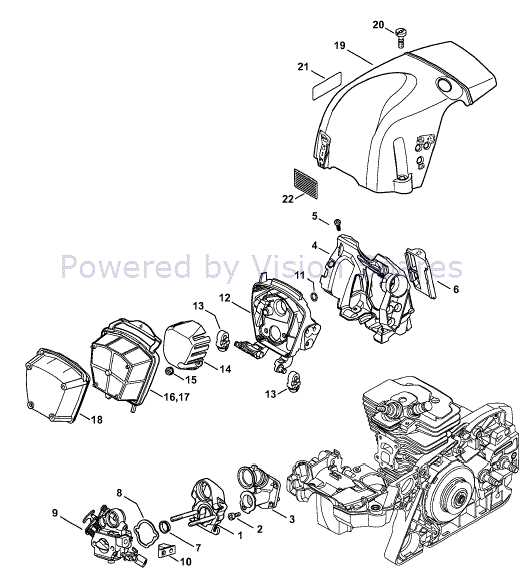

Overview of Ms311 Components

This section provides a comprehensive look at the various elements that comprise a specific model, detailing their roles and interactions within the system. Understanding these components is essential for effective utilization and maintenance.

Each element is designed to serve a unique function, contributing to the overall performance and reliability of the assembly. Connections between these parts are crucial, as they facilitate seamless operation and ensure efficiency. Key features include robust materials, precision engineering, and innovative design, which collectively enhance durability and functionality.

Moreover, an in-depth examination reveals how the arrangement of these components affects the overall system dynamics. Regular inspection and knowledge of each element’s characteristics can aid in troubleshooting and optimization. Awareness of component specifications and compatibility also plays a vital role in ensuring the longevity and effectiveness of the equipment.

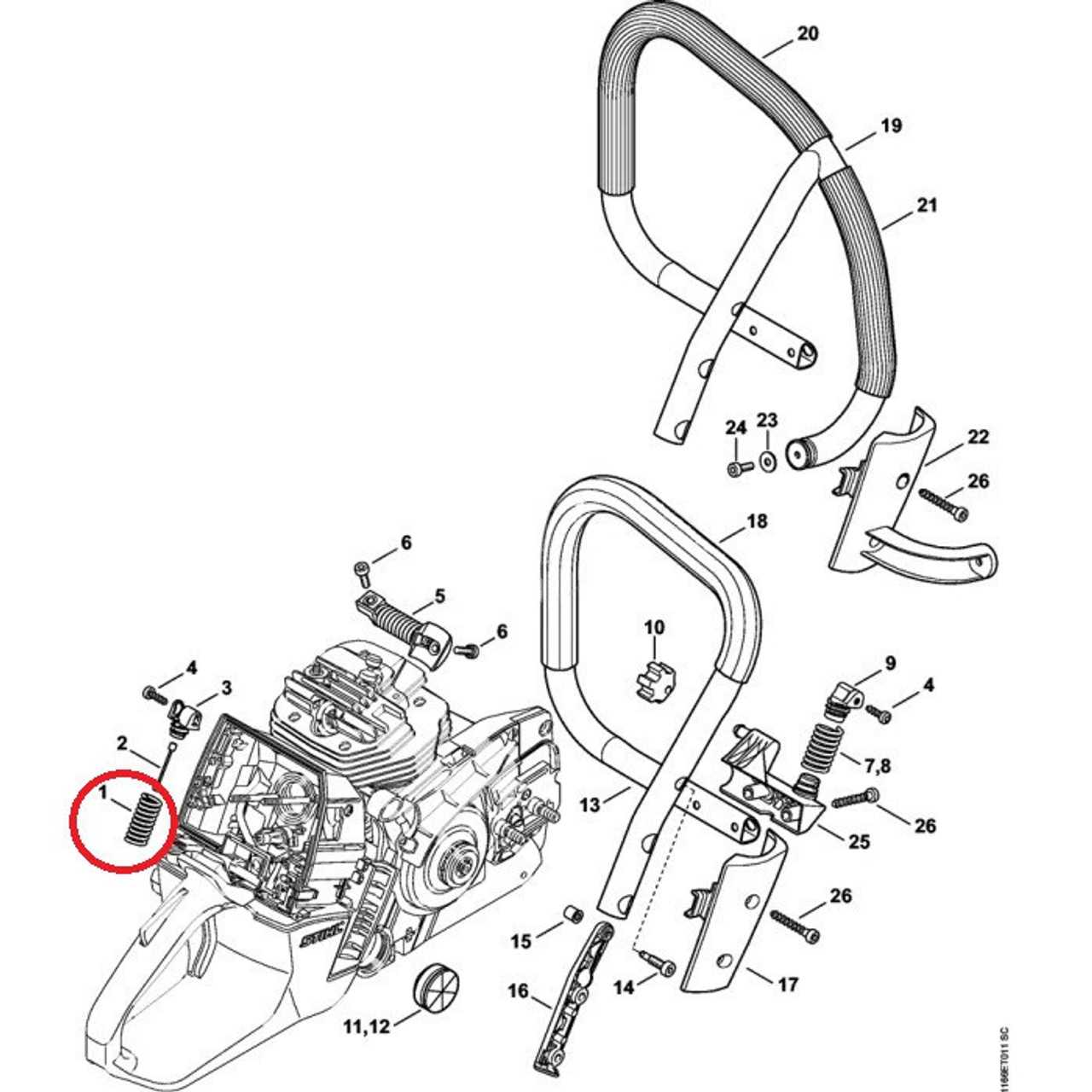

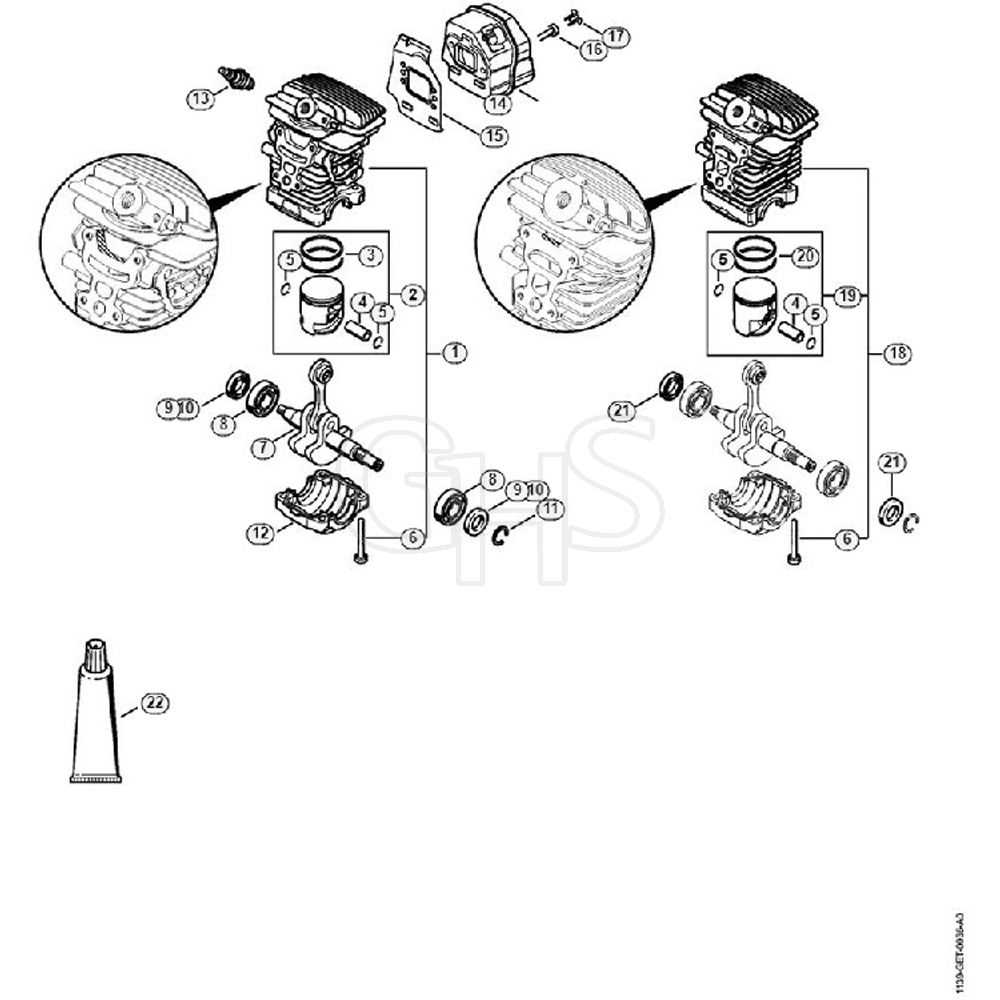

Understanding Ms311 Assembly Structure

The assembly framework of a particular device plays a crucial role in its functionality and performance. This section delves into the intricate composition of the system, highlighting the various components and their interconnections. A thorough comprehension of this assembly aids in effective maintenance, troubleshooting, and overall enhancement of the unit’s capabilities.

Key Components of the Structure

At the core of the assembly are several fundamental elements that contribute to its operational integrity. Each part serves a specific purpose, working in unison to achieve desired outcomes. Recognizing these components is essential for anyone looking to deepen their understanding of the overall system.

| Component | Function |

|---|---|

| Housing | Provides structural support and protection for internal components. |

| Connector Interfaces | Facilitates communication between different segments of the system. |

| Control Modules | Regulates the operation and coordination of various functions. |

| Power Supply Unit | Delivers the necessary energy to all components. |

| Sensors | Monitors environmental variables and system performance. |

Importance of Structural Integrity

Maintaining the integrity of the assembly is vital for ensuring optimal performance and longevity. Any degradation in the structure can lead to inefficiencies or failures. Regular inspections and timely repairs contribute significantly to the sustained effectiveness of the entire unit.

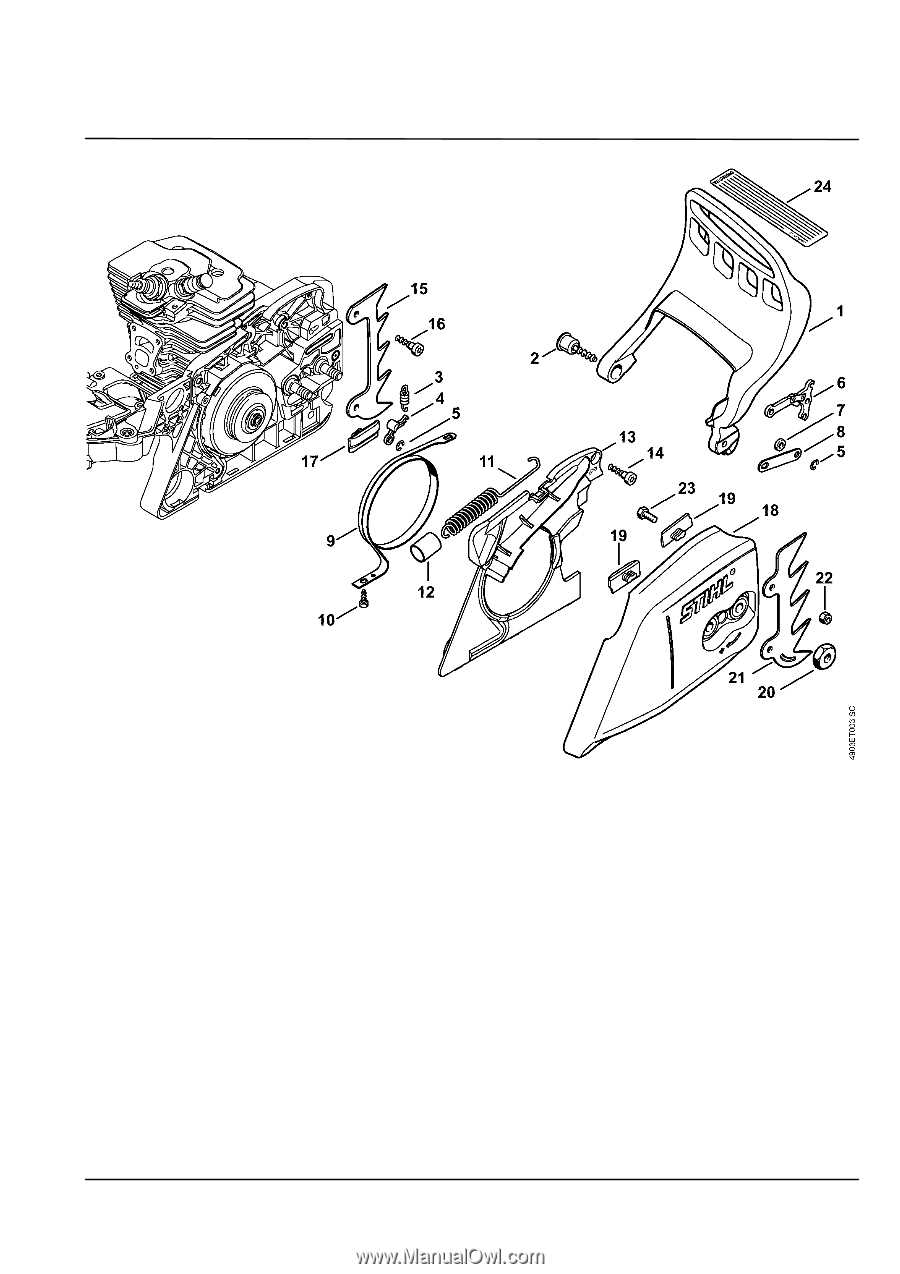

Key Features of Ms311 Parts

This section highlights the essential attributes of a specific series of components commonly used in various applications. Understanding these characteristics can help users make informed decisions about their functionality, compatibility, and overall performance. Each feature contributes significantly to the efficiency and reliability of the entire system.

Among the notable characteristics are the following:

| Feature | Description |

|---|---|

| Durability | Engineered to withstand harsh conditions, ensuring long-term reliability. |

| Compatibility | Designed to integrate seamlessly with various systems and configurations. |

| Efficiency | Optimized for high performance, minimizing energy consumption and waste. |

| Versatility | Suitable for a wide range of applications, providing flexibility in usage. |

| Maintenance | Low maintenance requirements, contributing to reduced operational costs. |

Functionality of Ms311 Connectors

The connectors in question play a crucial role in establishing reliable electrical connections in various applications. Their design ensures effective communication between components, facilitating seamless data transfer and power distribution. These connectors are engineered to meet specific standards, which guarantees durability and resilience in demanding environments.

These components are characterized by several key features that enhance their performance. Their robust construction provides protection against environmental factors, ensuring consistent functionality over time. Additionally, the design often includes features that facilitate easy installation and maintenance, contributing to overall system efficiency.

| Feature | Description |

|---|---|

| Durability | Engineered to withstand harsh conditions, preventing wear and tear. |

| Ease of Use | Designed for quick installation and simple maintenance procedures. |

| Standard Compliance | Manufactured to meet industry standards for safety and performance. |

| Versatility | Applicable in various fields, from automotive to telecommunications. |

In summary, these connectors are essential for ensuring efficient operations across multiple industries. Their advanced features and reliable performance make them indispensable components in modern technology.

Materials Used in Ms311 Construction

The construction of advanced machinery involves a carefully selected array of materials, each chosen for its unique properties and capabilities. Understanding the composition of these components is crucial for appreciating the overall functionality and durability of the equipment.

Core Material Categories

- Metals: Commonly utilized for their strength and durability, metals are fundamental in structural elements. Steel and aluminum alloys often serve as the primary choices due to their excellent mechanical properties.

- Plastics: Lightweight and versatile, plastics are employed in various non-structural components. They provide corrosion resistance and can be molded into complex shapes, enhancing design flexibility.

- Composites: Combining materials like fibers and resins, composites offer superior strength-to-weight ratios. These materials are increasingly used in applications requiring enhanced performance without adding excessive weight.

Functional Material Properties

- Corrosion Resistance: Many elements are treated or coated to resist oxidation and wear, ensuring longevity and reducing maintenance needs.

- Thermal Stability: Certain components must withstand high temperatures, requiring materials with excellent thermal resistance to prevent deformation or failure.

- Electrical Conductivity: In parts involving electronic functions, materials are chosen for their ability to conduct electricity efficiently.

Importance of Ms311 Wiring Diagrams

Understanding the layout and connections within complex systems is crucial for effective troubleshooting and maintenance. Visual representations serve as essential tools, allowing technicians to navigate intricate networks and identify potential issues quickly. By having access to these illustrations, professionals can ensure efficient repairs and modifications, enhancing the overall reliability of the system.

Facilitating Effective Repairs

One of the primary benefits of having access to comprehensive schematics is the ability to facilitate accurate repairs. Technicians can pinpoint specific components and their relationships, leading to faster diagnostics and reduced downtime. This structured approach minimizes the risk of errors during maintenance, ultimately contributing to better performance.

Enhancing Safety Protocols

In addition to streamlining repairs, these visual guides play a vital role in enhancing safety protocols. A clear understanding of the wiring structure helps prevent accidental damage to sensitive components. By following established layouts, technicians can work with confidence, ensuring that safety measures are upheld during any service operation.

| Benefit | Description |

|---|---|

| Faster Diagnostics | Enables quick identification of issues, reducing downtime. |

| Minimized Errors | Structured approach decreases the likelihood of mistakes during maintenance. |

| Improved Safety | Clear layouts help prevent accidental damage to components. |

Common Issues with Ms311 Components

When dealing with complex mechanical systems, various components can present challenges that affect overall functionality. Understanding these issues is crucial for effective troubleshooting and maintenance. Many users encounter similar problems that can arise from wear and tear, improper installation, or compatibility concerns, impacting performance and reliability.

Frequent Malfunctions

One of the most common malfunctions involves electrical connections. Loose or corroded terminals can lead to intermittent power loss or failure to operate. Additionally, components may overheat due to inadequate ventilation or prolonged use beyond recommended specifications, resulting in reduced efficiency and potential damage.

Compatibility Problems

Another significant issue arises from compatibility between different parts. Users often attempt to replace components with alternatives that may not meet the original specifications, leading to fitment problems or functionality issues. Ensuring that replacements are compatible with the existing setup is essential for maintaining optimal performance.

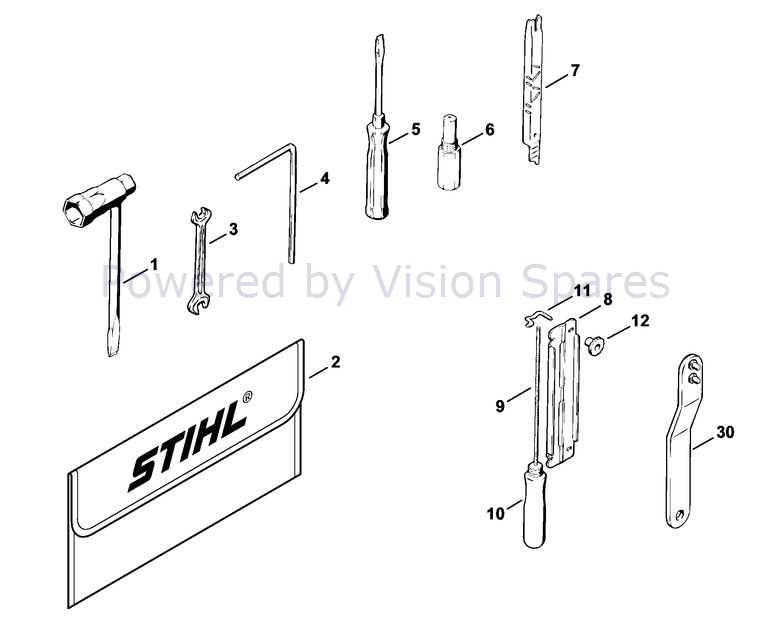

Maintenance Tips for Ms311 Parts

Ensuring the longevity and efficiency of your equipment involves regular upkeep and attention to detail. By following some essential care guidelines, you can enhance the performance and reliability of the various components, leading to a smoother operation and fewer unexpected issues.

Regularly inspect the individual elements for signs of wear or damage. This proactive approach helps identify potential problems before they escalate, ensuring that everything functions as intended. Additionally, keeping components clean from debris and contaminants will prevent malfunctions and promote better performance.

Utilize appropriate lubricants on moving parts to minimize friction and wear. Be sure to follow manufacturer recommendations regarding the type and frequency of lubrication. This practice not only extends the life of the components but also ensures they operate smoothly.

It’s crucial to adhere to the suggested maintenance schedule for each component. Regular servicing, including replacements of filters or seals, will ensure optimal performance and prevent breakdowns. Documenting these maintenance activities can also help track the condition of each part over time.

Lastly, consult the user manual or maintenance guide specific to your equipment for detailed instructions tailored to your model. By being diligent and following these tips, you can maintain the effectiveness of your machinery and ensure it remains in peak condition.

Replacement Options for Ms311 Components

When it comes to maintaining machinery, finding suitable alternatives for specific elements is essential. Many users seek reliable substitutes that not only match the original specifications but also enhance performance and longevity. Understanding available choices can significantly impact overall functionality and efficiency.

Here are some options to consider when looking for replacements:

- OEM Alternatives: Original equipment manufacturer components are often the best choice for those wanting to ensure compatibility and quality.

- Aftermarket Solutions: Various manufacturers produce compatible items that may offer enhanced features or lower costs, making them appealing for budget-conscious buyers.

- Reconditioned Parts: These components have been restored to a like-new condition, offering a cost-effective alternative without compromising on quality.

- Custom Solutions: For unique applications, tailored components can be manufactured to meet specific requirements, providing flexibility in design.

In conclusion, exploring various options for replacements can lead to improved performance and cost savings. It’s important to evaluate each alternative based on the specific needs of the application and the desired outcomes.

Benefits of Accurate Ms311 Diagrams

Having precise representations of components is essential for effective assembly and maintenance processes. These visual aids serve as valuable references, guiding technicians and engineers through complex systems. Their accuracy ensures that every element is understood, reducing the likelihood of errors during installation or repairs.

Enhanced Clarity and Understanding

Clear illustrations provide a comprehensive view of each element within a system. This clarity helps users grasp the interconnections and functionalities of various components, leading to better decision-making. Some key advantages include:

- Improved identification of parts and their specific functions.

- Facilitated troubleshooting by showcasing potential issues.

- Streamlined communication among team members regarding maintenance tasks.

Efficiency in Operations

Accurate representations contribute significantly to operational efficiency. By minimizing misunderstandings and mistakes, they save time and resources. The benefits include:

- Reduced downtime during repairs and installations.

- Quicker access to essential information when needed.

- Lower overall costs associated with project delays or errors.

Future of Ms311 Component Design

The evolution of component architecture plays a crucial role in enhancing performance and efficiency in various applications. As technology advances, the focus on creating innovative solutions that integrate seamlessly with existing systems is becoming increasingly important. This shift towards smarter designs aims to improve functionality while reducing manufacturing complexities.

Emphasis on Sustainability

One significant trend shaping the future of component design is the emphasis on sustainability. Engineers are now tasked with developing components that not only meet performance standards but also minimize environmental impact. This involves utilizing eco-friendly materials and designing for recyclability, which ultimately contributes to a more sustainable manufacturing process.

Integration of Smart Technologies

The integration of smart technologies into component design is another key aspect. The rise of the Internet of Things (IoT) necessitates the incorporation of intelligent features, enabling components to communicate and adapt to their surroundings. This interconnectedness leads to enhanced functionality and user experience, paving the way for the next generation of innovative solutions.