In the realm of agricultural equipment, the intricate design and functionality of machinery play a crucial role in enhancing efficiency and productivity. A comprehensive exploration of these mechanical elements reveals the interconnections that enable seamless operation. Knowledge of these components not only aids in maintenance but also empowers users to optimize performance.

To navigate the complexities of a specific model, it is essential to visualize its structural arrangement. This visualization serves as a valuable tool for technicians and enthusiasts alike, simplifying troubleshooting and repairs. By dissecting the various segments, one can appreciate the craftsmanship that underpins these robust machines.

Furthermore, an understanding of each individual piece contributes to better decision-making when it comes to upgrades or replacements. As technology evolves, so do the innovations in these tools, making it imperative for users to stay informed about the latest developments and solutions available in the market.

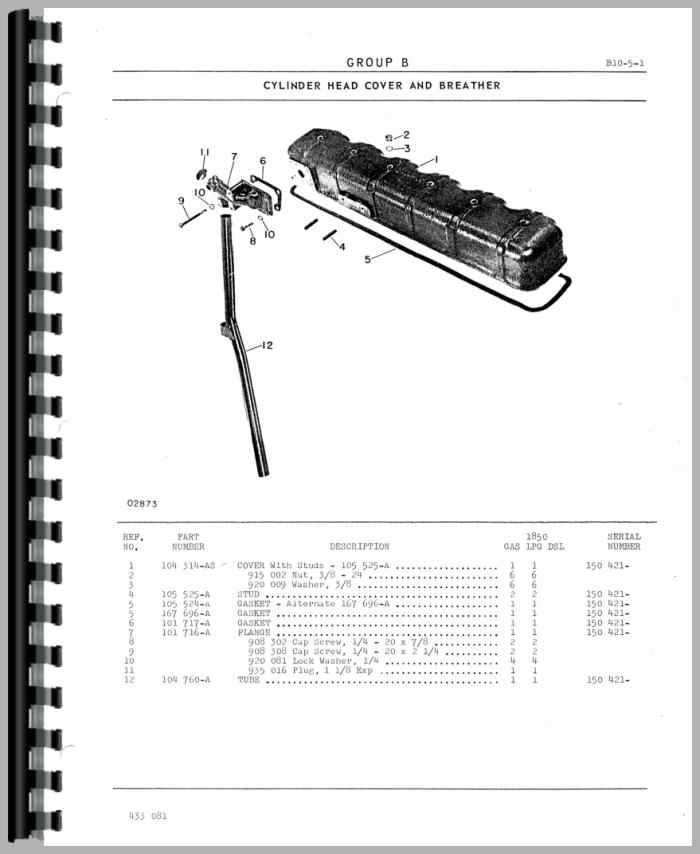

Understanding Oliver 1850 Parts Diagram

This section aims to provide clarity on the intricate layout and components of a specific agricultural machine, essential for effective maintenance and repair. A visual representation of the various elements involved can greatly enhance comprehension, enabling users to identify each part’s role and functionality within the system.

Importance of a Visual Representation

A graphical outline serves as a valuable tool for both seasoned technicians and newcomers alike. It simplifies the process of locating individual components and understanding their interrelationships, which is crucial for troubleshooting and ensuring optimal performance of the equipment.

Key Components and Their Functions

Each element depicted in the schematic plays a pivotal role in the overall operation. Familiarizing oneself with these components not only aids in repairs but also enhances the user’s ability to operate the machinery efficiently. Recognizing how each section interacts can lead to better maintenance practices and prolonged equipment life.

History of the Oliver 1850 Tractor

This section explores the evolution and significance of a renowned agricultural machine that has made a lasting impact on farming practices. The development of this powerhouse reflects advancements in engineering and design, catering to the needs of farmers in various regions.

The origins of this model can be traced back to the mid-20th century, a period marked by innovation in agricultural machinery. The following key points highlight its historical journey:

- Introduced in the 1960s as part of a broader line of farming equipment.

- Engineered for efficiency, reliability, and ease of use, making it a favorite among farmers.

- Incorporated advanced features for its time, such as a robust engine and user-friendly controls.

Throughout its production run, this tractor became synonymous with durability and performance, influencing farming practices across various landscapes. The design choices made during its creation set new standards in the industry, contributing to the legacy of agricultural innovation.

As farming technology evolved, the machine adapted to meet changing demands, showcasing the commitment of its manufacturers to quality and functionality. Its enduring presence in the field underscores its significance in the history of agricultural development.

- Recognition as a reliable workhorse in various farming operations.

- Influence on subsequent models and advancements in tractor technology.

- A lasting legacy that continues to inspire modern agricultural machinery.

In summary, the story of this iconic farming equipment is one of ingenuity and resilience, reflecting the ongoing journey of agriculture towards greater efficiency and productivity.

Key Components of the Tractor

This section explores the essential elements that contribute to the functionality and efficiency of a modern agricultural machine. Understanding these components is crucial for effective operation and maintenance.

Powertrain

- Engine: The heart of the machine, providing the necessary power.

- Transmission: Responsible for controlling speed and torque.

- Drivetrain: Transfers power to the wheels or tracks.

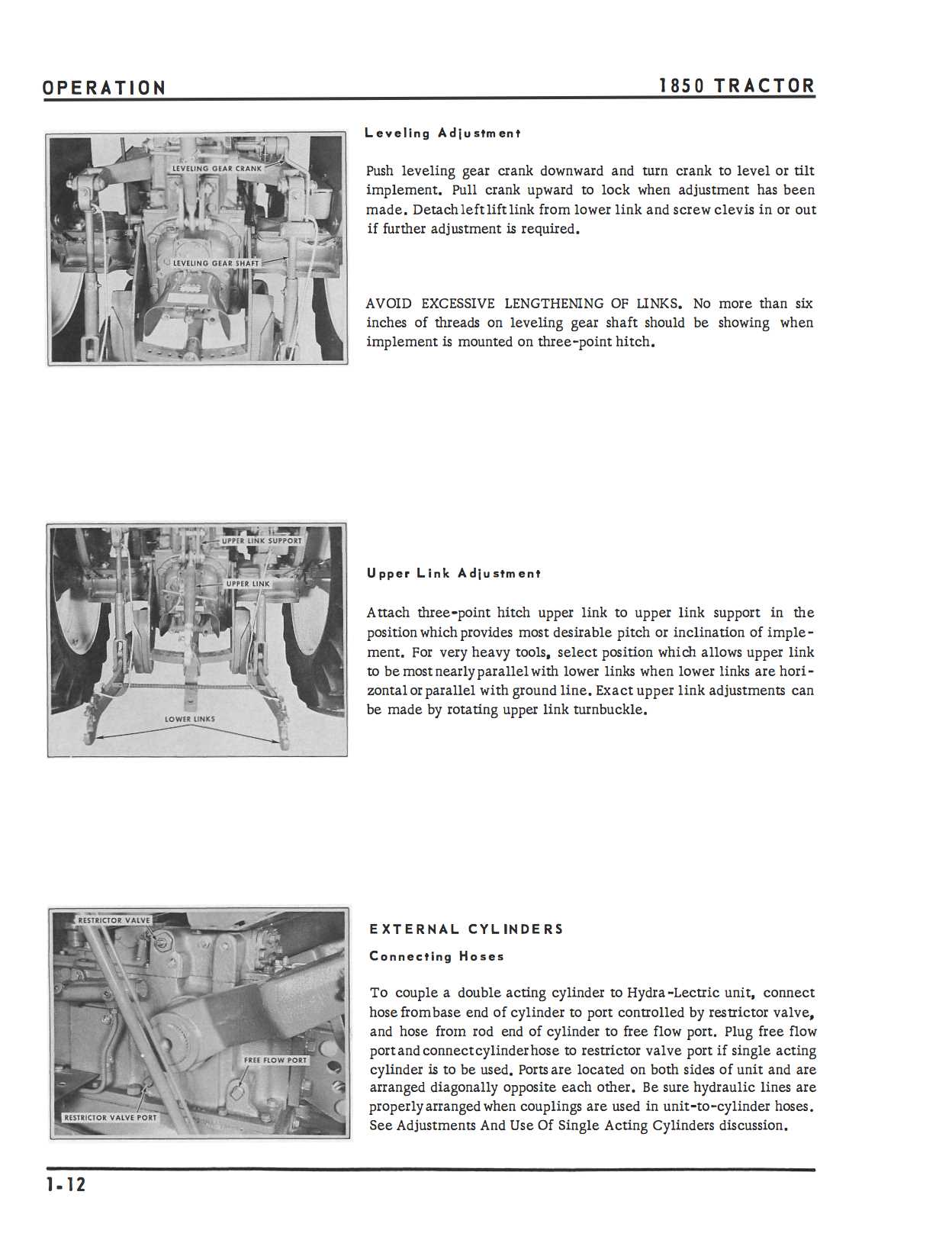

Hydraulic System

- Hydraulic Pump: Generates fluid pressure for various operations.

- Actuators: Facilitate movement of implements and attachments.

- Reservoir: Stores hydraulic fluid, ensuring efficient operation.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. This visual guide provides a detailed layout of each element, helping users identify and locate specific items needed for their tasks. Familiarizing oneself with the symbols and notations used in these representations is crucial for clarity and precision.

Begin by examining the legend or key, which explains the symbols and color codes. This foundational knowledge will enable you to navigate the layout more easily. As you delve deeper into the representation, take note of how various sections are labeled, ensuring you can match components with their respective functions.

Next, focus on the arrangement and connections between different elements. Understanding the relationships can provide insights into assembly or disassembly processes. Always cross-reference with an accompanying manual or guide for additional context and instructions, as these resources offer the ultimate support for successful repairs.

Practice is key; the more you engage with these visuals, the more intuitive they will become. Soon, you’ll be able to quickly identify what you need, making your repair work more efficient and effective.

Common Issues with Oliver 1850 Parts

In the realm of vintage machinery, certain challenges often arise concerning various components. Owners frequently encounter a range of issues that can affect performance and longevity. Understanding these common problems is essential for effective maintenance and repair.

Frequent Mechanical Failures

Many enthusiasts report issues with essential mechanisms, leading to decreased efficiency. Worn gears and faulty seals are typical culprits that can result in significant operational problems. Regular inspection and timely replacement are crucial to avoid escalating damage.

Compatibility Concerns

Another prevalent issue involves compatibility among replacement components. Finding the right fit can be challenging, as variations in design and production year can lead to mismatches. Ensuring the correct specifications is vital for optimal function and performance.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires regular upkeep and attention to detail. By following a structured maintenance routine, you can significantly extend the life of your equipment and improve its overall performance. This section provides essential practices to keep your machinery in optimal condition.

Regular Inspection

Consistent evaluations of your equipment can help identify potential issues before they escalate. Pay attention to signs of wear and tear, and address any concerns promptly. Establish a checklist for visual inspections, focusing on key components and systems that are critical to operation.

Lubrication and Fluid Checks

Proper lubrication is vital for reducing friction and wear. Ensure that all moving parts are adequately lubricated and that fluid levels are within recommended ranges. Regularly replace old fluids to maintain the efficiency of your systems.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for leaks and wear. |

| Lubrication | Monthly | Use the recommended lubricant. |

| Fluid Replacement | Every 6 months | Follow manufacturer guidelines. |

Where to Find Replacement Parts

Locating components for vintage machinery can be a challenge, but there are several reliable sources to explore. Whether you are in need of original items or high-quality alternatives, understanding where to look is crucial for keeping your equipment in optimal condition.

Online Marketplaces: Numerous e-commerce platforms specialize in agricultural machinery, offering a wide selection of components. Websites such as eBay and specialized forums can connect you with both new and used options. Always check seller ratings and reviews to ensure a satisfactory transaction.

Local Dealerships: Authorized dealerships often carry a range of original components. Establishing a relationship with your local dealer can provide access to exclusive inventory and expert advice tailored to your needs.

Salvage Yards: Salvage yards can be treasure troves for finding rare components. These facilities often stock dismantled machines, providing opportunities to obtain hard-to-find items at a lower cost. Be prepared to invest some time in searching through the inventory.

Online Forums and Communities: Joining online communities dedicated to machinery enthusiasts can be beneficial. Members often share leads on where to find specific components and may even have items for sale. Engaging with fellow enthusiasts can lead to valuable insights and connections.

Manufacturer’s Websites: Checking the official website of the manufacturer can yield information about available components and authorized distributors. Many manufacturers also provide resources for locating certified replacement options.

By exploring these avenues, you can effectively find the necessary components to ensure the longevity and efficiency of your machinery.

Using the Diagram for Repairs

When tackling maintenance or fixing issues, having a clear visual representation of components can be invaluable. This resource not only helps identify individual elements but also provides insight into their arrangement and functionality within the larger system.

Referencing this visual guide allows for efficient troubleshooting and ensures that replacements or adjustments are made with accuracy. Familiarity with the layout aids in understanding the relationships between parts, ultimately facilitating smoother repairs.

In addition, utilizing this tool during disassembly and reassembly can prevent mistakes, ensuring that everything is put back in its rightful place. This organized approach significantly enhances the repair process, saving both time and effort.

Aftermarket Parts vs. OEM Options

The decision between choosing replacement components from independent manufacturers and those produced by the original equipment maker often hinges on various factors, including cost, quality, and compatibility. Each option presents its own set of advantages and disadvantages, influencing the overall experience and satisfaction of the user.

Aftermarket alternatives typically offer a wider range of choices and often come at a lower price point. This affordability can be particularly appealing to those working within tight budgets. However, the quality of these components can vary significantly, leading to concerns about their longevity and performance. It is essential for buyers to conduct thorough research and select reputable brands to ensure they are investing in reliable substitutes.

On the other hand, OEM products are manufactured by the original creator and are designed to meet the exact specifications of the original design. This can lead to enhanced reliability and peace of mind regarding compatibility. However, these components usually come at a premium price, which may not be feasible for every customer. The trade-off between cost and assurance of quality is a crucial consideration when making a choice.

Ultimately, the decision will depend on individual needs, preferences, and the specific context in which these items will be used. Balancing factors such as budget, expected usage, and the desired level of quality will guide users in selecting the most suitable option for their requirements.

Best Practices for Parts Installation

Ensuring optimal functionality during assembly requires careful attention to detail and adherence to specific guidelines. Following a systematic approach can prevent issues and enhance the longevity of the equipment.

| Step | Description |

|---|---|

| 1 | Review the manual thoroughly to understand the components and their placements. |

| 2 | Gather all necessary tools and materials before beginning the installation process. |

| 3 | Inspect each element for defects or wear prior to installation. |

| 4 | Follow the specified torque settings to ensure secure fitting. |

| 5 | Maintain a clean workspace to prevent contamination or damage to components. |

| 6 | Test the assembly thoroughly after installation to confirm proper functionality. |

Customer Reviews on Parts Quality

This section delves into the feedback provided by users regarding the quality of components used in machinery. Understanding customer experiences offers valuable insights into the durability and performance of these essential items.

General Feedback

Many users express their satisfaction with the reliability and longevity of the components. They often highlight the effectiveness of these elements in enhancing overall functionality. However, some reviews mention occasional discrepancies in quality, prompting potential buyers to consider specific brands or suppliers.

Common Observations

| Aspect | Positive Comments | Negative Comments |

|---|---|---|

| Durability | Highly durable and withstands heavy use | Some parts wear out faster than expected |

| Fit | Perfect fit with easy installation | Occasional issues with compatibility |

| Performance | Significantly improves machine efficiency | Inconsistent performance reported |

Community Resources for Oliver Owners

For enthusiasts of vintage agricultural machinery, connecting with fellow aficionados can be invaluable. Various community resources provide support, information, and camaraderie for those dedicated to maintaining and restoring their beloved machines. These platforms not only facilitate the exchange of knowledge but also foster relationships among members who share a common passion.

Online Forums and Groups

Numerous online forums and social media groups cater to enthusiasts. These spaces allow individuals to ask questions, share experiences, and post tips related to maintenance and restoration. Members often showcase their projects, providing inspiration and practical advice to others. Participating in these communities can enhance one’s understanding and ability to tackle challenges that arise with vintage equipment.

Local Clubs and Meetups

Joining local clubs dedicated to classic machinery offers additional resources and networking opportunities. Many clubs organize events such as tractor shows, workshops, and social gatherings. These events not only allow members to display their machines but also facilitate hands-on learning and collaboration on restoration projects. Engaging with local enthusiasts can lead to lasting friendships and a wealth of shared knowledge.