In the realm of machinery and equipment, having a clear overview of the elements that comprise a system is essential for effective maintenance and troubleshooting. Such insights not only enhance operational efficiency but also facilitate informed decision-making during repairs. A comprehensive representation of these components allows users to navigate the complexities of their systems with greater ease.

When delving into the intricacies of any mechanical setup, it is crucial to familiarize oneself with the various segments and their interconnections. This exploration sheds light on how different parts interact, contributing to the overall functionality. By grasping the arrangement and relationship between these elements, users can pinpoint issues more accurately and streamline their repair processes.

Utilizing visual aids that showcase these relationships can significantly improve comprehension. By analyzing these illustrations, one can better appreciate the design and engineering behind the equipment. This not only serves as a guide for maintenance but also enriches the user’s understanding of the machine’s operational principles, leading to more proficient handling and care.

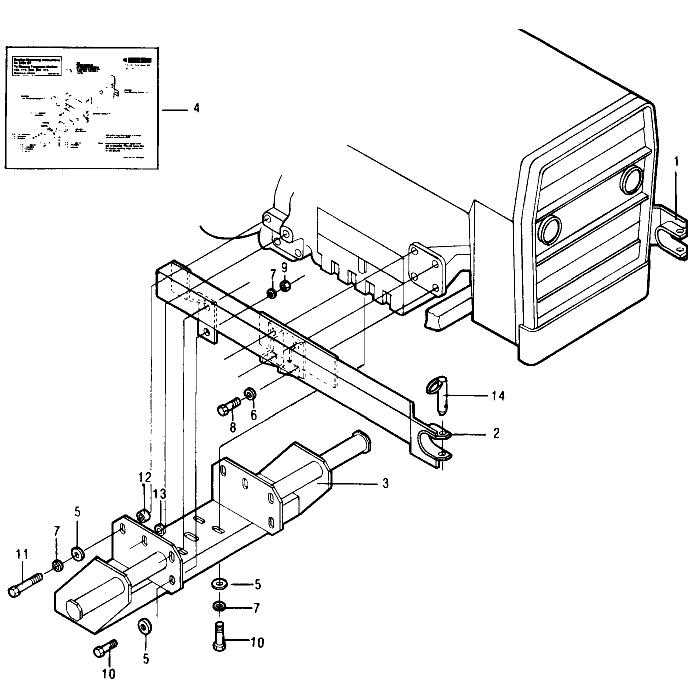

Mst-206-545c Overview

This section provides a comprehensive look into a specific model known for its robust design and functionality. It serves various applications, showcasing versatility and reliability in performance. Understanding its components is essential for effective maintenance and operation.

| Feature | Description |

|---|---|

| Design | Engineered for durability and efficiency. |

| Applications | Suitable for multiple operational scenarios. |

| Maintenance | Regular upkeep ensures optimal performance. |

| Support | Available resources for troubleshooting and repair. |

Key Components of Mst-206-545c

This section highlights the essential elements that contribute to the functionality and efficiency of the system. Understanding these components is crucial for anyone involved in maintenance, operation, or design. Each part plays a significant role in ensuring optimal performance and reliability.

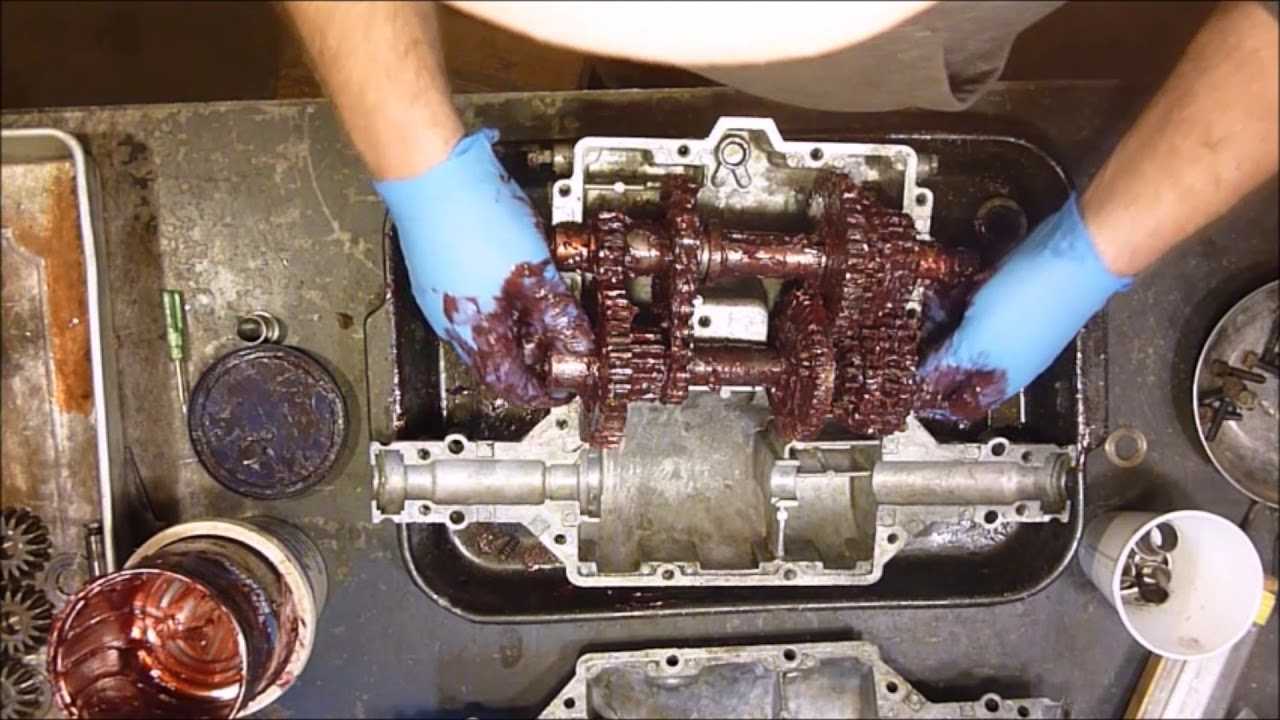

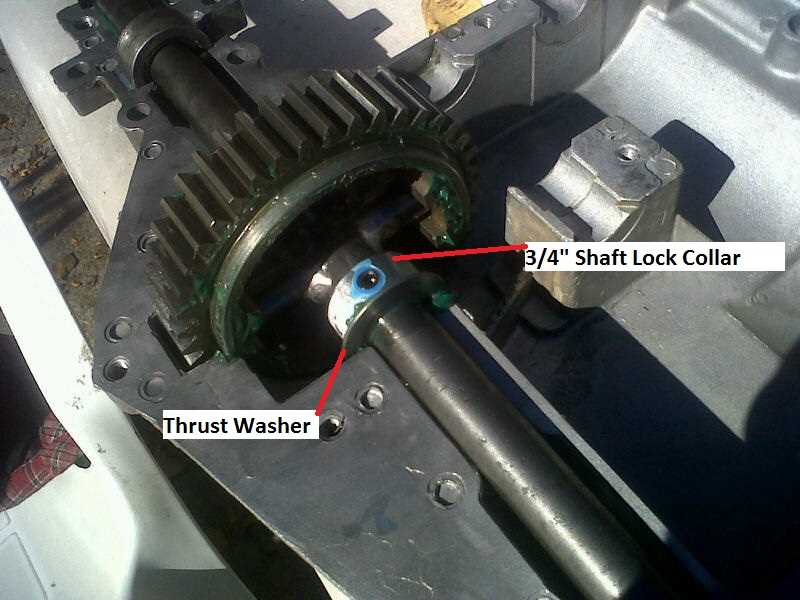

Main Functional Units

The primary units are designed to facilitate seamless operation. These include various mechanisms that control movement, energy transfer, and overall system stability. Their precise engineering ensures that all interactions are smooth, reducing wear and enhancing longevity.

Support mechanisms provide the necessary infrastructure for efficient operation. This encompasses components responsible for safety, monitoring, and diagnostics. Together, these systems work to create a robust environment, allowing for real-time assessment and intervention when needed.

Understanding the Parts Diagram

The visual representation of components serves as a vital tool for grasping the assembly and functionality of machinery. It offers clarity on how various elements interact and contribute to the overall operation. By analyzing this illustration, one can gain insights into the arrangement and significance of each segment.

Breaking down the structure allows for a comprehensive understanding of how each piece fits within the larger system. This approach not only aids in identifying individual components but also enhances troubleshooting and maintenance efforts.

Ultimately, familiarity with such visual aids empowers users to operate equipment more effectively and resolve issues with confidence. Delving into the specifics can significantly enhance one’s mechanical aptitude and operational efficiency.

Common Issues and Solutions

In any mechanical system, users often encounter various challenges that can hinder optimal performance. Understanding these common difficulties is crucial for effective maintenance and ensuring longevity. Here, we will explore prevalent problems and their practical solutions.

Issue 1: Overheating

One frequent concern is overheating, which can result from insufficient lubrication or debris buildup. Regular cleaning and timely oil changes can significantly mitigate this problem.

Issue 2: Unusual Noises

Strange sounds often indicate misalignment or wear. Inspecting components for proper alignment and replacing worn parts can resolve this issue effectively.

Issue 3: Inefficiency

A drop in efficiency may stem from outdated or damaged components. Upgrading key elements and ensuring all parts are in good condition can enhance overall performance.

Issue 4: Leaks

Fluid leaks are a common problem that can lead to further complications. Regular checks for cracks and ensuring seals are intact can help prevent these issues.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of any machinery. By following systematic practices, you can ensure optimal performance and minimize the risk of unexpected breakdowns.

- Regular Inspection: Frequently examine components for wear and tear to catch issues early.

- Lubrication: Apply appropriate lubricants to reduce friction and prevent overheating.

- Cleaning: Keep surfaces free of debris and contaminants to maintain efficiency.

- Storage: Store equipment in a dry, cool place to protect it from environmental damage.

- Calibration: Periodically check and adjust settings to ensure accurate operation.

Implementing these strategies will help you delve deeper into the maintenance process, leading to the ultimate longevity of your equipment.

How to Read the Diagram

Understanding a schematic representation is essential for effective maintenance and repair tasks. This guide will help you navigate the intricate visual layout, ensuring that you can identify components and their relationships with ease.

Follow these key steps to enhance your comprehension:

- Familiarize Yourself with Symbols: Each symbol represents a specific element. Review the legend or key that accompanies the visual to understand what each symbol denotes.

- Identify Main Components: Start by locating the primary elements of the system. These are typically highlighted or grouped together for easy identification.

- Trace Connections: Follow the lines connecting different elements. These lines indicate how components interact and work together within the assembly.

- Note Any Annotations: Look for notes or labels that provide additional information about the elements. These can offer insights into specifications or installation instructions.

- Use a Color Code Reference: If the visual uses color coding, refer to the provided legend. Colors can signify various functionalities or categories within the system.

By applying these strategies, you will gain a clearer understanding of the schematic, enabling you to tackle tasks with confidence and efficiency.

Parts Replacement Process

Replacing components in any machinery or equipment requires careful planning and execution to ensure optimal functionality. This procedure not only involves identifying the items that need to be swapped but also requires an understanding of how each element interacts within the larger system. Properly executing this task can enhance performance and prolong the life of the machinery.

Preparation Steps

- Review the user manual for specifications and instructions.

- Gather all necessary tools and replacement components.

- Ensure a clean and organized workspace to avoid misplacement of parts.

- Disconnect the power supply to prevent accidents during the process.

Replacement Procedure

- Carefully remove the faulty component, taking note of its connections and positioning.

- Inspect the surrounding area for any additional wear or damage.

- Install the new element, ensuring all connections are secure and aligned properly.

- Reconnect the power supply and conduct a test run to verify functionality.

- Document the changes made for future reference and maintenance schedules.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a challenging task, but there are various resources available to help streamline the process. Understanding where to look can significantly reduce downtime and ensure your machinery runs smoothly. Here are some reliable options for sourcing the necessary items.

Online Retailers

One of the most convenient ways to find suitable replacements is through online marketplaces. These platforms often have a vast selection, allowing you to compare prices and read reviews. Look for reputable websites that specialize in industrial supplies or specific brands.

Local Suppliers

Don’t overlook local suppliers and distributors. They can provide personalized service and often have parts in stock for immediate purchase. Establishing a relationship with these businesses can also lead to better deals and quicker access to items you need.

| Source | Description |

|---|---|

| Online Marketplaces | Wide variety, price comparison, customer reviews. |

| Local Distributors | Personalized service, immediate availability. |

| Manufacturer Websites | Official components, often with warranty. |

| Salvage Yards | Cost-effective options, unique finds. |

Compatibility with Other Models

Understanding how components interact across different units is crucial for optimal performance and functionality. This section explores the relationships and interchangeability among various models, highlighting which units can effectively work together without compromising efficiency.

Interchangeable Components: Many systems share similar designs, allowing certain elements to be swapped between models. This not only simplifies repairs but also enhances the overall adaptability of the machinery.

Performance Considerations: While compatibility can be a significant advantage, it’s essential to consider the potential impact on performance. Some units may function adequately with parts from other models, but could yield varied results in terms of reliability and efficiency.

Manufacturer Recommendations: Always refer to manufacturer guidelines when determining compatibility. Following these recommendations ensures that the chosen components meet safety and operational standards.

By delving into these aspects, users can make informed decisions about enhancing their systems through compatible components.

Expert Recommendations for Users

When navigating the complexities of mechanical components, it is essential to approach the task with a strategic mindset. Understanding the interrelations and functionality of various elements can greatly enhance the efficiency of any project. Experts emphasize the importance of thorough preparation and knowledge acquisition before diving into hands-on work.

Firstly, familiarizing oneself with the technical specifications and operational principles is crucial. Users are encouraged to consult reliable resources and documentation to gain a comprehensive understanding of the system at hand. This foundational knowledge aids in making informed decisions and reduces the likelihood of errors during assembly or maintenance.

Additionally, utilizing high-quality tools and materials cannot be overstated. Investing in reputable brands ensures longevity and reliability, which is particularly important in high-stakes environments. Users should also prioritize safety by adhering to recommended practices and wearing appropriate protective gear throughout the process.

Collaboration with experienced professionals can provide valuable insights and tips that may not be readily available in written resources. Engaging in discussions with peers or joining relevant communities can facilitate the exchange of ideas and best practices, further enriching the user’s understanding and capability.

Lastly, maintaining an organized workspace promotes efficiency and minimizes the risk of losing critical components. By keeping tools and materials neatly arranged, users can focus more on the task at hand, leading to better outcomes and a smoother workflow.

Visual Reference for Assembly

This section provides a comprehensive guide for assembling components, offering clear illustrations and detailed descriptions to facilitate the process. Understanding the arrangement of elements is crucial for achieving a seamless assembly experience.

Key Elements to Consider

- Identifying individual components

- Understanding their interconnections

- Ensuring proper orientation during assembly

Assembly Steps

- Gather all necessary components.

- Refer to the visual aids for clarity on each part’s placement.

- Follow the sequential instructions for efficient assembly.

- Verify connections and alignment before finalizing.